Behind the Veneer - Tasmanian Greens MPs

Behind the Veneer - Tasmanian Greens MPs

Behind the Veneer - Tasmanian Greens MPs

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

TA ANN: BEHIND THE VENEER<br />

Ta Ann Tasmania<br />

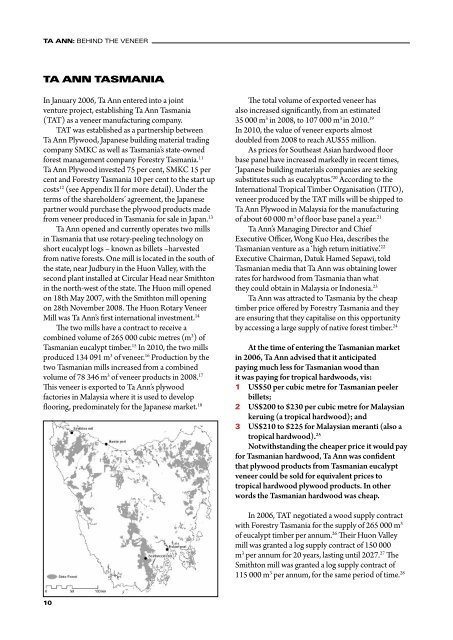

In January 2006, Ta Ann entered into a joint<br />

venture project, establishing Ta Ann Tasmania<br />

(TAT) as a veneer manufacturing company.<br />

TAT was established as a partnership between<br />

Ta Ann Plywood, Japanese building material trading<br />

company SMKC as well as Tasmania’s state-owned<br />

forest management company Forestry Tasmania. 11<br />

Ta Ann Plywood invested 75 per cent, SMKC 15 per<br />

cent and Forestry Tasmania 10 per cent to <strong>the</strong> start up<br />

costs 12 (see Appendix II for more detail). Under <strong>the</strong><br />

terms of <strong>the</strong> shareholders’ agreement, <strong>the</strong> Japanese<br />

partner would purchase <strong>the</strong> plywood products made<br />

from veneer produced in Tasmania for sale in Japan. 13<br />

Ta Ann opened and currently operates two mills<br />

in Tasmania that use rotary-peeling technology on<br />

short eucalypt logs – known as billets –harvested<br />

from native forests. One mill is located in <strong>the</strong> south of<br />

<strong>the</strong> state, near Judbury in <strong>the</strong> Huon Valley, with <strong>the</strong><br />

second plant installed at Circular Head near Smithton<br />

in <strong>the</strong> north-west of <strong>the</strong> state. The Huon mill opened<br />

on 18th May 2007, with <strong>the</strong> Smithton mill opening<br />

on 28th November 2008. The Huon Rotary <strong>Veneer</strong><br />

Mill was Ta Ann’s first international investment. 14<br />

The two mills have a contract to receive a<br />

combined volume of 265 000 cubic metres (m 3 ) of<br />

<strong>Tasmanian</strong> eucalypt timber. 15 In 2010, <strong>the</strong> two mills<br />

produced 134 091 m 3 of veneer. 16 Production by <strong>the</strong><br />

two <strong>Tasmanian</strong> mills increased from a combined<br />

volume of 78 346 m 3 of veneer products in 2008. 17<br />

This veneer is exported to Ta Ann’s plywood<br />

factories in Malaysia where it is used to develop<br />

flooring, predominately for <strong>the</strong> Japanese market. 18<br />

The total volume of exported veneer has<br />

also increased significantly, from an estimated<br />

35 000 m 3 in 2008, to 107 000 m 3 in 2010. 19<br />

In 2010, <strong>the</strong> value of veneer exports almost<br />

doubled from 2008 to reach AU$55 million.<br />

As prices for Sou<strong>the</strong>ast Asian hardwood floor<br />

base panel have increased markedly in recent times,<br />

‘Japanese building materials companies are seeking<br />

substitutes such as eucalyptus.’ 20 According to <strong>the</strong><br />

International Tropical Timber Organisation (ITTO),<br />

veneer produced by <strong>the</strong> TAT mills will be shipped to<br />

Ta Ann Plywood in Malaysia for <strong>the</strong> manufacturing<br />

of about 60 000 m 3 of floor base panel a year. 21<br />

Ta Ann’s Managing Director and Chief<br />

Executive Officer, Wong Kuo Hea, describes <strong>the</strong><br />

<strong>Tasmanian</strong> venture as a ‘high return initiative’. 22<br />

Executive Chairman, Datuk Hamed Sepawi, told<br />

<strong>Tasmanian</strong> media that Ta Ann was obtaining lower<br />

rates for hardwood from Tasmania than what<br />

<strong>the</strong>y could obtain in Malaysia or Indonesia. 23<br />

Ta Ann was attracted to Tasmania by <strong>the</strong> cheap<br />

timber price offered by Forestry Tasmania and <strong>the</strong>y<br />

are ensuring that <strong>the</strong>y capitalise on this opportunity<br />

by accessing a large supply of native forest timber. 24<br />

At <strong>the</strong> time of entering <strong>the</strong> <strong>Tasmanian</strong> market<br />

in 2006, Ta Ann advised that it anticipated<br />

paying much less for <strong>Tasmanian</strong> wood than<br />

it was paying for tropical hardwoods, vis:<br />

1 US$50 per cubic metre for <strong>Tasmanian</strong> peeler<br />

billets;<br />

2 US$200 to $230 per cubic metre for Malaysian<br />

keruing (a tropical hardwood); and<br />

3 US$210 to $225 for Malaysian meranti (also a<br />

tropical hardwood). 25<br />

Notwithstanding <strong>the</strong> cheaper price it would pay<br />

for <strong>Tasmanian</strong> hardwood, Ta Ann was confident<br />

that plywood products from <strong>Tasmanian</strong> eucalypt<br />

veneer could be sold for equivalent prices to<br />

tropical hardwood plywood products. In o<strong>the</strong>r<br />

words <strong>the</strong> <strong>Tasmanian</strong> hardwood was cheap.<br />

In 2006, TAT negotiated a wood supply contract<br />

with Forestry Tasmania for <strong>the</strong> supply of 265 000 m 3<br />

of eucalypt timber per annum. 26 Their Huon Valley<br />

mill was granted a log supply contract of 150 000<br />

m 3 per annum for 20 years, lasting until 2027. 27 The<br />

Smithton mill was granted a log supply contract of<br />

115 000 m 3 per annum, for <strong>the</strong> same period of time. 28<br />

10