STEELS FOR MOLDS - Villares Metals

STEELS FOR MOLDS - Villares Metals

STEELS FOR MOLDS - Villares Metals

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>STEELS</strong> <strong>FOR</strong><br />

<strong>MOLDS</strong>

Aspects related to Mold<br />

Manufacturing<br />

The machining and polishing processes can take up to 80% of the total resources needed for the<br />

manufacturing of molds and dies. And, for those molds that have long usage times and seldom get to<br />

the end of their life cycle, the main items associated with the fi nal mold cost can be considered.<br />

Amongst the conventional machining processes of a metal cavity, milling is the one responsible for<br />

the manufacturing of the complex surfaces. Several aspects must be taken into consideration, such<br />

as: cutting parameters, the material to be machined, the cutting tool, the cutting strategy and the<br />

technological resources provided by the machine/tooling.<br />

Another fundamental point in the manufacturing of molds are the fi nishing processes, especially<br />

polishing and texturizing. The following document refers to some basic considerations so as to facilitate<br />

the manufacturing operations of metal cavities.

Milling<br />

In the milling process, the knowledge of techniques is necessary in order to minimize fl ank wear and to control vibrations, so as to avoid damages.<br />

The cutting direction can be carried out both in concordance or in opposition. In the concordance mode milling, the cutting and travel forward<br />

movements have the same direction, while in the opposition mode they have different directions (see Figure on the right).<br />

The cutting parameters exert the following influences:<br />

Concordance mode milling<br />

Opposition mode milling<br />

• Cutting speed (Vc) – it infl uences the cutting tool wear, as it amplifi es the friction conditions, thus increasing the temperature at the cutting zone, resulting from diffusion related phenomena to problems associated<br />

with thermal and/or mechanical origin shocks.<br />

• Travel forward per tooth (fZ) – with the increase in travel forward per tooth, greater mechanical strains occur, increasing the tool defl ection. With low travel forward there happens an increase of the machined path<br />

by the cutting edge, causing a high fl ank wear. One aims here at an intermediate condition.<br />

• Axial depth of cut (ap) – it is the direct factor responsible for the increase in cutting power, thus limiting the roughing process.<br />

• Radial depth of cut (ae) – large radial increments(>50% of the tool diameter) increase the machined path for each cutting edge. However, they do improve the impact characteristic, directing the stress towards the<br />

tool inner part. The opposite case occurs for small engagement conditions (

Table 1- Summary of the applications as a function of the tool pitch.<br />

Type of Milling Cutter<br />

Coarse Pitch – few teeth.<br />

Fine Pitch – greater number of teeth and spaces between<br />

small teeth.<br />

Extra Fine Pitch – many teeth and bags for storage of very<br />

small chips.<br />

Application<br />

Roughing and semi-finishing of steel or where there is a<br />

vibration trend.<br />

Cast iron cutting, light roughing and steel finishing.<br />

Interrupted cutting of cast iron and titanium alloys steel<br />

finishing.<br />

Some Additional Practical Recommendations<br />

• Roughen as much as possible with tools with large sharp corner radius.<br />

• A surface must be fi nished with the largest tool possible.<br />

• Machining should have a continuous contact of the milling cutter with concordance cutting and with a minimum of travel variation<br />

in relation to the milling line.<br />

• It is recommended to use smooth approximation movements and always towards one cutting direction in hard-to-machine<br />

materials.<br />

• It is important to make the tool stay in contact with the work as long as possible (in order to increase the useful life).<br />

Parameter Calculation<br />

Cutting speed<br />

(in/min)<br />

v c<br />

d n<br />

1000<br />

Travel Forward<br />

Speed (mm/<br />

min)<br />

v<br />

f<br />

Chip Removal<br />

Rate (mm/min)<br />

= z ⋅ f ⋅ n Q = ae<br />

⋅ a<br />

p<br />

⋅ v<br />

f<br />

Where d = tool diameter (mm); rotation (rpm); z = number of teeth of the tool; fz =<br />

travel forward per tooth (mm/tooth); ae = working penetration (mm); ap = depth or<br />

width of the machining (mm)<br />

z<br />

• During fi nishing or super-fi nishing, it is recommended to use small cutting depths. The ratio axial depth of cut (ap) and radial depth<br />

of cut (ae) must be equal to or less than 0.2 (ap/ae < 0.2).<br />

• Quite often it is advantageous to use the travel forward per tooth (fz) equal to the radial depth of cut (ae), with advantages in terms<br />

of machining time and lesser roughness (better fi nish).<br />

• Invest time in the interpolation method to be applied, so as to reduce the machining time and improve the fi nishing conditions of<br />

the machined surface.<br />

Example of Cutting Parameters<br />

Recommended cutting speeds for milling facing with coated hard metal.<br />

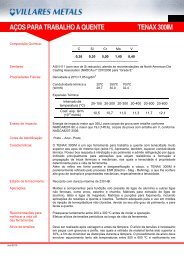

Material VP20ISO VP20ISOF VP20ISOFS VH13IM VP420IM N2711M VP50IM<br />

Condition Machined Machined Machined Annealed Annealed Machined Machined<br />

Hardness 32 HRC 32 HRC 32 HRC 200 HB 200 HB 40 HRC 40 HRC<br />

Roughing* 120 to 150 120 to 150 170 to 190 180 to 260 180 to 260 80 to 110 100 to 150<br />

Finishing** 220 to 240 220 to 240 260 to 280 220 to 300 260 to 300 100 to 150 110 to 160<br />

* fz = 0.15 to 0.3 mm/tooth and ap = 2 to 4 mm Class : P25 – P35<br />

** fz = 0.05 to 0.2 mm/tooth and ap = 0.5 to 1 mm Class P10 – P20

<strong>STEELS</strong> <strong>FOR</strong> <strong>MOLDS</strong> USED IN THE PLASTIC<br />

VILLARES METALS VP20ISO VP20ISOFS VP50IM VP100 N2711M<br />

SIMILAR ALLOYS Wnr 1.2738 Wnr 1.2312 NO SIMILAR STEEL NO SIMILAR STEEL Wnr 1.2711 MOD.<br />

CHEMICAL COMPOSITION (%)<br />

C 0.36 – Mn 1.60 - Cr 1.80 –<br />

Mo 0.20 – Ni 0.70<br />

C 0.36 – Mn 1.60 – Cr 1.80 –<br />

Mo 0.20 S 0.06<br />

C 0.15 - Cu 1.00 – Ni 3.00 – Mo 0.30 –<br />

Al 1.00 – S 0.10<br />

Cr-Ni-Mn<br />

C 0.56 – Mn 0.70 – Cr 0.70 –<br />

Mo 0.30 Ni 1.65 V 0.075<br />

CHARACTERISTICS<br />

Steel supplied as machined. It has good<br />

polishability and response on texturization.<br />

It has improved machinability through<br />

special melt shop treatment. For improvement<br />

of the wear resistance it can be nitrided or<br />

cemented.<br />

Steel supplied as machined. Excellent<br />

machinability. Good response to nitriding.<br />

Not recommended for parts that require<br />

texturization processing, chromium plat ing<br />

and higher polishability.<br />

Tool steel for molds especially developed<br />

to be hardened via ageing heat treatment,<br />

with resistance higher than the VP20. It has<br />

excellent polishing and texturizing properties.<br />

It has an excellent weldability.<br />

Steel made under vacuum degassing,<br />

having an improved machinability through<br />

Calcium inclusion treatment. The main<br />

benefits are: high uniformity in hardness<br />

with a less than 2 HRC variation along<br />

the whole part’s cross section. Excellent<br />

weldability. High polishability (except<br />

mirror finish) and high reproducibility of<br />

performance and manufacturing.<br />

Steel supplied as machined. It has<br />

good polishability and response on<br />

texturization. For improvement of the<br />

wear resistance it can be nitrided or<br />

cemented. Due to the as supplied high<br />

hardness, special care in machining is<br />

necessary, particularly boring.<br />

SUPPLYING STATE<br />

Hardened and tempered<br />

(30 - 34 HRC)<br />

Hardened and Tempered (30-34 HRC)<br />

Solubilized and aged (40-42 HRC) or<br />

Solubilized (330 HB max)<br />

Supplied as machined (285 to 321 HB)<br />

Hardened and Tempered (38-42HRC)<br />

RECOMMENDED HEAT<br />

TREATMENT<br />

- -<br />

Ageing (in case it is supplied in the<br />

solubilized state)<br />

- -<br />

MOLD HARDNESS TYPICAL<br />

RANGE<br />

28 - 37 HRC 28-37 HRC 38-42 HRC 30-34 HRC 38 - 42 HRC<br />

POLISHABILITY Medium to High Low High High Medium to High<br />

CORROSION RESISTANCE Low Low Low to Medium Low Low<br />

RESPONSE TO NITRIDING Medium Medium High Medium Medium<br />

RESPONSE ON TEXTURIZATION Medium to High Low High Medium to High Medium to High<br />

WELDABILITY Medium Medium High High Medium<br />

WEAR RESISTANCE Low to Medium Low to Medium Medium Low to Medium Medium to High<br />

STEEL IDENTIFICATION COLOR Lavender – Black – Lavender Green-Brown- Green Lavender-Gold-Lavender Red-Blue-Red Green-Yellow<br />

APPLICATIONS<br />

Molds for injection and extrusion of<br />

non-chlorinated thermo-plastics and little<br />

abrasive. Large dimension molds.<br />

Molds for injection and extrusion of<br />

non-chlorinated and little abrasive<br />

thermo-plastics that have low polishability<br />

requirements. Bases and structures for<br />

plastic molds. Cores for injection molds.<br />

Molds for injection and extrusion of<br />

non-chlorinated thermo-plastics. Molds<br />

for load reinforced thermo-plastics.<br />

Mold carriers, molds for non-chlorinated<br />

plastic injection, dies for non-chlorinated<br />

plastic extrusion, molds for blowing,<br />

hot chambers, when a high corrosion<br />

resistance is not necessary and several<br />

applications in molds for plastics. Not<br />

recommended for applications in which<br />

toughness and mirror finish are design<br />

requirements.<br />

Molds for injection of non-chlorinated<br />

thermo-plastics. Molds for blowing.<br />

Extrusion dies for non-chlorinated<br />

thermo-plastics.<br />

The classification Low, Low to Medium, Medium to High and High are for guidance, and serve as a comparative guide just for this group of steels.<br />

* Due to the need to break the passive layer (stainless steels), it is recommended to use the ion plasma nitriding process.

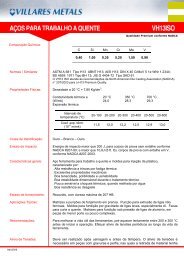

AND GLASS INDUSTRY<br />

VP ATLAS VH13IM VP420IM V630 VIMCOR<br />

- AISI H13 Wnr 1.2344<br />

AISI 420<br />

Wnr 1.2083<br />

AISI 630<br />

Wnr 1.4548<br />

NO SIMILAR STEEL<br />

Cr – Mo – Mn<br />

C 0.40 – Si 1.00 – Cr 5.20 – Mo 1.50 – V<br />

0.90 – P 0.015 max - S 0.003 max<br />

C 0.40 – Si 0.80 – Cr 13.5 – V 0.25<br />

C 0.035 – Cr 15.40 – Ni 4.40 –<br />

Cu 3.50 – Nb+Ta 0.25<br />

C 0.05 – Mn 2.5 Cr 12 –<br />

Si 0.40 – S 0.1<br />

Steel supplied as machined. It has good<br />

polishability and response on texturization.<br />

For improvement of the wear resistance it<br />

can be nitrided or cemented. Due to the<br />

as supplied high hardness, special care in<br />

machining is necessary, particularly boring.<br />

However, it has machinability advantages<br />

when compared to the DIN 1.2711.<br />

Tool steel used for applications in molds<br />

when hardness higher than VP20 and VP50<br />

hardnesses are desired. It has an excellent<br />

polishing capacity.<br />

Stainless steel after hardening and<br />

tempering. It has as its main advantage<br />

an elevated corrosion resistance, which<br />

allows working in humid environments..<br />

Precipitation hardening stainless<br />

steel. It has the following excellent<br />

properties:<br />

- Dimensional and shape stability<br />

- Weldability<br />

- Corrosion resistance<br />

- Polishability and response on texturization<br />

Resulfurized stainless steel, supplied<br />

as machined. It has an excellent<br />

performance in machinability, mainly<br />

in deep boring. Properties:<br />

- Excellent machinability<br />

- Excellent weldability<br />

- Good corrosion resistance<br />

- Hardness homogeneity<br />

Quenched and Tempered (38 – 42 HRC)<br />

Annealed (235 HB max)<br />

Annealed (200 HB max) or hardened<br />

and tempered (30 – 34 HRC)<br />

Solubilized (38 HRC max) or solubilized<br />

and aged (40 HRC max)<br />

Machined (290 – 330 HB)<br />

- Hardening and Tempering<br />

Hardening and Tempering<br />

(for the annealed material)<br />

Ageing (in case it is supplied in the<br />

solubilized state)<br />

-<br />

38-42 HRC 42 - 52 HRC 48-54 HRC 24-40 HRC 29-34 HRC<br />

Medium to High High High High Low<br />

Low Low to Medium High High High<br />

High High High * High* High*<br />

Medium to High High High High Low<br />

Medium to High Low to Medium Low to Medium High High<br />

Medium to High Medium to High Medium to High Medium Low to Medium<br />

Blue - White Green – Silver – Green Blue-Brown Silver-Red Black – White<br />

Cr-Mo-Mn alloyed steel, with micro-additions,<br />

and already supplied in the machined<br />

state. Due t o its balanced chemical<br />

composition, this material has good<br />

machinability, weldability, polishability,<br />

good response on texturization and good<br />

response to nitriding. It is indicated for<br />

molds for injection of non-chlorinated<br />

plastics, especially for applications that<br />

need higher mechanical resistance and<br />

higher wear resistance than AISI P20 or<br />

DIN 1.2738 steels; dies for extrusion of<br />

non-chlorinated thermoplastics. Several<br />

applications in molds for plastic.<br />

Molds for injection of non-chlorinated<br />

thermo-plastics for which a higher<br />

resistance to wear is required, coupled to<br />

good polishability. Molds for glass.<br />

Molds for injection of chlorinated<br />

thermo-plastics. Processing or storage in<br />

humid environment. Glass industry.<br />

Tools for thermoplastic forming, including<br />

corrosive processing (chlorinated polymer<br />

forming). It can be worked and stored in<br />

humid places.<br />

Hot chambers, Cooling Plates, Mold<br />

Carriers. It can be worked and stored<br />

in humid atmosphere.

Mold Polishing<br />

Polishing is used in molds to meet various requirements of the injected part:<br />

• Aesthetic requirements: gloss and transparency.<br />

• Mechanical: to avoid nicks and breaks by fatigue or overload.<br />

• Functional: ex.: optical devices (lenses).<br />

Polishing is a stage that takes up time and resources. The average time spent in the manual polishing of large size molds is<br />

around 300 to 400 hours per mold. Two observations are important in the evaluation of the mold surface quality. First, the surface<br />

must have the correct geometrical form, without any waving. These are derived from recent machining operations. Second, the<br />

evaluation of the mirror polished condition of the metallic mold is often carried out by visual comparison of the mold or of the<br />

surface of the injected part, based upon the operator’s experience.<br />

The fi nal quality of the polished surface of a steel depends on factors such as: the polishing technique, the type of tool steel and<br />

the heat treatment applied to the material. In general, one can say that the polishing technique is the most important factor. A<br />

typical example is shown on the graph below, the excessive polishing known as over polishing, caused by a mechanical cold work<br />

of very fi ne layers on the mold surface. In over polishing, roughness increases with the increase in polishing time. The problem<br />

is only solved with the removal of part of the surface (tenths of mm) through machining and the application of a new polishing.<br />

Visually, the phenomenon appears as “orange peel”.<br />

Roughness Rugosidade RA (mm) RA (mm)<br />

50<br />

45<br />

40<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

Overpolishing<br />

VA2 - 60 HRC<br />

P20 - 32 HRC<br />

0 5 10 15 20 25<br />

Roughness Tempo RA (min) (mm)<br />

Graph showing the effect of excessive polishing (over polishing) for two steels with different<br />

hardness levels.

For a good polishing, the mold surface must be free from scratches, pores, orange peel effect, pitting and pinholes. In Brazil, the problem of pitting and pinholes are commonly called “porosity”. Although visually correct,<br />

the term porosity is erroneously applied here, as it should be used only for pre-existing voids in the material. In the case of pinholes or pitting observed after polishing, the problem is normally caused by a process not<br />

well carried out (for a given steel and hardness), using steels with an inadequate level of nonmetallic inclusions or even by the combination of these two factors. Other possible sources of problems are surfaces with<br />

electro-erosion defects or excessive machining cold work.<br />

As to the inclusions, they can be mechanically understood as particles on the steel surface with hardness and ductility rather different from the metal. All steels have inclusions. However, the quantity and distribution<br />

depend on the manufacturing process. For high polishing applications, therefore, remelting via ESR is recommended (ISOMAX® process). As shown in the scheme below, there is a signifi cant reduction of the level of<br />

inclusions.<br />

a) Conventional ASTM G 2.0<br />

b) ISOMAX, ASTM 1.0 F<br />

Type D inclusions<br />

a) Level 2.0 acceptable for Conventional materials<br />

b) Level 1.0, Typical of material made via ESR (Source: ASTM E 45)

Texturization<br />

The response on texturization measures how easy it is to apply a texture to the tool steel used in the mold. The texturizing treatment is normally carried out by photo-etching differentially applied on the mold surface,<br />

thus generating the “negative” of the fi nal desired aspect of the injected part.<br />

The process control, in terms of the acid medium used and of the applied procedure, is essential for a good texturization result. As to the quality of the steel, similar polishing requirements are necessary: homogeneity<br />

of microstructure and hardness, besides a high level of cleanliness as to nonmetallic inclusions.<br />

4 mm<br />

2 mm<br />

4 mm<br />

2 mm<br />

Several examples of texturized surfaces in VP 100 steel, observed in stereoscope.

Junho/2012<br />

0800 19 0577<br />

0800 707 0577<br />

55 19 3303.8160<br />

arnaldo.zangueri@villaresmetals.com.br<br />

www.villaresmetals.com.br<br />

Rua Alfredo Dumont <strong>Villares</strong>, 155<br />

Jardim Santa Carolina - Sumaré / SP<br />

CEP 13178-902