Electric Nutrunners â Corded Transducer Control - Apex Tool Group ...

Electric Nutrunners â Corded Transducer Control - Apex Tool Group ...

Electric Nutrunners â Corded Transducer Control - Apex Tool Group ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

UII<br />

DET<br />

180<br />

215<br />

180<br />

215<br />

UII<br />

DET<br />

Accessories<br />

Fixtured Nutrunner Articulating Arms & Cable Management<br />

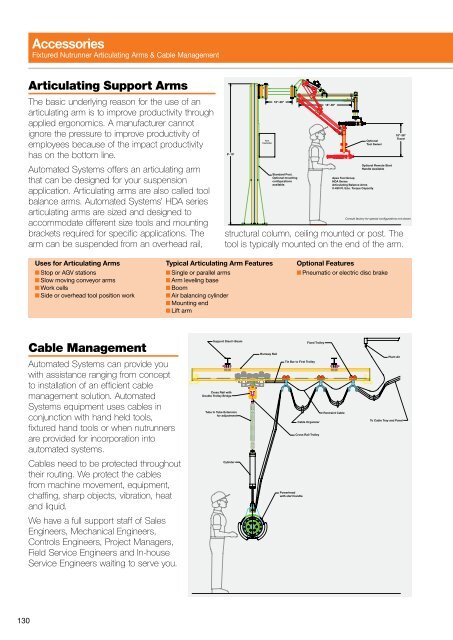

Articulating Support Arms<br />

The basic underlying reason for the use of an<br />

articulating arm is to improve productivity through<br />

applied ergonomics. A manufacturer cannot<br />

ignore the pressure to improve productivity of<br />

employees because of the impact productivity<br />

has on the bottom line.<br />

8’-10’<br />

<strong>Tool</strong><br />

<strong>Control</strong>ler<br />

18”-36”<br />

18”-36”<br />

Optional<br />

<strong>Tool</strong> Swivel<br />

18”-36”<br />

Travel<br />

Automated Systems offers an articulating arm<br />

that can be designed for your suspension<br />

application. Articulating arms are also called tool<br />

balance arms. Automated Systems’ HDA series<br />

articulating arms are sized and designed to<br />

accommodate different size tools and mounting<br />

brackets required for specific applications. The<br />

arm can be suspended from an overhead rail,<br />

Standard Post.<br />

Optional mounting<br />

configurations<br />

available.<br />

<strong>Apex</strong> <strong>Tool</strong> <strong>Group</strong><br />

HDA Series<br />

Articulating Balance Arms<br />

0-450 Ft./Lbs. Torque Capacity<br />

Optional Remote Start<br />

Handle Available<br />

Consult factory for special configurations not shown.<br />

structural column, ceiling mounted or post. The<br />

tool is typically mounted on the end of the arm.<br />

Uses for Articulating Arms<br />

n Stop or AGV stations<br />

n Slow moving conveyor arms<br />

n Work cells<br />

n Side or overhead tool position work<br />

Typical Articulating Arm Features<br />

n Single or parallel arms<br />

n Arm leveling base<br />

n Boom<br />

n Air balancing cylinder<br />

n Mounting end<br />

n Lift arm<br />

Optional Features<br />

n Pneumatic or electric disc brake<br />

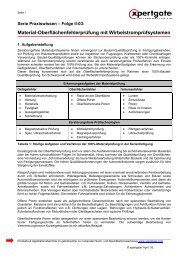

Cable Management<br />

Automated Systems can provide you<br />

with assistance ranging from concept<br />

to installation of an efficient cable<br />

management solution. Automated<br />

Systems equipment uses cables in<br />

conjunction with hand held tools,<br />

fixtured hand tools or when nutrunners<br />

are provided for incorporation into<br />

automated systems.<br />

Support Steel I-Beam<br />

Cross Rail with<br />

Double Trolley Bridge<br />

Tube In Tube Extension<br />

for adjustment<br />

Runway Rail<br />

Fixed Trolley<br />

Tie Bar to First Trolley<br />

Restraint Cable<br />

Cable Organizer<br />

Cross Rail Trolley<br />

Plant Air<br />

To Cable Tray and Panel<br />

Cables need to be protected throughout<br />

their routing. We protect the cables<br />

from machine movement, equipment,<br />

chaffing, sharp objects, vibration, heat<br />

and liquid.<br />

Cylinder<br />

Powerhead<br />

with start handle<br />

We have a full support staff of Sales<br />

Engineers, Mechanical Engineers,<br />

<strong>Control</strong>s Engineers, Project Managers,<br />

Field Service Engineers and In-house<br />

Service Engineers waiting to serve you.<br />

130