INNOVA E3 - Scican.uk.com

INNOVA E3 - Scican.uk.com

INNOVA E3 - Scican.uk.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>INNOVA</strong>® CC (Channel Check) – Compliant to<br />

the Highest Level of prEN ISO 15883-4 Requirements<br />

C h e c k i n g & C l e a n i n g o f I n d i v i d u a l C h a n n e l s<br />

BHT developed the <strong>INNOVA</strong>® CC with adaptation<br />

of individual channels to check<br />

all channels of an endoscope for any restrictions.<br />

Biofilms, obstructions<br />

or any other causes which narrow a<br />

channel will be detected and the operator<br />

will be warned in time. Even changes<br />

in or at the channels will be identified rapidly,<br />

thus avoiding further damage and<br />

minimizing repair costs.<br />

The <strong>INNOVA</strong>® CC offers highest quality<br />

and validatable process security, thus<br />

improving<br />

the safety for operator and patient<br />

handling for the reprocessing staff<br />

cost savings for the institution<br />

the quality and life time of the endoscope<br />

in <strong>com</strong>parison to conventional<br />

methods of reprocessing.<br />

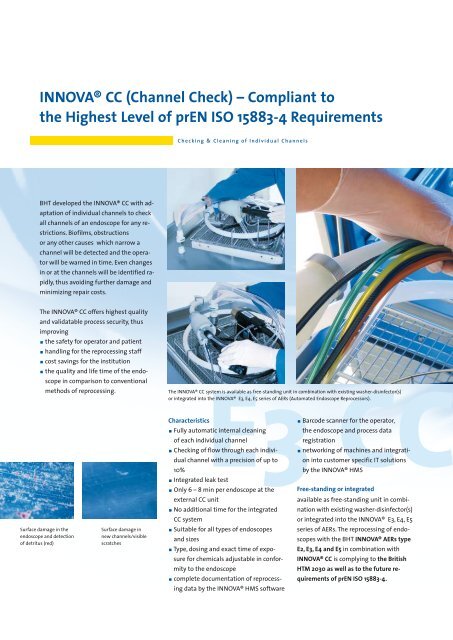

Surface damage in the<br />

endoscope and detection<br />

of detritus (red)<br />

Surface damage in<br />

new channels/visible<br />

scratches<br />

<strong>E3</strong> CC<br />

Barcode scanner for the operator,<br />

The <strong>INNOVA</strong>® CC system is available as free-standing unit in <strong>com</strong>bination with existing washer-disinfector(s)<br />

or integrated into the <strong>INNOVA</strong>® <strong>E3</strong>, E4, E5 series of AERs (Automated Endoscope Reprocessors).<br />

Characteristics<br />

Fully automatic internal cleaning<br />

of each individual channel<br />

Checking of flow through each individual<br />

channel with a precision of up to<br />

10%<br />

Integrated leak test<br />

Only 6 – 8 min per endoscope at the<br />

external CC unit<br />

No additional time for the integrated<br />

CC system<br />

Suitable for all types of endoscopes<br />

and sizes<br />

Type, dosing and exact time of exposure<br />

for chemicals adjustable in conformity<br />

to the endoscope<br />

<strong>com</strong>plete documentation of reprocessing<br />

data by the <strong>INNOVA</strong>® HMS software<br />

the endoscope and process data<br />

registration<br />

networking of machines and integration<br />

into customer specific IT solutions<br />

by the <strong>INNOVA</strong>® HMS<br />

Free-standing or integrated<br />

available as free-standing unit in <strong>com</strong>bination<br />

with existing washer-disinfector(s)<br />

or integrated into the <strong>INNOVA</strong>® <strong>E3</strong>, E4, E5<br />

series of AERs. The reprocessing of endoscopes<br />

with the BHT <strong>INNOVA</strong>® AERs type<br />

E2, <strong>E3</strong>, E4 and E5 in <strong>com</strong>bination with<br />

<strong>INNOVA</strong>® CC is <strong>com</strong>plying to the British<br />

HTM 2030 as well as to the future requirements<br />

of prEN ISO 15883-4.