STRUCTURAL STEEL ERECTION TABLE OF CONTENTS PAGE I ...

STRUCTURAL STEEL ERECTION TABLE OF CONTENTS PAGE I ...

STRUCTURAL STEEL ERECTION TABLE OF CONTENTS PAGE I ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

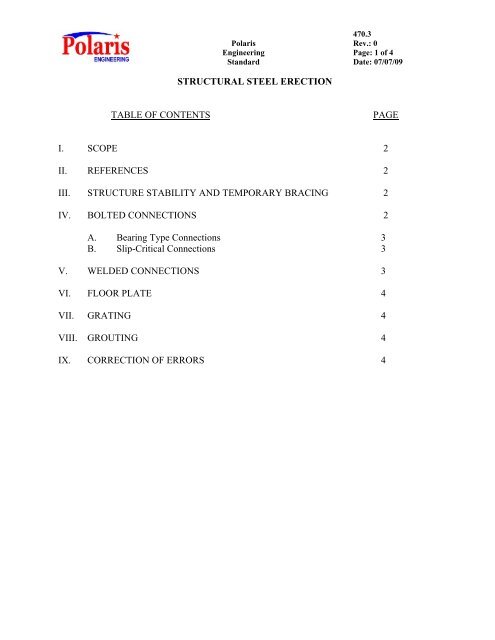

Polaris<br />

Engineering<br />

Standard<br />

470.3<br />

Rev.: 0<br />

Page: 1 of 4<br />

Date: 07/07/09<br />

<strong>STRUCTURAL</strong> <strong>STEEL</strong> <strong>ERECTION</strong><br />

<strong>TABLE</strong> <strong>OF</strong> <strong>CONTENTS</strong><br />

<strong>PAGE</strong><br />

I. SCOPE 2<br />

II. REFERENCES 2<br />

III. STRUCTURE STABILITY AND TEMPORARY BRACING 2<br />

IV. BOLTED CONNECTIONS 2<br />

A. Bearing Type Connections 3<br />

B. Slip-Critical Connections 3<br />

V. WELDED CONNECTIONS 3<br />

VI. FLOOR PLATE 4<br />

VII. GRATING 4<br />

VIII. GROUTING 4<br />

IX. CORRECTION <strong>OF</strong> ERRORS 4

Polaris<br />

Engineering<br />

Standard<br />

470.3<br />

Rev.: 0<br />

Page: 2 of 4<br />

Date: 07/07/09<br />

<strong>STRUCTURAL</strong> <strong>STEEL</strong> <strong>ERECTION</strong><br />

I. SCOPE<br />

This Standard covers the erection of structural steel in accordance with the referenced codes and<br />

specifications, except as noted on the design drawings or within this Standard. Whenever a<br />

difference exists between the design drawings and this Standard, the drawings shall govern. When<br />

ever a difference exists between the purchase order and the specification or drawings, the purchase<br />

order shall generally govern, however in this case, differences shall be brought to the attention of the<br />

Owner or Owner's Engineer for final resolution.<br />

II.<br />

REFERENCES<br />

A. AISC Manual of Steel Construction, ninth edition, including:<br />

1. AISC Code of Standard Practice for Steel Buildings<br />

2. Specification for Structural Joints Using ASTM A325 or A490 Bolts<br />

B. AWS D1.1 Structural Welding Code<br />

C. Polaris Engineering Standards<br />

1. 430.4 Grouting<br />

2. 470.2 Structural Steel Fabrication<br />

III.<br />

STRUCTURE STABILITY AND TEMPORARY BRACING<br />

A. The steel Erector is responsible for the stability of the structure during its erection.<br />

B. In braced structures, bracing should be erected simultaneously with columns and<br />

girders. Should this be impossible, temporary flexible bracing, such as rods or cables,<br />

must be provided until installation of permanent bracing is completed.<br />

IV.<br />

BOLTED CONNECTIONS<br />

Field connections shall be made using high strength bolts in bearing type connections, unless<br />

noted otherwise on the design drawings. High strength bolts shall not be reused.<br />

A. Bearing Type Connections<br />

1. High strength bolts shall be installed in accordance with the "Specification for<br />

Structural Joints using ASTM A325 or A490 Bolts."

Polaris<br />

Engineering<br />

Standard<br />

470.3<br />

Rev.: 0<br />

Page: 3 of 4<br />

Date: 07/07/09<br />

2. The sides of bolt heads and nuts tightened with an impact wrench shall appear<br />

slightly peened. Visual evidence of this peening is adequate indication that<br />

the bolt has been tightened to a snug tight condition.<br />

B. Slip-Critical Connections<br />

1. Bolts in slip-critical connections shall be tightened to full pretension force in<br />

accordance with subsections 8(d)(1) through 8(d)(4) of "Specification For<br />

Structural Joints using ASTM A325 or A490 Bolts."<br />

2. Slip-Critical Connections:<br />

a. Moment connections<br />

b. Connections in direct tension<br />

c. Column splices<br />

d. Beam splices<br />

e. Other connections defined as "slip-critical" on design drawings.<br />

3. Galvanized connection surfaces shall be roughened by steel Erector before<br />

erection.<br />

V. WELDED CONNECTIONS<br />

A. All field welding shall be indicated on the drawings.<br />

B. Welding electrodes with a tensile strength of 70 ksi shall be used. Electrodes shall be<br />

compatible with the welding process selected as required by Table 4.1.1 of AWS<br />

D1.1.<br />

C. All welders must be qualified in accordance with the AWS D1.1. Evidence of this<br />

qualification must be given to the field Construction Manager prior to starting work.<br />

D. Erection clips for fit-up of field welded connections will be provided by the structural<br />

steel Fabricator.<br />

E. Any galvanizing or paint which becomes damaged in performing field welding shall<br />

be repaired in accordance with Polaris Engineering Standard 1400.1 section V.C.<br />

VI.<br />

FLOOR PLATE<br />

A. All openings in floor plate not dimensioned on the drawings shall be cut in the field.<br />

All openings that are dimensioned on the drawings shall be cut by the structural steel<br />

Fabricator. Repair of galvanizing or painting after cutting shall be as described in<br />

Section V. E of this Standard.

Polaris<br />

Engineering<br />

Standard<br />

470.3<br />

Rev.: 0<br />

Page: 4 of 4<br />

Date: 07/07/09<br />

B. Painted floor plate shall be secured in place by intermittent welding of plate to<br />

support beam. Continuous plates shall be plug welded to intermediate support beams.<br />

C. Galvanized floor plate shall be attached to the support beams with self-tapping<br />

screws. Holes in the floor plate and the support beams shall be drilled in the field by<br />

the steel Erector.<br />

VII.<br />

GRATING<br />

A. All openings in grating not dimensioned on the drawings shall be cut in the field. All<br />

openings that are dimensioned on the drawing shall be cut and banded by the<br />

structural steel Fabricator. Repair of galvanizing after cutting shall be as described in<br />

Section V. E of this Standard. Fiberglass grating which requires cutting shall have<br />

the affected surfaces sealed with catalyzed resin sealant of equal or superior corrosion<br />

resistance to the grating.<br />

B. Grating shall be fixed to support members by clips or clamping. Removable grating<br />

shall be specified on the drawings.<br />

C. Grating shall be secured to the supporting steel with gun welded studs, power tool<br />

fastened studs, bolts or Teks self drilling and tapping studs and saddle clip anchors.<br />

Two fasteners per panel shall be used at each support with a minimum of four per<br />

panel. Fiberglass grating shall have additional clips to tie unsupported sides of panels<br />

together to reduce excessive deflection between adjacent panels (one clip per panel<br />

interface per span). The clips shall be supplied by the structural steel Fabricator.<br />

VIII.<br />

GROUTING<br />

Grouting of base plates will be by the steel Erector. Grouting should be performed as soon as<br />

possible after the columns are plumbed and before any large axial loads or moments are<br />

applied to the baseplate. Grouting shall be in accordance with Polaris Engineering Standard<br />

430.4.<br />

IX.<br />

CORRECTION <strong>OF</strong> ERRORS<br />

The steel Erector shall perform moderate amounts of reaming, chipping and cutting to allow<br />

proper fit-up of structural steel members. Any errors which prevent the proper assembly of<br />

the structure must be immediately reported to the field Construction Manager. The<br />

Contractor's field Construction Manager shall report any such errors to the Fabricator, who is<br />

responsible either to correct the error or approve the most efficient and economical method of<br />

correction to be made by the steel Erector. The cost of such corrections shall be borne by the<br />

Fabricator.