Welding Practice - The Hong Kong Polytechnic University

Welding Practice - The Hong Kong Polytechnic University

Welding Practice - The Hong Kong Polytechnic University

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Welding</strong> <strong>Practice</strong><br />

metal. By this continuous process of oxidation, the metal can be cut through very<br />

rapidly.<br />

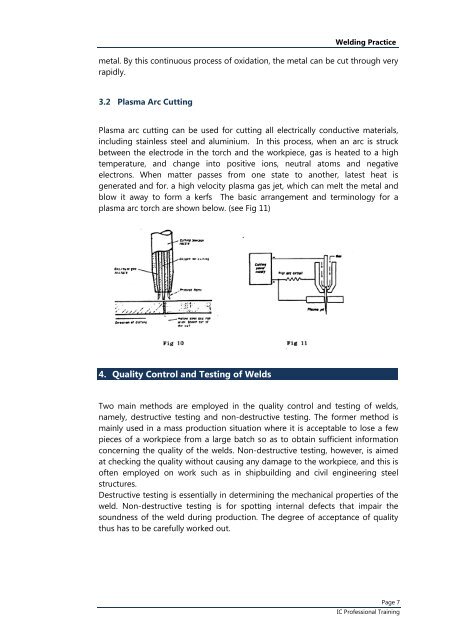

3.2 Plasma Arc Cutting<br />

Plasma arc cutting can be used for cutting all electrically conductive materials,<br />

including stainless steel and aluminium. In this process, when an arc is struck<br />

between the electrode in the torch and the workpiece, gas is heated to a high<br />

temperature, and change into positive ions, neutral atoms and negative<br />

electrons. When matter passes from one state to another, latest heat is<br />

generated and for. a high velocity plasma gas jet, which can melt the metal and<br />

blow it away to form a kerfs <strong>The</strong> basic arrangement and terminology for a<br />

plasma arc torch are shown below. (see Fig 11)<br />

4. Quality Control and Testing of Welds<br />

Two main methods are employed in the quality control and testing of welds,<br />

namely, destructive testing and non-destructive testing. <strong>The</strong> former method is<br />

mainly used in a mass production situation where it is acceptable to lose a few<br />

pieces of a workpiece from a large batch so as to obtain sufficient information<br />

concerning the quality of the welds. Non-destructive testing, however, is aimed<br />

at checking the quality without causing any damage to the workpiece, and this is<br />

often employed on work such as in shipbuilding and civil engineering steel<br />

structures.<br />

Destructive testing is essentially in determining the mechanical properties of the<br />

weld. Non-destructive testing is for spotting internal defects that impair the<br />

soundness of the weld during production. <strong>The</strong> degree of acceptance of quality<br />

thus has to be carefully worked out.<br />

Page 7<br />

IC Professional Training