February 2012 Issue - Target Shooter Magazine

February 2012 Issue - Target Shooter Magazine

February 2012 Issue - Target Shooter Magazine

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

QUIGLEY SHOOTING<br />

ASSOCIATION NEWS<br />

LOADING THE<br />

BLACKPOWDER SHOTSHELL<br />

Part 2 by Ken Hall<br />

In the previous chapter on this subject, I hopefully<br />

whetted your appetite enough to encourage you<br />

to try handloading the black powder shotshell<br />

yourselves. Traditionally, shotshell cartridges were<br />

made of paper or card tube, with a brass base<br />

containing a thick base wad with a hole for the large<br />

shotgun primer. This design has hardly changed<br />

except the outer tube is now made of plastic and<br />

the brass base has been replaced with a brass plated<br />

ferrous metal to keep production costs down. This<br />

means that reloading tools designed in the 19th<br />

century to reload the paper shotshell will work just as<br />

well in the 21st century with today’s cases.<br />

Let’s look at the way I reload the 12 gauge black<br />

powder shotshell but first, as usual, I want to say<br />

that what has proven to be safe in my own turn of<br />

the century hammer gun may not prove to be so in<br />

other vintage guns so, if you intend to use the load<br />

in anything other than a modern nitro proofed gun,<br />

please have it checked by a competent gunsmith to<br />

determine its’ serviceability.<br />

I tend to use once-fired cases for reloading; this<br />

means that if the case has been fired in a different<br />

gun than the shell is intended for, then the brass base<br />

will need to be resized to standard dimensions in order<br />

to freely enter the chamber. Simple hand tools exist<br />

for this purpose but I cheat and use the resizing die<br />

with my Lee ‘Load-All’ machine as it is much quicker<br />

to use. (If new bought cases are preferred then this<br />

process is not necessary).<br />

Next, the spent primer needs to be removed, I use<br />

an antique de-priming and re-priming tool for this<br />

purpose but it could be simply knocked out with a<br />

nail punch. As I sometimes use reclaimed (salvaged)<br />

cases which are of different overall lengths, I then take<br />

the unprimed case and trim it to the required length<br />

using another vintage tool which was illustrated in the<br />

last instalment. If you don’t have this tool then this<br />

process can be completed later using a simple home<br />

made tool. The new primer is then seated using the<br />

previously mentioned re-priming tool; once again<br />

this can also be achieved simply by placing the primer<br />

on a flat surface and pressing the case over it using a<br />

suitably sized dowel inside the case.<br />

bowl to vary the volume. English and American made<br />

tools are usually graduated in drams for powder and<br />

ounces for shot, whilst continental ones are usually in<br />

decigrammes for powder and grammes for shot.<br />

What simplifies things is that once you have adjusted<br />

the measure for the weight of shot, it is customary<br />

to use the same volume setting for powder. Using<br />

my English measure, I have settled on a load of 1oz<br />

Shotshell component parts<br />

shot, this approximates to 28grams. At this setting<br />

the measure indicates a powder weight of 2½ drams,<br />

(74grains in common reloading parlance). This load<br />

should be more than adequate for CAS steel plate<br />

shooting.<br />

So, using a cartridge filler tube, I take my primed case,<br />

pour in a measure of 2½drams of Swiss No 4, I then<br />

take a 3mm thick over-powder card wad and push this<br />

onto the powder, next comes a 13mm fibre cushioning<br />

wad, then a 3mm felt wad to prevent the shot<br />

embedding in the fibre. Next, using the same measure<br />

setting, I pour in 1oz of shot, (anything from No7s to<br />

No5s is good for knocking over steel plates) followed<br />

by a thin over-shot card wad. All that is left to do is to<br />

form the crimp to hold the components together. If, as<br />

I mentioned earlier, the case has not been previously<br />

cut to length, then that will be necessary before the<br />

crimping stage.<br />

Even though modern nitro game and target cartridges<br />

are still relatively cheap to purchase, the tools and<br />

components required to manufacture ammunition at<br />

home are still being made and are readily available<br />

from several retailers, of note are Henry Krank & Co at<br />

Typical hand tools<br />

www.henrykrank.com and Clay & Game Reloaders at<br />

www.claygame.co.uk . Also of interest is the extract<br />

from the Parker Hale catalogue showing vintage tools<br />

still available at least as late as 1958.<br />

Comments and questions please to;<br />

khall6548@aol.com<br />

QUIGLEY SHOOTING<br />

ASSOCIATION NEWS<br />

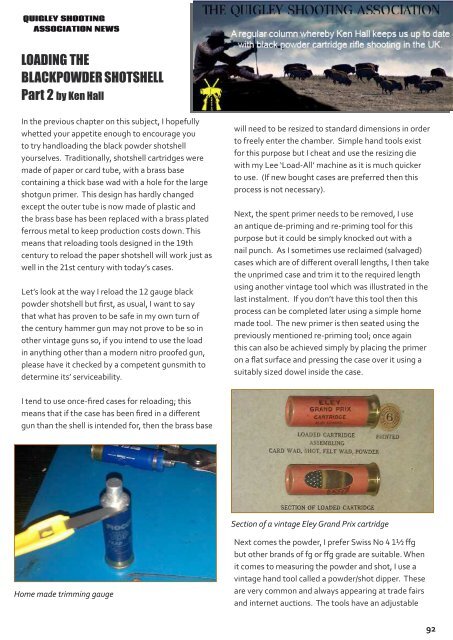

Home made trimming gauge<br />

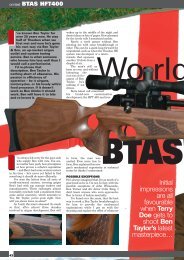

Section of a vintage Eley Grand Prix cartridge<br />

Next comes the powder, I prefer Swiss No 4 1½ ffg<br />

but other brands of fg or ffg grade are suitable. When<br />

it comes to measuring the powder and shot, I use a<br />

vintage hand tool called a powder/shot dipper. These<br />

are very common and always appearing at trade fairs<br />

and internet auctions. The tools have an adjustable<br />

I made a simple gauge out of a piece of aluminium<br />

rod as pictured, which allows for an overlap of 3mm<br />

for crimping. The whole is now placed in the vintage<br />

cartridge closer and the roll crimp applied. I generally<br />

now mark the cartridge with an indelible pen to show<br />

it is charged with black powder.<br />

Parker Hale cat 58<br />

92 93