Untitled - Bharat Petroleum

Untitled - Bharat Petroleum

Untitled - Bharat Petroleum

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

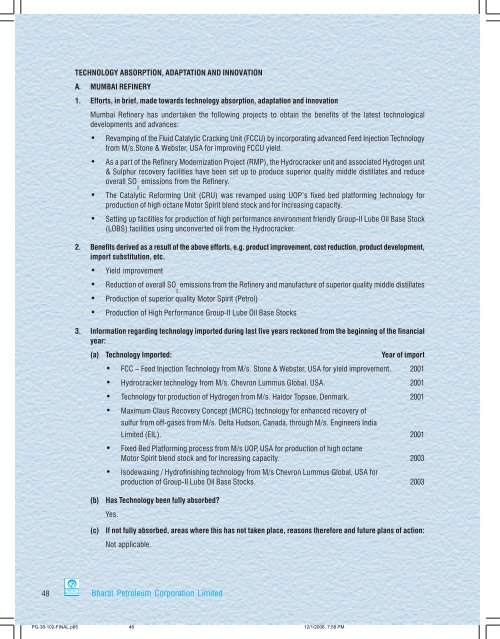

TECHNOLOGY ABSORPTION, ADAPTATION AND INNOVATION<br />

A. MUMBAI REFINERY<br />

1. Efforts, in brief, made towards technology absorption, adaptation and innovation<br />

Mumbai Refinery has undertaken the following projects to obtain the benefits of the latest technological<br />

developments and advances:<br />

• Revamping of the Fluid Catalytic Cracking Unit (FCCU) by incorporating advanced Feed Injection Technology<br />

from M/s.Stone & Webster, USA for improving FCCU yield.<br />

• As a part of the Refinery Modernization Project (RMP), the Hydrocracker unit and associated Hydrogen unit<br />

& Sulphur recovery facilities have been set up to produce superior quality middle distillates and reduce<br />

overall SO emissions from the Refinery.<br />

2<br />

• The Catalytic Reforming Unit (CRU) was revamped using UOP’s fixed bed platforming technology for<br />

production of high octane Motor Spirit blend stock and for increasing capacity.<br />

• Setting up facilities for production of high performance environment friendly Group-II Lube Oil Base Stock<br />

(LOBS) facilities using unconverted oil from the Hydrocracker.<br />

2. Benefits derived as a result of the above efforts, e.g. product improvement, cost reduction, product development,<br />

import substitution, etc.<br />

• Yield improvement<br />

• Reduction of overall SO emissions from the Refinery and manufacture of superior quality middle distillates<br />

2<br />

• Production of superior quality Motor Spirit (Petrol)<br />

• Production of High Performance Group-II Lube Oil Base Stocks<br />

3. Information regarding technology imported during last five years reckoned from the beginning of the financial<br />

year:<br />

(a) Technology Imported: Year of import<br />

• FCC – Feed Injection Technology from M/s. Stone & Webster, USA for yield improvement. 2001<br />

• Hydrocracker technology from M/s. Chevron Lummus Global, USA. 2001<br />

• Technology for production of Hydrogen from M/s. Haldor Topsoe, Denmark. 2001<br />

• Maximum Claus Recovery Concept (MCRC) technology for enhanced recovery of<br />

sulfur from off-gases from M/s. Delta Hudson, Canada, through M/s. Engineers India<br />

Limited (EIL). 2001<br />

• Fixed Bed Platforming process from M/s UOP, USA for production of high octane<br />

Motor Spirit blend stock and for increasing capacity. 2003<br />

• Isodewaxing / Hydrofinishing technology from M/s Chevron Lummus Global, USA for<br />

production of Group-II Lube Oil Base Stocks. 2003<br />

(b)<br />

(c)<br />

Has Technology been fully absorbed?<br />

Yes.<br />

If not fully absorbed, areas where this has not taken place, reasons therefore and future plans of action:<br />

Not applicable.<br />

48 <strong>Bharat</strong> <strong>Petroleum</strong> Corporation Limited<br />

PG-38-102-FINAL.p65<br />

48<br />

12/1/2006, 7:58 PM