FOLGER ADAM 310-3-1 Install Instructions - Hes

FOLGER ADAM 310-3-1 Install Instructions - Hes

FOLGER ADAM 310-3-1 Install Instructions - Hes

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

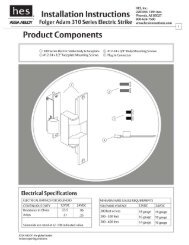

<strong>Install</strong>ation <strong>Instructions</strong><br />

Folger Adam <strong>310</strong> Series Electric Strike<br />

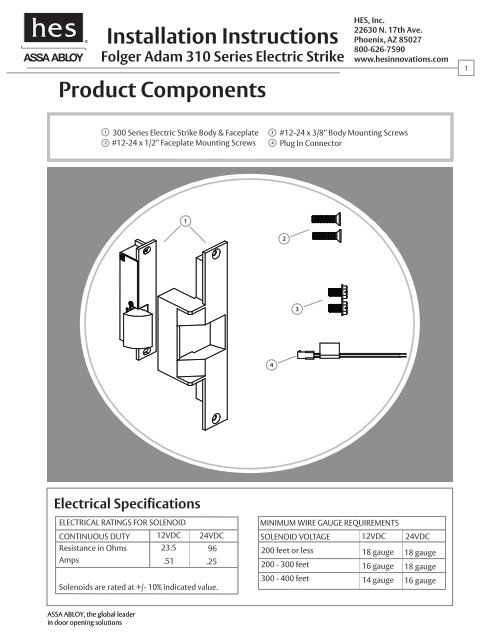

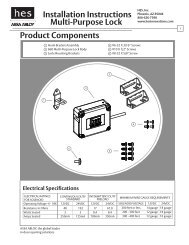

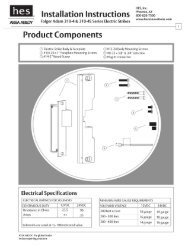

Product Components<br />

HES, Inc.<br />

22630 N. 17th Ave.<br />

Phoenix, AZ 85027<br />

800-626-7590<br />

www.hesinnovations.com<br />

1<br />

1<br />

2<br />

300 Series Electric Strike Body & Faceplate 3<br />

#12-24 x 1/2” Faceplate Mounting Screws 4<br />

#12-24 x 3/8” Body Mounting Screws<br />

Plug In Connector<br />

1<br />

2<br />

3<br />

4<br />

Electrical Specifications<br />

ELECTRICAL RATINGS FOR SOLENOID<br />

MINIMUM WIRE GAUGE REQUIREMENTS<br />

CONTINUOUS DUTY 12VDC 24VDC<br />

SOLENOID VOLTAGE 12VDC<br />

Resistance in Ohms<br />

23.5 96<br />

200 feet or less<br />

18 gauge<br />

Amps<br />

.51 .25<br />

200 - 300 feet<br />

16 gauge<br />

300 - 400 feet<br />

14 gauge<br />

Solenoids are rated at +/- 10% indicated value.<br />

24VDC<br />

18 gauge<br />

18 gauge<br />

16 gauge

<strong>Install</strong>ation Directions<br />

2<br />

CAUTION! Before connecting any device at the installation site, verify input voltage using a multimeter.<br />

Many power supplies and low voltage transformers operate at higher levels than listed. Any input voltage exceeding<br />

10% of the solenoid rating may cause severe damage to the unit and will void the warranty.<br />

Prepare Strike<br />

1. Attach the faceplate to the strike body using the #12-24 x<br />

3/8” Body Mounting screws as illustrated on page 3,<br />

Diagram 2.<br />

2. If using the LCBMA (Latchbolt & Locking Cam Monitor),<br />

see Diagram 1 for wiring instructions.<br />

3. The strike body ships as either a 12 or 24 volt<br />

unit and is not field selectable. Verify the available<br />

voltage is +/- 10% of the rated voltage of the strike body.<br />

Prepare Frame<br />

4. If using a mortise lockset, calculate offset using Diagram<br />

3 on page 3.<br />

5. Prepare frame using the template for your strike<br />

located on pages 4-6.<br />

Finish <strong>Install</strong>ing<br />

6. Connect the Plug In Connector to the electric strike, and<br />

connect wires from the Plug In Connector leads to the<br />

power source.<br />

7. <strong>Install</strong> the electric strike unit in jamb cutout, using the<br />

#12-24 x 1/2” faceplate mounting screws provided.<br />

Latchbolt Monitor (LBM)<br />

White Common<br />

Orange Normally Open<br />

Green Normally Closed<br />

Locking Cam Monitor (LCM)<br />

Brown<br />

Blue<br />

Common<br />

Normally Open<br />

Yellow Normally Closed<br />

White<br />

Orange<br />

Green<br />

Brown<br />

Blue<br />

Yellow

<strong>Install</strong>ation Directions<br />

3<br />

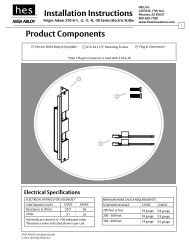

Diagram 2: Faceplate Attachment<br />

To install the <strong>310</strong> series electric strike body to the<br />

faceplate, install two #12-24 body mounting screws<br />

as shown. Make sure bolts are tightened and secured.<br />

Keeper position can be adjusted by loosening the #12-24<br />

body mounting screws, and repositioning the strike body<br />

as needed. Retighten body mounting screws after<br />

adjustment is made<br />

Diagram 3: Determining Mortise Offset<br />

C L Mortise<br />

Door Prep<br />

8”<br />

[203.2]<br />

4”<br />

[101.60]<br />

B<br />

C L<br />

Strike<br />

MORTISE LOCK B<br />

CORBIN/RUSSWIN<br />

ARROW, FALCON<br />

0"<br />

BEST 34H-37H 1/4"<br />

SARGENT (8200)<br />

YALE (8800)<br />

3/16"<br />

SCHLAGE 3 /4"<br />

YALE (8700) 7/8"<br />

BEST 45H & 47H 1/8"

Cutout Templates<br />

1-3/8”<br />

[35]<br />

11/16”<br />

[17.5]<br />

<strong>310</strong>-2 Template & Dimensions<br />

5/16”<br />

[7.9]<br />

Inches [mm]<br />

4<br />

9"<br />

[228.6]<br />

8-3/8"<br />

[212.7]<br />

3-3/4”<br />

[95.3]<br />

1-3/4”<br />

[44.5]<br />

9”<br />

[228.6]<br />

7-23/32”<br />

[196.1]<br />

3-3/4"<br />

[95.3]<br />

2-5/8”<br />

[66.7]<br />

11/16”<br />

[17.5]<br />

1-3/8”<br />

[35]<br />

8-3/8”<br />

[212.7]<br />

11/16”<br />

[17.5]<br />

21/32”<br />

[16.6]<br />

1-1/2”<br />

[38.4]<br />

5/32”<br />

[3.9]<br />

1/2”<br />

[13]<br />

1-5/8”<br />

[41.3]<br />

1-1/2"<br />

[38.4]<br />

<strong>310</strong>-2 3/4 Template & Dimensions<br />

1-3/8”<br />

[35]<br />

11/16”<br />

[17.5]<br />

5/16”<br />

[7.9]<br />

9"<br />

[228.6]<br />

8-3/8"<br />

[212.7]<br />

3-3/4”<br />

[95.3]<br />

1-3/4”<br />

[44.5]<br />

9”<br />

[228.6]<br />

7-1/8”<br />

[180.9]<br />

3-3/4"<br />

[95.3]<br />

2-5/8”<br />

[66.7]<br />

15/16”<br />

[23.8]<br />

1-3/8”<br />

[35]<br />

8-3/8”<br />

[212.7]<br />

11/16”<br />

[17.5]<br />

1-1/4”<br />

[31.8]<br />

2”<br />

[50.8]<br />

5/32”<br />

[3.9]<br />

3/4”<br />

[19]<br />

2"<br />

[50.8]

Cutout Templates<br />

<strong>310</strong>-2 3/4 OB Template & Dimensions<br />

Inches [mm]<br />

5<br />

11/16”<br />

[17.5]<br />

1-3/8”<br />

[35]<br />

5/16”<br />

[7.9]<br />

9"<br />

[228.6]<br />

8-3/8"<br />

[212.7]<br />

3-3/4"<br />

[95.3]<br />

3-3/4” 1-3/4”<br />

[95.3] [44.5]<br />

8-3/8”<br />

[212.7]<br />

9”<br />

[228.6]<br />

7-1/8”<br />

[181]<br />

2-5/8”<br />

[66.7]<br />

2"<br />

[50.8]<br />

15/16”<br />

[23.8]<br />

1-3/8”<br />

[35]<br />

11/16”<br />

[17.5]<br />

1-1/4”<br />

[31.7]<br />

3/4”<br />

[19]<br />

2”<br />

[50.8]<br />

5/32”<br />

[3.9]<br />

<strong>310</strong>-2 3/4U Template & Dimensions<br />

1-3/8”<br />

[35]<br />

11/16”<br />

[17.5]<br />

5/16”<br />

[7.9]<br />

9"<br />

[228.6]<br />

8-3/8"<br />

[212.7]<br />

3-3/4”<br />

[95.3]<br />

1-3/4”<br />

[44.5]<br />

1/2”<br />

[13]<br />

9”<br />

[228.6]<br />

7-1/8”<br />

[181]<br />

3-3/4"<br />

[95.3]<br />

2-5/8”<br />

[66.7]<br />

15/16”<br />

[23.8]<br />

1-3/8”<br />

[35]<br />

8-3/8”<br />

[212.7]<br />

11/16”<br />

[17.5]<br />

1-1/4”<br />

[31.7]<br />

3/4”<br />

[19]<br />

2”<br />

[50.8]<br />

5/32”<br />

[3.9]<br />

2"<br />

[50.8]

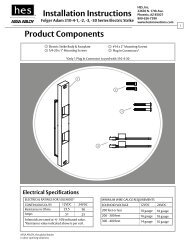

Cutout Templates<br />

<strong>310</strong>-3-1 Template & Dimensions<br />

Inches [mm]<br />

6<br />

1-3/8”<br />

[35]<br />

11/16”<br />

[17.5]<br />

9"<br />

[228.6]<br />

8-3/8"<br />

[212.7]<br />

3/4”<br />

[19.16]<br />

3-3/4”<br />

[95.25]<br />

1-3/4”<br />

[44.45]<br />

8-3/8”<br />

[212.7]<br />

9”<br />

[229.86]<br />

*Deadlock<br />

Block<br />

7-3/64”<br />

[179.2]<br />

2-3/8”<br />

[60.33]<br />

3-3/4"<br />

[95.3]<br />

2-1/4”<br />

[57.15]<br />

5/16”<br />

[7.98]<br />

1-1/4”<br />

[31.75]<br />

5/32”<br />

[3.99]<br />

2-1/2"<br />

[63.5]<br />

15/16”<br />

[23.94]<br />

1-3/8”<br />

[34.93]<br />

11/16”<br />

[17.6]<br />

2-1/2”<br />

[63.5]<br />

*The deadlock block that depresses the auxiliary latch can be rotated<br />

180° to move the block 1/4” [6.4] higher if necessary. Handing of the<br />

strike can be changed by moving the deadlock block and cavity plug<br />

to the opposite cavities in the face plate.<br />

3810006.001 rev B.<br />

© 2010 HES, Inc.