Welding Practice - The Hong Kong Polytechnic University

Welding Practice - The Hong Kong Polytechnic University

Welding Practice - The Hong Kong Polytechnic University

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Welding</strong> <strong>Practice</strong><br />

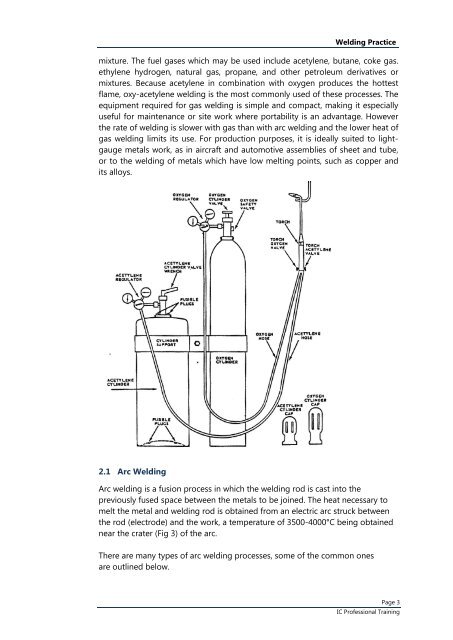

mixture. <strong>The</strong> fuel gases which may be used include acetylene, butane, coke gas.<br />

ethylene hydrogen, natural gas, propane, and other petroleum derivatives or<br />

mixtures. Because acetylene in combination with oxygen produces the hottest<br />

flame, oxy-acetylene welding is the most commonly used of these processes. <strong>The</strong><br />

equipment required for gas welding is simple and compact, making it especially<br />

useful for maintenance or site work where portability is an advantage. However<br />

the rate of welding is slower with gas than with arc welding and the lower heat of<br />

gas welding limits its use. For production purposes, it is ideally suited to lightgauge<br />

metals work, as in aircraft and automotive assemblies of sheet and tube,<br />

or to the welding of metals which have low melting points, such as copper and<br />

its alloys.<br />

2.1 Arc <strong>Welding</strong><br />

Arc welding is a fusion process in which the welding rod is cast into the<br />

previously fused space between the metals to be joined. <strong>The</strong> heat necessary to<br />

melt the metal and welding rod is obtained from an electric arc struck between<br />

the rod (electrode) and the work, a temperature of 3500-4000°C being obtained<br />

near the crater (Fig 3) of the arc.<br />

<strong>The</strong>re are many types of arc welding processes, some of the common ones<br />

are outlined below.<br />

Page 3<br />

IC Professional Training