HCD-220 (3-V Blade) - Greenheck

HCD-220 (3-V Blade) - Greenheck

HCD-220 (3-V Blade) - Greenheck

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Application and Design<br />

Ratings (See pages 2 and 3 for specific limitations)<br />

Pressure: Up to 15 in. wg (3.7 kPa) -<br />

differential pressure<br />

Velocity: Up to 4000 fpm (20.3 m/s)<br />

Temperature: -60°F to 600°F (-51°C to 315°C). Consult<br />

factory for other temperatures.<br />

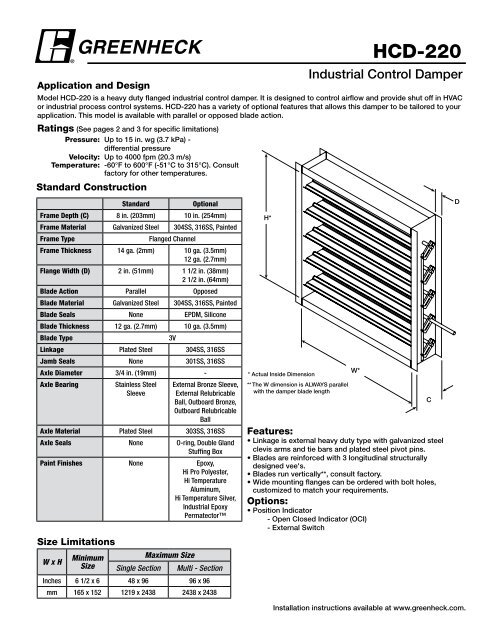

H*<br />

<strong>HCD</strong>-<strong>220</strong><br />

Industrial Control Damper<br />

Model <strong>HCD</strong>-<strong>220</strong> is a heavy duty flanged industrial control damper. It is designed to control airflow and provide shut off in HVAC<br />

or industrial process control systems. <strong>HCD</strong>-<strong>220</strong> has a variety of optional features that allows this damper to be tailored to your<br />

application. This model is available with parallel or opposed blade action.<br />

Standard Construction<br />

Standard<br />

Optional<br />

Frame Depth (C) 8 in. (203mm) 10 in. (254mm)<br />

Frame Material Galvanized Steel 304SS, 316SS, Painted<br />

Frame Type<br />

Flanged Channel<br />

Frame Thickness 14 ga. (2mm) 10 ga. (3.5mm)<br />

12 ga. (2.7mm)<br />

Flange Width (D) 2 in. (51mm) 1 1/2 in. (38mm)<br />

2 1/2 in. (64mm)<br />

<strong>Blade</strong> Action Parallel Opposed<br />

<strong>Blade</strong> Material Galvanized Steel 304SS, 316SS, Painted<br />

<strong>Blade</strong> Seals None EPDM, Silicone<br />

<strong>Blade</strong> Thickness 12 ga. (2.7mm) 10 ga. (3.5mm)<br />

<strong>Blade</strong> Type<br />

3V<br />

Linkage Plated Steel 304SS, 316SS<br />

Jamb Seals None 301SS, 316SS<br />

Axle Diameter 3/4 in. (19mm) -<br />

Axle Bearing<br />

Stainless Steel<br />

Sleeve<br />

External Bronze Sleeve,<br />

External Relubricable<br />

Ball, Outboard Bronze,<br />

Outboard Relubricable<br />

Ball<br />

Axle Material Plated Steel 303SS, 316SS<br />

Axle Seals None O-ring, Double Gland<br />

Stuffing Box<br />

Paint Finishes None Epoxy,<br />

Hi Pro Polyester,<br />

Hi Temperature<br />

Aluminum,<br />

Hi Temperature Silver,<br />

Industrial Epoxy<br />

Permatector<br />

Size Limitations<br />

W x H<br />

Minimum<br />

Maximum Size<br />

Size Single Section Multi - Section<br />

Inches 6 1/2 x 6 48 x 96 96 x 96<br />

mm 165 x 152 1219 x 2438 2438 x 2438<br />

* Actual Inside Dimension<br />

** The W dimension is ALWAYS parallel<br />

with the damper blade length<br />

Features:<br />

• Linkage is external heavy duty type with galvanized steel<br />

clevis arms and tie bars and plated steel pivot pins.<br />

• <strong>Blade</strong>s are reinforced with 3 longitudinal structurally<br />

designed vee's.<br />

• <strong>Blade</strong>s run vertically**, consult factory.<br />

• Wide mounting flanges can be ordered with bolt holes,<br />

customized to match your requirements.<br />

Options:<br />

• Position Indicator<br />

- Open Closed Indicator (OCI)<br />

- External Switch<br />

W*<br />

Installation instructions available at www.greenheck.com.<br />

C<br />

D

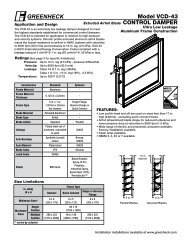

Pr essur e ( in. w g)<br />

230<br />

Performance Data<br />

Pressure Limitations<br />

20<br />

96<br />

16 15 in. w g<br />

on a maximum blade deflection of L/360.<br />

4000 fpm<br />

12<br />

Temperature 8.5 in. w g Limitations 72<br />

8<br />

<strong>Blade</strong> seals:<br />

4<br />

(-40° to 60 +204°C)<br />

0 0 12 24 36 48 60 72 (-29° to 48 +121°C) 5000 fpm<br />

Damper Width ( in.)<br />

Jamb seals:<br />

Pr essur e Limitations<br />

The chart at the right shows conservative pressure limitations based<br />

Silicone Rubber -40° to +400°F<br />

Damper Height ( in. )<br />

EPDM -20° to +250°F<br />

For higher temperatures consult <strong>Greenheck</strong><br />

Flexible stainless steel -40° to +400°F<br />

(-40° to +204°C)<br />

24<br />

Velocity Limitations<br />

The chart at far right shows conservative velocity limitations based<br />

on damper size.<br />

0<br />

12 36 48 60<br />

Damper Width ( in.)<br />

Ve locity Limitations<br />

Pr essur e ( in. w g)<br />

16<br />

12<br />

8.5 in. w g<br />

8<br />

4<br />

15 in. w g<br />

0 12 24 36 48<br />

Damper Width ( in.)<br />

Pr essur e Limitations<br />

<strong>220</strong><br />

Damper Height ( in.)<br />

96<br />

72<br />

60<br />

48<br />

36<br />

24<br />

12<br />

0<br />

<strong>HCD</strong>-<strong>220</strong><br />

3000 fpm<br />

3500 fpm<br />

4000 fpm<br />

12 24 36 48<br />

Damper Width ( in.)<br />

Ve locity Limitations<br />

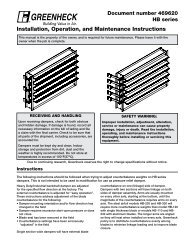

Pressure Drop Data<br />

This pressure drop data was conducted in accordance with AMCA Standard 500-D using the three configurations shown. All<br />

data has been corrected to represent standard air at a density of .075 lb/ft 3 (1.2 kg/m 3 ).<br />

Actual pressure drop found in any HVAC system is a combination of many factors. This pressure drop information along with an<br />

analysis of other system influences should be used to estimate actual pressure losses for a damper installed in a given HVAC<br />

system.<br />

AMCA Test Figures<br />

Figure 5.3 Illustrates a fully ducted damper. This configuration has the lowest pressure drop of the three test configurations<br />

because entrance and exit losses are minimized by straight duct runs upstream and downstream of the damper.<br />

Figure 5.2 Illustrates a ducted damper exhausting air into an open area. This configuration has a lower pressure drop than<br />

Figure 5.5 because the entrance losses are minimized by a straight duct run upstream of the damper.<br />

Figure 5.5 Illustrates a plenum mounted damper. This configuration has the highest pressure drop because of the high<br />

entrance and exit losses due to the sudden changes of area in the system.<br />

5D<br />

6D<br />

Fig. 5.3<br />

5D<br />

D=<br />

4 (W) (H)<br />

3.14<br />

Fig. 5.2<br />

Fig. 5.5

3<br />

performance data<br />

Leakage Data<br />

Static Pressure Difference (in. wg)<br />

Pr essur e Loss ( in. w g )<br />

15<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1.0<br />

.9<br />

.8<br />

.7<br />

.6<br />

.5<br />

.4<br />

.3<br />

.2<br />

2.00<br />

Pressure Drop<br />

36 in. x 36 in. (914mm x 914mm) Damper<br />

<strong>220</strong><br />

1.00<br />

.80<br />

.60<br />

.40<br />

.20<br />

.10<br />

.08<br />

.06<br />

.04<br />

.02<br />

.02<br />

2 3 4 5 6 7 8 9 10 2 3<br />

x 100 x 1000<br />

With Seals<br />

Velocity (fpm)<br />

120<br />

Without Seals<br />

1 2 3 4 5 6 7 8 910 20 30 4050 60 708090100 150<br />

Air Leakage in CFM/Sq. Ft.<br />

5. 5<br />

5 .2<br />

5 .3<br />

2 4 6 8 10 2 4<br />

x 100 x 1000<br />

Velocity (fpm)<br />

.02<br />

Pr essur e Loss ( in. w g )<br />

.6<br />

.5<br />

.4<br />

.3<br />

.2<br />

.10<br />

.09<br />

.08<br />

.07<br />

.06<br />

.05<br />

.04<br />

.03<br />

.0 2<br />

Static Pr essur e Dif fer ence (in. wg)<br />

Static Pr essur e Dif fer ence (in. wg)<br />

1. 0<br />

.9<br />

.8<br />

.7<br />

.6<br />

.5<br />

.4<br />

8. 5<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1. 0<br />

.9<br />

.8<br />

.7<br />

.6<br />

.5<br />

.4<br />

.3<br />

.2<br />

2<br />

<strong>HCD</strong>-<strong>220</strong><br />

3 4 5 6 7 8 9 10 2 3 4<br />

x 100 x 1000<br />

Velocity (fpm)<br />

.3<br />

.2<br />

230/330<br />

1 2 3 4 5 6 7 8 9 10<br />

W ith S e a ls<br />

1 2 3 4 5 6 7 8 9 10<br />

Air Leakage in<br />

4 5 6 7 8 910<br />

2 3 4 5<br />

x 100 x 1000<br />

Velocity (fpm)<br />

Damper leakage (with blades fully closed) varies based on the type of low leakage seals applied. Model <strong>HCD</strong>-120 is available<br />

with no jamb seals (standard) or with stainless steel jamb seals and EPDM or silicone rubber blade seals. Leakage testing was<br />

conducted in accordance with AMCA Standard 500-D and is expressed as CFM per sq.ft. of damper face area. All data has<br />

been corrected to represent standard air at a density of .075 lb/ft 3 (1.2 kg/m 3 ).<br />

5.5<br />

5.2<br />

5.3<br />

13<br />

Air Leakage in<br />

Leakage<br />

36 in. x 36 in. (914mm x 914mm) Damper<br />

(based on 5 in. lb/ft 2 of torque)<br />

22 0<br />

230/3<br />

15<br />

15<br />

10<br />

9<br />

8<br />

7<br />

6<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

5<br />

Static Pr essur e Dif fer ence (in. wg)<br />

4<br />

3<br />

2<br />

1. 0<br />

.9<br />

.8<br />

.7<br />

.6<br />

.5<br />

W it h S e a ls<br />

W it h o u t S e a ls<br />

Static Pr essur e Dif fer ence (in. wg)<br />

4<br />

3<br />

2<br />

1. 0<br />

.9<br />

.8<br />

.7<br />

.6<br />

.5<br />

W it h S e a ls<br />

.4<br />

.4<br />

.3<br />

.3<br />

.2<br />

.2<br />

1 2 3 4 5 6 7 8 910 20 30 40 50 60 70 80 90100 200<br />

Air Leakage in CFM/Sq. Ft.<br />

1 2 3 4 5 6 7 8 9 10<br />

Air Leakage in CFM/

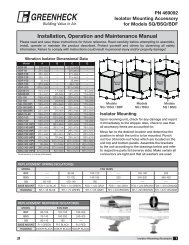

BOLT HOLES<br />

<strong>HCD</strong>-<strong>220</strong><br />

Bolt holes are available as an option. <strong>Greenheck</strong>'s standard pattern is 7/16 in. (11mm) diameter holes (M dimension) spaced 6<br />

in. (152mm) on center (L dimension). Also, available is custom bolt hole pattern within the limitations of the chart below.<br />

Dim.<br />

W<br />

Standard<br />

-<br />

Formula<br />

-<br />

VARIABLE<br />

FORMULA<br />

Description<br />

W = DAMPER WIDTH<br />

Damper Width H = DAMPER HEIGHT<br />

D = FLANGE WIDTH<br />

H - - Damper Height L = HOLE SPACING STD. = 6<br />

D - - Flange WidthM = MOUNTING HOLE DIAMETER STD. = .4375<br />

Y = JAMB GAGE LINE D/2<br />

L 6 in.<br />

- Hole SpacingV = NO. OF SPACES IN HEAD/SILL INT((W-1.5)/L)<br />

(152mm)<br />

F = NO. OF SPACES IN JAMB INT((H+2*Y)/L)<br />

U = FIRST/LAST SPACE IN HEAD/SILL (W-(L*V))/2<br />

M 7/16 in.<br />

- Mounting Hole Diameter<br />

J = FIRST LAST SPACE IN JAMB (H+2*D-(L*F))/2<br />

(11mm)<br />

Y - D/2 Jamb Gauge Line<br />

V - INT((W-1.5)/L) Number of Spaces in Head/Sill<br />

F - INT((H+2*Y)/L) Number of Spaces in Jamb<br />

U - (W-(L*V))/2 First/Last Spce in Head/Sill<br />

J - (H+2*D - (L*F))/2 First Last Space in Jamb<br />

Specifications<br />

Industrial grade control dampers meeting the following<br />

specifications shall be furnished and installed where shown<br />

on plans and/or as described in schedules.<br />

Dampers shall consist of: a 14 ga. (2mm) galvanized steel<br />

channel frame with 8 in. (203mm) minimum depth and 2 in.<br />

(51mm) flanges; 3V type blades fabricated from 12 ga. (2.7mm)<br />

galvanized steel; 3 ⁄4 in. (19mm) dia. plated steel axles turning<br />

in stainless steel sleeve bearings; and external (out of the<br />

airstream) blade-to-blade linkage.<br />

Damper manufacturer's printed application and performance<br />

data including pressure, velocity and temperature limitations<br />

shall be submitted for approval showing damper suitable for<br />

pressures to 15 in. wg (3.7 kPa), velocities to 4000 fpm<br />

(20.3 m/s) and temperatures to 1500°F (816°C). Testing<br />

and ratings to be in accordance with AMCA Standard<br />

500-D.<br />

Specifier may add the following:<br />

Dampers shall be equipped with blade and jamb seals<br />

for low leakage performance. <strong>Blade</strong> seals shall be: select<br />

one of the following EPDM synthetic rubber for 250°F<br />

(121°C) maximum temperature, or Silicone Rubber for<br />

400°F (204°C) maximum temperature. Jamb seals shall be<br />

flexible stainless steel.<br />

Basis of design is <strong>Greenheck</strong> model <strong>HCD</strong>-<strong>220</strong>.<br />

Copyright © 2013 <strong>Greenheck</strong> Fan Corporation<br />

<strong>HCD</strong>-<strong>220</strong> Rev. 11 Sept 2013