Stirling Power Cooler LPC-RL - Stirling Cryogenics

Stirling Power Cooler LPC-RL - Stirling Cryogenics

Stirling Power Cooler LPC-RL - Stirling Cryogenics

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

SC.1.1.1003<br />

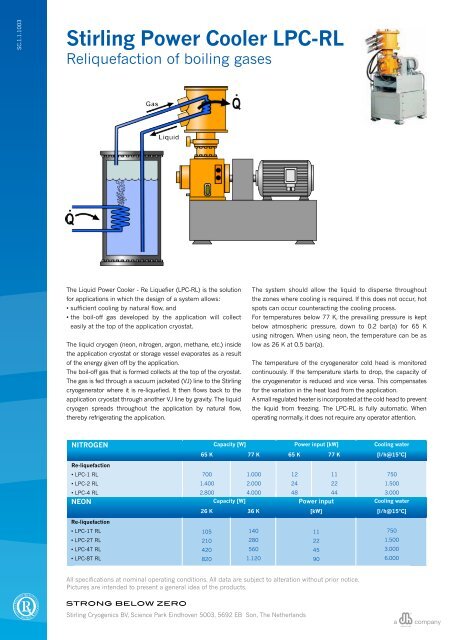

<strong>Stirling</strong> <strong>Power</strong> <strong>Cooler</strong> <strong>LPC</strong>-<strong>RL</strong><br />

Reliquefaction of boiling gases<br />

The Liquid <strong>Power</strong> <strong>Cooler</strong> - Re Liquefier (<strong>LPC</strong>-<strong>RL</strong>) is the solution<br />

for applications in which the design of a system allows:<br />

• sufficient cooling by natural flow, and<br />

• the boil-off gas developed by the application will collect<br />

easily at the top of the application cryostat.<br />

The liquid cryogen (neon, nitrogen, argon, methane, etc.) inside<br />

the application cryostat or storage vessel evaporates as a result<br />

of the energy given off by the application.<br />

The boil-off gas that is formed collects at the top of the cryostat.<br />

The gas is fed through a vacuum jacketed (VJ) line to the <strong>Stirling</strong><br />

cryogenerator where it is re-liquefied. It then flows back to the<br />

application cryostat through another VJ line by gravity. The liquid<br />

cryogen spreads throughout the application by natural flow,<br />

thereby refrigerating the application.<br />

The system should allow the liquid to disperse throughout<br />

the zones where cooling is required. If this does not occur, hot<br />

spots can occur counteracting the cooling process.<br />

For temperatures below 77 K, the prevailing pressure is kept<br />

below atmospheric pressure, down to 0.2 bar(a) for 65 K<br />

using nitrogen. When using neon, the temperature can be as<br />

low as 26 K at 0.5 bar(a).<br />

The temperature of the cryogenerator cold head is monitored<br />

continuously. If the temperature starts to drop, the capacity of<br />

the cryogenerator is reduced and vice versa. This compensates<br />

for the variation in the heat load from the application.<br />

A small regulated heater is incorporated at the cold head to prevent<br />

the liquid from freezing. The <strong>LPC</strong>-<strong>RL</strong> is fully automatic. When<br />

operating normally, it does not require any operator attention.<br />

NITROGEN Capacity [W] <strong>Power</strong> input [kW] Cooling water<br />

65 K 77 K 65 K 77 K [l/h@15°C]<br />

Re-liquefaction<br />

• <strong>LPC</strong>-1 <strong>RL</strong><br />

• <strong>LPC</strong>-2 <strong>RL</strong><br />

• <strong>LPC</strong>-4 <strong>RL</strong><br />

700<br />

1.400<br />

2.800<br />

1.000<br />

2.000<br />

4.000<br />

12<br />

24<br />

48<br />

11<br />

22<br />

44<br />

750<br />

1.500<br />

3.000<br />

NEON • <strong>LPC</strong>-8 <strong>RL</strong><br />

5.600Capacity [W] 8.000<br />

96 <strong>Power</strong> input 88<br />

Cooling 6.000 water<br />

26 K 36 K [kW] [l/h@15°C]<br />

Re-liquefaction<br />

• <strong>LPC</strong>-1T <strong>RL</strong><br />

105<br />

140<br />

11<br />

750<br />

• <strong>LPC</strong>-2T <strong>RL</strong><br />

210<br />

280<br />

22<br />

1.500<br />

• <strong>LPC</strong>-4T <strong>RL</strong><br />

420<br />

560<br />

45<br />

3.000<br />

• <strong>LPC</strong>-8T <strong>RL</strong><br />

820<br />

1.120<br />

90<br />

6.000<br />

All specifications at nominal operating conditions. All data are subject to alteration without prior notice.<br />

Pictures are intended to present a general idea of the products.<br />

<strong>Stirling</strong> <strong>Cryogenics</strong> BV, Science Park Eindhoven 5003, 5692 EB Son, The Netherlands<br />

a<br />

company

SC.1.1.1003<br />

<strong>Stirling</strong> <strong>Power</strong> <strong>Cooler</strong> GPC<br />

gas power cooler<br />

The Gas <strong>Power</strong> <strong>Cooler</strong> (GPC) uses pressurized helium gas<br />

(typically 20 barg) as medium to transfer cold to the application.<br />

as a shield for the 20 K loop, maximizing the cooling power<br />

available to the 20 K target.<br />

The GPC is a two-stage <strong>Stirling</strong> cryogenerator which<br />

simultaneously provides refrigeration at 20 K and at 80 K<br />

by means of two separate heat exchangers. Each of them<br />

consists of a wound spiral tube and a cold gas pump. The two<br />

pumps circulate the gas in seperate loops, from the two heat<br />

exchangers in the application (where energy in injected into<br />

the medium) to the GPC (where energy in extracted from the<br />

medium).<br />

The GPC is connected to the application by two delivery<br />

and return lines ducted together in a single flexible vacuum<br />

insulated line. This offers flexibility for the positioning and<br />

installation of the GPC (up to a radius of 10 meters). In both<br />

the application and transfer lines, the 80 K loop can be used<br />

Operation of the GPC is fully automatic. It runs down to the<br />

lowest possible temperature depending on the application<br />

load. If required, the GPC can be equipped with a set-point<br />

controller that maintains a fixed temperature regardless of<br />

fluctuations in the application load.<br />

The delivery of a GPC system consistst of a two stage<br />

cryogenerator with two cold gas pumps and optional flexible<br />

connection lines.<br />

The figures mentioned below are only an indication, correct<br />

values can only be given after detailed technical discussion and<br />

optimization.<br />

GAS POWER COOLERS<br />

Capacity [W]** <strong>Power</strong> input Cooling water<br />

20 K/80 K 20 K/80 K 30 K/80 K He gas flow [kW] [l/h@15°C]<br />

• GPC-1<br />

75/0<br />

50/400<br />

90/400<br />

Will be a result<br />

11<br />

750<br />

• GPC-2<br />

150/0<br />

100/800<br />

180/800<br />

of customers<br />

22<br />

1.000<br />

• GPC-4<br />

350/0<br />

200/1.600<br />

360/1.600<br />

process conditions.<br />

45<br />

3.500<br />

** simultaneously at 2nd stage ad 1st stage<br />

All specifications at nominal operating conditions. All data are subject to alteration without prior notice.<br />

Pictures are intended to present a general idea of the products.<br />

<strong>Stirling</strong> <strong>Cryogenics</strong> BV, Science Park Eindhoven 5003, 5692 EB Son, The Netherlands<br />

a<br />

company

SC.1.1.1003<br />

<strong>Stirling</strong> <strong>Power</strong> <strong>Cooler</strong> FF<br />

forced flow liquid cooler<br />

with pump cryostat<br />

The Liquid <strong>Power</strong> <strong>Cooler</strong> - Forced Flow (<strong>LPC</strong>-FF) transfers energy<br />

generated by the customers application (i.e. HTS power cables,<br />

etc.) to the cryogenerator via a closed loop of liquid gas. The<br />

<strong>LPC</strong>‐FF consists of the <strong>Stirling</strong> cryogenerator, a pump cryostat<br />

and connecting lines.<br />

This <strong>LPC</strong>-FF type is effective for those applications where the<br />

application does not allow sufficient cooling by natural flow only.<br />

In this application sub cooled nitrogen (10 - 15 K below its boiling<br />

point) is used. Therefore the heat dissipated by the application<br />

only causes a temperature raise. As there is no boiling there will<br />

be no gas bubbles. This assures that the complete application is<br />

always fully filled with liquid, providing for optimal heat exchange.<br />

The warmed LN 2<br />

(still sub-cooled) re-enters the <strong>LPC</strong>-FF flowing<br />

through a heat exchanger which heats up the buffer serving as a<br />

thermal mass.<br />

In the heat exchanger the LN 2<br />

is cooled down and pumped<br />

through the application again by means of a cryogenic pump.<br />

A second volume is connected parallel to this application loop. This<br />

volume incorporates a heater to increase pressure throughout the<br />

system to ensure that the liquid remains sub-cooled. It also acts<br />

as an expansion vessel to compensate for density fluctuation.<br />

In the buffer tank liquid nitrogen will be boiling. The nitrogen<br />

boil‐off is fed to the <strong>Stirling</strong> cryogenerator through a vacuum<br />

jacketed (VJ) line where it is re-liquefied. The LN 2<br />

flows back to<br />

the buffer through a VJ line by gravity. In order to regulate the<br />

temperature of the buffer the pressure is controlled between 0,2<br />

bar(a) for 65K and 1 bar(a) for 77K. As the heat exchanger between<br />

the buffer tank and the application loop can be considered ideal,<br />

the temperature of the LN 2<br />

at the exit of the heat exchanger will<br />

be the same as the LN 2<br />

in the buffer tank.<br />

The LN 2<br />

exit temperature of the <strong>LPC</strong>-FF is measured continuously.<br />

The cryogenerator capacity is reduced if the temperature starts to<br />

drop and vice versa. This compensates for the heat load variation<br />

of the application.<br />

The system can be equipped with the hardware and software<br />

needed to permit a “soft cool down” from ambient to its operating<br />

temperature and for initial filling and start up. Refrigeration mode<br />

is fully automatic and does not require any operator intervention<br />

to run or regulate it. Manual operation of certain valves is only<br />

needed when modes are changed or in temporary modes.<br />

The cooling capacity of the <strong>LPC</strong>-FF system will depend on several<br />

operating parameters like allowable ΔT across the application and<br />

required ΔP. These conditions and the associated pump losses<br />

result in a calculated flow through the application.<br />

The figures mentioned below are only an indication, correct<br />

values can only be given after detailed technical discussion and<br />

optimization.<br />

NITROGEN<br />

Capacity [W] Liquid gas flow <strong>Power</strong> input [kW] Cooling water<br />

65 K 77 K and ΔP 65 K 77 K [l/h@15°C]<br />

• <strong>LPC</strong>-1 FF<br />

500<br />

840<br />

Will be a<br />

13<br />

12<br />

750<br />

• <strong>LPC</strong>-2 FF<br />

950<br />

1700<br />

result of<br />

26<br />

24<br />

1500<br />

• <strong>LPC</strong>-4 FF<br />

2450<br />

3750<br />

customers process<br />

53<br />

49<br />

3000<br />

• <strong>LPC</strong>-8 FF<br />

4500<br />

7300<br />

conditions.<br />

106<br />

98<br />

6000<br />

All specifications at nominal operating conditions. All data are subject to alteration without prior notice.<br />

Pictures are intended to present a general idea of the products.<br />

<strong>Stirling</strong> <strong>Cryogenics</strong> BV, Science Park Eindhoven 5003, 5692 EB Son, The Netherlands<br />

a<br />

company