STAUFF Clean

STAUFF Clean

STAUFF Clean

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

All through manner tees, of pipework elbows, etc., configurations of up to 90° incan the be normal accommodated size range of by6mm the projectiles. to 60mm can be handled by<br />

TIME, the Stauff SAVES <strong>Clean</strong> System COSTS. regardless of pipe length, type of fittings or components. Change of direction<br />

through THE PROJECTILE tees, elbows, – etc., The of Stauff up to<strong>Clean</strong> 90° can System be accommodated works on the principle by the projectiles. of propelling foam pellets or<br />

hose TIME, assemblers SAVES<br />

projectiles of involvedCOSTS.<br />

varying density with: and texture Stauff throughTube pipework<strong>Clean</strong> at very highSystem<br />

velocities while maintaining<br />

THE sufficient PROJECTILE contact with – The the Stauff inside<strong>Clean</strong> surface System to remove works unwanted on the principle contaminant. of propelling foam pellets or<br />

d OCESSING hose assemblers projectiles ofinvolved varying – FUEL density with: and LINES texture through –<br />

pipework at very high velocities while maintaining<br />

sufficient contact with the inside surface to remove unwanted contaminant.<br />

.<br />

OCESSING – FUEL LINES –<br />

THE FORCE – The propelling force for the projectile is produced by standard industrial compressed<br />

air (7 Projectile bar/100 psi) via & aNozzle lightweight, Selection pistol-grip Launcher. This provides a safe and environmentallyfriendly<br />

tool that requires little formal expertise to operate and apply.<br />

THE FORCE – The propelling force for the projectile is produced by standard industrial compressed<br />

.<br />

rovidesair a simple (7 bar/100<br />

To exploit andpsi) lowvia the cost a lightweight,<br />

maximum solution forpistol-grip cleaning the removal Launcher.<br />

capability of This provides a safe and environmentallyfriendly<br />

of the system,<br />

es, Tubes PERFECT and careful Hoses. tool<br />

PRE-CLEANING<br />

that requires little<br />

selection of the PARTNER<br />

formal expertise<br />

nozzle and – Pipework<br />

to operate<br />

projectile fabricators<br />

and apply.<br />

is important. will find that the Stauff <strong>Clean</strong> System<br />

rovides normalprovides asize simple range<br />

The<br />

the and of<br />

nozzles<br />

perfect low 6mmcost are<br />

partner, to 60mm solution<br />

selected<br />

ascan a for pre-cleaning bethe handled removal<br />

to suit the<br />

device, byof<br />

tube to<br />

hose<br />

dramatically<br />

end tting<br />

reduce flushing times when<br />

es, length, Tubes type<br />

PERFECT<br />

preparing and of fittings Hoses. pipework<br />

PRE-CLEANING components. to meet predetermined<br />

PARTNER<br />

Change<br />

–<br />

of<br />

Pipework<br />

cleanliness direction<br />

fabricators<br />

specifications.<br />

will find that the Stauff <strong>Clean</strong> System<br />

provides the perfect partner, as a pre-cleaning device, to dramatically reduce flushing times when<br />

be normal accommodated size and range apart<br />

by of the 6mm from<br />

projectiles. to the 60mm Universal can beNozzles, handled by there are specifi c nozzles<br />

length, preparing type THE set of PROCESS fittings for pipework JIC, – BSP, components. A<br />

to<br />

variety<br />

meet and predetermined<br />

of metric projectiles Change fittings. are of cleanliness direction available The Universal specifications.<br />

to suit the Nozzle degree and is suitable type of contaminant<br />

em be accommodated works likely for almost and thread type or hose or tube end.<br />

THE<br />

on to<br />

PROCESS<br />

thebe principle experienced by the<br />

– A<br />

of projectiles.<br />

variety<br />

propelling and these<br />

of projectiles<br />

foam can be pellets varied<br />

are available<br />

orduring the cleaning process as required. Projectiles<br />

to suit the degree and type of contaminant<br />

ough pipework can be visually<br />

likely to be at very inspected<br />

experienced high velocities after use<br />

and these while to<br />

canmaintaining<br />

determine the remaining cleanliness level and the need for<br />

be varied during the cleaning process as required. Projectiles<br />

tem emove works<br />

can unwanted further on<br />

be<br />

The the application.<br />

visually<br />

projectile principle contaminant. For<br />

inspected<br />

of selection propelling good housekeeping<br />

after use<br />

will foam<br />

to<br />

depend<br />

determine<br />

pellets andon the<br />

or safe what operation,<br />

remaining<br />

fi ttings, a mesh<br />

cleanliness<br />

if any, projectile<br />

level<br />

are attached collection<br />

and the need<br />

to bag<br />

for<br />

the tube or hose and<br />

ough pipework should<br />

further the be<br />

application. at degree secured very high of to<br />

For contamination. velocities the pipe exit.<br />

good housekeeping while maintaining As a and guide, safe operation, users should a meshselect projectile from collection the charts bag below with respect<br />

remove projectileshould unwanted is to produced be fi ttings secured contaminant. by and standard tocontaminant. the pipeindustrial exit. As compressed a general rule, projectiles should be approximately 15% larger in<br />

Selection of projectiles and attachment nozzles is made simple by the easy reference selection charts<br />

ip Launcher.<br />

provided diameter This provides<br />

on thethat adjoining the a safe internal and environmentallyise<br />

projectile to operate Selection is produced andofapply.<br />

projectiles by standard attachment industrial nozzles compressed is made simple by the easy reference selection charts<br />

pages. diameter of the pipe of hose.<br />

rip Launcher. provided on the adjoining pages.<br />

TheFor This<br />

Stauff optimum<br />

provides<br />

<strong>Clean</strong> System cleaning,<br />

a safe and<br />

is available it<br />

environmentallyise<br />

ipework to operate<br />

is recommended as separate components that projectiles or in a variety are used of Kit forms once comprising and then discarded.<br />

various fabricators and<br />

nozzle<br />

apply. will types, find that adaptor the Stauff and launcher, <strong>Clean</strong> System all contained in a heavy duty carrying case.<br />

ing device, ThetoStauff dramatically <strong>Clean</strong> System reduce is available flushing times as separate when components or in a variety of Kit forms comprising<br />

various Styles nozzle of types, Projectiles<br />

cleanliness ipework adaptor and launcher, all contained in a heavy duty carrying case.<br />

Four fabricators specifications. Styles will findof thatProjectiles<br />

the Stauff <strong>Clean</strong> System<br />

ing device, to dramatically reduce flushing times when<br />

Four There Styles are four of types Projectiles<br />

of projectiles available for the cleaning of hose, tube or pipe.<br />

ecleanliness available tospecifications.<br />

suit the degree and type of contaminant<br />

(A) Abrasive Series<br />

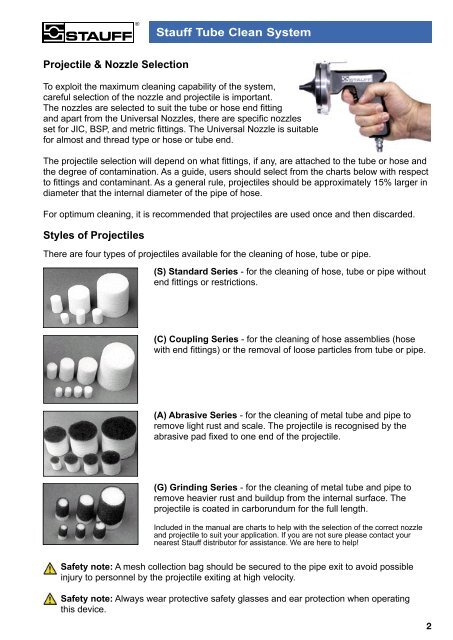

(S) Standard Series<br />

aried during the cleaning process as required. - for the cleaning of<br />

- for(S) the cleaning Projectiles Standard of Series - for the cleaning (A) of Abrasive Series<br />

(S) Standard Series<br />

metal<br />

hose,<br />

tube<br />

tube<br />

and pipe<br />

or pipe without<br />

eine available the remaining to suit the cleanliness degree and level type andhose, ofthe contaminant<br />

tube needorfor<br />

pipe<br />

- for the cleaning of<br />

- for the end cleaning fi ttings of or restrictions.<br />

to remove light rust<br />

aried and safe during operation, the cleaning a mesh process projectile as required. collection without endbag<br />

fittings<br />

metal tube and pipe<br />

hose, tube<br />

Projectiles<br />

or pipe<br />

and scale<br />

ine the remaining cleanliness level and to remove light rust<br />

without theend need fittings for<br />

and scale<br />

and safe operation, a mesh projectile collection bag<br />

les is made simple by the easy reference selection charts<br />

zles is made simple by the easy reference selection charts<br />

(C) Coupling Series<br />

arate components or in a variety of Kit forms comprising<br />

- for the cleaning of<br />

all contained in a heavy duty carrying (C) case. Coupling Series<br />

hose assemblies<br />

- for the cleaning of<br />

arate components or in a variety of Kit(hose with end<br />

hose forms assemblies comprising<br />

all contained in a heavy duty carrying fittings) or the removal<br />

of loose<br />

(hose case. with end<br />

fittings) or the removal<br />

(A) Abrasive of loose Series<br />

particles from tube or<br />

d Series<br />

pipe<br />

ning of<br />

particles - for thefrom cleaning tube or of<br />

pipe metal tube and pipe<br />

r pipe<br />

(A) Abrasive Series<br />

d Series<br />

to remove light rust<br />

fittings<br />

- for the cleaning of<br />

aning of<br />

and scale<br />

metal tube and pipe<br />

r pipe<br />

to remove light rust<br />

fittings<br />

and scale<br />

(C) Coupling Series - for the cleaning of hose assemblies (hose<br />

with end fi ttings) or the removal of loose particles from tube or pipe.<br />

(G) Grinding Series<br />

- to remove heavier<br />

(G) Grinding Series<br />

rust and buildup.<br />

- to remove heavier<br />

These are available<br />

rust and buildup.<br />

on special order.<br />

These are available<br />

on special order.<br />

(A) Abrasive Series - for the cleaning of metal tube and pipe to<br />

remove light rust and scale. The projectile is recognised by the<br />

abrasive pad fi xed to one end of the projectile.<br />

g Series<br />

ning of<br />

blies<br />

nd g Series<br />

aning e rese<br />

blies<br />

of<br />

mndtube or<br />

e rese<br />

m tube or<br />

(G) Grinding Series<br />

- to(G) remove Grinding heavier Series - for the cleaning of metal tube and pipe to<br />

rustremove and buildup. heavier rust and buildup from the internal surface. The<br />

These (G) Grinding are available Series<br />

projectile is coated in carborundum for the full length.<br />

on - tospecial remove order. heavier<br />

rust and buildup.<br />

Included in the manual are charts to help with the selection of the correct nozzle<br />

These<br />

and<br />

are<br />

projectile<br />

available<br />

to suit your application. If you are not sure please contact your<br />

onnearest special order. Stauff distributor for assistance. We are here to help!<br />

Safety note: A mesh collection bag should be secured to the pipe exit to avoid possible<br />

injury to personnel by the projectile exiting at high velocity.<br />

Safety note: Always wear protective safety glasses and ear protection when operating<br />

this device.<br />

2