Edge Spacing of Pegs in Mortise and Tenon Joints - Timber Frame ...

Edge Spacing of Pegs in Mortise and Tenon Joints - Timber Frame ...

Edge Spacing of Pegs in Mortise and Tenon Joints - Timber Frame ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Methods <strong>and</strong> Materials<br />

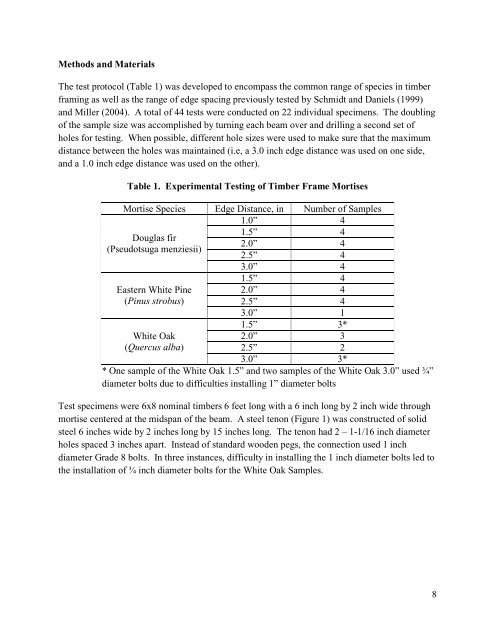

The test protocol (Table 1) was developed to encompass the common range <strong>of</strong> species <strong>in</strong> timber<br />

fram<strong>in</strong>g as well as the range <strong>of</strong> edge spac<strong>in</strong>g previously tested by Schmidt <strong>and</strong> Daniels (1999)<br />

<strong>and</strong> Miller (2004). A total <strong>of</strong> 44 tests were conducted on 22 <strong>in</strong>dividual specimens. The doubl<strong>in</strong>g<br />

<strong>of</strong> the sample size was accomplished by turn<strong>in</strong>g each beam over <strong>and</strong> drill<strong>in</strong>g a second set <strong>of</strong><br />

holes for test<strong>in</strong>g. When possible, different hole sizes were used to make sure that the maximum<br />

distance between the holes was ma<strong>in</strong>ta<strong>in</strong>ed (i.e, a 3.0 <strong>in</strong>ch edge distance was used on one side,<br />

<strong>and</strong> a 1.0 <strong>in</strong>ch edge distance was used on the other).<br />

Table 1. Experimental Test<strong>in</strong>g <strong>of</strong> <strong>Timber</strong> <strong>Frame</strong> <strong>Mortise</strong>s<br />

<strong>Mortise</strong> Species <strong>Edge</strong> Distance, <strong>in</strong> Number <strong>of</strong> Samples<br />

1.0” 4<br />

1.5” 4<br />

Douglas fir<br />

2.0” 4<br />

(Pseudotsuga menziesii)<br />

2.5” 4<br />

3.0” 4<br />

Eastern White P<strong>in</strong>e<br />

(P<strong>in</strong>us strobus)<br />

White Oak<br />

(Quercus alba)<br />

1.5” 4<br />

2.0” 4<br />

2.5” 4<br />

3.0” 1<br />

1.5” 3*<br />

2.0” 3<br />

2.5” 2<br />

3.0” 3*<br />

* One sample <strong>of</strong> the White Oak 1.5” <strong>and</strong> two samples <strong>of</strong> the White Oak 3.0” used ¾”<br />

diameter bolts due to difficulties <strong>in</strong>stall<strong>in</strong>g 1” diameter bolts<br />

Test specimens were 6x8 nom<strong>in</strong>al timbers 6 feet long with a 6 <strong>in</strong>ch long by 2 <strong>in</strong>ch wide through<br />

mortise centered at the midspan <strong>of</strong> the beam. A steel tenon (Figure 1) was constructed <strong>of</strong> solid<br />

steel 6 <strong>in</strong>ches wide by 2 <strong>in</strong>ches long by 15 <strong>in</strong>ches long. The tenon had 2 – 1-1/16 <strong>in</strong>ch diameter<br />

holes spaced 3 <strong>in</strong>ches apart. Instead <strong>of</strong> st<strong>and</strong>ard wooden pegs, the connection used 1 <strong>in</strong>ch<br />

diameter Grade 8 bolts. In three <strong>in</strong>stances, difficulty <strong>in</strong> <strong>in</strong>stall<strong>in</strong>g the 1 <strong>in</strong>ch diameter bolts led to<br />

the <strong>in</strong>stallation <strong>of</strong> ¾ <strong>in</strong>ch diameter bolts for the White Oak Samples.<br />

8