HPC DIGITAL Process - Air Liquide Welding

HPC DIGITAL Process - Air Liquide Welding

HPC DIGITAL Process - Air Liquide Welding

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

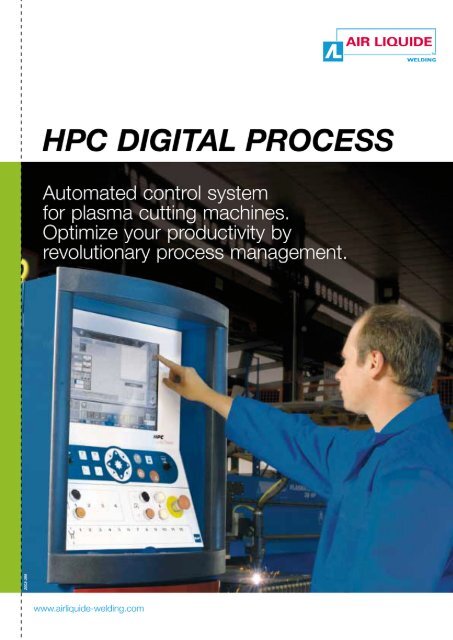

High-performance machineQuality cutting requires fast and efficient control of pathsand programs and multitasking capability. This functionis provided by the numeric control part of the <strong>HPC</strong> <strong>DIGITAL</strong>PROCESS.Motion controlReal-time motioncontrol systemUnlike other Windows-basedproducts, the Windows 2000sophisticated contouring algorithmallows real-time dynamic controlof the path and inputs/outputs.The standard 3-axis configurationallows digital synchronization, idealfor dual-drive gantry machines.Speed controlThis technology, also usedto control laser machines,allows the speed to be changedat any time during a program run.ProgrammingSelectable English or Metric operationPrograms can be run in metric or English units.Accepts ESSI programming formatsISO and WORD adressPrograms can be run in either programming format as required.Code conversation tablesThree settable conversion tables allow the use of other types of programs usingspecific codes.50 pre-programmedstandard shapes• <strong>HPC</strong> <strong>DIGITAL</strong> PROCESSfeatures graphically assisted partdimensioning allowingstraightforward, fast and intuitiveset-up of 50 standard shapes.• Our selection of standardshapes is based on the mostcommonly used parts.• A dynamic, constantly available display function allows shapes to be graphed toinput dimensions for easy visual verification.• Management of cutting inputs and outputs: innovative input/output managementdesigned for strip metal cutting provides a greater diversity of settings for highercut part quality, especially on internal cuts.<strong>HPC</strong> <strong>DIGITAL</strong> PROCESS adapts the type of lead-in to internal or external cuts.It proposes various settable forms of lead-in – corner, length and overlap – tooptimize the quality of your work according to the material and processes usedand the applications.6

managementProgrammable functionsImportant functions can becontrolled in the part program:• dynamic kerf correction:several kerf values can be managedin the same program.• tool offset: offset can beprogrammed for each tool.• eight offset values can beprogrammed• storage of four different work sitelocations• two major programminginnovations enable you to:- select one of work tools for amulti-process application,- set process parameters accordingto the quality required,- modify kerf correction.Program messagesImportant messages can beincorporated into the program toassist the operator.GeometryPart geometry<strong>HPC</strong> <strong>DIGITAL</strong> PROCESS proposesgeometrical operations to adaptyour part quickly and easily to yourjob:• scale factor• mirror function in X or Y axis• rotation of the part.Plate geometry<strong>HPC</strong> <strong>DIGITAL</strong> PROCESS allows youto dimension your plates and settheir physical and angular position:a graphics tool allows quick andeasy alignment of your plate. Fourdifferent plates can be manuallyselected using specific programcodes.DuplicationWith <strong>HPC</strong> <strong>DIGITAL</strong> PROCESS youcan duplicate your job on one of thefour selected plates. Using thiseasy-to-set program you canposition your parts in a row orcolumn and also control the gapbetween the plate edge of eachpart.<strong>HPC</strong> <strong>DIGITAL</strong> PROCESS alsofeatures a function allowing youto duplicate automaticallythe maximum number of partsor programs on the plate you haveselected.7

Communications and file managementSerial link<strong>HPC</strong> <strong>DIGITAL</strong> PROCESS allows fast downloading of compatible part files from aremote PC. The serial link can be easily set for the application and can operate atspeeds up to 115 Kbaud.3.5" - 1.44 MB floppy disk drive (read or write)This drive is installed in a protected location and allows you to load part programsand other types of files to your <strong>HPC</strong> <strong>DIGITAL</strong> PROCESS.RUSH functionThe RUSH function of <strong>HPC</strong> <strong>DIGITAL</strong>PROCESS is available if you needto interrupt a long job to fit in a rushjob. With this function, you caneasily pick up your original jobwhere you left off.Connectable to your networkThe PC architecture offers the possibility as an option of connecting to yournetwork for higher transmission speeds.Program selectionYour programs and JOB can be easily accessed via a scrolling menu. Eachprogram and JOB has a graphical illustration and can be named usingalphanumeric characters.Running and checkingNC RUN keyThe NC RUN key, available in all menus, gives direct access to the job run.It contains:• a reminder of the main cutting parameters• part numbers of consumables needed for your cutting tool• manual selection of your work site• program check tools• JOB backup or selection functions.Return, forward alongpath, return to originThese essential functions for plasmacutting and oxycutting processesare easy to carry out and increaseoperating flexibility.Graphically-assisted cutrestartPoint to an area of the part onthe screen and <strong>HPC</strong> <strong>DIGITAL</strong>PROCESS will return automaticallyto the closest cut starting point.The operation is even easier usingthe ZOOM function.8

Graphics assistant• for real-time monitoring ofmachine progress with possibilityof zooming in on details of yourprogram,• for monitoring the status of thevarious cutting phases,• to monitor wear on consumablesused with your cutting tool.Four levels of use<strong>HPC</strong> <strong>DIGITAL</strong> PROCESSestablishes SET UP access rights toprotect your work tool. You can limitaccess to prevent adjustmentby the operator during productionor you can quickly accessthe password-protected expert levelto optimize your data base andadapt cuts to your specificrequirements. <strong>HPC</strong> <strong>DIGITAL</strong>PROCESS is an open-endedarchitecture system capable ofadapting to specific demands.Program checkIn addition to running the programin "without cutting" or "step-by-step" modes,<strong>HPC</strong> <strong>DIGITAL</strong> PROCESS offers youa function that automatically checksprogram syntax without machinemotion. A graphical representationcan be viewed and accessed at anytime.SET UPPersonalized configurationof your installationYour machine is personalized viaSET UP. This contains the utilizationconfiguration defined according tothe components and processes.Main characteristics:<strong>Process</strong>or<strong>HPC</strong> <strong>DIGITAL</strong> PROCESS utilizes state of the art processing powerand capabilities for efficient multitasking.Industrial grade 306 x 230 mm flat touch screenFeatures large buttons and simplified message bars to make control and learning easy.20 Gbit hard diskThe hard disk provides ample space for programs and jobs.1.44 MB floppy driveFloppy disk drive for fast and simple loading or saving.8-direction touch padThe 8 direction keys of the <strong>HPC</strong> <strong>DIGITAL</strong> PROCESS allow you to move your machine easilyto your work surface.Real-time message and history display<strong>HPC</strong> <strong>DIGITAL</strong> PROCESS monitors all the machine elements and displays informationand error messages. A list providing a message history is available for diagnostics help.RS232 communication portsAllow easy communication with a large number of configurations adapting to your serial link.USB connectionTo connect a CD-ROM drive, additional floppy disk drive, etc.Environment and operation<strong>HPC</strong> <strong>DIGITAL</strong> PROCESS is designed to work in the harshest environments.From 0 to 50 °C (32 to 122 °F), 95% humidity.9