Gyrmatic 350/500 - Air Liquide Welding

Gyrmatic 350/500 - Air Liquide Welding

Gyrmatic 350/500 - Air Liquide Welding

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

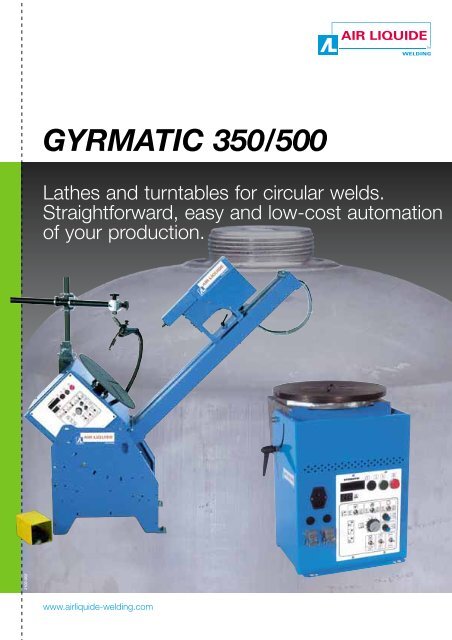

GYRMATIC <strong>350</strong>/<strong>500</strong><br />

Lathes and turntables for circular welds.<br />

Straightforward, easy and low-cost automation<br />

of your production.<br />

3100-002<br />

www.airliquide-welding.com

ALW GYRMATIC<br />

Straightforward, modular, low-cost equipment for automating<br />

or mechanizing a wide range of circular welding applications.<br />

2002-437<br />

The GYRMATIC <strong>350</strong> & <strong>500</strong><br />

are modular systems designed<br />

to adapt easily and quickly to all<br />

conditions for circular welding<br />

around a horizontal or vertical axis or<br />

in intermediate positions set using a<br />

manual tilt device.<br />

They are designed for manual<br />

or automatic MIG / MAG or TIG<br />

welding of circular parts<br />

secured to the turntable<br />

or between tailstocks.<br />

They are currently used<br />

to manufacture a wide range<br />

of products:<br />

• gas bottles<br />

• fire extinguishers<br />

• compressors<br />

• pipe flange welds<br />

• cylinder bodies<br />

•rims<br />

• dampers<br />

• exhaust pipes, etc.,<br />

GYRMATIC systems provide<br />

a straightforward, efficient<br />

and low-cost solution<br />

for automated welding<br />

of all circular parts,<br />

guaranteeing:<br />

• increased productivity<br />

• high-quality repetitive welds<br />

• operator comfort.<br />

2

Some examples of <strong>Gyrmatic</strong> configuration<br />

GYRMATIC <strong>350</strong>:<br />

Standard configuration:<br />

Torch on manual support<br />

Customized configuration:<br />

Tailstock on CTP beam<br />

+ double push button<br />

GYRMATIC <strong>500</strong>:<br />

Standard configuration:<br />

Torch on manual support<br />

Customized configuration:<br />

Torch on structure with carriage + removed control box<br />

3

GYRMATIC <strong>350</strong><br />

For workpieces up to 20 kg: refer to load curves for the rotation and tilting capacity.<br />

GYRMATIC <strong>350</strong><br />

1 Machined turntable<br />

Dia. <strong>350</strong> mm to secure the part.<br />

2 Tilt device<br />

Manual no-tool tilt device with automatic<br />

indexing for 6 positions at 15° intervals.<br />

3 Switch<br />

Power ON/OFF switch.<br />

4 Control unit<br />

Built into case (can be operated from remote unit)<br />

2<br />

1<br />

3<br />

2000-240<br />

C<br />

4<br />

E<br />

B<br />

D<br />

2000-236<br />

F<br />

A<br />

GYRMATIC <strong>350</strong><br />

assembly with add-ons:<br />

A stand<br />

B torch support with PROMIG torch<br />

collar or automatic torch collar<br />

C pneumatic torch retraction facility<br />

D remote control unit<br />

E rotation speed display<br />

F back gas.<br />

4

GYRMATIC <strong>500</strong><br />

For workpieces up to 100 kg.<br />

• without tailstock: refer to load curves for the rotation and tilting capacity.<br />

• with tailstock (manual or pneumatic): Workpiece dimensions with standard equipment:<br />

- maxi diameter <strong>500</strong> mm,<br />

- maxi length 800 mm,<br />

GYRMATIC <strong>500</strong><br />

1<br />

6<br />

7<br />

1<br />

2<br />

3<br />

4<br />

5<br />

Torch support<br />

with manual retraction system for<br />

easier loading and unloading of<br />

workpiece. Automatic torch retraction<br />

system can be fitted as option.<br />

Operating comfort<br />

provided by electrical controls<br />

with automatic cycle built into<br />

support frame.<br />

Support frame<br />

with cradle tilting to 7 fixed<br />

positions at 15° intervals for<br />

welding under optimum conditions.<br />

Manual welding<br />

with optional footpedal for<br />

controlling the turntable(plug-in<br />

connector for quick connection).<br />

Workpiece secured<br />

on machined turntable,<br />

diameter 490 mm.<br />

4<br />

2<br />

3<br />

5<br />

6<br />

7<br />

8<br />

8<br />

Fine adjustment system<br />

for accurate positioning<br />

of the torch in the joint.<br />

Add-ons<br />

for manual tailstock (80 mm travel)<br />

or pneumatic tailstock<br />

(100 mm travel) with rotating point.<br />

Linear positioning<br />

with handle for locking<br />

the tailstock to the support beam,<br />

allowing fast adjustment to the<br />

length of the workpiece.<br />

Vertical axis<br />

configuration.<br />

45° axis<br />

configuration.<br />

GYRMATIC <strong>500</strong><br />

basic version<br />

fitted with<br />

retractable torch<br />

support add-on.<br />

1210-28<br />

1210-33<br />

GYRMATIC <strong>500</strong><br />

fitted with torch<br />

support and<br />

pneumatic<br />

tailstock<br />

add-ons with<br />

support beam.<br />

1210-29<br />

5

GYRMATIC <strong>350</strong><br />

The synoptic of the GYRMATIC <strong>350</strong> gives an overview of the elements able to be<br />

mounted on the base.<br />

Synoptic GYRMATIC <strong>350</strong><br />

6<br />

5<br />

14<br />

4<br />

3<br />

19<br />

13<br />

11<br />

12 10<br />

9<br />

17<br />

1<br />

18<br />

16<br />

15<br />

2<br />

7<br />

8<br />

6

References and characteristics GYRMATIC <strong>350</strong><br />

Turntables<br />

Rotation speed 0.9 to 18.5 tr/min 0.29 to 7.4 tr/min<br />

1 Base <strong>Gyrmatic</strong> W 000 315 895 W 000 315 276<br />

Characteristics<br />

Machined turntable diameter<br />

Ø <strong>350</strong> mm<br />

Max. rotation torque 1 m/daN 2 m/daN<br />

Maxi load in vertical axis (load) centered<br />

20 kg<br />

Possible Manual Tilt<br />

From 0° to 90° (7 positions at 15° intervals)<br />

Dimensions (L x H x D)<br />

430 x 508 x 408 mm<br />

Unloaded weight without welding equipment<br />

38 kg<br />

Power supply<br />

230V / 50-60 Hz<br />

Support table / horizontal turntable height of 930 mm<br />

2 Support table W 000 315 282<br />

Torch support column<br />

3 Torch support column (fastens on support table) W 000 315 281<br />

Add-ons depending on use: Horizontal slide, 50 mm travel W 000 315 508<br />

4 PROMIG torch support collar W 000 315 263<br />

Pneumatic torch retraction facility<br />

5 Pneumatic slide, 100 mm travel W 000 315 478<br />

6 Pneumatic slide, 200 mm travel W 000 315 479<br />

7 Pneumatic power cabinet W 000 275 357<br />

8 Addition panel for pneumatic torch retraction W 000 315 <strong>500</strong><br />

Intermittent welding<br />

9 Cam for intermittent welding W 000 315 277<br />

Chuck<br />

10 Adapter for dia. 125 mm chuck W 000 275 304<br />

11 3-jaw chuck, diameter 125 W 000 315 315<br />

12 Adapter for dia. 250 mm chuck W 000 275 310<br />

13 3-jaw chuck, diameter 250 W 000 274 993<br />

Remote control<br />

14 Remote control unit W 000 315 280<br />

Other add-ons<br />

Primary circuit box for welding application / CE-compliant cut-off W 000 315 502<br />

15 Control footpedal W 000 315 442<br />

16 GYRMATIC speed display option W 000 315 278<br />

17 Tachy on rotation motor W 000 315 279<br />

18 Rotating gas joint for back gas protection W 000 315 283<br />

19 Additional 250 A rotating earth clip (total <strong>500</strong> A) W 000 315 267<br />

7

GYRMATIC <strong>500</strong><br />

The synoptic of the GYRMATIC <strong>500</strong> gives an overview of the elements able to be<br />

mounted on the base.<br />

Synoptic GYRMATIC <strong>500</strong><br />

4<br />

5<br />

18<br />

17<br />

2<br />

10<br />

21<br />

3<br />

20<br />

15<br />

11<br />

16<br />

22<br />

14<br />

23<br />

13<br />

9<br />

12<br />

1<br />

19<br />

24<br />

6<br />

7<br />

8

References and characteristics GYRMATIC <strong>500</strong><br />

Turntables<br />

Rotation speed 0.25 to 4.5 tr/min 0.5 to 10 tr/min<br />

1 Base <strong>Gyrmatic</strong> W 000 315 265 W 000 315 269<br />

Characteristics<br />

Machined turntable diameter<br />

Ø 490 mm<br />

Max. rotation torque 10 m/daN 5 m/daN<br />

Maxi load in vertical axis (load centered)<br />

Possible Manual Tilt<br />

Max workpiece diameter with tailstock<br />

Max workpiece length with tailstock<br />

Dimensions (LxHxD)<br />

Unloaded weight without welding equipment<br />

Power supply<br />

Torch support column<br />

150 kg<br />

From 0° to 90° (7 positions at 15° intervals)<br />

Ø <strong>500</strong> mm<br />

800 mm<br />

600 x 1150 x 750 mm<br />

140 kg<br />

230V / 50-60 Hz<br />

2 Torch support column (fastens on support table) W 000 315 272<br />

Add-ons depending on use: Horizontal slide, 50 mm travel W 000 315 508<br />

3 PROMIG torch support collar W 000 315 263<br />

Pneumatic torch retraction facility<br />

4 Pneumatic slide, 100 mm travel W 000 315 478<br />

5 Pneumatic slide, 200 mm travel W 000 315 479<br />

6 Pneumatic power cabinet W 000 275 357<br />

7 Addition panel for pneumatic torch retraction W 000 315 <strong>500</strong><br />

Use with manual or pneumatic tailstock<br />

8 Tailstock support beam W 000 315 270<br />

9 Manual tailstock, travel 80 mm W 000 315 286<br />

10 Pneumatic tailstock, travel 100 mm includ pneumatic supply fittings W 000 315 262<br />

11 Large tailstock point, diameter 50 mm W 000 315 266<br />

Intermittent welding<br />

12 Cam for intermittent welding W 000 315 271<br />

Chuck<br />

13 Adapter for dia. 125 mm chuck W 000 275 303<br />

14 3-jaw chuck, diameter 125 W 000 315 315<br />

15 Adapter for dia. 250 mm chuck W 000 275 309<br />

16 3-jaw chuck, diameter 250 W 000 274 993<br />

Remote control<br />

17 Remote control unit W 000 315 280<br />

Other add-ons<br />

Primary circuit box for welding application / CE-compliant cut-off W 000 315 502<br />

18 X-support W 000 315 264<br />

19 Control footpedal W 000 315 442<br />

20 GYRMATIC speed display option W 000 315 278<br />

21 Tachy on rotation motor W 000 315 279<br />

22 Rotating gas joint for back gas protection W 000 275 383<br />

23 Additional 250 A rotating earth clip (total <strong>500</strong> A) W 000 315 267<br />

24 Support for torch set-up W 000 315 268<br />

9

Technical datas<br />

Control panel description and Operating diagram.<br />

Manual control<br />

to start up part rotation<br />

with direction selector.<br />

Display<br />

of rotation speed<br />

(option).<br />

Raise/lower<br />

torch (option).<br />

Automatic<br />

cycle start/stop.<br />

Selection<br />

of part rotation<br />

direction<br />

in footpedal<br />

control mode.<br />

LED display<br />

of current<br />

cycle status.<br />

Selection<br />

of workpiece rotation<br />

direction in automatic<br />

mode.<br />

Time-delays<br />

controlling overlap<br />

area and stop<br />

time before reset.<br />

Selection<br />

of welding mode:<br />

continuous or intermittent<br />

Adjustment<br />

of workpiece rotation speed<br />

by potentiometer to guarantee<br />

constant, regular movement.<br />

2000-240<br />

Selection<br />

of automatic<br />

cycle mode:<br />

with or without<br />

welding.<br />

Selection<br />

of one or two lathes.<br />

Simplified operating diagram<br />

10<br />

0 + –<br />

E21<br />

E22<br />

One-lathe continuous weld cycle<br />

T1<br />

T2<br />

E21<br />

E22<br />

0 + –<br />

Normal operation<br />

intermittent cycle<br />

E31<br />

Key:<br />

Auto cycle<br />

command<br />

Detection<br />

of part weld origin<br />

Intermittent welding<br />

T1 Overlap time<br />

T2 Time before return<br />

Clockwise<br />

rotation<br />

Anti-clockwise<br />

rotation<br />

E31 Post-gas time<br />

E21 Trigger command<br />

E22 <strong>Welding</strong> arc present

The dimensions and load curves for tilting and rotation torque.<br />

GYRMATIC <strong>350</strong><br />

Dimensions:<br />

Supported loads:<br />

GYRMATIC <strong>500</strong><br />

Dimensions:<br />

Supported loads:<br />

11

Contacts<br />

BELGIUM<br />

AIR LIQUIDE WELDING BELGIUM SA<br />

Z.I. West Grijpen - Grijpenlaan 5 - 3300 TIENEN<br />

Tel.: +32 16 80 48 20 - Fax: +32 16 78 29 22<br />

CHINA<br />

SAF SHANGHAI REP. OFF.<br />

Rm. 722. Pine City Hotel<br />

777 Zhao Jia Bang Lu - SHANGHAI 200032<br />

Tel.: +86 21 64 43 89 69 - Fax: +86 21 64 43 58 97<br />

CZECH REPUBLIC<br />

AIR LIQUIDE WELDING CZ S.R.O.<br />

Podnikatelská 565 - Areál SVUM<br />

190 11 PRAHA 9 - Bûchovice<br />

Tel.: +420 274 023 163 - Fax: +420 274 023 233<br />

FRANCE<br />

AIR LIQUIDE WELDING FRANCE<br />

13, rue d’Épluches - BP 70024 Saint-Ouen l'Aumône<br />

95315 CERGY PONTOISE Cedex<br />

Tel.: +33 1 34 21 33 33 - Fax: +33 1 34 21 31 30<br />

GERMANY<br />

OERLIKON SCHWEISSTECHNIK GmbH<br />

Industriestrasse 12 - D-67304 EISENBERG/PFALZ<br />

Tel.: +49 6351 4760 - Fax: +49 6351 476 335<br />

OERLIKON SCHWEISSTECHNIK GmbH<br />

Automationszentrum Schneiden<br />

Christinenstrasse 25 - D-40880 RATINGEN<br />

Tel.: +49-(0)2102 -94216-0 - Fax: +49-(0)2166 -94216-91<br />

HUNGARY<br />

AIR LIQUIDE WELDING HUNGARY - Kft<br />

Krisztina krt. 39/b - H-1013 Budapest<br />

Tel.: +36 1 339 8650 - Fax: +36 1 339 8649<br />

ITALY<br />

AIR LIQUIDE WELDING ITALY<br />

Via Torricelli 15/A - 37135 VERONA<br />

Tel.: +39 045 82 91 511 - Fax: +39 045 82 91 536<br />

LUXEMBOURG<br />

AIR LIQUIDE WELDING LUXEMBOURG S.A.<br />

5 rue de la Déportation - BP 1385 - L-1415 LUXEMBOURG<br />

Tel.: +352 48 54 56 - Fax: +352 48 54 57<br />

MALAYSIA<br />

SAF-OERLIKON MALAYSIA SDN BHD<br />

No 10, Jalan TPP 5/1 - Taman Perindustrian Puchong<br />

47100 PUCHONG, SELANGOR<br />

Tel.: +603 8060 8638 - Fax: +603 8061 620<br />

NETHERLANDS<br />

AIR LIQUIDE WELDING NETHERLANDS<br />

Rudonk 6 B - NL 4824 AJ BREDA<br />

Tel.: +31 76 541 00 80 - Fax: +31 76 541 58 96<br />

POLAND<br />

AIR LIQUIDE WELDING POLSKA - SP. Z.o.o<br />

UL. Porcelanowa 10 - 40-246 KATOWICE<br />

Tel.: +48 32 609 04 50 - Fax: +48 32 609 04 60<br />

ALW<br />

International Development Department<br />

Italy<br />

FRO - AIR LIQUIDE WELDING ITALIE<br />

Via Torricelli15/A<br />

37135 VERONA<br />

Tel: +39 045 82 91 511<br />

Fax: +39 045 82 91 536<br />

Email: export.alwitaly@airliquide.com<br />

Contacts for other coutries<br />

ALW<br />

International Development Department<br />

France<br />

13, rue d'Epluches<br />

BP 70024 Saint Ouen l'Aumône<br />

95315 CERGY-PONTOISE Cedex<br />

Tel: +33 1 34 21 33 33<br />

Fax: +33 1 30 37 19 73<br />

Email: export.alwfrance@airliquide.com<br />

www.airliquidewelding.com<br />

www.airliquide.com<br />

PORTUGAL<br />

AIR LIQUIDE SOLDADURA LDA<br />

Rua Dr. António Loureiro Borges, 4-2° Arquiparque<br />

Miraflores - 1495-131 ALGÉS<br />

Tel: +351 21 41 64 900 - Fax: +351 21 41 69 40<br />

ROMANIA<br />

DUCTIL<br />

Aleea Industriilor Nr 1 - 120224 BUZAU<br />

Tel.: +40 238 722 058 - Fax: +40 238 716 861<br />

RUSSIA<br />

AIR LIQUIDE WELDING<br />

17 Vorontsovskaya Str. - 109147 MOSCOW<br />

Tel.: +7 495 641 28 98 - Fax: +7 495 641 28 91<br />

SCANDINAVIA<br />

OERLIKON SKANDINAVIEN AB<br />

Krossverksgatan 7 - 216 16 LIMHAMN<br />

Tel.: +46 (0)40 670 15 00 - Fax: +46 (0)40 670 15 01<br />

SLOVAKIA<br />

AIR LIQUIDE WELDING CENTRAL EUROPE S.R.O.<br />

Hlohovecká 6 - 951 41 NITRA - LUŽIANKY<br />

Tel.: +421 37 692 4610 - Fax : + 421 37 651 28 04<br />

SPAIN<br />

OERLIKON SOLDADURA SA<br />

Poligono Industrial la Noria Carretera de Castellon<br />

Km-15,<strong>500</strong> - 50730 El Burgo de Ebro - ZARAGOZA<br />

Tel.: +34 976 10 47 00 - Fax: +34 976 10 42 67<br />

SWITZERLAND<br />

OERLIKON - SCHWEISSTECHNIK-AG<br />

Mandachstrasse 54 - CH 8155 NIEDERHASLI<br />

Tel: + 41 44 307 61 11 - Fax: + 41 44 307 61 12<br />

THAILAND<br />

AIR LIQUIDE WELDING THAILAND Co Ltd<br />

40 Moo 6 - Ramindra Road Km. 9.5<br />

KHANNAYAO, BANGKOK 10230<br />

Tel.: +66 2 9432250 - Fax: +66 2 9432256<br />

U.A.E.<br />

AIR LIQUIDE WELDING MIDDLE EAST FZE<br />

Jebel Ali free zone warehouse No. FZS1AH05<br />

P.O. BOX 18734 - Jebel Ali - DUBAI<br />

Tel.: +971(0)48861606 - Fax: +971(0)48861608<br />

U. K.<br />

AIR LIQUIDE WELDING Ltd<br />

Low March / London Road - DAVENTRY<br />

Northants NN11 4SD<br />

Tel.: +44 1 327 70 55 11 - Fax: +44 1 327 70 13 10<br />

UKRAINE<br />

AIR LIQUIDE WELDING UKRAINE, Llc.<br />

1 rue Proskura - bureau 106A - 61070 KHARKOV<br />

Tel.: +380 577 546 867 - Fax: +380 577 546 867<br />

ALW<br />

International Development Department<br />

Switzerland<br />

OERLIKON - SCHWEISSTECHNIK-AG<br />

Mandachstrasse 54<br />

CH 8155 NIEDERHASLI<br />

Tel: + 41 44 307 61 11<br />

Fax: + 41 44 307 61 12<br />

Email: export.oerlikonwelding@airliquide.com<br />

<strong>Air</strong> <strong>Liquide</strong> is the world leader in gases for industry, health and the environment, and is present in over 75 countries with 43,000 employees. Oxygen, nitrogen,<br />

hydrogen and rare gases have been at the core of <strong>Air</strong> <strong>Liquide</strong>’s activities since its creation in 1902. Using these molecules, <strong>Air</strong> <strong>Liquide</strong> continuously reinvents its<br />

business, anticipating the needs of current and future markets. The Group innovates to enable progress, to achieve dynamic growth and a consistent performance.<br />

<strong>Air</strong> <strong>Liquide</strong> combines many products and technologies to develop valuable applications and services not only for its customers but also for society.<br />

<strong>Air</strong> <strong>Liquide</strong> <strong>Welding</strong> France se réserve le droit de modifier ses appareils sans préavis.<br />

Les illustrations, descriptions et caractéristiques sont données à titre indicatif et ne peuvent engager le constructeur.<br />

© ALWF 1515-4240 - 11 2008 - S 0? Ed. 2<br />

QB : 2462 - Photos : François