INNOVA E3 - Scican.uk.com

INNOVA E3 - Scican.uk.com

INNOVA E3 - Scican.uk.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Perfect Match of Reprocessing<br />

Parameters at Maximum Flexibility<br />

R e p r o c e s s i n g P r o c e s s a n d Te c h n o l o g y<br />

BHT – the expert for innovative<br />

cleaning and disinfection<br />

technology for the reprocessing<br />

of endoscopes<br />

For more than 25 years BHT has<br />

been one of the acknowledged leaders<br />

in the development and production of<br />

innovative washer-disinfectors in the<br />

areas of healthcare, laboratory and<br />

pharmaceutical industry. BHT is a<br />

medium sized , internationally active<br />

enterprise with 2 production sites in<br />

the heart of Bavaria, Germany.<br />

Frost & Sullivan appreciated the<br />

innovative power, specifically in the<br />

field of endoscopy reprocessing by<br />

awarding the Product Innovation<br />

Price Healthcare 2005 for the BHT<br />

<strong>INNOVA</strong>® CC for checking the individual<br />

channels of flexible endoscopes.<br />

Extensive patents and other protective<br />

rights document the high potential<br />

of BHT. Of course, BHT is certified<br />

according to ISO 9001:2000 and<br />

EN 13485:2003.<br />

The technology of endoscopy has open ed<br />

new avenidas in healthcare for diagno sis<br />

and treatment. At the same time it has<br />

created new risks: Endoscopes can be<br />

a dangerous sources of infections. The<br />

cleaning and disinfection of these sensitive<br />

devices requires a <strong>com</strong>prehensive<br />

know-how of the manufacturer of washer-disinfectors<br />

(WDs). BHT has proven<br />

its <strong>com</strong>petence by introducing the first<br />

fully automatic WD already in 1988. Since<br />

that time BHT is actively engaged to<br />

improve the safety conditions in reprocessing<br />

of medical devices, e.g. within<br />

the <strong>com</strong>mittee for preparing the new<br />

standard<br />

prEN ISO 15883 -1/5.<br />

In all BHT WDs parameters such as time,<br />

temperature and used chemicals are<br />

precisely adjusted to the medical device<br />

to be reprocessed. BHT has realized a<br />

validatable reprocessing process where<br />

all phases are supervised.<br />

1. Reliable sensors monitor the process<br />

data important for the result of the<br />

process.<br />

2 . The micro<strong>com</strong>puter supervises and<br />

registers all parameters.<br />

3. Patented cleaning mechanics and<br />

process technology ensures superior<br />

efficiency and hygienic safety.<br />

4. Patented, electronically supervised<br />

volume dosing guarantees the optimal<br />

employment of chemicals.<br />

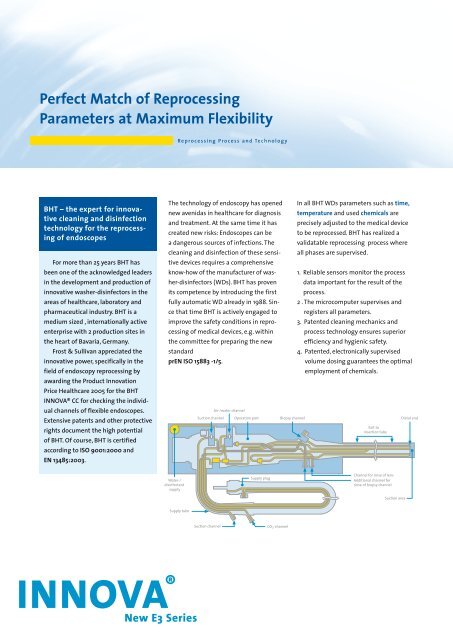

Air-/water channel<br />

Suction channel Operation part Biopsy channel Distal end<br />

Exit to<br />

insertion tube<br />

Water-/<br />

disinfectant<br />

supply<br />

Supply plug<br />

Channel for rinse of lens<br />

Additional channel for<br />

rinse of biopsy channel<br />

Suction area<br />

Supply tube<br />

Suction channel<br />

CO2-channel<br />

Innova ®<br />

New <strong>E3</strong> Series