Jim Bridger Plant Brochure - PacifiCorp

Jim Bridger Plant Brochure - PacifiCorp

Jim Bridger Plant Brochure - PacifiCorp

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

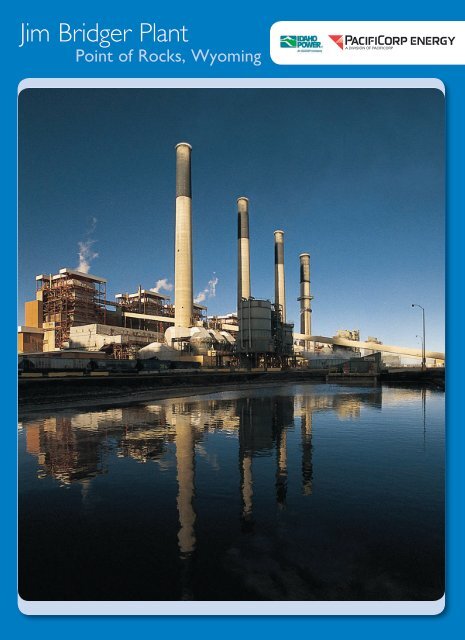

<strong>Jim</strong> <strong>Bridger</strong> <strong>Plant</strong><br />

Point of Rocks, Wyoming

<strong>Jim</strong> <strong>Bridger</strong> <strong>Plant</strong> is named for the renowned<br />

explorer and mountain man, John “<strong>Jim</strong>” <strong>Bridger</strong>.<br />

His pioneering spirit is alive<br />

today in the way this power<br />

facility has responded to its<br />

role as a low-cost energy<br />

producer, resource manager<br />

and environmental steward.<br />

Energy, a natural resource<br />

A massive amount of energy is held by<br />

nature beneath the rugged, beautiful face<br />

of Wyoming: oil, gas, uranium, coal.<br />

That geologic legacy is the foundation of what today is one<br />

of the largest electric generating complexes in the Rocky<br />

Mountain area: the coal-fueled <strong>Jim</strong> <strong>Bridger</strong> steam-electric plant.<br />

Sub-bituminous coal stretches out for miles just beneath<br />

the surface of southwestern Wyoming; the product of<br />

forests and swamps changed by time into vast coal seams.<br />

It is the energy locked in that coal that enables this facility<br />

to produce up to 2,119,000 kilowatts of electricity per hour<br />

from four generating units. That electricity serves people<br />

throughout the West. To get the job done requires the talents<br />

of nearly 350 skilled and dedicated Wyoming residents.<br />

People, power and production<br />

Converting coal into electric energy available at the flip<br />

of a switch can be described in just a few words: coal is<br />

burned to produce high-pressure steam that spins large<br />

turbine-generators, which produce electricity. In practice,<br />

this process requires a complex blending of systems.<br />

The coal is crushed and transported by a four-mile-long<br />

conveyor belt from the <strong>Bridger</strong> Mine to the plant and by<br />

train from the Black Butte Mine. Here, fuel handlers mix<br />

and blend coal from different seams to gain<br />

optimum blend for a clean, efficient fuel.<br />

Once blended, the coal is conveyed inside<br />

the plant. There, pulverizers grind the coal to<br />

a talcum powder consistency. This mixture<br />

fuels the boiler. At full load, all four units will<br />

consume 1,100 tons of coal per hour.<br />

The boiler heats water to produce steam that<br />

is superheated and conducted to the turbine,<br />

driving the electric generator.<br />

Electricity produced leaves the plant on<br />

345,000-volt transmission lines to enter the<br />

regional power grid.<br />

Spent steam is condensed back into water using cooling<br />

towers (from which billow large clouds of white water<br />

vapor, giving the plant one of its most distinctive hallmarks).<br />

The cooled water then returns to the boiler to start the<br />

process all over again. Water for the plant comes from the<br />

Green River through a 50-mile-long pipeline.<br />

Engineered for the environment<br />

At every step of production, the <strong>Jim</strong> <strong>Bridger</strong> <strong>Plant</strong><br />

exemplifies an emphasis on environmental stewardship. On<br />

the mining side, the surface mines near the plant are subject<br />

to rigorous reclamation. What was grazing land before,<br />

returns to grazing land. The land is restored to original or<br />

better condition. Nesting platforms are installed for hawks.<br />

Natural grass and shrub seed is planted for cattle and<br />

wildlife grazing.<br />

Four operating units, each with a 2,800-degree furnace,<br />

produce 1,000-degree steam, which turn turbines. At full<br />

load, the four turbines generate enough electricity to light<br />

three cities the size of Salt Lake City. To accomplish this<br />

task takes a well-trained workforce operating as a team<br />

24-hours a day.<br />

Coal, the starting point<br />

The production process begins with the extraction of<br />

coal from mines located just a few miles from the plant.

How electricity is made at <strong>Jim</strong> <strong>Bridger</strong> <strong>Plant</strong><br />

TRANSMISSION LINE<br />

COAL FROM MINE<br />

COAL SILO<br />

HOT REHEAT<br />

STEAM<br />

COLD REHEAT<br />

EXCITER<br />

GENERATOR<br />

TURBINE<br />

ECONOMIZER<br />

ELECTROSTATIC<br />

PRECIPITATOR<br />

SCRUBBER<br />

MAIN<br />

TRANSFORMER<br />

CONDENSER<br />

PULVERIZER<br />

FEEDER<br />

BOTTOM ASH<br />

BOILER<br />

AIR PREHEATER<br />

FORCED DRAFT FAN<br />

PRIMARY AIR SUPPLY<br />

INDUCED DRAFT FAN<br />

STACK<br />

FLY ASH<br />

COOLING TOWER<br />

BOILER FEED PUMP<br />

The power production process meets Wyoming’s tough<br />

air and water quality standards.<br />

A by-product of coal burning is fine fly ash, which<br />

is removed from the stream of hot gasses by use of<br />

electrostatic precipitators. These precipitators trap 99.3<br />

percent of the fly ash, much of which is marketed to the<br />

concrete industry.<br />

<strong>Jim</strong> <strong>Bridger</strong> coal is low in sulfur content. Sulfur dioxide,<br />

another by-product of combustion, is removed by scrubbers<br />

from all four units.<br />

In addition, <strong>Jim</strong> <strong>Bridger</strong> is constantly improving the<br />

containment of airborne dust through such actions as<br />

paving roads and sealing coal stockpiles. There is also strong<br />

emphasis placed on recycling of materials and seeking new<br />

ways to constructively deal with environmental issues as<br />

they arise.

<strong>Jim</strong> <strong>Bridger</strong> at a glance<br />

Sponsoring companies:<br />

<strong>PacifiCorp</strong> Energy, Idaho Power Company<br />

Generating capacity:<br />

2,119,000 kilowatts per hour in four units<br />

Fuel:<br />

Sub-bituminous coal is delivered to the plant by an overland<br />

conveyor from the <strong>Bridger</strong> Mine. Coal is also transported by unit<br />

train from the Black Butte Mine.<br />

Coal reserves:<br />

The <strong>Jim</strong> <strong>Bridger</strong> field has usable reserves of 140 million tons of<br />

low-sulfur coal.<br />

<strong>Plant</strong> operating personnel:<br />

350 people are employed at the <strong>Jim</strong> <strong>Bridger</strong> <strong>Plant</strong>.<br />

Chimneys:<br />

Each of the generating units has a chimney 500 feet high.<br />

Water supply:<br />

The water supply necessary to operate the plant is delivered from<br />

the Green River through a 50-mile steel pipeline to a reservoir at<br />

the plant site.<br />

Boilers:<br />

Each of the four boilers is designed to produce 3,980,000 pounds<br />

of steam per hour at a throttle pressure of 2,400 PSI. Each<br />

consumes 275 tons of coal per hour. Per year, on average<br />

8 million tons of coal are used. The boilers are 240 feet tall.<br />

Turbine-generators:<br />

Each of the turbine-generators has a nameplate rating of<br />

555,100 gross kilowatts. The units are 131 feet long and weigh<br />

approximately 1 million pounds each.<br />

Completion dates:<br />

Unit 1: November 1974, capacity currently 535,000 net kilowatts<br />

Unit 2: December 1975, capacity currently 527,000 net kilowatts<br />

Unit 3: September 1976, capacity currently 527,000 net kilowatts<br />

Unit 4: December 1979, capacity currently 530,000 net kilowatts

Power network<br />

C A N A<br />

D A<br />

W A S H I N G T O N<br />

ASTORIA<br />

CHEHALIS<br />

LEWIS RIVER PROJECT<br />

TOPPENISH<br />

YAKIMA<br />

MARENGO 1<br />

MARENGO II<br />

M O N T A N A<br />

SEASIDE<br />

SUNNYSIDE<br />

DAYTON<br />

GOODNOE HILLS<br />

WALLA WALLA<br />

PORTLAND<br />

HOOD RIVER<br />

HERMISTON<br />

P A C I F I<br />

C O C E A N<br />

LINCOLN CITY<br />

PENDLETON<br />

LEANING JUNIPER 1<br />

DALLAS<br />

COLSTRIP<br />

ENTERPRISE<br />

INDEPENDENCE<br />

ALBANY<br />

STAY TON<br />

SALMON<br />

CORVALLIS LEBANON<br />

MADRAS<br />

SWEET HOME<br />

JUNCTION CITY<br />

LOVELL<br />

REDMOND PRINEVILLE<br />

CRESWELL<br />

BEND<br />

CODY<br />

COTTAGE GROVE<br />

BUFFALO<br />

WYODAK<br />

COOS BAY/NORTH BEND<br />

O R E G O N<br />

I D A H O<br />

ST. ANTHONY<br />

WORLAND<br />

ROSEBURG NORTH UMPQUA PROJECT<br />

BOISE<br />

COQUILLE<br />

GLENROCK<br />

MYRTLE CREEK<br />

RIGBY<br />

ROLLING HILLS<br />

ARCO<br />

THERMOPOLIS<br />

GLENROCK III<br />

ROGUE RIVER PROJECT<br />

SHELLEY<br />

W Y O M I N G<br />

GRANTS PASS EAGLE POINT<br />

ROGUE RIVER<br />

RIVERTON<br />

DAVE JOHNSTON<br />

CENTRAL POINT<br />

ST. ANTHONY<br />

CASPER<br />

KLAMATH FALLS<br />

DOUGLAS<br />

CAVE JUNCTION<br />

PINEDALE<br />

MEDFORD<br />

LANDER<br />

LAVA HOT SPRINGS<br />

LAKEVIEW<br />

BIG PINEY<br />

KLAMATH RIVER PROJECT<br />

DUNLAP I<br />

CRESCENT CITY<br />

MONTPELIER<br />

YREKA<br />

BEAR RIVER PROJECT<br />

SEVEN MILE HILL<br />

MALAD CITY<br />

PRESTON<br />

SEVEN MILE HILL II<br />

LAKETOWN KEMMERER<br />

JIM BRIDGER<br />

MT. SHASTA<br />

SMITHFIELD<br />

RAWLINS<br />

HIGH PLAINS<br />

TREMONTON<br />

NAUGHTON<br />

MCFADDEN RIDGE I<br />

ROCK SPRINGS<br />

FOOTE CREEK I<br />

LITTLE MOUNTAIN<br />

GREEN RIVER<br />

LARAMIE<br />

Rocky Mountain Power and Pacific Power<br />

service area<br />

Idaho Power Company service area<br />

C A L I F O R N I A<br />

Thermal plants<br />

Gas-fueled thermal plants<br />

N EWind V projects A D A<br />

Geothermal plants<br />

Coal plants<br />

Principal communities served<br />

<strong>PacifiCorp</strong>-owned transmission lines<br />

Transmission access<br />

OGDEN<br />

EVANSTON<br />

LAYTON<br />

GADSBY SALT LAKE CITY<br />

WEST VALLEY CITY<br />

PARK CITY<br />

TOOELE<br />

MIDVALE<br />

CRAIG HAYDEN<br />

DRAPER<br />

VERNAL<br />

LAKE SIDE<br />

AMERICAN FORK<br />

PLEASANT GROVE<br />

OREM<br />

SANTAQUIN<br />

CARBON<br />

CURRANT<br />

CREEK MORONI PRICE<br />

HUNTINGTON<br />

DELTA<br />

GUNNISON<br />

CASTLE DALE<br />

HUNTER<br />

SALINA<br />

C O L O R A D O<br />

Other transmission<br />

RICHFIELD<br />

BLUNDELL<br />

MILFORD<br />

U T A H<br />

MOAB<br />

CEDAR CITY<br />

PANGUITCH<br />

BLANDING<br />

IVINS<br />

LA VERKIN<br />

<strong>PacifiCorp</strong> is one of the lowest-cost electricity producers in the United States, providing approximately 1.7 million customers<br />

in the West with reliable, efficient energy. <strong>PacifiCorp</strong> operates as Rocky Mountain Power in CHOLLA Utah, NO. 4 Wyoming and Idaho, and<br />

A R I Z O N A<br />

as Pacific Power in Oregon, Washington and California. <strong>PacifiCorp</strong>’s electric generation, commercial and energy trading, and<br />

mining functions are operated as <strong>PacifiCorp</strong> Energy.<br />

For more company information, please visit pacificorp.com and idahopower.com.<br />

N E W M E X I C O<br />

Recreation on the <strong>Jim</strong> <strong>Bridger</strong> Reservoir<br />

Generating recreation opportunities with the same<br />

resources we use to generate power is one additional<br />

way we provide for the community.<br />

The recreation opportunities along the <strong>Jim</strong> <strong>Bridger</strong><br />

Reservoir are open year round for day use. Located<br />

approximately 35 miles east of Rock Springs, Wyoming,<br />

our facilities provide river and reservoir fishing, picnicking<br />

and hiking opportunities.<br />

Visit pacificorp.com/recreation for details about recreation<br />

amenities – and any fees – at our recreation areas.<br />

01/11 PC © 2011 <strong>PacifiCorp</strong>