Nertajet HP High Plasma - Air Liquide Welding

Nertajet HP High Plasma - Air Liquide Welding

Nertajet HP High Plasma - Air Liquide Welding

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

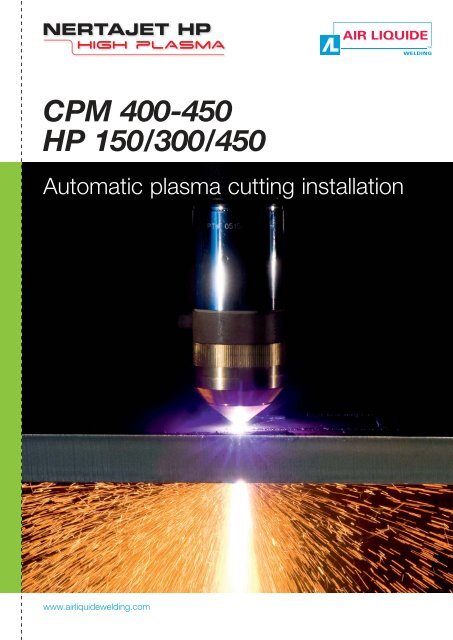

CPM 400-450<strong>HP</strong> 150/300/450Automatic plasma cutting installationwww.airliquidewelding.com

CPM 400-450NERTAJET 150/300/450In many industries, the cutting of ferrous and non-ferrousmetals is a major operation for which the requirementsfor quality, productivity, availability and efficiency ofinstallations have a significant effect on the businessperformance. Cut quality in this respect is a key elementthat determines the choice of production equipment.Major sectors of activity which cut metal sheets:boiler fabrication, shipbuilding, railroad, rolling stock,road vehicles, agriculture, agrifoods, ventilationand air conditioning, sheet metalwork, pattern cutting,street furniture, lamp posts…Main cuttingquality criteriaVarious characteristics can be evaluated to understand the cutting quality.EN standard ISO 9013 retains mainly three:- geometric accuracy- surface roughness- angle/concentricityThis last criteria determines, based on the thickness, the perpendicularitytolerance in five classifications (ranges 1-5).Regular kerfa = angle and concentricity2Tolerances of perpendicularity or angularityBurrsRz = roughnessGeometricprecisionWeldabilityAngleTolerance u, in mm1,510,500 5 10 15 20 25 30Cutting thickness in mm54321RANGE2

Our complete offer:CPM 400-450NERTAJET <strong>HP</strong> 150/300/450The guarantee of optimised operation and the achievement of maximumperformance of cutting installations are enabled by:The use of a complete technical solution:■ A machine dedicated to cutting■ Process control with the <strong>HP</strong>Cnumerical control system■ NERTAJET <strong>HP</strong> power source■ CPM 400-450 plasma torch■ A nesting software■ An adapted working environment (extraction and treatment of fumes)The development of the skills of youroperators through dedicated training(software, machine andplasma process)Your system can be maintained under anagreement adapted to your type of business:■ Inclusive package (PREMIUM agreement)■ Preventive and corrective package exclusiveof spare parts (PREFERENCE agreement)■ Preventive package (STANDARD agreement)3

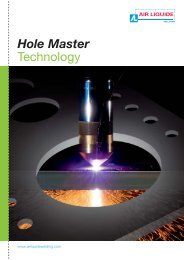

With its NERTAJET <strong>HP</strong> <strong>High</strong> <strong>Plasma</strong> range,<strong>Air</strong> <strong>Liquide</strong> <strong>Welding</strong> offers a powerful plasma cuttingsolution which provides an interesting alternative tolaser cutting especially in terms of machine investment,range of thicknesses of material to be cut as well asthe cutting quality.NERTAJET <strong>HP</strong> <strong>High</strong> <strong>Plasma</strong> is a developmentof the classic plasma process offering analternative to laser cutting:■ Quality- dimensional and geometrical precision of cut partsand/or holes in a wide range of materials,- consistent surface condition and quality of the cut faces.■ Productivity- adjustment of electrical power to suit the speed requiredfor each thickness,- facility to combine several ranges of speed in a single geometry,- possibility to combine cutting and marking operationswith the same torch.Installationwith lowelectricityconsumptionGuidance values:■ 58 kVA (84 A - 400 V) fora current of 260 A at 180 Vwith steel■ 21 kVA (30 A - 400 V) fora current of 130 A at 130 Vwith steel■ Operating costs- extension of the lifetime of consumable parts or reductionof the number of consumables,- low gas consumption.Hole Master technology<strong>Air</strong> <strong>Liquide</strong> <strong>Welding</strong> continuously offersthe best in plasma cutting technologyto its customers. Having identified thatthe cutting of small diameter holes is a major issue in manysectors of activity, <strong>Air</strong> <strong>Liquide</strong> <strong>Welding</strong> answers these needswith Hole Master technology.Based on the latest generation plasma cutting torch CPM 400and optimised management of parameters via <strong>HP</strong>C, Hole Mastertechnology achieves a high level of quality during productionof holes in carbon and low alloy steels with a diameter to sheetthickness ratio close to 1.BevellingThe CPM 400-450 torchcan be mounted on a chamferingunit fully controlled by thenumerical control in rotationand angle. That is to say that viaprogramming, the bevel anglecan be changed along the path.This equipment is particularlylightweight, has high rigidityand hence ensures an excellentcutting result.4

Our technical offer:CPM 400-450 torch solutionThickness ranges according to installationsNERTAJET <strong>HP</strong> <strong>High</strong> <strong>Plasma</strong>Carbon steelsThickness in mm 0,8 1 2 2,5 3 4 5 6 8 10 12 15 20 22 25 30 35 40 50 60 70 80<strong>HP</strong> 150<strong>HP</strong> 300Stainless steelsThickness in mm 0,8 1 2 2,5 3 4 5 6 8 10 12 15 20 22 25 30 35 40 50 60 70 80<strong>HP</strong> 150<strong>HP</strong> 300<strong>HP</strong> 450Aluminium and alloysO2-O2O2-O2O2-N2O2O2-N2O2Thickness in mm 0,8 1 2 2,5 3 4 5 6 8 10 12 15 20 22 25 30 35 40 50 60 70 80<strong>HP</strong> 150N2-N2O2 or N2-N2N2-N2O2 or N2-N2N2-N2O2 or N2-N2N2-N2O2 or N2-N2N2-ArH2 or ArH2-N2N2-ArH2 or ArH2-N2N2-ArH2 or ArH2-N2ArH2-N2The CPM 400-450 torch,a range of benefits:■ <strong>High</strong> cutting capacity(thicknesses and materials)■ Range 2-4 cutting qualityaccording to standard ISO 9013■ Cut with no adhering burrs■ Direct weldability of cut parts■ Improved productivity withoptimised cutting speed■ Versatility of marking andcutting operations■ Ease of use due to a removabletorch and digital process <strong>HP</strong>Ccontrol■ Longer lifetime of consumables<strong>HP</strong> 300<strong>HP</strong> 450N2-N2O2 or N2-N2N2-N2O2 or N2-N2N2-ArH2 or ArH2-N2N2-ArH2 or ArH2-N2Key:O2 : OxygenN2 : NitrogenCutting speedN2O2 : Industrial airArH2 : Argon/Hydrogen<strong>HP</strong> Cut Quality cut IndustrialcutLimit of mid-plate piercingSeparationcutAngle:Range 2-4ISO 9013NERTAJET <strong>HP</strong> 150/300 - CPM 400Carbon steelsCutting speed (m/min)30 A550 A4,580 A <strong>HP</strong> 1504100 A <strong>HP</strong> 300130 A3,5200 A3260 A2,521,510,500 5 10 15 20 25 30 35Thickness (mm)NERTAJET <strong>HP</strong> 150/300/450 - CPM 450Stainless steelsCutting speed (m/min)43,532,521,510,500 5 10 15 20 25 30 35Thickness (mm)20 A40 A60 A <strong>HP</strong> 15090 A <strong>HP</strong> 300120 A<strong>HP</strong> 450200 A280 A400 A40 45 50 555

Components of the plasma installationNERTAJET <strong>HP</strong> <strong>High</strong> <strong>Plasma</strong>CPM 400-450Tool-holderPOC 151-251BRT 400GasmanagementNERTAJET <strong>HP</strong> 150Power sourceFRIOJET 300Cooling unit<strong>HP</strong>CNumericalcontrol<strong>HP</strong>C-CA3<strong>Plasma</strong>cycleNERTAJET <strong>HP</strong> 300Power sourceFRIOJET 300Cooling unitHF 400ArcignitionTorchCPM 400-450<strong>HP</strong> 300 + <strong>HP</strong> 150NERTAJET <strong>HP</strong> 450Power sourceFRIOJET 720Cooling unit6

Advantages and benefits of the automaticplasma cutting installationCPM 400-450NERTAJET <strong>HP</strong> 150/300/450Specifications Advantages Benefits<strong>HP</strong>C-CA3 Numerical control Synchronisation of processmanagement with the cutting path.Control the quality and precisionof the cuts.Automatic adjustmentof cutting parametersmaterial / thicknessIntuitive and simple adjustmentwith the possibility to savecustomer parameters.Save time and capitalise onexpertise.BRT 400System of selection& automatic regulationof gasAutomatic switching of gasdepending on the process.Avoid manual operations andtherefore increase safety andproductivity.Specific settingof gas flow ratesand currentControl of the processthrough real-time adjustment ofparameters: gas and currentslopes, flow rates, etc...Increases the lifetime ofconsumables.Maintain cutting quality all alongthe production.HF 400Unit for the ignitionof the arcProvides a direct and repetitiveignition of the plasma arc.No down time of the production.« Touch & Go » system Detection of torch contactwith the sheet or cut pieces.Increase productivity by reducingincidents.NERTAJET<strong>HP</strong> 150& <strong>HP</strong> 300Power sourceRegulates perfectly the current.Optimum responsiveness in allphases of the cutting cycle.Sturdiness and reliability recognisedby the plasma cutting market.Contributes to the cutting qualityand increases the availabilityof the installation.FRIOJET300 & 720Torch cooling unitMaintains the plasma torchat normal operating temperatureby monitoring critical parameters.Increases the lifetime ofconsumables.Maintains the quality of cut.POC 151or 251<strong>High</strong> quality tool-holderQuick and precise positioningof the torch in each phaseof the cycle.Increase the productivity and allowsgain the best process performance.Ensures the lifetime ofconsumables and the consistencyof the cutting quality.CPM400/450<strong>Plasma</strong> torches integratingthe latest technologicaldevelopments.Very rigid and regular plasma arc.Consumables lifetime in line withmarket standards.<strong>High</strong> quality and repeatablecutting according to ISO 9013ranges 2 - 4.« Hole Master » technology Cutting of high quality holes onblack steels and low alloy steels.Reduces rework operations andhence the cost of finished parts.7

ContactsBELGIUMAIR LIQUIDE WELDING BELGIUM SAZ.I. West Grijpen - Grijpenlaan 5 - 3300 TIENENTel.: +32 16 80 48 20 - Fax: +32 16 78 29 22CHINASAF SHANGHAI REP.OFF.Rm 722 Pine City Hotel777 Zhao Jia Bang Lu - SHANGHAI 200032Tel.: +86 21 64 43 89 69 - Fax: +86 21 64 43 58 97CZECH REPUBLICAIR LIQUIDE CZ S.R.O. - <strong>Welding</strong> and CuttingPodnikatelská 565 - Areál SVUM - 190 11 PRAHA 9 - BúchoviceTel.: +420 274 023 163 - Fax: +420 274 023 233FRANCEAIR LIQUIDE WELDING FRANCE13, rue d’Épluches - BP 70024 Saint-Ouen l'Aumône95315 CERGY PONTOISE CedexTel.: +33 1 34 21 33 33 - Fax: +33 1 34 21 31 30GERMANYOERLIKON SCHWEISSTECHNIK GmbHIndustriestrasse 12 - D-67304 EISENBERG/PFALZTel.: +49 6351 4760 - Fax: +49 6351 476 335HUNGARYAIR LIQUIDE HUNGARY - <strong>Welding</strong> & CuttingKrisztina krt. 39/b - H-1013 BUDAPESTTel.: +36 1 339 8650 - Fax: +36 1 339 8649ITALYFRO-AIR LIQUIDE WELDING ITALIAVia Torricelli 15/A - 37135 VERONATel.: +39 045 82 91 511 - Fax: +39 045 82 91 536LUXEMBOURGAIR LIQUIDE WELDING LUXEMBOURG S.A.5 rue de la Déportation - BP 1385 - L-1415 LUXEMBOURGTel.: +352 48 54 56 - Fax: +352 48 54 57MALAYSIASAF-OERLIKON MALAYSIA SDN BHDNo 10, Jalan TPP 5/1Taman Perindustrian Puchong - 47100 PUCHONG, SELANGORTel.: +603 8060 8638 - Fax: +603 8061 620NETHERLANDSAIR LIQUIDE WELDING NETHERLANDSRudonk 6 B - NL 4824 AJ BREDATel.: +31 76 541 00 80 - Fax: +31 76 541 58 96POLANDAIR LIQUIDE WELDING POLSKA - SP. Z.o.oUL. Porcelanowa 10 - 40-246 KATOWICETel.: +48 32 609 04 50 - Fax: +48 32 609 04 60ALW International Development Department ItalyFRO - AIR LIQUIDE WELDING ITALIAVia Torricelli15/A37135 VERONATel.: +39 045 82 91 511- Fax: +39 045 82 91 536Contacts for other countrieswww.airliquidewelding.comwww.airliquide.comPORTUGALAIR LIQUIDE SOLDADURA LDARua Dr. António Loureiro Borges, 4-2° ArquiparqueMiraflores - 1495-131 ALGÉSTel: +351 21 41 64 900 - Fax: +351 21 41 69 40ROMANIADUCTILAleea Industriilor Nr 1 - 120224 BUZAUTel.: +40 238 722 058 - Fax: +40 238 716 861RUSSIAAIR LIQUIDE WELDING17 Vorontsovskaya Str. - 109147 MOSCOWTel.: +7 495 641 28 98 - Fax: +7 495 641 28 91SCANDINAVIAOERLIKON SKANDINAVIEN ABKrossverksgatan 7 - 216 16 LIMHAMNTel.: +46 (0)40 670 15 00 - Fax: +46 (0)40 670 15 01SLOVAKIAAIR LIQUIDE WELDING CENTRAL EUROPE S.R.O.Hlohovecká 6 - 951 41 NITRA - LUŽIANKYTel.: +421 37 692 4610 - Fax : + 421 37 651 28 04SPAINOERLIKON SOLDADURA SAPoligono Industrial la Noria Carretera de CastellonKm-15,500 - 50730 El Burgo de Ebro - ZARAGOZATel.: +34 976 10 47 00 - Fax: +34 976 10 42 67SWITZERLANDOERLIKON SCHWEISSTECHNIK AGMandachstrasse 54 - CH 8155 NIEDERHASLITel.:+41 44 3076 111 - Fax: +41 44 3076 112THAILANDAIR LIQUIDE WELDING THAILAND Co. Ltd.40 Moo 6 - Ramindra Road Km 9.5 - KHANNAYAO, BANGKOK 10230Tel.: +66 29 43 2250 - Fax: +66 29 43 2256UAEAIR LIQUIDE WELDING MIDDLE EAST FZEJebel Ali free zone warehouse No. FZS1AH05P.O. BOX 18734 - Jebel Ali - DUBAITel.: +971(0)48861606 - Fax: +971(0)48861608U. K.AIR LIQUIDE WELDING LtdLow March / London Road - DAVENTRY - Northants NN11 4SDTel.: +44 1 327 70 55 11 - Fax: +44 1 327 70 13 10UKRAINEAIR LIQUIDE WELDING UKRAINE, Llc.199, Moskovski avenue, office 339 - 61037 KHARKOVTel.: +38 (057) 728 08 52 - Fax : +38 (057) 728 08 53ALW International Development Department FranceAIR LIQUIDE WELDING FRANCE13, rue d’Epluches - Saint Ouen l’Aumône95315 CERGY-PONTOISE CedexTel.: +33 1 34 21 33 33 - Fax: +33 1 30 37 19 73©ALWF - W000374476 - 03-2012 - PLDB 7657 – Photos ALW – François - JSR<strong>Air</strong> <strong>Liquide</strong> <strong>Welding</strong> France reserves the right to carry out modifications to its machinery without prior notice.The manufacturer accepts no liability for illustrations, descriptions and characteristics, which are for information only.<strong>Air</strong> <strong>Liquide</strong> is the world leader in gases for industry, health and the environment, and is present in over 80 countries with 46 200 employees. Oxygen, nitrogen,hydrogen and rare gases have been at the core of <strong>Air</strong> <strong>Liquide</strong>’s activities since its creation in 1902. Using these molecules, <strong>Air</strong> <strong>Liquide</strong> continuously reinvents its business,anticipating the needs of current and future markets. The Group innovates to enable progress, to achieve dynamic growth and a consistent performance. <strong>Air</strong> <strong>Liquide</strong>combines many products and technologies to develop valuable applications and services not only for its customers but also for society.