Boring tools with ISO elements - MAPAL Dr. Kress KG

Boring tools with ISO elements - MAPAL Dr. Kress KG

Boring tools with ISO elements - MAPAL Dr. Kress KG

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

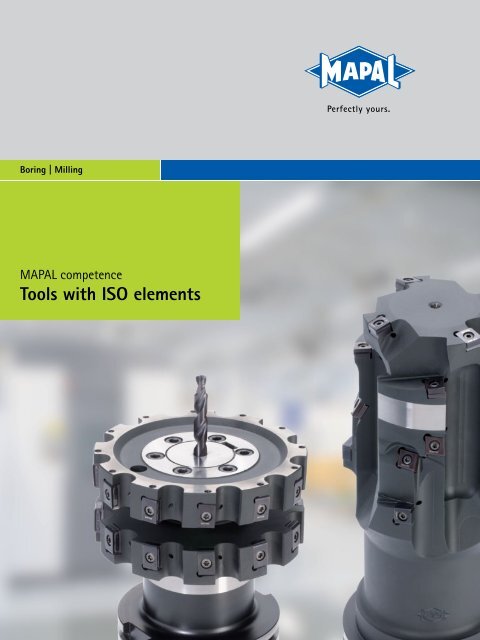

<strong>Boring</strong> | Milling<br />

<strong>MAPAL</strong> competence<br />

Tools <strong>with</strong> <strong>ISO</strong> <strong>elements</strong>

Perfect machining technology<br />

<strong>MAPAL</strong> stands for innovative machining solutions <strong>with</strong> the<br />

highest quality, precision and cost-effectiveness.<br />

Starting from fine bore machining, we offer our customers a<br />

comprehensive range of precision <strong>tools</strong> for machining cubic<br />

parts. In conjunction <strong>with</strong> tailored services we can design<br />

complete machining processes so that reliable, cost-effective<br />

manufacturing is guaranteed.<br />

<strong>ISO</strong> <strong>tools</strong> from <strong>MAPAL</strong> have achieved a leading role in the areas<br />

of boring, precision boring and milling. Building on<br />

its knowledge of fine machining, in recent<br />

years <strong>MAPAL</strong> has produced a wide range of<br />

cost-effective standard <strong>tools</strong> and a broad<br />

technological basis for customer-specific<br />

solutions.<br />

Our specialists tap major productivity<br />

potential for every machining task by<br />

means of a wide variety of design options<br />

and their deep process understanding.<br />

<strong>Dr</strong>. Jochen <strong>Kress</strong>

Reliable service – Worldwide<br />

Complete support from planning to<br />

the process<br />

c Planning and organising the<br />

complete machining process<br />

c Technical support during<br />

commissioning<br />

c Reliable and cost-effective tool<br />

supply by means of tool<br />

management<br />

c Worldwide availability<br />

The sound experience of <strong>MAPAL</strong><br />

specialists is available to customers<br />

worldwide during the entire<br />

collaboration process up to and<br />

including process support. Depending<br />

on the customers needs, individual<br />

custom <strong>tools</strong> are designed or the<br />

complete planning and process<br />

support taken over. However, support<br />

from <strong>MAPAL</strong> does not end <strong>with</strong> the<br />

start of production. Even during<br />

the production phase specialists<br />

from <strong>MAPAL</strong> assist the customer,<br />

optimise parameters or tool details,<br />

provide advice related to the process<br />

<strong>with</strong> their know-how and produce<br />

significant added value for the<br />

customer. With its complete range of<br />

services including tool management,<br />

<strong>MAPAL</strong> helps to keep production<br />

top notch: highly productive, costeffective<br />

and reliable.<br />

<strong>ISO</strong> <strong>tools</strong> and services from <strong>MAPAL</strong><br />

are available worldwide. With<br />

production facilities, sales and<br />

service offices in all relevant markets<br />

of the world, short channels for<br />

delivery and support are guaranteed.<br />

The systematic know-how transfer<br />

between the subsidiaries ensures<br />

consistent quality collaboration at<br />

the highest technical level.<br />

• Subsidiaries<br />

◦ Representatives

Competent in the standard<br />

Broad standard programme of <strong>tools</strong><br />

and indexable inserts<br />

c <strong>Boring</strong> large diameters <strong>with</strong> short<br />

machining times<br />

c High-performance milling cutters<br />

for a large number of machining<br />

tasks<br />

c Precise, cost-effective indexable<br />

inserts<br />

The usage of high performance,<br />

cost-effective standard <strong>tools</strong> plays a<br />

significant role in process design. In<br />

this area <strong>MAPAL</strong> has produced and<br />

brought to market maturity a broad<br />

range of <strong>tools</strong> and indexable inserts<br />

in recent years.<br />

For boring large diameters <strong>with</strong><br />

short machining times the tangential<br />

<strong>tools</strong> TSW and TFB have been further<br />

developed as a uniform and highly<br />

productive program for roughing and<br />

fine machining. In the milling area<br />

a high performance range of <strong>tools</strong><br />

is available as standard for a large<br />

number of machining tasks. And<br />

finally there is a completely new, costeffective<br />

range of indexable inserts for<br />

<strong>ISO</strong> <strong>tools</strong> available from stock.

Leading process solutions<br />

Optimised processes <strong>with</strong> matched<br />

complete machining <strong>tools</strong><br />

Reduced machining costs through<br />

<strong>ISO</strong> complete machining <strong>tools</strong> and<br />

hybrid <strong>tools</strong><br />

Intelligent engineering guarantees<br />

process reliability and<br />

straightforward handling<br />

The latest manufacturing facilities<br />

for precision <strong>tools</strong> at the highest<br />

level<br />

During the planning of new<br />

machining processes as well as the<br />

optimisation of existing processes,<br />

the focus is on the assessment of<br />

the machining time and the Cost Per<br />

Part (CPP). By means of intelligent,<br />

multi-stage, multi-cutting edge<br />

<strong>ISO</strong> combination <strong>tools</strong> or complete<br />

machining <strong>tools</strong>, both the productive<br />

times and the non-productive times<br />

can be significantly reduced. Here the<br />

design of intelligent tool solutions is<br />

not limited to just the <strong>ISO</strong> area. To<br />

prepare a solution that is optimal for<br />

the customer, different machining<br />

systems are combined into socalled<br />

hybrid <strong>tools</strong>. <strong>ISO</strong> <strong>tools</strong> from<br />

<strong>MAPAL</strong> meet both the requirement<br />

for process reliability and the<br />

requirement for straightforward<br />

handling – <strong>with</strong> intelligent and<br />

precise adapter solutions along<br />

<strong>with</strong> reliable, quick indexable insert<br />

mounting. The reliable principle<br />

of operation of <strong>MAPAL</strong> <strong>ISO</strong> <strong>tools</strong><br />

is ensured by the latest design<br />

methods that make it possible to<br />

assess collisions or to determine tool<br />

restrictions even during the planning<br />

phase. Production in the latest<br />

manufacturing facilities guarantees<br />

maximum tool precision.

Demanding machining tasks require<br />

maximum productivity<br />

Components such as engine blocks, brakes, turbochargers or swivel bearings, and also<br />

many other cubic parts from the automotive and commercial vehicle industry, mechanical<br />

engineering and systems engineering or the energy and aerospace industry require<br />

accuracies in the machining process in the range from IT 9 to IT 7. It must be possible to<br />

optimally machine mostly cored parts <strong>with</strong> high stock removal, large bore diameters and<br />

varying structures while taking into account the tolerance parameters, the stability of the<br />

part and the performance of the machine.<br />

<strong>ISO</strong> tool solutions are predestined for these requirements and cover the complete range<br />

of workpiece materials, in particular cast parts. Due to the large selection of cutting<br />

geometries, insert shapes and cutting materials, they are versatile in use and offer<br />

significant rationalisation potential during boring or milling in pre-machining or fine<br />

machining. The replaceable indexable inserts make the reconditioning of <strong>tools</strong> particularly<br />

straightforward and reduce the tool costs and as a consequence the Cost Per Part (CPP).<br />

Requirements on<br />

innovative tool solutions<br />

For all materials<br />

For numerous<br />

applications<br />

Increase productivity and quality<br />

Reduce productive and<br />

non-productive times<br />

Reduce costs<br />

Easy handling<br />

Universal use<br />

Conservation of resources<br />

P M K N S<br />

The numerous possibilities continue<br />

<strong>with</strong> the list of workpiece materials.<br />

The applications range from machining<br />

castings and steel, through the<br />

machining of demanding, high-alloy<br />

materials such as titanium or Inconel, to<br />

aluminium.<br />

Engine blocks<br />

6

Tools <strong>with</strong> <strong>ISO</strong> <strong>elements</strong> | Introduction<br />

Suspension<br />

Brakes Turbochargers Connecting rods<br />

Compressors<br />

Large engines<br />

Gearbox housing:<br />

mechanical engineering /<br />

system engineering<br />

Wind power<br />

7

<strong>ISO</strong> <strong>tools</strong> from <strong>MAPAL</strong> –<br />

the leading technology<br />

The high customer requirements are met by <strong>MAPAL</strong> from the design to the manufacture<br />

of the <strong>tools</strong> by means of extensive know-how and the latest technology. For this reason<br />

<strong>ISO</strong> <strong>tools</strong> from <strong>MAPAL</strong> are leading in the custom sector and standard sector.<br />

The combination of continuous product innovations and a wealth of experience from<br />

more than 15 years gives the <strong>tools</strong> their high performance – <strong>with</strong> the objective of<br />

achieving higher part qualities, better tool lives and increased productivity.<br />

<br />

Precision, performance and innovative technology<br />

<br />

Process solutions –<br />

Perfectly yours<br />

<br />

<strong>MAPAL</strong> precision in design<br />

and production<br />

Advantages of<br />

<strong>MAPAL</strong> <strong>ISO</strong> <strong>tools</strong><br />

Reduction of the<br />

manufacturing costs per unit<br />

due to short machining times<br />

Combination <strong>tools</strong> for the<br />

reduction of the number of<br />

<strong>tools</strong> required<br />

High process reliability<br />

Maximum cost-effectiveness<br />

due to tangential technology<br />

Technology available<br />

worldwide<br />

To reduce productive and non-productive<br />

times simultaneously, <strong>MAPAL</strong> offers<br />

particularly high performance complete<br />

machining <strong>tools</strong>. Reduced cycle times, lower<br />

energy consumption and the related higher<br />

cost-effectiveness are the result. These<br />

effects are achieved by innovative processes<br />

such as helix milling or interpolation turning.<br />

Among the success stories of processes<br />

optimised by <strong>MAPAL</strong> specialists there are<br />

some applications where it was possible to<br />

save up to 60 % of the machining time.<br />

The latest 3D design and computer-aided<br />

studies make it possible to develop and<br />

design complex tangential <strong>tools</strong>. The data<br />

on the insert seats and chip spaces exactly<br />

defined in this manner and other machining<br />

tasks are sent via a CAM interface to<br />

the controller for high-accuracy, highperformance<br />

5-axis machining centres. In<br />

this way <strong>MAPAL</strong> <strong>ISO</strong> <strong>tools</strong> are produced <strong>with</strong><br />

monitoring and control by experienced staff.<br />

Highly accurate manufacturing tolerances<br />

are required and met. This aspect guarantees<br />

a real multi-cutting edge capability and the<br />

high performance of the <strong>tools</strong>.<br />

8

Tools <strong>with</strong> <strong>ISO</strong> <strong>elements</strong> | Introduction<br />

Maximum cost-effectiveness Always the right cutting edge Finishing machining possible<br />

due to tangential technology<br />

Crucial for the high performance of the<br />

<strong>MAPAL</strong> <strong>ISO</strong> <strong>tools</strong> is tangential technology.<br />

Compared to the usage of radially mounted<br />

indexable inserts, this technology permits<br />

the usage of several cutting edges <strong>with</strong> the<br />

same power consumption. So that, higher<br />

machining values and a higher machining<br />

volume are possible. Tangential <strong>tools</strong> also<br />

feature very smooth running. As a result<br />

excellent tool lives and very good part<br />

qualities are achieved.<br />

In the area of <strong>ISO</strong> boring and milling<br />

<strong>tools</strong> <strong>MAPAL</strong> offers a wide selection of<br />

geometries and cutting materials. Due to the<br />

comprehensive programme it is ensured that<br />

the right cutting edge can be used for every<br />

application. Along <strong>with</strong> the different shapes<br />

and sizes, this programme also includes<br />

cutting materials such as carbide, ceramic<br />

and PCD or PcBN-tipped inserts. This variety<br />

has a positive effect on cost-effectiveness<br />

and the efficiency of the usage of resources.<br />

Depending upon the application, up to eightcutting<br />

edges on the indexable inserts ensure<br />

the cutting material is utilised optimally.<br />

The indexable inserts are straightforward<br />

and reliable to change. The combination of<br />

highly accurate inserts and a precise insert<br />

seat in the tool body guarantees a consistent<br />

machining result after every insert change.<br />

To be able to achieve very high accuracies,<br />

particularly during bore machining, <strong>MAPAL</strong><br />

uses a special, simple adjusting system that is<br />

accurate to the μ.<br />

9

Significant advantages due to innovative tool solutions<br />

The perfect interaction – TSW/TFB <strong>tools</strong><br />

The <strong>MAPAL</strong> tangential roughing <strong>tools</strong> TSW and tangential fine boring <strong>tools</strong> TFB are designed<br />

as a complete programme from pre-machining to fine machining, especially for large bore<br />

diameters. The TSW roughing <strong>tools</strong> feature an indexable insert <strong>with</strong> six usable cutting edges.<br />

The special effect of the arc shaped land is even more apparent on indexable inserts for the TFB<br />

fine boring <strong>tools</strong>. Using these <strong>tools</strong>, machining results of reaming quality are achieved – <strong>with</strong><br />

significantly shorter machining times than one or two-cutting edge boring <strong>tools</strong>.<br />

For example:<br />

During the pre-machining of cylinder<br />

bores in engine blocks made of GG25<br />

using a tangential roughing tool, it was<br />

possible to reduce the machining time<br />

from 16 seconds to eight seconds. Prior<br />

to the conversion it was necessary to<br />

divide the high stock removal over two<br />

boring <strong>tools</strong>.<br />

50 % less machining time<br />

more from page 18<br />

Win in every process – complex combination <strong>tools</strong><br />

For example:<br />

It was possible to reduce the total<br />

machining time for a gearbox housing<br />

made of grey cast iron from 46 minutes<br />

to 18 minutes. This saving was possible<br />

due to the usage of various <strong>MAPAL</strong> <strong>ISO</strong><br />

<strong>tools</strong> for the combination machining and<br />

for the interpolation turning.<br />

60 % less machining time<br />

The optimisation of each individual machining step in a machining process results in the most<br />

cost-effective result in the end. During the machining of large numbers of parts, around two<br />

thirds of the non-productive time and a third of the productive time is avoided. Accordingly,<br />

there is significant potential for reducing the process time by means of reduced tool changing<br />

and movement times. <strong>MAPAL</strong> has the know-how and the facilities to exploit this potential by<br />

means of complex combination <strong>tools</strong> and modern machining technologies. The combination of<br />

different machining systems into so-called hybrid <strong>tools</strong> also opens up numerous possibilities.<br />

more examples from page 127<br />

10

Tools <strong>with</strong> <strong>ISO</strong> <strong>elements</strong> | Introduction<br />

Eight cutting edges on the disc milling cutter – LTHU indexable<br />

inserts<br />

High stability, a soft cut and a large number of cutting edges characterise the <strong>MAPAL</strong><br />

tangential milling programme. The disc and shoulder milling cutters fitted <strong>with</strong> the<br />

4+4-cutting edge indexable inserts of type LTHU are a highlight. These peripheral ground<br />

indexable inserts combined <strong>with</strong> the highly accurate <strong>MAPAL</strong> fixed insert seats in the tool<br />

achieve real multi-cutting edge capability during roughing and semi-finishing. On the milling<br />

cutters shown below all eight cutting edges can be used in the same machining direction and<br />

offer excellent cost-effectiveness.<br />

For example:<br />

During the milling of the disc slot and<br />

the pad seat on a car brake caliper, it<br />

was possible to significantly reduce<br />

the Cost Per Part (CPP) for the milling<br />

process using a disc milling cutter <strong>with</strong><br />

eight-cutting edge LTHU indexable<br />

inserts.<br />

Costs per part reduced<br />

by 66 %<br />

more on the milling cutter range from page 64, more on indexable inserts from page 121<br />

Machine extensively and quickly – the <strong>MAPAL</strong> helix milling cutter<br />

For roughing different, in particular large diameters on a workpiece, circular milling is often<br />

used. However, a circular milling cutter often requires a large number of cycles until all the<br />

machining is complete. This means a low material removal rate and a long machining time. The<br />

alternative is the <strong>MAPAL</strong> helix milling cutter: it superimposes an axial feed movement on the<br />

circular movement. With the specially arranged tangential indexable inserts, the tool plunges<br />

into the workpiece at full cutting depth. Up to 50 % higher material removal rates secure<br />

significant efficiency advantages compared to conventional circular milling.<br />

For example:<br />

Compared to a porcupine milling cutter,<br />

by changing to the <strong>MAPAL</strong> helix milling<br />

cutter it was possible to increase<br />

the material removal rate during the<br />

machining of a bore <strong>with</strong> a diameter of<br />

1,300 mm in a GG25 housing from 1,450<br />

to 2,150 cm³/min.<br />

Material removal rate<br />

increased by 48 %<br />

more on helix milling from page 192<br />

11

Tools <strong>with</strong> <strong>ISO</strong> <strong>elements</strong> | Introduction | Index<br />

<strong>Boring</strong> 15<br />

Milling 35<br />

Indexable inserts 67<br />

<br />

Innovative complete<br />

solutions 127<br />

Cartridges 137<br />

Accessories and spare parts 153<br />

Technical appendix 171<br />

13

Tools <strong>with</strong> <strong>ISO</strong> <strong>elements</strong> | <strong>Boring</strong><br />

<strong>Boring</strong><br />

Introduction<br />

<strong>Boring</strong> <strong>tools</strong> for<br />

pre-machining and<br />

fine machining<br />

Pre-machining places major challenges on<br />

machining manufacture. For this reason a costeffective<br />

pre-machining tool is important in the<br />

machining process.<br />

With a background of fine machining and many<br />

years of experience related to bore machining,<br />

<strong>MAPAL</strong> has obtained sound know-how that is<br />

manifested in the innovative and very productive<br />

boring <strong>tools</strong> <strong>with</strong> <strong>ISO</strong> <strong>elements</strong>. <strong>ISO</strong> combination<br />

<strong>tools</strong> tap new productivity potential on a daily<br />

basis – also in conjunction <strong>with</strong> other product<br />

groups. The tangential roughing and fine boring<br />

<strong>tools</strong> were specially developed for pre-machining<br />

and fine machining large diameters; today these<br />

<strong>tools</strong> are available as standard.<br />

Programme overview boring 16-17<br />

Tangential roughing <strong>tools</strong> TSW 18<br />

Application notes TSW 19<br />

Designation key and series TSW 20-25<br />

Tangential fine boring <strong>tools</strong> TFB 26<br />

Application notes TFB 27<br />

Designation key and series TFB 28-33<br />

Through bore<br />

Suitable for open bores. Not suitable for machining shoulders<br />

if a 90° angle is required.<br />

Blind bore<br />

Suitable for closed bores and machining shoulders taking into<br />

account the cutting edge length.<br />

Internal cooling<br />

Tools designed <strong>with</strong> internal coolant supply.<br />

15

Tools <strong>with</strong> <strong>ISO</strong> <strong>elements</strong> | <strong>Boring</strong> | Programme overview<br />

<strong>Boring</strong> <strong>tools</strong> <strong>with</strong> <strong>ISO</strong> <strong>elements</strong><br />

Programme overview<br />

1 – 2 Standard <strong>tools</strong><br />

1 TFB – tangential fine boring tool<br />

2 TSW – tangential roughing tool<br />

The <strong>MAPAL</strong> tangential roughing <strong>tools</strong> TSW<br />

and tangential fine boring <strong>tools</strong> TFB are<br />

designed as a complete range from the<br />

pre-machining to fine machining especially<br />

of large bore diameters.<br />

3 Hybrid <strong>tools</strong><br />

<strong>MAPAL</strong> hybrid <strong>tools</strong> combine different<br />

machining systems for maximum<br />

productivity.<br />

Example: combination tool <strong>with</strong> solid<br />

carbide drill and <strong>ISO</strong> countersink step.<br />

4 Multi-step capability and<br />

Tangential technology<br />

The multi-step design reduces the <strong>tools</strong><br />

needed and shortens the machining<br />

time. The tangential technology ensures<br />

particularly quiet running. In combination<br />

<strong>with</strong> guide pads, the <strong>tools</strong> achieve very<br />

high positioning accuracy.<br />

5 Modular construction of <strong>ISO</strong><br />

combination <strong>tools</strong><br />

The modular design of <strong>ISO</strong> combination<br />

<strong>tools</strong> offers many advantages. For example,<br />

entire part families can be machined <strong>with</strong><br />

fewer <strong>tools</strong> as only part of the tool needs<br />

to be changed. By using connections,<br />

for instance a highly accurate HSK-C<br />

connection, particularly complex <strong>tools</strong><br />

can be constructed. Even more machining<br />

steps are combined into one tool and the<br />

productivity increased even further.<br />

6 External machining <strong>tools</strong><br />

<strong>ISO</strong> <strong>tools</strong> for external machining are<br />

individually adapted to the machining task.<br />

Whether turning diameters, chamfering<br />

or producing special external contours,<br />

<strong>MAPAL</strong> <strong>ISO</strong> <strong>tools</strong> are the right solution.<br />

The usage of tangential indexable inserts<br />

also increases the performance of the <strong>tools</strong><br />

here.<br />

7 Fixed insert seat and cartridge<br />

High accuracy manufacturing tolerances on<br />

insert seats and indexable inserts guarantee<br />

the real multi-cutting edge capability of the<br />

<strong>ISO</strong> <strong>tools</strong> <strong>with</strong> fixed insert seats. Cartridges<br />

<strong>with</strong> standard dimensions or in a compact<br />

design further increase the flexibility of<br />

<strong>MAPAL</strong> <strong>ISO</strong> <strong>tools</strong>.<br />

8 <strong>Boring</strong> <strong>tools</strong> <strong>with</strong> radial technology<br />

Depending on the requirements of the part<br />

and machining situation, <strong>ISO</strong> boring <strong>tools</strong> are<br />

also designed <strong>with</strong> radial indexable inserts.<br />

2<br />

1<br />

3<br />

8 7<br />

16

Tools <strong>with</strong> <strong>ISO</strong> <strong>elements</strong> | <strong>Boring</strong> | Programme overview<br />

Exact adjustment<br />

<strong>Boring</strong><br />

Introduction<br />

For the cases in which high accuracy indexable inserts and precision milled insert seats are<br />

insufficient for the required accuracy, <strong>MAPAL</strong> uses an adjustment system specially developed<br />

for <strong>ISO</strong> inserts. Here the insert sits on an adjusting wedge <strong>with</strong> a large contact area. This<br />

feature is completely embedded in the tool body and as a result offers the indexable insert<br />

a stable seat. The adjusting wedge has an angled surface and can be moved using a lefthand<br />

- right-hand threaded adjusting screw. This design produces an indirect, very accurate<br />

and easy to use setting feature. As a consequence <strong>MAPAL</strong> <strong>ISO</strong> <strong>tools</strong> achieve accuracies not<br />

normally achieved using <strong>ISO</strong> <strong>tools</strong>.<br />

4<br />

5<br />

Best machining results due to<br />

arc shaped land<br />

Due to the normal clearance angle<br />

on <strong>ISO</strong> indexable inserts there is only<br />

limited support for the tool during<br />

bore machining. Tools then tend to<br />

vibration; this vibration effects the<br />

surface finish and tool life expectancy.<br />

To counteract this problem, <strong>MAPAL</strong><br />

developed the arc shaped land. This<br />

special geometry is a support surface<br />

on the cutting edge that supports the<br />

tool in the bore and is comparable to<br />

an arc land chamfer on fixed reamers.<br />

6<br />

17

Tools <strong>with</strong> <strong>ISO</strong> <strong>elements</strong> | <strong>Boring</strong> | Tangential roughing <strong>tools</strong> TSW<br />

Tangential roughing <strong>tools</strong> TSW<br />

The <strong>MAPAL</strong> tangential roughing <strong>tools</strong> set new standards<br />

in relation to stability and performance, particularly in the<br />

case of higher stock removal. An innovative, six-cutting<br />

edge indexable insert <strong>with</strong> special support chamfer prevents<br />

chatter and vibration. Perfect multi-cutting edge capability<br />

<strong>with</strong> increased stability is ensured by the tangential<br />

installation of the indexable inserts in precision insert seats<br />

on the front face.<br />

Tangential roughing <strong>tools</strong><br />

Series<br />

TSW 101/111 and TSW 201/211<br />

The ground clamping geometry combined<br />

<strong>with</strong> the tangential installation position on<br />

the face of the tool body results in a highly<br />

positive rake angle and therefore a soft cut<br />

and very quiet tool cutting behaviour. This<br />

property is further supported by a special<br />

support surface on the cutting edges, an arc<br />

shaped land, which supports the tool in the<br />

bore like an arc land chamfer on reamers.<br />

Along <strong>with</strong> the excellent cutting behaviour of<br />

the tangential roughing <strong>tools</strong>, the necessary<br />

drive power required is also reduced, as the<br />

machining forces are comparatively low. As a<br />

result the <strong>tools</strong> can also be used on machines<br />

<strong>with</strong> lower torques. It is, however, much more<br />

important that, <strong>with</strong> the same drive power,<br />

it is possible to fit more cutting edges to the<br />

<strong>tools</strong>, so that the feeds are increased and<br />

machining times drastically reduced.<br />

The diameter range of the <strong>tools</strong> from the<br />

standard series is 37 - 280 mm; larger<br />

diameters are also possible as a custom<br />

solution. Two insert sizes available in<br />

different substrates cover the entire diameter<br />

range.<br />

The TSW are available in a monoblock design<br />

and as a modular system for larger diameters.<br />

The TSW <strong>tools</strong> are also designed <strong>with</strong> two<br />

different contact angles on the insert seats.<br />

The contact angle is 0° on the TSW 101/201<br />

<strong>tools</strong> for blind bores and 10° on the TSW<br />

111/211 <strong>tools</strong> for through bores.<br />

Features<br />

Six-cutting edge tangential<br />

indexable insert<br />

Soft cutting behaviour<br />

Reduced drive power<br />

Tool life increased by up to 30 %<br />

High cutting depths<br />

Six to eight times faster than<br />

boring <strong>tools</strong><br />

18<br />

The indexable insert has six cutting edges (marked<br />

in red) that are used by rotating and turning.

Tools <strong>with</strong> <strong>ISO</strong> <strong>elements</strong> | <strong>Boring</strong> | Tangential roughing <strong>tools</strong> TSW<br />

Application notes<br />

TSW monoblock ø 37 - 120 mm<br />

TSW modular design ø 60 - 280 mm<br />

<strong>Boring</strong><br />

TSW / TFB<br />

Tool holders<br />

Tangential roughing head<br />

General figures for determining the maximum tool length<br />

350<br />

300<br />

250<br />

HSK 100<br />

SK 50 / HSK 80<br />

In case of unfavourable diameter-length<br />

ratios a pilot bore is recommended.<br />

Length<br />

200<br />

150<br />

SK 40 / HSK 63<br />

lmax<br />

100<br />

50<br />

0<br />

40 60 80 100 120 140 160 180 200 220 240 260 280<br />

Diameter<br />

Ordering example TSW 111<br />

Pre-machining of a<br />

through bore in GGG40<br />

The following are required:<br />

Nominal diameter<br />

Depth of the bore<br />

Material<br />

Machine spindle<br />

88,5 mm<br />

138.0 mm<br />

GGG40<br />

HSK-A100<br />

Number of cutting edges (pay attention to machine performance, see page 174) Z = 4<br />

<br />

<br />

Tool model for the stated machining application:<br />

d=88,5<br />

Z=4<br />

TSW111-ø 088.50-Z4-200.0-A100<br />

(L 2 =55)<br />

L B =138<br />

2<br />

5<br />

L 1 =200<br />

Selected indexable inserts see page 99<br />

WTHQ090608H03L10B041-HP455<br />

19

Tools <strong>with</strong> <strong>ISO</strong> <strong>elements</strong> | <strong>Boring</strong> | Designation key<br />

Designation key for tangential roughing <strong>tools</strong> TSW<br />

Tools:<br />

TSW monoblock / TSW roughing heads<br />

l h<br />

d 1<br />

d 1<br />

TSW 101 and 111 TSW 201 and 211<br />

T S W 1 0 1 - Ø 1 0 0 . 0 0 - Z 4<br />

Tool type<br />

Tool diameter d 1 and number of teeth<br />

TSW 101 + 111 TSW 201 + 211 TSW 101 + 111 TSW 201 + 211<br />

Monoblock design<br />

TSW 101 =0° contact angle<br />

for blind bores and bores <strong>with</strong> shoulders<br />

TSW 111 =10° contact angle<br />

for through bores<br />

Modular design<br />

TSW 201 =0° contact angle<br />

for blind bores and bores <strong>with</strong> shoulders<br />

TSW 211 =10° contact angle<br />

for through bores<br />

Diameter d 1 No. of teeth Diameter d 1 No. of teeth<br />

37,00-40,40 Z = 2 59,50-74,40 Z = 3<br />

40,50-59,40 Z = 3 74,50-89,40 Z = 4<br />

59,50-74,40 Z = 3 89,50-104,40 Z = 4<br />

74,50-104,40 Z = 4 104,50-119,40 Z = 5<br />

104,50-120,00 Z = 5 119,50-174,40 Z = 5<br />

174,50-280,00 Z = 5<br />

Tool holders:<br />

TSW 201 and 211<br />

l h<br />

M C A - H S K - A 1 0 0 - 6 0 - 1 8 0 - 9 - 0 - W<br />

Type<br />

Shank connection<br />

Clamping<br />

diameter<br />

Projection<br />

length l h<br />

Internal<br />

cooling<br />

Alignment<br />

MCA Arbor<br />

HSK-A<br />

Custom<br />

Hollow shank taper<br />

Diameter Nominal length<br />

9 (not<br />

Form A<br />

of arbor<br />

of the arbor<br />

specified)<br />

0<br />

HSK-C<br />

Hollow shank taper<br />

Form C<br />

Dimensions in mm.<br />

SK<br />

Taper shank<br />

in acc. <strong>with</strong> <strong>ISO</strong> AD/B<br />

Without<br />

alignment<br />

W<br />

Length<br />

adjustment<br />

Without<br />

length<br />

adjustment<br />

20

Tools <strong>with</strong> <strong>ISO</strong> <strong>elements</strong> | <strong>Boring</strong> | Designation key<br />

<strong>Boring</strong><br />

TSW / TFB<br />

- 1 0 0 . 5 - A D B 5 0<br />

Tool length<br />

Shank form<br />

TSW 101 + 111 TSW 201 + 211<br />

Connection Size Code<br />

l 1 = Can be configured<br />

as per lengthdiameter<br />

diagram<br />

l k = 40,0<br />

HSK-C 63 C63<br />

HSK-C 80 C80<br />

HSK-C 100 C100<br />

HSK-A 63 A63<br />

HSK-A 80 A80<br />

HSK-A 100 A100<br />

SK-AD/B 40 ADB40<br />

SK-AD/B 50 ADB50<br />

21

Tools <strong>with</strong> <strong>ISO</strong> <strong>elements</strong> | <strong>Boring</strong> | Tangential roughing <strong>tools</strong><br />

TSW 101 – tangential roughing <strong>tools</strong><br />

Monoblock design<br />

Contact angle 0°<br />

For blind bores and bores <strong>with</strong> shoulders<br />

l 2<br />

l 1<br />

d 1<br />

Machine connection HSK<br />

d 1 Number Nominal<br />

Tool lengths Indexable insert TORX® screw<br />

of cutting size<br />

edges HSK<br />

l 2 l 1 min l 1 max<br />

Order No.<br />

37,00 - 40,40 2<br />

40,50 - 59,40 3<br />

59,50 - 74,40 3<br />

74,50 - 104,40 4<br />

104,50 - 120,00 5<br />

HSK-A HSK-C HSK-A HSK-C HSK-A HSK-C<br />

63 47 20 55 50<br />

80 47 25 55 55<br />

100 55 30 70 70<br />

63 47 20 60 50<br />

80 47 25 55 55<br />

100 55 30 65 65<br />

63 47 20 65 50<br />

80 47 25 60 55<br />

100 55 30 60 65<br />

63 47 20 75 55<br />

80 47 25 70 55<br />

100 55 30 70 65<br />

80 47 25 75 60<br />

100 55 30 75 65<br />

l 2<br />

l 1<br />

See diagram<br />

Page 19<br />

See diagram<br />

Page 19<br />

WTHQ 0705<br />

L00BO26<br />

WTHQ 0906<br />

L00BO41<br />

Page 98<br />

Page 98<br />

TX15-M4x11<br />

10018468<br />

TX20-M5x13<br />

10105084<br />

d 1<br />

Machine connection SK<br />

d 1 Number Nominal<br />

Tool lengths Indexable insert TORX® screw<br />

of cutting size<br />

edges SK<br />

l 2 l 1 min l 1 max<br />

Order No.<br />

37,00 - 40,40 2<br />

40,50 - 59,40 3<br />

59,50 - 74,40 3<br />

74,50 - 104,40 4<br />

104,50 - 120,00 5<br />

Further dimensions and lengths on request.<br />

Dimensions in mm.<br />

22<br />

SK-AD / SK-B SK-AD / SK-B SK-AD / SK-B<br />

40 40 50<br />

50 45 60<br />

40 40 55<br />

50 45 60<br />

40 40 60<br />

50 45 50<br />

40 40 70<br />

50 45 60<br />

40 40 75<br />

50 45 65<br />

See diagram<br />

Page 19<br />

See diagram<br />

Page 19<br />

WTHQ 0705<br />

L00BO26<br />

WTHQ 0906<br />

L00BO41<br />

TX15-M4x11<br />

10018468<br />

TX20-M5x13<br />

10105084<br />

Please note: If the collar diameter at l 2 is smaller than d 1 , it is also to be taken into<br />

account in the machining length.<br />

Page 98<br />

Page 98

Tools <strong>with</strong> <strong>ISO</strong> <strong>elements</strong> | <strong>Boring</strong> | Tangential roughing <strong>tools</strong><br />

TSW 111 – tangential roughing <strong>tools</strong><br />

Monoblock design<br />

Contact angle 10°<br />

For through bores<br />

<strong>Boring</strong><br />

TSW / TFB<br />

l 1<br />

10°<br />

l 2<br />

l 1<br />

10˚<br />

d 1<br />

d 1<br />

Machine connection HSK<br />

d 1 Number Nominal<br />

Tool lengths Indexable insert TORX® screw<br />

of cutting size<br />

edges HSK<br />

l 2 l 1 min l 1 max<br />

Order No.<br />

37,0 - 40,40 2<br />

40,50 - 59,40 3<br />

59,50 - 74,40 3<br />

74,50 - 104,40 4<br />

104,50 - 120,00 5<br />

HSK-A HSK-C HSK-A HSK-C HSK-A HSK-C<br />

63 47 20 55 50<br />

80 47 25 55 55<br />

100 55 30 70 70<br />

63 47 20 60 50<br />

80 47 25 55 55<br />

100 55 30 65 65<br />

63 47 20 65 50<br />

80 47 25 60 55<br />

100 55 30 60 65<br />

63 47 20 75 55<br />

80 47 25 70 55<br />

100 55 30 70 65<br />

80 47 25 75 60<br />

100 55 30 75 65<br />

See diagram<br />

Page 19<br />

See diagram<br />

Page 19<br />

WTHQ 0705<br />

L10BO26<br />

WTHQ 0906<br />

L10BO41<br />

Page 99<br />

Page 99<br />

TX15-M4x11<br />

10018468<br />

TX20-M5x13<br />

10105084<br />

l 2<br />

Machine connection SK<br />

d 1 Number Nominal<br />

Tool lengths Indexable insert TORX® screw<br />

of cutting size<br />

edges SK<br />

l 2 l 1 min l 1 max<br />

Order No.<br />

37,00 - 40,40 2<br />

40,50 - 59,40 3<br />

59,50 - 74,40 3<br />

74,50 - 104,40 4<br />

104,50 - 120,00 5<br />

Further dimensions and lengths on request.<br />

Dimensions in mm.<br />

SK-AD / SK-B SK-AD / SK-B SK-AD / SK-B<br />

40 40 50<br />

50 45 60<br />

40 40 55<br />

50 45 60<br />

40 40 60<br />

50 45 50<br />

40 40 70<br />

50 45 60<br />

40 40 75<br />

50 45 65<br />

See diagram<br />

Page 19<br />

See diagram<br />

Page 19<br />

WTHQ 0705<br />

L10BO26<br />

WTHQ 0906<br />

L10BO41<br />

TX15-M4x11<br />

10018468<br />

TX20-M5x13<br />

10105084<br />

Please note: If the collar diameter at l 2 is smaller than d 1 , it is also to be taken into<br />

account in the machining length.<br />

Page 99<br />

Page 99<br />

23

Tools <strong>with</strong> <strong>ISO</strong> <strong>elements</strong> | <strong>Boring</strong> | Tangential roughing heads<br />

TSW 201 – tangential roughing heads<br />

Modular design<br />

Contact angle 0°<br />

For blind bores and bores <strong>with</strong> shoulders<br />

l k<br />

d 2<br />

d 3<br />

d 1<br />

d 1 Number of cutting d 3 l k d 2<br />

edges<br />

Indexable insert<br />

TORX® screw<br />

Order No.<br />

59,50 - 74,40<br />

74,50 - 89,40<br />

3<br />

4<br />

18<br />

22<br />

39<br />

50<br />

89,50 - 104,40 4 27 40<br />

60<br />

104,50 - 119,40 5 27 60<br />

119,50 - 174,40 5 40 89<br />

WTHQ 0906<br />

L00B041<br />

Page 98<br />

10105084<br />

174,50 - 280,00 5 60 40 140<br />

WTHQ 0906<br />

L00B081<br />

Page 98<br />

10105084<br />

TSW 211 – tangential roughing heads<br />

Modular design<br />

Contact angle 10°<br />

For through bores<br />

l k<br />

10˚<br />

d 2<br />

d 3<br />

d 1<br />

d 1 Number of cutting d 3 l k d 2<br />

edges<br />

Indexable insert<br />

TORX® screw<br />

Order No.<br />

59,50 - 74,40<br />

74,50 - 89,40<br />

3<br />

4<br />

18<br />

22<br />

39<br />

50<br />

89,50 - 104,40 4 27 40<br />

60<br />

104,50 - 119,40 5 27 60<br />

119,50 - 174,40 5 40 89<br />

WTHQ 0906<br />

L10B041<br />

Page 99<br />

10105084<br />

174,50 - 280,00 5 60 40 140<br />

WTHQ 0906<br />

L10B081<br />

Page 99<br />

10105084<br />

Further dimensions and lengths on request.<br />

Dimensions in mm.<br />

24

Tools <strong>with</strong> <strong>ISO</strong> <strong>elements</strong> | <strong>Boring</strong> | Tool holders for tangential roughing heads<br />

TH-TSW 201 and 211 – tool holders<br />

for tangential roughing heads<br />

l 2<br />

l h<br />

d 3<br />

<strong>Boring</strong><br />

TSW / TFB<br />

d 2<br />

Machine connection HSK (DIN 69893-1)<br />

For tool ø<br />

d 3 d 2 Nominal size<br />

Tool holder lengths<br />

HSK<br />

l 2 l h min l h max<br />

HSK-A HSK-C HSK-A HSK-C HSK-A HSK-C<br />

63 47 20 70 60 200 160<br />

59,50 - 74,40 18 39<br />

80 47 25 70 60 250 210<br />

100 55 30 70 60 300 260<br />

63 47 20 65 50 200 160<br />

74,50 - 89,40 22 50<br />

80 47 25 70 55 250 210<br />

100 55 30 70 55 300 260<br />

89,50 - 119,40 27 60<br />

80 47 25 70 55 250 210<br />

100 55 30 70 55 300 260<br />

119,50 - 174,40 40 89<br />

80 47 25 85 70 250 210<br />

100 55 30 85 70 250 210<br />

174,50 - 280,00 60 140 100 55 30 95 80 250 210<br />

l 2<br />

l h<br />

d 3<br />

d 2<br />

Machine connection SK (DIN 69871 Form AD / B)<br />

For tool ø<br />

59,50 - 74,40 18 39<br />

74,50 - 89,40 22 50<br />

89,50 - 119,40 27 60<br />

119,50 - 174,40 40 89<br />

174,50 - 280,00 60 140<br />

Further dimensions and lengths on request.<br />

Dimensions in mm.<br />

d 3 d 2 Nominal size<br />

SK<br />

l 2<br />

SK-AD / SK-B<br />

Tool holder lengths<br />

l h min<br />

SK-AD / SK-B<br />

l h max<br />

SK-AD / SK-B<br />

40 40 50 160<br />

50 45 50 210<br />

40 40 50 160<br />

50 45 50 210<br />

40 40 – –<br />

50 45 55 210<br />

40 40 – –<br />

50 45 65 210<br />

40 40 – –<br />

50 45 85 210<br />

25

Tools <strong>with</strong> <strong>ISO</strong> <strong>elements</strong> | <strong>Boring</strong> | Tangential fine boring <strong>tools</strong> TFB<br />

Tangential fine boring <strong>tools</strong> TFB<br />

Tangential technology now also for fine machining. Newly<br />

developed reaming cutting edges are mounted in precision<br />

insert seats and set sensitively and highly accurately to a<br />

defined amount above the reference setting pads using the<br />

<strong>MAPAL</strong> wedge adjustment.<br />

Up to IT<br />

7<br />

The tool is guided in the bore by the special arc shaped<br />

land. The <strong>MAPAL</strong> TFB series impresses due to easy, precise<br />

handling, quiet running at high feeds and the best<br />

machining results.<br />

Tangential fine boring <strong>tools</strong><br />

Series<br />

TFB 101/111<br />

The tangential fine boring <strong>tools</strong> are far<br />

superior to the previous conventional tool<br />

systems for the fine machining of large<br />

diameters. Compared to one or two-cutting<br />

edge boring <strong>tools</strong> the TFB <strong>tools</strong> are six to<br />

eight times faster <strong>with</strong> machining results in<br />

reaming quality.<br />

During fine machining the effect of the arc<br />

shaped land is even more significant than<br />

on the roughing <strong>tools</strong> – it guides the tool in<br />

the bore and at the same time smoothes the<br />

surface. The TFB <strong>tools</strong> are equipped <strong>with</strong> six<br />

to eight indexable inserts that are embedded<br />

in the tool body unevenly in relation to each<br />

other.<br />

The reaming cutting edges are mounted<br />

in precision insert seats; a <strong>MAPAL</strong> wedge<br />

adjustment feature for exact and very<br />

sensitive adjustment is fitted for each cutting<br />

edge. Precision ground reference pads are<br />

used as a setting aid. The setting of the <strong>tools</strong><br />

is enormously simplified, as the cutting edge<br />

only needs to be set to a specific amount<br />

beyond the pad diameter, a task that is very<br />

easy using commonly available measuring<br />

equipment and the sensitive adjustment<br />

accurate to the μm (see setting instructions<br />

on page 178).<br />

The TFB tangential fine boring <strong>tools</strong> comprise<br />

of three assemblies. The machine adapter and<br />

the intermediate adapter are connected via<br />

a <strong>MAPAL</strong> Module connection <strong>with</strong> radial and<br />

axial alignment, as a result the radial run-out<br />

error on the spindle can be compensated.<br />

The tangential fine boring head is connected<br />

to the intermediate adapter via an HSK<br />

connection. The standard diameter range is<br />

from ø 60 to 280 mm.<br />

The TFB <strong>tools</strong> are available in two different<br />

series. TFB 101 for blind bores and TFB 111 for<br />

through bores.<br />

Features<br />

<strong>MAPAL</strong> arc shaped land guides the<br />

tool and smoothes the bore<br />

Highly positive rake angle for<br />

soft cut<br />

High precision insert seats<br />

Bores in reaming quality<br />

Six to eight times faster than<br />

boring <strong>tools</strong><br />

Straightforward, sensitive<br />

adjustment<br />

26

Tools <strong>with</strong> <strong>ISO</strong> <strong>elements</strong> | <strong>Boring</strong> | Tangential fine boring <strong>tools</strong> TFB<br />

Application notes<br />

TFB modular design ø 60 - 280 mm<br />

Machine adapter Intermediate adapter Tangential fine boring head<br />

Standard lead geometries<br />

1<br />

30° For improved<br />

MG<br />

surface finish<br />

<strong>Boring</strong><br />

TSW / TFB<br />

0,55<br />

MC<br />

0,4<br />

MA<br />

45°<br />

75°<br />

Without any specific<br />

requirements (standard)<br />

For a specific<br />

requirement on the<br />

positioning accuracy<br />

General figures for determining the maximum tool length<br />

Length<br />

350<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

HSK 100<br />

SK 50 / HSK 80<br />

SK 40 / HSK 63<br />

In case of unfavourable diameter-length<br />

ratios a pilot bore is recommended.<br />

lmax1<br />

lmax2<br />

0<br />

60 80 100 120 140 160 180 200 220 240 260 280<br />

Diameter<br />

Ordering example TFB 111<br />

Fine machining of a<br />

through bore in GGG40<br />

<br />

<br />

<br />

4 L B =138<br />

2<br />

The following are required:<br />

Nominal diameter<br />

89,0 mm<br />

Tolerance ( < IT7) H7 (+0.035/0)<br />

Depth of the bore<br />

138.0 mm<br />

Material<br />

GGG40<br />

Machine spindle<br />

HSK-A100<br />

Number of cutting edges (pay attention to machine performance) Z = 6<br />

Tool for the stated machining application:<br />

d 1 =89 H7<br />

<br />

<br />

<br />

OS-AD-HSK-A100-MOD100-065-11<br />

KS-VL-MOD100-HSK-C63-100-21<br />

TFB111-ø089.00-Z6-065.0-C63<br />

L Ma =65 L Za =100 L k =65<br />

L 1 =230<br />

Selected For indexable inserts see page 96<br />

<br />

FTHW0905MCD01L00B030-CP131<br />

27

Tools <strong>with</strong> <strong>ISO</strong> <strong>elements</strong> | <strong>Boring</strong> | Designation key<br />

Designation key for tangential fine boring <strong>tools</strong> TFB<br />

Tool:<br />

TFB fine boring heads<br />

l k<br />

d 1<br />

d 1<br />

TFB 101 and 111<br />

T F B 1 0 1 - Ø 1 0 0 . 0 0 - Z 8<br />

Tool type<br />

Tool diameter d 1 and number of teeth<br />

TFB 101 + 111 TFB 101 + 111<br />

Modular design<br />

TFB 101 = Blind bores and bores <strong>with</strong> shoulders<br />

TFB 111 = Through bores<br />

Diameter d 1 No. of teeth<br />

60,00-74,99 Z = 6<br />

75,00-89,99 Z = 6<br />

90,00-109,99 Z = 8<br />

110,00-119.99 Z = 8<br />

120,00-159,99 Z = 8<br />

160,00-179,99 Z = 8<br />

180,00-280,00 Z = 8<br />

Machine adapter:<br />

TFB 101 and 111<br />

l MA<br />

l ZA<br />

O S - A D - H S K - A 1 0 0 - M O D 1 0 0 - 0 6 5 - 1 1<br />

Type<br />

Adaptation<br />

Shank |<br />

Form and size<br />

Adaptation |<br />

Form and size<br />

Projection<br />

length L MA<br />

Alignment<br />

Internal<br />

cooling<br />

OS<br />

Without<br />

clamping<br />

unit<br />

Dimensions in mm.<br />

AD<br />

Adapters<br />

HSK-A<br />

HSK-C<br />

SK<br />

Hollow shank<br />

taper<br />

Form A<br />

Hollow shank<br />

taper<br />

Form C<br />

Taper shank<br />

in acc. <strong>with</strong> <strong>ISO</strong><br />

AD/B<br />

MOD<br />

Module connection<br />

Nominal length<br />

of the machine<br />

adapter<br />

0 Without<br />

alignment<br />

1<br />

2<br />

Radial<br />

alignment<br />

Radial and<br />

angular<br />

alignment<br />

1<br />

Internal<br />

28

Tools <strong>with</strong> <strong>ISO</strong> <strong>elements</strong> | <strong>Boring</strong> | Designation key<br />

<strong>Boring</strong><br />

TSW / TFB<br />

- 0 6 5 . 0 - C 1 0 0<br />

Tool length<br />

Shank form<br />

Tool diameter<br />

Tool length<br />

Connection Size Code<br />

60,00-74,99 65,0<br />

75,00-89,99 65,0<br />

90,00-109,99 65,0<br />

110,00-119,99 75,0<br />

120,00-159,99 75,0<br />

160,00-179,99 95,0<br />

180,00-280,00 95,0<br />

HSK-C 50 C50<br />

HSK-C 63 C63<br />

HSK-C 80 C80<br />

HSK-C 100 C100<br />

Intermediate adapter:<br />

l MA<br />

TFB 101 and 111<br />

l ZA<br />

K S - V L - M O D 1 0 0 - H S K - C 6 3 - 1 0 0 - 2 1<br />

Clamping<br />

unit<br />

Adaptation<br />

Shank |<br />

Form and size<br />

Adaptation |<br />

Form and size<br />

Projection<br />

length l ZA<br />

Alignment<br />

Internal<br />

cooling<br />

KS<br />

KS<br />

clamping<br />

cartridge<br />

VL<br />

Flange<br />

adapter<br />

MOD<br />

Module<br />

connection<br />

HSK-C<br />

Hollow<br />

Nominal length<br />

shank taper<br />

of the adapter<br />

Form C<br />

0<br />

1<br />

Without<br />

alignment<br />

Radial<br />

alignment<br />

1<br />

Internal<br />

2<br />

Radial and<br />

angular<br />

alignment<br />

29

Tools <strong>with</strong> <strong>ISO</strong> <strong>elements</strong> | <strong>Boring</strong> | Tangential fine boring heads<br />

TFB 101 – tangential fine boring heads<br />

Modular design<br />

l k<br />

d 1<br />

d 1<br />

Number of cutting<br />

edges<br />

Number of setting<br />

pads<br />

Nominal size<br />

HSK<br />

l k<br />

Indexable insert<br />

TORX PLUS® screw<br />

60,00 - 74,99 6 2 HSK-C50 65<br />

75,00 - 89,99 6 2 HSK-C63 65<br />

90,00 - 109,99 8 4 HSK-C63 65<br />

FTHW 0905<br />

BO30<br />

Page 96<br />

TX-M3,5x11<br />

10105079<br />

110,00 - 119,99 8 4 HSK-C80 75<br />

120,00 - 159,99 8 4 HSK-C80 75<br />

160,00 - 179,99 8 4 HSK-C80 95<br />

FTHW 0905<br />

BO60<br />

Page 96<br />

TX-M3,5x11<br />

10105079<br />

180,00 - 280,00 8 4 HSK-C100 95<br />

FTHW 0905<br />

BO90<br />

Page 96<br />

TX-M3,5x11<br />

10105079<br />

Further dimensions and lengths on request.<br />

Dimensions in mm.<br />

30

Tools <strong>with</strong> <strong>ISO</strong> <strong>elements</strong> | <strong>Boring</strong> | Tangential fine boring heads<br />

TFB 111 – tangential fine boring heads<br />

Modular design<br />

l k<br />

<strong>Boring</strong><br />

TSW / TFB<br />

d 1<br />

d 1<br />

Number of cutting<br />

edges<br />

Number of setting<br />

pads<br />

Nominal size<br />

HSK<br />

l k<br />

Indexable insert<br />

TORX PLUS® screw<br />

60,00 - 74,99 6 2 HSK-C50 65<br />

75,00 - 89,99 6 2 HSK-C63 65<br />

90,00 - 109,99 8 4 HSK-C63 65<br />

FTHW 0905<br />

BO30<br />

Page 96<br />

TX-M3,5x11<br />

10105079<br />

110,00 - 119,99 8 4 HSK-C80 75<br />

120,00 - 159,99 8 4 HSK-C80 75<br />

160,00 - 179,99 8 4 HSK-C80 95<br />

FTHW 0905<br />

BO60<br />

Page 96<br />

TX-M3,5x11<br />

10105079<br />

180,00 - 280,00 8 4 HSK-C100 95<br />

FTHW 0905<br />

BO90<br />

Page 96<br />

TX-M3,5x11<br />

10105079<br />

Further dimensions and lengths on request.<br />

Dimensions in mm.<br />

31

Tools <strong>with</strong> <strong>ISO</strong> <strong>elements</strong> | <strong>Boring</strong> | Intermediate adapters<br />

Intermediate adapter<br />

<br />

D<br />

d 1<br />

<br />

l 2<br />

l ZA<br />

With radial and angular alignment<br />

For tool ø<br />

Module<br />

diameter<br />

Nominal size<br />

HSK<br />

Dimensions Weight Specification Order No.<br />

D<br />

d 1 l ZA l 2<br />

kg<br />

60,00 - 74,99 80 50<br />

75,00 - 109,99 100 63<br />

110,00 - 159,99 117 80<br />

160,00 - 280,00 140 100<br />

55 35 18 0,9 KS-VL-MOD080-HSK-C050-035-21 30320018<br />

55 100 83 1,9 KS-VL-MOD080-HSK-C050-100-21 30327001<br />

55 150 133 2,65 KS-VL-MOD080-HSK-C050-150-21 30327002<br />

55 200 183 3,4 KS-VL-MOD080-HSK-C050-200-21 30327004<br />

70 43 22 1,8 KS-VL-MOD100-HSK-C063-043-21 30320019<br />

70 100 79 3,2 KS-VL-MOD100-HSK-C063-100-21 30327005<br />

70 150 129 4,8 KS-VL-MOD100-HSK-C063-150-21 30327007<br />

70 200 179 5,6 KS-VL-MOD100-HSK-C063-200-21 30327008<br />

87 50 29 2,7 KS-VL-MOD117-HSK-C080-050-21 30320020<br />

87 100 79 4,7 KS-VL-MOD117-HSK-C080-100-21 30327009<br />

87 150 129 6,65 KS-VL-MOD117-HSK-C080-150-21 30327010<br />

87 200 179 8,6 KS-VL-MOD117-HSK-C080-200-21 30327012<br />

110 70 42 4,9 KS-VL-MOD140-HSK-C100-070-21 30320021<br />

110 100 72 7,6 KS-VL-MOD140-HSK-C100-100-21 30327013<br />

110 150 122 10,6 KS-VL-MOD140-HSK-C100-150-21 30327014<br />

Items included:<br />

Standard KS clamping cartridge, thrust pad and threaded pin, stop ring and<br />

cylinder head screws (for fastening the KS flange adapter).<br />

Dimensions in mm.<br />

For spare parts for intermediate adapters see page 155.<br />

32

Tools <strong>with</strong> <strong>ISO</strong> <strong>elements</strong> | <strong>Boring</strong> | Machine adapters<br />

Machine adapter<br />

<br />

G 1<br />

G<br />

<strong>Boring</strong><br />

TSW / TFB<br />

D<br />

l MA<br />

For tool ø Locating shank Module<br />

diameter<br />

Dimensions Weight Specification Order No.<br />

D<br />

l MA G G 1<br />

kg<br />

60,00 - 74,99<br />

75,00 - 109,99<br />

110,00 - 159,99<br />

160,00 - 280,00<br />

HSK-A<br />

SK<br />

BT<br />

CAT<br />

HSK-A<br />

SK<br />

BT<br />

CAT<br />

HSK-A<br />

SK<br />

BT<br />

CAT<br />

HSK-A<br />

SK<br />

BT<br />

CAT<br />

63<br />

60 M6 M8x1 1,4 OS-AD-HSK-A063-MOD080-060-11 30319389<br />

80 60 M6 M8x1 2,1 OS-AD-HSK-A080-MOD080-060-11 30319394<br />

100 55 M6 M8x1 3 OS-AD-HSK-A100-MOD080-055-11 30319400<br />

AD/B 40 55 M6 M8x1 1,7 OS-AD-SK040-MOD080-055-13 10058661<br />

AD/B 50 80 50 M6 M8x1 3,6 OS-AD-SK050-MOD080-050-13 10058671<br />

40 65 M6 M8x1 2 OS-AD-BT040-MOD080-065-11 30320088<br />

50 70 M6 M8x1 5,1 OS-AD-BT050-MOD080-070-11 30320097<br />

40 55 M6 M8x1 1,7 OS-AD-CAT040-MOD080-055-11 30320128<br />

50 50 M6 M8x1 3,6 OS-AD-CAT050-MOD080-050-11 30320137<br />

63<br />

65 M8 M10x1 2,1 OS-AD-HSK-A063-MOD100-065-11 30319390<br />

80 65 M8 M10x1 2,6 OS-AD-HSK-A080-MOD100-065-11 30319395<br />

100 65 M8 M10x1 3,7 OS-AD-HSK-A100-MOD100-065-11 30319401<br />

AD/B 40 60 M8 M10x1 2,2 OS-AD-SK040-MOD100-060-13 10058662<br />

AD/B 50 100 60 M8 M10x1 4,4 OS-AD-SK050-MOD100-060-13 10058672<br />

40 70 M8 M10x1 2,6 OS-AD-BT040-MOD100-070-11 30320089<br />

50 70 M8 M10x1 5,3 OS-AD-BT050-MOD100-070-11 30320098<br />

40 60 M8 M10x1 2,2 OS-AD-CAT040-MOD100-060-11 30320129<br />

50 60 M8 M10x1 4,4 OS-AD-CAT050-MOD100-060-11 30320138<br />

63<br />

65 M8 M10x1 2,5 OS-AD-HSK-A063-MOD117-065-11 30319391<br />

80 65 M8 M10x1 3,1 OS-AD-HSK-A080-MOD117-065-11 30319396<br />

100 65 M8 M10x1 4 OS-AD-HSK-A100-MOD117-065-11 30319402<br />

AD/B 40 - - - - - -<br />

AD/B 50 117 60 M8 M10x1 4,5 OS-AD-SK050-MOD117-060-13 10058673<br />

40 - - - - - -<br />

50 80 M8 M10x1 6,3 OS-AD-BT050-MOD117-080-11 30320099<br />

40 - - - - - -<br />

50 60 M8 M10x1 4,5 OS-AD-CAT050-MOD117-060-11 30320139<br />

63<br />

- - - - - -<br />

80 75 M10 M10x1 4,2 OS-AD-HSK-A080-MOD140-075-11 30319397<br />

100 75 M10 M10x1 5,2 OS-AD-HSK-A100-MOD140-075-11 30319403<br />

AD/B 40 - - - - - -<br />

AD/B 50 140 60 M10 M10x1 4,7 OS-AD-SK050-MOD140-060-13 10058675<br />

40 - - - - - -<br />

50 80 M8 M10x1 6,6 OS-AD-BT050-MOD140-080-11 30320100<br />

40 - - - - - -<br />

50 60 M8 M10x1 4,7 OS-AD-CAT050-MOD140-060-11 30320140<br />

Items included:<br />

Complete <strong>with</strong> threaded pins for aligning the radial run-out, does not include coolant<br />

tube.<br />

Dimensions in mm.<br />

For spare parts for machine adapters see page 155.<br />

33

Tools <strong>with</strong> <strong>ISO</strong> <strong>elements</strong> | Milling<br />

Milling<br />

Introduction<br />

<strong>MAPAL</strong> PerformanceMill<br />

<strong>ISO</strong> milling cutters<br />

<strong>MAPAL</strong>s experience in the area of high<br />

performance custom <strong>ISO</strong> <strong>tools</strong> has been<br />

implemented in a standard programme of radial<br />

and tangential <strong>tools</strong> for a very wide range of<br />

applications.<br />

The PerformanceMill milling cutters are designed<br />

<strong>with</strong> high accuracy insert seats and include,<br />

along <strong>with</strong> face and shoulder cutter heads, also<br />

shell end face and disc milling cutters as well as<br />

the particularly innovative helix milling cutters<br />

for end face and bore machining. Perfectly<br />

matched cutting edge geometries and high<br />

performance coatings are basic features of the<br />

milling cutter indexable inserts.<br />

Programme overview milling 36-37<br />

Designation key 38-39<br />

Face milling cutters 40-42<br />

Shoulder milling cutters 43-50<br />

Shell end milling cutters 51-55<br />

Helix milling cutters 56-58<br />

Disc milling cutters 59-64<br />

Custom milling cutters 65<br />

Trimming /<br />

edge milling<br />

Shoulder milling<br />

Disc milling<br />

cutters<br />

Shoulder milling<br />

deep<br />

Face milling<br />

Shoulder milling<br />

Gang milling<br />

cutters<br />

Shoulder milling<br />

(face circumferential<br />

milling)<br />

Groove milling<br />

Plunge milling<br />

linear<br />

Helix milling<br />

Internal cooling<br />

Tools are designed <strong>with</strong> internal<br />

coolant supply.<br />

35

Tools <strong>with</strong> <strong>ISO</strong> <strong>elements</strong> | Milling | Programme overview<br />

Programme overview milling<br />

Milling cutter type<br />

Face milling cutters<br />

IFM75-C2/C4<br />

Shoulder milling cutters<br />

ICM90-C2/C4<br />

Wide pitch<br />

Close pitch<br />

Number of cutting edges 2 or 4 2 or 4<br />

Application<br />

Cutting depth a p max. (mm)<br />

Tool ø (mm)<br />

Indexable insert<br />

7 7<br />

63 - 160 63 - 160<br />

CT_D... / CT_Q…<br />

CT_D... / CT_Q…<br />

P<br />

M<br />

K<br />

N<br />

S<br />

Roughing<br />

Medium machining<br />

Finishing<br />

Page<br />

41 - 42 44 / 46<br />

Milling cutter type<br />

Shell end milling cutters<br />

ISM90-B2-Shank ISM90-B2 ISM90-C2/C4-HSK/SK<br />

Number of cutting edges 2 2<br />

2 or 4<br />

Application<br />

Cutting depth a p max. (mm)<br />

Tool ø (mm)<br />

Indexable insert<br />

37 / 55 37 / 59 75<br />

25 - 40 40 - 100 63 - 100<br />

BD_T.. BD_T.. CT_D... / CT_Q…<br />

P<br />

M<br />

K<br />

N<br />

S<br />

Roughing<br />

Medium machining<br />

Finishing<br />

Page<br />

36<br />

52 53 54 - 55<br />

highly suitable suitable in some situations not suitable

Tools <strong>with</strong> <strong>ISO</strong> <strong>elements</strong> | Milling | Programme overview<br />

Shoulder milling cutters<br />

ICM90-C2/C4-Finishing ICM90-S4 ICM90-B2-Shank ICM90-B2<br />

Milling<br />

Introduction<br />

2 or 4<br />

4 2 2<br />

3 7 / 13 8 / 14 14<br />

63 - 160 40 - 100 16 - 40 50 - 200<br />

CT_H... / CT_A… SE_T… BD_T.. BD_T..<br />

45 / 47 48 49 50<br />

Helix milling cutters<br />

Disc milling cutters<br />

IHM90-C2/C4-HSK IHM90-C2/C4 IDM90-C2/C4 IDM88-L8<br />

2 or 4 2 or 4 2 or 4 4 + 4<br />

35 35 7 / 17 11<br />

80 - 160 125 - 160 100 - 200 100 - 200<br />

CT_D... / CT_Q… CT_D... / CT_Q… CT_D... / CT_Q… LT_U…<br />

57 58 60 - 63 64<br />

37

Tools <strong>with</strong> <strong>ISO</strong> <strong>elements</strong> | Milling | Designation key<br />

Designation key milling cutter programme<br />

I F M 7 5 0 - 1 2 5 - C A 3 2 -<br />

Milling cutter type<br />

Internal cooling<br />

Tool diameter<br />

Connection<br />

(Examples)<br />

IFM<br />

Face milling cutters<br />

0<br />

Without IC<br />

125<br />

Milling cutter ø =125 mm<br />

HA32<br />

Cylindrical shank HA ø = 32 mm<br />

1<br />

With IC<br />

HB32<br />

Cylindrical shank HB ø = 32 mm<br />

ICM<br />

Shoulder milling cutters<br />

HE32<br />

Cylindrical shank HE ø = 32 mm<br />

ISM<br />

Shell end milling cutters<br />

CA22<br />

Milling cutter arbor ø = 22 mm<br />

CA27<br />

Milling cutter arbor ø = 27 mm<br />

IHM<br />

Helix milling cutters<br />

CA32<br />

Milling cutter arbor ø = 32 mm<br />

IDM<br />

Disc milling cutters<br />

CA40<br />

Milling cutter arbor ø = 40 mm<br />

CA60<br />

Milling cutter arbor ø = 60 mm<br />

A063<br />

HSK-A63<br />

Contact angle /<br />

insert installation<br />

position<br />

45 45°<br />

75 75°<br />

90 90°<br />

A080<br />

A100<br />

C063<br />

C100<br />

T063<br />

HSK-A80<br />

HSK-A100<br />

HSK-C63<br />

HSK-C100<br />

HSK-T63<br />

S050<br />

SK50<br />

S040<br />

SK40<br />

38

Tools <strong>with</strong> <strong>ISO</strong> <strong>elements</strong> | Milling | Designation key<br />

Z 1 0 R - C T _ D 0 9 -<br />

M<br />

Milling<br />

Introduction<br />

Effective number of cutting edges<br />

(eff.) (Examples)<br />

Direction of rotation<br />

Indexable insert<br />

Z5<br />

Z10<br />

Z9+3<br />

Eff. number of teeth = 5<br />

Eff. number of teeth = 10<br />

Eff. number of teeth = 12 of<br />

which 3 adjustable cutting<br />

edges<br />

R<br />

L<br />

R1<br />

Right<br />

Left<br />

Right / milling cutter<br />

(left-side cutting)<br />

2. digit "T"<br />

2. digit "E, D"<br />

CT... Tangential<br />

LT... Tangential<br />

BD... Radial<br />

SE... Radial<br />

Z12+4<br />

Eff. number of teeth = 16 of<br />

which 4 adjustable cutting<br />

edges<br />

R2<br />

Right / milling cutter<br />

(right-side cutting)<br />

Optional<br />

Z6+6<br />

Disc milling cutters<br />

Eff. number of teeth = 6<br />

(both sides, 3-sided cutting)<br />

R3<br />

Right / milling cutter<br />

(both sides, 3-sided cutting)<br />

Modified body material<br />

39

Tools <strong>with</strong> <strong>ISO</strong> <strong>elements</strong> | Milling | Face milling cutters<br />

Face milling cutter IFM<br />

Face milling cutter 75°<br />

Tangential<br />

IFM75-C2<br />

IFM75-C4<br />

Properties<br />

- Internal coolant supply<br />

- Enlarged face connection<br />

- Fixed insert seats<br />

- Wide and narrow pitch<br />

- 75° contact – therefore lower radial forces<br />

Application notes<br />

- For roughing and semi-machining<br />

- Large chip spaces for high chip volume<br />

Two-cutting edge indexable insert<br />

CT_D09T3<br />

Four-cutting edge indexable insert<br />

CT_Q0905<br />

Preferred for aluminium also PCD-tipped.<br />

Preferred for castings and steel.<br />

For castings also PcBN-tipped.<br />

40

Tools <strong>with</strong> <strong>ISO</strong> <strong>elements</strong> | Milling | Face milling cutters<br />

Face milling head <strong>with</strong> tangential technology<br />

IFM75-C2<br />

κ 75°<br />

l 1<br />

a p<br />

κ<br />

d 2<br />

d 3<br />

d 4<br />

d 1<br />

Face milling<br />

cutters<br />

CT_D09T3 / wide pitch<br />

Dimensions a p max. Weight<br />

kg<br />

Max. spindle<br />

speed (min -1 )<br />

Specification<br />

Order No.<br />

ø d 1 Z e ff ø d 2 l 1 ø d 3 ø d 4<br />

63 4 22 50 48 28 7 0,6 10.000 IFM751-063-CA22-Z4R-CT_D09 30395560<br />

80 5 27 50 60 38 7 0,9 8.000 IFM751-080-CA27-Z5R-CT_D09 30395567<br />

100 6 32 50 78 44 7 1,9 6.400 IFM751-100-CA32-Z6R-CT_D09 30383562<br />

125 7 40 63 89 56 7 2,6 5.100 IFM751-125-CA40-Z7R-CT_D09 30395590<br />

160 8 40 63 89 56 7 4,4 4.000 IFM751-160-CA40-Z8R-CT_D09 30395616<br />

CT_D09T3 / narrow pitch<br />

Dimensions a p max. Weight<br />

kg<br />

Max. spindle<br />

speed (min -1 )<br />

Specification<br />

Order No.<br />

ø d 1 Z e ff ø d 2 l 1 ø d 3 ø d 4<br />

63 6 22 50 48 28 7 0,6 10.000 IFM751-063-CA22-Z6R-CT_D09 30395561<br />

80 7 27 50 60 38 7 0,9 8.000 IFM751-080-CA27-Z7R-CT_D09 30395587<br />

100 9 32 50 78 44 7 1,7 6.400 IFM751-100-CA32-Z9R-CT_D09 30383563<br />

125 10 40 63 89 56 7 2,8 5.100 IFM751-125-CA40-Z10R-CT_D09 30395591<br />

160 12 40 63 89 56 7 4,5 4.000 IFM751-160-CA40-Z12R-CT_D09 30395617<br />

Accessories<br />

Spare parts*<br />

CT_D09T3…<br />

Indexable insert Page 116-117<br />

Clamping systems / adapters<br />

See section Accessories<br />

Page 160<br />

CT_D09T3…<br />

CT_D09T3…<br />

Clamping screw for<br />

indexable insert<br />

TORX PLUS®<br />

M3.5x9.4-TX10-IP<br />

TORX PLUS® screwdriver<br />

<strong>with</strong> handle 10IPx80x191<br />

Order No.<br />

10007315<br />

Order No.<br />

30414763<br />

Milling cutter clamping screws<br />

See section Accessories<br />

Page 156<br />

* Included.<br />

Dimensions in mm.<br />

41

d 2<br />

d 3<br />

Tools <strong>with</strong> <strong>ISO</strong> <strong>elements</strong> | Milling | Face milling cutters<br />

Face milling head <strong>with</strong> tangential technology<br />

IFM75-C4<br />

κ 75°<br />

l 1<br />

a p<br />

κ<br />

d 4<br />

d 1<br />

CT_Q0905 / wide pitch<br />

Dimensions a p max. Weight<br />

kg<br />

Max. spindle<br />

speed (min -1 )<br />

Specification<br />

Order No.<br />

ø d 1 Z e ff ø d 2 l 1 ø d 3 ø d 4<br />

63 4 22 50 48 28 7 0,6 8.000 IFM751-063-CA22-Z4R-CT_Q09 30395562<br />

80 5 27 50 60 38 7 0,9 6.500 IFM751-080-CA27-Z5R-CT_Q09 30395588<br />

100 6 32 50 78 44 7 1,6 5.300 IFM751-100-CA32-Z6R-CT_Q09 30382219<br />

125 7 40 63 89 56 7 2,7 4.300 IFM751-125-CA40-Z7R-CT_Q09 30395592<br />

160 8 40 63 89 56 7 4,4 3.300 IFM751-160-CA40-Z8R-CT_Q09 30395618<br />

CT_Q0905 / narrow pitch<br />

Dimensions<br />

a p<br />

Max.<br />

Weight<br />

kg<br />

Max. spindle<br />

speed (min -1 )<br />

Specification<br />

Order No.<br />

ø d 1 Z e ff ø d 2 l 1 ø d 3 ø d 4<br />

63 6 22 50 48 28 7 0,6 8.000 IFM751-063-CA22-Z6R-CT_Q09 30395564<br />

80 7 27 50 60 38 7 0,9 6.500 IFM751-080-CA27-Z7R-CT_Q09 30395589<br />

100 9 32 50 78 44 7 1,7 5.300 IFM751-100-CA32-Z9R-CT_Q09 30382221<br />

125 10 40 63 89 56 7 2,9 4.300 IFM751-125-CA40-Z10R-CT_Q09 30395615<br />

160 12 40 63 89 56 7 4,6 3.300 IFM751-160-CA40-Z12R-CT_Q09 30395619<br />

Accessories<br />

Spare parts*<br />

CT_Q0905…<br />

Indexable insert Page 119<br />

Clamping systems / adapters<br />

See section Accessories<br />

Page 160<br />

CT_Q0905…<br />

CT_Q0905…<br />

Clamping screw for<br />

indexable insert<br />

TORX PLUS®<br />

M3.5x11-TX10-IP<br />

TORX PLUS® screwdriver<br />

<strong>with</strong> handle 10IPx80x191<br />

Order No.<br />

10105079<br />

Order No.<br />

30414763<br />

Milling cutter clamping screws<br />

See section Accessories<br />

Page 156<br />

* Included.<br />

Dimensions in mm.<br />

42

Tools <strong>with</strong> <strong>ISO</strong> <strong>elements</strong> | Milling | Shoulder milling cutters<br />

Shoulder milling cutter ICM<br />

Shoulder milling cutter 90°<br />

Tangential<br />

Radial<br />

ICM90-C2/C4 ICM90-C2/C4 Finishing ICM90-S4 ICM90-B2-<br />

Shank<br />

Shoulder milling<br />

cutters<br />

ICM90-B2<br />

Properties<br />

- Internal coolant supply<br />

- Enlarged face connection<br />

- Fixed insert seats<br />

- Wider pitch<br />

- Internal coolant supply<br />

- Enlarged face connection<br />

- Adjustable finishing<br />

indexable insert<br />

- Close pitch<br />

- Internal coolant supply<br />

- Fixed insert seats<br />

- Positive installation position<br />

of the indexable insert for<br />

short projection length<br />

- Internal coolant supply<br />

- Fixed insert seats<br />

Application notes<br />

- For roughing and<br />

semi-finish machining<br />

- 90° shoulder surfaces possible<br />

- For roughing and<br />

semi-finish machining<br />

- 90° shoulder surfaces possible<br />

Adjustable finishing indexable<br />

insert<br />

- For roughing and<br />

semi-finish machining<br />

- 90° shoulder surfaces possible<br />

Preferred for castings and steel.<br />

- For roughing and<br />

semi-finish machining<br />

- 90° shoulder surfaces possible<br />

- Ramping milling is possible to<br />

a limited extent (up ø 63)<br />

- Plunging possible<br />

Preferred for castings and steel.<br />

Initial value for adjustable finishing<br />

indexable inserts 0.02 mm –<br />

0.04 mm.<br />

Two-cutting edge indexable<br />

insert<br />

Four-cutting edge indexable<br />

insert<br />

CT_D09T3<br />

CT_Q0905<br />

Preferred for aluminium also<br />

PCD-tipped.<br />

Preferred for castings and steel.<br />

For castings also PcBN-tipped.<br />

43

d 2<br />

d 3<br />

Tools <strong>with</strong> <strong>ISO</strong> <strong>elements</strong> | Milling | Shoulder milling cutters<br />

Shoulder milling head <strong>with</strong><br />

tangential technology<br />

ICM90-C2<br />

κ 90°<br />

l 1<br />

a p<br />

κ<br />

d 4<br />

d 1<br />

CT_D09T3 / wide pitch<br />

Dimensions<br />

a p<br />

max.<br />

Weight<br />

kg<br />

Max. spindle<br />

speed (min -1 )<br />

Specification<br />