You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

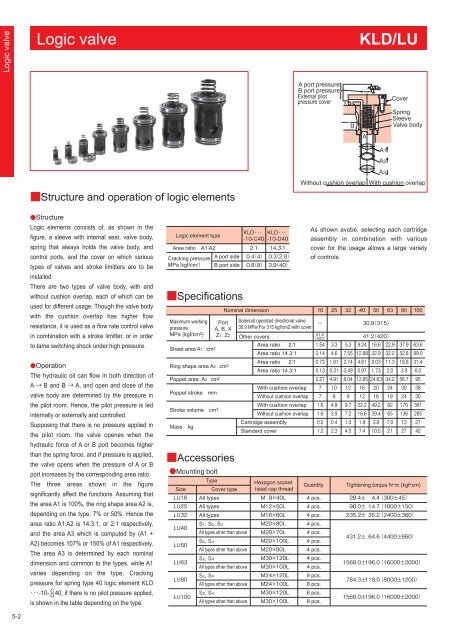

Logic valve<br />

Logic valve<br />

KLD/LU<br />

A port pressure<br />

B port pressure<br />

External pilot<br />

pressure cover<br />

<br />

<br />

<br />

Cover<br />

Spring<br />

Sleeve<br />

Valve body<br />

<br />

<br />

<br />

Structure and operation of logic elements<br />

Without cushion overlap With cushion overlap<br />

Structure<br />

Logic elements consists of, as shown in the<br />

figure, a sleeve with internal seat, valve body,<br />

spring that always holds the valve body, and<br />

control ports, and the cover on which various<br />

types of valves and stroke limitters are to be<br />

installed.<br />

There are two types of valve body, with and<br />

without cushion overlap, each of which can be<br />

used for different usage. Though the valve body<br />

with the cushion overlap has higher flow<br />

resistance, it is used as a flow rate control valve<br />

in combination with a stroke limitter, or in order<br />

to tame switching shock under high pressure.<br />

Operation<br />

The hydraulic oil can flow in both direction of<br />

A B and B A, and open and close of the<br />

valve body are determined by the pressure in<br />

the pilot room. Hence, the pilot pressure is led<br />

internally or externally and controlled.<br />

Supposing that there is no pressure applied in<br />

the pilot room, the valve openes when the<br />

hydraulic force of A or B port becomes higher<br />

than the spring force, and if pressure is applied,<br />

the valve opens when the pressure of A or B<br />

port increases by the corresponding area ratio.<br />

The three areas shown in the figure<br />

significantly affect the functions. Assuming that<br />

the area A1 is <strong>10</strong>0%, the ring shape area A2 is,<br />

depending on the type, 7% or 50%. Hence the<br />

area ratio A1:A2 is 14.3:1, or 2:1 respectively,<br />

and the area A3 which is computed by (A1 +<br />

A2) becomes <strong>10</strong>7% or 150% of A1 respectively.<br />

The area A3 is determined by each nominal<br />

dimension and common to the types, while A1<br />

varies depending on the type. Cracking<br />

pressure for spring type 40 logic element KLD<br />

-<strong>10</strong>- <br />

40, if there is no pilot pressure applied,<br />

is shown in the table depending on the type.<br />

Logic element type<br />

<br />

<br />

Area ratioA1A2<br />

<br />

Cracking pressure A port side <br />

MPakgf/cm 2 B port side <br />

Specifications<br />

As shown avobe, selecting each cartridge<br />

assembly in combination with various<br />

cover for the usage allows a large variety<br />

of controls.<br />

16 25 32 40 50 63 80 <strong>10</strong>0<br />

Nominal dimension<br />

Poppet area A3cm 2 <br />

Maximum working Port Solenoid operated directional valve<br />

pressure<br />

ABX 30.9 MPaFor 315 kgf/cm2with cover<br />

<br />

<br />

MPakgf/cm 2 Z1Z2<br />

<br />

Other covers<br />

<br />

<br />

Sheet area A1cm 2<br />

Ring shape area A2cm 2<br />

Poppet strokemm<br />

Stroke volumecm 3<br />

Area ratio 21<br />

Area ratio 14.31<br />

Area ratio 21<br />

Area ratio 14.31<br />

With cushion overlap<br />

Without cushion overlap<br />

With cushion overlap<br />

Without cushion overlap<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Masskg<br />

Cartridge assembly<br />

<br />

Standard cover<br />

<br />

Accessories<br />

Mounting bolt<br />

Type<br />

Size Cover type<br />

All types<br />

Hexagon socket<br />

head cap thread<br />

<br />

Quantity<br />

4 pcs.<br />

All types 4 pcs.<br />

All types 4 pcs.<br />

<br />

<br />

4 pcs.<br />

All types other than above 4 pcs.<br />

<br />

<br />

4 pcs.<br />

All types other than above 4 pcs.<br />

<br />

<br />

4 pcs.<br />

All types other than above 4 pcs.<br />

<br />

<br />

8 pcs.<br />

All types other than above 8 pcs.<br />

<br />

<br />

8 pcs.<br />

All types other than above 8 pcs.<br />

Tightening torque Nm (kgfcm)<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

5-2