GEA Tuchenhagen Rotating Equipment - Tri-Canada

GEA Tuchenhagen Rotating Equipment - Tri-Canada

GEA Tuchenhagen Rotating Equipment - Tri-Canada

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

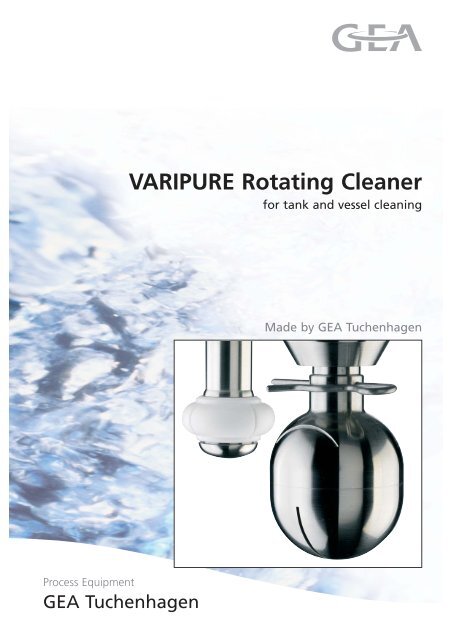

VARIPURE <strong>Rotating</strong> Cleaner<br />

for tank and vessel cleaning<br />

Made by <strong>GEA</strong> <strong>Tuchenhagen</strong><br />

ATEX exempt<br />

Process <strong>Equipment</strong><br />

<strong>GEA</strong> <strong>Tuchenhagen</strong>

VARIPURE ® rotating Cleaner<br />

<strong>GEA</strong> <strong>Tuchenhagen</strong> offers a comprehensive product range for almost all cleaning tasks.<br />

All VARIPURE cleaner are to the latest state-of-the-art designed and manufactured. The devices meet your<br />

high hygiene claims considered by the geometrical shape and the best surface texture. These parameters<br />

proven best meet the requirements to use our cleaners in the brewing and beverage industries, in the<br />

cosmetic and pharmaceutical, chemical, paint and coatings as well as in the biotechnology industry.<br />

The new <strong>GEA</strong> <strong>Tuchenhagen</strong> VARIPURE cleaners - that is where environmental protection<br />

starts!<br />

In hygienic processes, tank cleaning priorities have<br />

changed during the past years. In the past, the<br />

most important task was to have a clean tank after<br />

being subjected to a certain cleaning method, but<br />

today a higher awareness of environmental as well<br />

as economical issues do play a decisive role also.<br />

The new VARIPURE cleaners for tank and vessel<br />

cleaning as well as for special applications can help<br />

you to make an important contribution to protecting<br />

the environment and also to save on investment<br />

costs.<br />

Carefully designed cleaners by <strong>GEA</strong> <strong>Tuchenhagen</strong><br />

do need a minimum of cleaning medium and still<br />

achieve an optimal cleaning result - due to a<br />

strong, mechanical spray pattern.<br />

The savings as well as the benefit for the environment<br />

are obvious:<br />

Due to the considerably reduced volumes of<br />

cleaning media smaller quantities of chemicals will<br />

be required. And there is less need of heating energy<br />

during the cleaning process.<br />

Supply and return pumps as well as the necessary<br />

piping can also be smaller. All this together reduces<br />

energy consumption and minimizes investment<br />

costs.<br />

The amount of expensive waste water is considerably<br />

reduced, too.<br />

<strong>GEA</strong> <strong>Tuchenhagen</strong> offers a comprehensive<br />

VARIPURE cleaner program – static cleaners,<br />

rotating cleaners and orbital cleaners, each tailored<br />

to the specific cleaning task.<br />

ATEX and FDA certification is possible for almost all<br />

cleaners.<br />

The field of application thus extends to use our<br />

cleaners in hygienic and potentially explosive areas<br />

in all industries. The cleaners are driven entirely by<br />

the cleaning fluid without external energy.<br />

A special sensor system developed by <strong>GEA</strong><br />

<strong>Tuchenhagen</strong> is integrated in the tank when orbital<br />

cleaning heads are used to verify the cleaning process.<br />

In this system the medium jet hits the sensor<br />

at regular intervals. The signals issued by the sensor<br />

can be used to monitor the function of the cleaner<br />

electronically and to document the successful<br />

cleaning process.<br />

2

VARIPURE ® rotating Cleaner<br />

Sanitor … compact, ultra-hygienic<br />

• Slow, constant rotation<br />

• Ball bearing free-increased service life<br />

• Large operating pressure range<br />

• Hydrodynamic bearing<br />

- FDA conform and ATEX exempt<br />

- Maintenance-free and durable<br />

- Working pressure 2 - 20 bar<br />

- Cleaning diameter up to 4.8 m<br />

- Flow rate 1.5 – 4.8 m 3 /h<br />

- Spray pattern 360°<br />

- Operation temperature 95 °C max.<br />

- Ambient temperature 140 °C max.<br />

- SIP through the nozzle possible<br />

- Insertion Ø 32 mm min.<br />

- Materials: Stainless Steel 316L (1.4404)<br />

- Pipe connection: 3/8“ BSP Female<br />

Prefered mounting position: vertical down<br />

FDA conform and ATEX exempt<br />

3

VARIPURE rotating Cleaner<br />

Turbo SSB … constant rotation speed at different pressure<br />

• Slow, constant rotation<br />

• Ball bearing free-increased service life<br />

• Economic flow rates<br />

• High efficiency fan jets<br />

- FDA conform or ATEX exempt<br />

- Working pressure 2 - 20 bar<br />

- Cleaning diameter up to 4.6 m<br />

- Flow rate 2.4 – 6 m 3 /h<br />

- Spray pattern 360°, optional 180°<br />

- Operation temperature 95 °C max.<br />

- Ambient temperature 140 °C max.<br />

- SIP through the nozzle possible<br />

- Insertion Ø 50 mm min.<br />

- Materials:<br />

Stainless Steel 316L (1.4404), P-PTFE or C-PTFE<br />

- Pipe connection:<br />

3/4“ BSP Female, optional Pin Fix<br />

Prefered mounting position: vertical down<br />

4

VARIPURE rotating Cleaner<br />

Torus 50 / 75 … ideal for low pressure applications with small amounts of cleaning agents<br />

• Hygienic design<br />

• Economic flow rates<br />

• Ball bearing free-increased service life<br />

• Low operating pressure<br />

- FDA conform or ATEX exempt<br />

- Versatile range of applications<br />

- Pressure 0.5 - 4 bar<br />

- Cleaning diameter up to 3.2 m<br />

- Flow rate 0.5 – 3,9 m 3 /h<br />

- Spray pattern 360°, optional 180°<br />

- Operation temperature 95 °C max.<br />

- Ambient temperature 140 °C max.<br />

- Insertion Ø 42 mm or 52 mm min.<br />

- Materials:<br />

Stainless Steel 316L (1.4404), PTFE or C-PTFE,<br />

optional Hastelloy<br />

- Option: CHEMITORUS complete PTFE or C-PTFE<br />

- Pipe connection: 3/8“ resp. 1/2“ BSP Female,<br />

optional Pin Fix<br />

Prefered mounting position: any<br />

5

VARIPURE rotating Cleaners<br />

Torus 100 … ideal for low pressure applications with small amounts of cleaning agents<br />

• Hygienic design<br />

• Economic flow rates<br />

• Ball bearing free-increased service life<br />

• Powerful fan jets<br />

- FDA conform or ATEX exempt<br />

- Versatile range of applications<br />

- Working Pressure 1 - 6 bar<br />

- Cleaning diameter up to 5 m<br />

- Flow rate 3 – 7.2 m 3 /h<br />

- Spray pattern 360°, optional 180°<br />

- Operation temperature 95 °C max.<br />

- Ambient temperature 140 °C max.<br />

- Insertion Ø 70 mm min.<br />

- Materials:<br />

Stainless Steel 316L (1.4404),<br />

PTFE or C-PTFE, optional Hastelloy<br />

- Option: CHEMITORUS complete PTFE<br />

or C-PTFE<br />

- Pipe connection:<br />

Pin Fix to suit 1” OD tube (25.4x1.6 mm)<br />

Prefered mounting position: any<br />

6

VARIPURE rotating Cleaners<br />

Troll Ball 2 Zoll … the economic alternative to the spray ball<br />

• Economic flow rates<br />

• Ball bearing free-increased service life<br />

• Slow, constant rotation<br />

• Powerful round jets<br />

- FDA conform or ATEX exempt<br />

- Working pressure 3 – 12 bar<br />

- Cleaning diameter up to 4.4 m<br />

- Flow rate 3 – 6 m 3 /h<br />

- Spray pattern 360°, optional 180°<br />

- Operation temperature 120 °C max.<br />

- Ambient temperature 140 °C max.<br />

- Insertion Ø 60 mm min.<br />

- Materials:<br />

Stainless Steel 316L (1.4404), PTFE or C-PTFE<br />

- Pipe connection:<br />

3/4“ BSPT Female<br />

- Weight 1 kg<br />

Prefered mounting position: vertical down<br />

7

VARIPURE rotating Cleaners<br />

Troll Ball 3 Zoll … ideal for cleaning at high temperatures<br />

• Economic flow rates<br />

• Ball bearing free-increased service life<br />

• Slow, constant rotation<br />

• Powerful round jets<br />

- FDA conform or ATEX exempt<br />

- Working pressure 3 – 12 bar<br />

- Cleaning diameter up to 6.4 m<br />

- Flow rate 8.1 – 16.2 m 3 /h<br />

- Spray pattern 360°, optional 180°<br />

- Operation temperature 120 °C max.<br />

- Ambient temperature 140 °C, max.<br />

- Insertion Ø 90 mm min.<br />

- Materials:<br />

Stainless Steel 316L (1.4404), PTFE or C-PTFE<br />

- Pipe connection:<br />

11/2“ BSPT Female<br />

- Weight 2.3 kg<br />

Prefered mounting position: vertical down<br />

8

VARIPURE rotating Cleaners<br />

Turbodisc TD25 / TD75 / TD100 / TD150 … one of the strongest in its class<br />

• Economic flow rates<br />

• Ball bearing free-increased service life<br />

• Maintenance free<br />

• Hydrodynamic bearing<br />

• Insensitive to blockage<br />

- FDA conform or ATEX exempt<br />

- Working pressure 2 - 4 bar<br />

- Cleaning diameter up to 4.8 m<br />

- Flow rate 2.7 - 14.7 m 3 /h<br />

- Spray pattern 360°, optional 180°<br />

- Operation temperature 95 °C max.<br />

- Ambient temperature 140 °C max.<br />

- SIP through the nozzle possible<br />

- Insertion Ø 31 mm, 41 mm, 55 mm, 75 mm<br />

- Materials:<br />

Stainless Steel 316L (1.4404), PTFE or C-PTFE,<br />

optional Hastelloy<br />

- Pipe connection:<br />

1/4” BSP Male, 3/4”, 1”, 11/2” BSP Female<br />

Prefered mounting position: any<br />

ATEX exempt<br />

9

VARIPURE rotating Cleaners<br />

<strong>Rotating</strong> Jet Cleaner Type 2E for hanging in tanks … in levels circulating fan jets<br />

• Interval flushing by slowly rotating fan jets<br />

• Multiple increased swell compared with<br />

a spray ball<br />

• Various spray pattern by different nozzle<br />

arrangements<br />

• Driven by liquid flow gear<br />

Type No. of Flow rate Pressure Spraying circle<br />

nozzles m 3 /h bar 1/min dia. m<br />

A 1 13 – 14 2.7 8 – 12 4<br />

B 2 23 – 24 3.7 4 – 6 7<br />

B1 2 18 – 19 3.0 3 – 4 6<br />

C1 2 23 – 24 3.7 4 – 6 10<br />

C2 3 28 – 29 4.3 5 – 8 10<br />

C4 3 24 – 25 3.9 5 – 7 6<br />

D1 2 24 – 25 3.8 4 – 6 4.2<br />

D2 2 14 – 15 2.8 3 – 4 3.8<br />

D3 2 19 – 20 3.4 4 – 5 4<br />

E 2 22 – 23 3.6 4 – 6 8<br />

E1 2 23 – 24 3.7 4 – 6 8.5<br />

F2 3 17 – 18 2.8 3 – 5 3.5<br />

F3 3 20 – 21 3.2 3 – 5 4<br />

F4 3 20 – 21 3.2 4 – 6 4<br />

F5 3 11 – 12 2.6 6 – 10 3<br />

F6 3 7 – 8 2.3 4 – 6 2<br />

F8 3 11 – 12 2.6 6 – 10 3<br />

- Rotation Monitoring<br />

by Proximity Switch (optional)<br />

- Working pressure 2.3 – 4.3 bar<br />

- Flow rate 7 – 29 m 3 /h<br />

- Cleaning diameter 2 – 10 m<br />

- Operating temperature 80 °C max, optional 100 °C<br />

- Ambient temperature 130 °C max.<br />

(with PTFE design)<br />

- Insertion Ø 100 mm min.<br />

- Materials:<br />

Stainless steel 1.4571/ PP at 80 °C<br />

Stainless steel 1.4571/ PTFE at 100 °C<br />

- Various opportunities for pressure tank connection<br />

Prefered mounting position: vertical down<br />

10

VARIPURE rotating Cleaners<br />

<strong>Rotating</strong> Jet Cleaner, Type 2B … to be placed into the tank<br />

• Interval flushing by slowly rotating fan jets<br />

• Multiple increased swell compared with<br />

a spray ball<br />

• Various spray pattern by different nozzle<br />

arrangements<br />

• Driven by liquid flow gear<br />

- Rotation Monitoring<br />

by Proximity Switch (optional)<br />

- Working pressure 2.3 – 3.2 bar<br />

- Flow rate 10 – 22 m 3 /h<br />

- Cleaning diameter 2 – 10 m<br />

- Operating temperature 80 °C max, optional 100 °C<br />

- Ambient temperature 130 °C max.<br />

(with PTFE design)<br />

- Installation sleeve 440 mm suitable for oval<br />

manholes 330/440mm<br />

- Materials:<br />

Stainless steel 1.4571/ PP at 80 °C<br />

Stainless steel 1.4571/ PTFE at 100 °C<br />

- Various opportunities for pressure tank connection<br />

Prefered mounting position: vertical up<br />

Type No. of Flow rate Pressure Spraying circle<br />

nozzles m 3 /h bar 1/min dia. m<br />

A 1 13 – 14 2.7 8 – 12 4<br />

G 1 10 – 11 2.3 7 – 10 3<br />

H 2 21 – 22 3.2 4 – 6 3<br />

M 1 11 – 12 2.4 7 – 10 3 – 4<br />

N1 2 21 – 22 3.2 4 – 6 6<br />

N2 2 21 – 22 3.2 4 – 6 6<br />

11

Process <strong>Equipment</strong><br />

<strong>GEA</strong> <strong>Tuchenhagen</strong> GmbH<br />

Am Industriepark 2-10, 21514 Büchen, Germany<br />

Phone +49-4155 49-0, Fax +49-4155 49-2423<br />

sales.geatuchenhagen@geagroup.com, www.tuchenhagen.com<br />

Fa 613e-05/09