Architect 2014-03.pdf

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

58<br />

PRODUCTS<br />

ARCHITECT THE AIA MAGAZINE MARCH <strong>2014</strong> WWW.ARCHITECTMAGAZINE.COM<br />

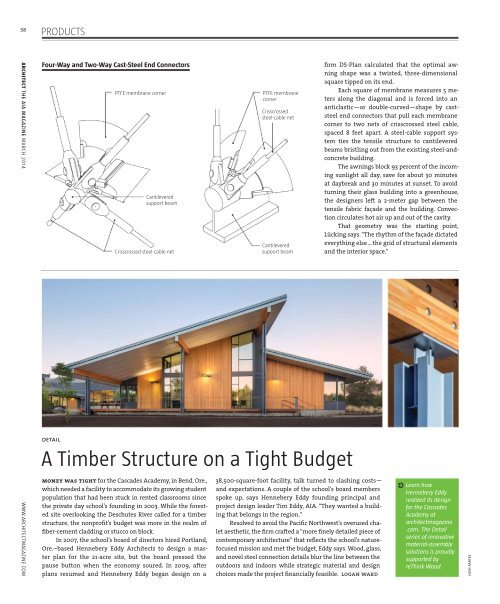

Four-Way and Two-Way Cast-Steel End Connectors<br />

PTFE membrane corner<br />

Cantilevered<br />

support beam<br />

Crisscrossed steel-cable net<br />

PTFE membrane<br />

corner<br />

Crisscrossed<br />

steel-cable net<br />

Cantilevered<br />

support beam<br />

DETAIL<br />

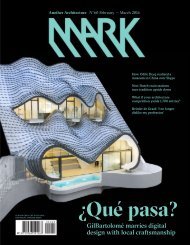

A Timber Structure on a Tight Budget<br />

MONEY WAS TIGHT for the Cascades Academy, in Bend, Ore.,<br />

which needed a facility to accommodate its growing student<br />

population that had been stuck in rented classrooms since<br />

the private day school’s founding in 2003. While the forested<br />

site overlooking the Deschutes River called for a timber<br />

structure, the nonprofit’s budget was more in the realm of<br />

fiber-cement cladding or stucco on block.<br />

In 2007, the school’s board of directors hired Portland,<br />

Ore.–based Hennebery Eddy <strong>Architect</strong>s to design a master<br />

plan for the 21-acre site, but the board pressed the<br />

pause button when the economy soured. In 2009, after<br />

plans resumed and Hennebery Eddy began design on a<br />

38,500-square-foot facility, talk turned to slashing costs—<br />

and expectations. A couple of the school’s board members<br />

spoke up, says Hennebery Eddy founding principal and<br />

project design leader Tim Eddy, AIA. “They wanted a building<br />

that belongs in the region.”<br />

Resolved to avoid the Pacific Northwest’s overused chalet<br />

aesthetic, the firm crafted a “more finely detailed piece of<br />

contemporary architecture” that reflects the school’s naturefocused<br />

mission and met the budget, Eddy says. Wood, glass,<br />

and novel steel connection details blur the line between the<br />

outdoors and indoors while strategic material and design<br />

choices made the project financially feasible. LOGAN WARD<br />

firm DS-Plan calculated that the optimal awning<br />

shape was a twisted, three-dimensional<br />

square tipped on its end.<br />

Each square of membrane measures 5 meters<br />

along the diagonal and is forced into an<br />

anticlastic—or double-curved—shape by caststeel<br />

end connectors that pull each membrane<br />

corner to two nets of crisscrossed steel cable,<br />

spaced 8 feet apart. A steel-cable support system<br />

ties the tensile structure to cantilevered<br />

beams bristling out from the existing steel-andconcrete<br />

building.<br />

The awnings block 93 percent of the incoming<br />

sunlight all day, save for about 30 minutes<br />

at daybreak and 30 minutes at sunset. To avoid<br />

turning their glass building into a greenhouse,<br />

the designers left a 2-meter gap between the<br />

tensile fabric façade and the building. Convection<br />

circulates hot air up and out of the cavity.<br />

That geometry was the starting point,<br />

Lücking says. “The rhythm of the façade dictated<br />

everything else … the grid of structural elements<br />

and the interior space.”<br />

Learn how<br />

Hennebery Eddy<br />

realized its design<br />

for the Cascades<br />

Academy at<br />

architectmagazine<br />

.com. The Detail<br />

series of innovative<br />

material-assembly<br />

solutions is proudly<br />

supported by<br />

reThink Wood.<br />

JOSH PARTEE