MOTORISED HOE - Benassi

MOTORISED HOE - Benassi

MOTORISED HOE - Benassi

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

S.p.A.<br />

USE AND MAINTENANCE HANDBOOK<br />

<strong>MOTORISED</strong> <strong>HOE</strong><br />

RT 80<br />

06/07/01

S.p.A. RT 80<br />

1) Introduction<br />

2) After-sales service and Warranty<br />

3) Technical details<br />

4) Packing and transport<br />

5) Accessories<br />

6) Safety rules and limits on use<br />

7) Starting and stopping<br />

CONTENTS<br />

8) Operating and regulating the machine<br />

9) Mill assembling<br />

10) Maintenance and lubrication<br />

11) End-of season servicing<br />

12) Possible problems and solutions<br />

13) Instructions for a good operation of the<br />

machine<br />

1 -INTRODUCTION<br />

We are pleased that you chose a machine built by BENASSI SPA.<br />

This booklet provides the information and data needed to preserve and use the machine properly.<br />

The more you get to know your farming machine, the better you will work. Therefore we strongly suggest that before starting work, you carefully read and<br />

understand this "USER AND MAINTENANCE" booklet.<br />

You will find important information on using the machine which will allow you to get the most of its technical capacities. You will also find precious<br />

information on how to care for it and service it, in terms of safety, and a guide on running and servicing it in the best possible way during the lifetime of your<br />

machine.<br />

For reasons of technical progress, BENASSI SPA reserves the right to modify the mechanical parts, the finishes and the accessories. The data<br />

regarding measures, weights and performance are specified within DIN tolerance. The figures, the descriptions and the technical data are not binding.<br />

2 - AFTER-SALES SERVICE AND WARRANTY<br />

BENASSI SPA provides its customers with an after-sales service for solving any problem involving the use and the maintenance of its machinery. All the<br />

machines are guaranteed for defective material for 12 months (one year) from purchase. For any need, refer to your dealer.<br />

N.B. IMPORTANT WARNING FOR YOUR SAFETY<br />

Always use original BENASSI SPA products, spare parts and accessories; any modification or application using non-original parts exempts BENASSI<br />

SPA from any responsibility<br />

BENASSI SPA disclaims all responsibility in case of application of accessories made by other firms to its machines: Any warranty will be given for said<br />

applications even when such modifications have been tested by boards of control or certified by public bodies as tests on single machines are not valid.<br />

BENASSI SPA W ISHES YOU A PLEASANT W ORK W ITH OUR MACHINES<br />

N.B. PAY SPECIAL ATTENTION TO THE INSTRUCTIONS MARKED OUT BY THE<br />

FOLLOWING SIGN<br />

THIS SYMBOL INDICATES DANGER: FAILURE TO COMPLY WITH THESE<br />

INSTRUCTIONS MAY CAUSE INSIDIOUS OR EVEN FATAL INJURY.<br />

3 – TECHNICAL DETAILS<br />

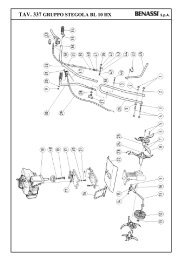

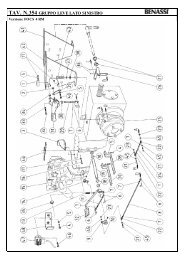

LIST OF MACHINE PARTS<br />

1. Accelerator<br />

2. Stop engine<br />

3. Clutch lev er<br />

4. Clutch adjuster<br />

5. Handle-bar adjuster<br />

6. Tool-case<br />

7. Start engine<br />

8. Fuel inserting<br />

9. Air f ilter<br />

10. Oil lev el<br />

11. Power take-of f<br />

12. Driv ing wheel<br />

13. Mill<br />

14. Mills bonnet<br />

15. Bonnet adjustment<br />

16. Oil inlet<br />

17. Mills lev er<br />

18. Gearbox lev er<br />

19. Blocking push button<br />

2

SpA RT 80<br />

ENGINE<br />

MINSEL COMPACT 7 HP<br />

CYCLE 8<br />

STROKE 2<br />

FUEL TYPE Gasoline-oil mixture 4%<br />

DISPLACEMENT<br />

148 cc.<br />

NET W EIGHT<br />

Kg. 100 complete with accessories<br />

RPM 4500<br />

MAX. POW ER OF THE DRIVING SHAFT 6 HP (Kw. 4,4) whit a consumption of 2,0 Kg/H<br />

CLUTCH<br />

Oil bath cone clutch<br />

GEARBOX<br />

Oil bath gearbox , four forward speeds and 1 reverse speed.<br />

HANDLE-BAR<br />

Height and side adjustment<br />

W HEELS<br />

3.50.8 rubber or metal wheels<br />

MOVING SPEED with:<br />

•tyres 3.50.8<br />

•the engine at 5.000 RPM<br />

GEAR FORW ARD SPEED : Km/h REVERSE SPEED : Km/h<br />

1° 1.5 2.6<br />

2° 3.2<br />

3° 4.5<br />

4° 9.4<br />

The engine f itted on this cultiv ator has f ollowing f eatures:<br />

• Exhaust guard<br />

• Recoil starter<br />

• Oil bath air f ilter<br />

• Saf ety dev ice f or both f orward and backward gear stopping the tiller.<br />

• Standard handlebar with v ertical and side adjustment.<br />

MACHINE IDENTIFICATION<br />

The machine can be identif ied through its gearbox unit model and serial<br />

number. The motor serial number is printed on the motor plate or on the motor<br />

carburetor manif old by the manuf acturer.<br />

The machine identif ication data are reproduced on a plate located on the handlebar<br />

support (right-hand side looking f rom the operating position), and the serial<br />

number is reproduced both on the motor f lange and on the unit (see picture<br />

sideway s)<br />

Copy the plate data and the complete serial number on this manual in order to<br />

hav e them at hand when necessary .<br />

4 - PACKING AND TRANSPORT<br />

The machine is generally supplied without its accessories, in carton boxes hav ing the f ollowing ov erall dimensions:<br />

• WIDTH : cm. 95<br />

• HEIGHT: cm. 42<br />

• LENGTH : cm. 85<br />

• NET WEIGHT : Kg. 75 (without rotary tiller)<br />

During start-up the total exclusion of kinematic motions<br />

through blocking push button on clutch is scheduled<br />

Accessories are generally supplied separately f rom the<br />

machine, with or without packing<br />

Free the machine f rom its packing in order to prepare it to<br />

operate in the f ollowing way :<br />

98+-15<br />

a) Open the packing and f ree the machine f rom it, with the<br />

help of another person lif t the machine: one taking it f rom<br />

the wheels, the other f rom the handle-bars;<br />

b) Adjust handle-bars as desired;<br />

c) Apply the accessories<br />

1410<br />

3

SpA RT 80<br />

Spacer with pin f or 2^ wheel<br />

application<br />

Cod. 94904400<br />

Second rubber wheel 3.50.8<br />

Cod. 97004400<br />

5 -ACCESSORIES<br />

Front ballast Kg. 21,5<br />

Cod. 98000402<br />

Wheel ballast Kg. 9,5<br />

Cod. 98060100<br />

1^ iron wheel<br />

Cod. 97004300<br />

Adjustable f urrow-opener with<br />

connection<br />

Cod. 91002511<br />

2^ iron wheel<br />

Cod. 97004500<br />

(it is necessary to apply a<br />

spacer cod.94904400)<br />

6 - SAFETY RULES AND LIMITS ON USE<br />

IMPORTANT:<br />

Before using the machine read carefully this operation and<br />

maintenance manual; It w ill allow you to get from your machine the<br />

best performance of use and duration.<br />

• The use of the machine is f orbidden to persons y ounger than 16 y ears.<br />

• The operator is responsible of any possible damage and he should alway s driv e the machine caref ully and saf ely .<br />

• Bef ore carry ing the machine alway s empty the f uel tank.<br />

• Bef ore leav ing the machine be sure that it is f ully stopped.<br />

• Nev er use the machine without heav y shoes and long transf ers. Alway s inspect the area where y ou want to work<br />

taking of f stones, branches, cables and any other thing which can be dangerous.<br />

• Bef ore starting working, make sure that a radius of minimum 5 m. is completely f ree.<br />

• Clean any possible leakage of f uel.<br />

• Fill up when the engine is of f and not hot, alway s in an open space f ar f rom f ires or any heating source and ref rain<br />

f rom smoking during this operation.<br />

• Bef ore starting the machine make sure that y ou can quickly stop the engine and that y ou are f amiliar with the control<br />

lev ers.<br />

• Nev er allow the engine to run in enclosed spaces where the highly toxic carbon monoxide could not ev acuate.<br />

• Nev er start or use the machine not completely assembled especially concerning the saf ety dev ices and the tiller<br />

protection guards which should alway s be completely assembled with all its extensions.<br />

• Nev er f ix or clean the tiller blades or any other tools when the engine is running.<br />

• Nev er work in ov er 50% sloping ground.<br />

• We are not responsible f or accidents due to the wrong use of the machine neglecting the abov e basic instructions.<br />

• The elimination of the lubricants used must be carried out according to the norms existing in the country of use.<br />

7 – STARTING AND STOPPING<br />

Whenev er y ou set about starting a cold engine, make sure :<br />

• That the gasoline cock “A” is alway s open. The lev er must be<br />

placed towards the outlet pipe.<br />

• That the gasoline has reached the carburetor. If so, by pumping<br />

piston “B”, the gasoline will drop down f rom the hole on the<br />

upper section of carburetor.<br />

• Then, turn the accelerator control lev er placed on the handle-bar<br />

of about ¼.<br />

• Check that the gear-lev er and the mill-control lev er are idle.<br />

4

SpA RT 80<br />

Check that stop lev er and clutch lev er are blocked through the<br />

blocking push button (Ref . ”F”)<br />

• Seize the starting-handle “C” by one only hand, pull it gently until the ratchet<br />

gear is engaged. Then giv e a pull. The cord must nev er be lef t f ree quite<br />

suddenly with the engine running, but f ollowed till when it’s completely<br />

winded-up.<br />

8 - OPERATING AND REGULATING THE MACHINE<br />

FUEL INLET<br />

FOR<br />

REPLENISHING<br />

The ref uelling must be alway s perf ormed bef ore starting the work, with cold and<br />

stopped engine, using a f unnel, and in the open air.<br />

If f uel comes out f rom the tank, mov e the machine at once bef ore starting the engine<br />

and dry well the parts wet of gasoline.<br />

We recommend to use alway s a f unnel with a net-f ilter in order to keep back the<br />

possible impurities.<br />

FUEL-TYPE: gasoline-oil mixture 4%<br />

SAFETY LEVER : The motor hoe is prov ided with a red saf ety stop lev er connected<br />

to the clutch lev er (Ref . G)through side blocking push button (Ref . “F”).<br />

The main f unction of this lev er consists in stopping the engine in the moment in which<br />

the hands are remov ed f rom the driv ing-beams.<br />

It’s recommended not to bind the stop-engine lev er “E” to the handle-bar hand-grip.<br />

CLUTCH LEVER : To assure a regular clutch working it is a good rule to check f rom<br />

time to time the play that the clutch-lev er must hav e: (as shown in the picture) the<br />

lev er idle-stroke must be f rom 8 to 10 mm. In the opposite, act on the adjuster (G)<br />

increasing or decreasing the play according to the need.<br />

DRIVING-BEAMS :<br />

Adjustable in height and transv ersally , with possibility of locking in the wished<br />

position. This operation must be carried out by means of the screw-handle (“A”) placed<br />

on the lowest section of driv ing-beams.<br />

SPEED AND MILL CONTROL LEVERS :<br />

The shif ting of speed-lev er (Ref . “I”)must alway s happen under the f ollowing<br />

conditions:<br />

• With engine idling<br />

• With the hand-clutch-lev er (Ref . G) pulled towards the hand-grip.<br />

Any how, nev er f orce the lev er in its shif ting.<br />

ATTENTION: The mills rotation must never occur, when the machine is in reverse speed, an<br />

inner lever-system disengages the mill or the reverse-speed.<br />

5

SpA RT 80<br />

If this should not occur, apply to a skilled workshop by our concessionary agents.<br />

In the picture, turning lever “A” left the rotary tiller is activated, on the contrary turning it right it is stopped.<br />

POWER TAKE-OFF :<br />

The motor hoe is equipped with a lateral power take of f , which may be<br />

employ ed both with stopped and running machine.<br />

The power take of f and its own couplings are unif ied with most of commercial<br />

fittings.<br />

POWER TAKE-OFF OUTLINE:<br />

Splined 16 UNI 221X120 mm. Working<br />

Turning direction: lef t.<br />

Max. rev . 440 at 5,000 engine/RPM.<br />

MILL BONNET :<br />

The milling-depth may be adjusted as f ollows: f or working on the surf ace,<br />

it’s recommended to keep the saf ety -mill-bonnet lowered.<br />

For a deep working, to sink more in the ground.<br />

For these operations it’s suf f icient to act on the pin f ixing the bonnet “L” and on<br />

adjusting pin “M”.<br />

DIRECTION - JOINTER :<br />

For getting a more regular machine adv ancement it is suf f icient to operate the<br />

adjustable direction-jointer.<br />

When working on sof t ground, it is required to keep the spur up, to help the<br />

machine adv ancement.<br />

On solid ground it’s right to keep the jointer down, so that sinking in the earth it<br />

prev ents a too quick machine adv ancement.<br />

For this adjustment, act on the pin “N” f ixing the jointer.<br />

The machine presented in this manual has been designed to be used only in<br />

agriculture and especially f or ground milling.<br />

Any dif f erent use is considered contrary to its proper use.<br />

The builder does not assume responsibility f or damages or injuries due to improper<br />

use of the machine.<br />

According to the norms, ev en the respect of the operation, maintenance, and repairing conditions f ixed by the Firm<br />

BENASSI SPA is part of a correct use<br />

The machine can be operated, maintained and repaired only by those operators who hav e read this manual and are<br />

inf ormed of possible dangers.<br />

Any arbitrary modif ication on the machine exempts the Firm BENASSI SPA f rom any responsibility in case of<br />

damages.<br />

9 – MILL ASSEMBLING<br />

WORKING WIDTH : 18 cm.<br />

2 one-side joiners<br />

1 pin cm.17<br />

1 bonnet cm.18<br />

WORKING WIDTH : 32 cm.<br />

2 two-side joiners<br />

2 one-side joiners<br />

2 spacers<br />

1 pin cm.31<br />

1 bonnet cm.33<br />

WORKING WIDTH : 26 cm.<br />

2 two-side joiners<br />

1 pin cm.17<br />

1 bonnet cm.26<br />

WORKING WIDTH : 38 cm.<br />

2 two-side joiners<br />

2 one-side joiners<br />

2 spacers<br />

1 pin cm.36<br />

1 bonnet cm.38<br />

6

SpA RT 80<br />

WORKING WIDTH : 45 cm.<br />

4 two-side joiners<br />

2 spacers<br />

1 pin cm.36<br />

1 bonnet cm.45<br />

WORKING WIDTH : 65 cm.<br />

WORKING WIDTH : 58 cm.<br />

4 two-side joiners<br />

2 one-side joiners<br />

4 spacers<br />

1 pin cm.55<br />

1 bonnet cm.58<br />

6 two-side joiners<br />

4 spacers<br />

1 pin cm.55<br />

1 bonnet cm.65<br />

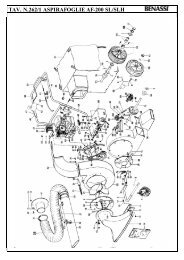

10 - MAINTENANCE AND LUBRICATION<br />

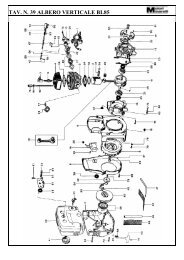

PLUG-CONTROL :<br />

From time to time it’s necessary to check the plug wear-lev el and the<br />

electrodes-distance, which must be of 0.5 mm , as shown in the near drawing.<br />

AIR FILTER CLEANING :<br />

This operation must be perf ormed regularly in the f ollowing way :<br />

• clean the f ilter externally , so to av oid that some earth f alls inside during the<br />

disassembling.<br />

• Loose the clips “P”, remov e the oil-cup “Q”, take away the f ilter-element “R”<br />

and wash caref ully the dif f erent parts with gasoline oil.<br />

• Fill the cup with new oil till reaching the lev el, as pointed out in the picture.<br />

OIL INLET BLEED :<br />

Ev ery component of the gear-box and transmission is in oil-bath. It’s<br />

necessary to check f rom time to time the oil-lev el through screw “S” and f ill it up<br />

again, if required, through the v ent plug “T”.<br />

USE ONLY OIL FOR TRANSMISSION SAE 30<br />

on<br />

oil<br />

FRONT-WHEEL OIL LEVEL PLUG :<br />

Check f rom time to time the oil lev el on the f ront wheel through plug “U”, placed<br />

one side, as shown in the picture. For a perf ect machine ef f iciency , a good<br />

maintenance and a perf ect lubrication are necessary .<br />

Check that air f ilter is clean, in case of oil bath f ilter check lev el ev ery 8-10<br />

operating hours or ev en more f requently when working in dusty grounds. Use motor<br />

to restore oil lev el and clean the cup bef ore f illing it.<br />

GEARBOX Check oil lev el ev ery 50 operating hours remov ing the cap on the<br />

gearbox sump keeping the machine in horizontal position.<br />

If necessary add SAE 30 oil. It is adv isable to replace oil at least ev ery 100<br />

hours.<br />

MILLS Bef ore starting to work check that all screws are tight, check especially<br />

rotary tiller hoe f astening screws.<br />

7

SpA RT 80<br />

11 - END-OF-SEASON MAINTENANCE<br />

OIL DRAG PLUG :<br />

For whatev er mechanical repair in the ear-box or in the mill-descent, it’s<br />

necessary to remov e the oil.<br />

To make the transmission empty , unscrew the plug “V” placed in the lowest<br />

section of the gear-box.<br />

Before parking the machine:<br />

• wash it accurately with gas oil,<br />

• empty the carburetor tank and clean or replace air f ilter,<br />

• lubricate and grease all articulated joints and gears,<br />

• replace or repair possible worn parts,<br />

• lubricate cy linder with motor oil through the spark plug hole, pull the start-up<br />

cord so that the piston makes some strokes<br />

• Park the machine in a dry place with wheels on wood tables or ev en better with wheels up f rom the f loor.<br />

12 - POSSIBLE PROBLEMS AND SOLUTIONS<br />

Possible problems that can be solv ed by the machine operator:<br />

MOTOR - The motor does not start; check that:<br />

• the gasoline in the tank is more then half .<br />

• the gasoline cock is open<br />

• if the motor is cold , the starter lev er is pulled<br />

• the gasoline reaches the carburetor<br />

• the bleed on the tank cap is not clogged<br />

• carburetor jets are not clogged, if necessary , clean<br />

them with air jet<br />

• the spark plug sparks, in order to carry out this check<br />

operation unscrew the spark plug; connect it to the power<br />

supply cable, place the spark plug earthed metal part<br />

(motor cy linder) and make the motor pulley turn as in the<br />

start-up phase. If electrodes do not spark, check the<br />

supply cable junctions, and if this does not solv e y our<br />

problems, replace the spark plug with one of the same<br />

ty pe. If ev en this time y ou should not obtain positiv e<br />

results, the def ect concerns the electric plant (points,<br />

condenser, coil etc.)In this case it is adv isable to contact<br />

the nearest serv ice (according to the motor assembled on<br />

the machine).<br />

13 - INSTRUCTIONS FOR A GOOD OPERATION OF THE MACHINE<br />

• Carry out a good breaking-in of the motor and of the<br />

machine (f or at least 10 hours do not exceed 70%of motor<br />

power)<br />

• alway s use the clutch bef ore using any lev er<br />

• do not keep the clutch disengaged f or long periods of<br />

time<br />

• nev er f orce gear lev ers, if y ou cannot engage them,<br />

jerkily release the clutch<br />

• nev er f orce the motor.<br />

• do not work at f ull speed f or long periods, in particular<br />

during hot day s<br />

• periodically check ty res pressure ( Atm. 1.3)<br />

• when assembling the dif f erent tools, do not damage<br />

shaf t spigot and spline, check that tool screws and lockpin<br />

are tight, in particular the rotary tiller hoe screws and the<br />

screws f astening the mowing bar<br />

• do not leav e the machine in the rain.<br />

IMPORTANT: using the machine for a<br />

long time you should use ear<br />

protection system.<br />

8

SpA RT 80<br />

TESTS FOR CE CERTIFICATION<br />

EC Certif icate of conf ormity conf orming to EEC directions 89/392<br />

40010 SanMatteo della Decima BO Italy Via Lampedusa n°1 Tel. (051) 682.46.56<br />

Declare in sole responsibility , that the product CULTIVATOR RT 80 to which this certif icate applies, conf orms<br />

to the basic saf ety and health requirements to EEC directions 89/392 and to the other relev ant EEC directions : PREN<br />

709/94 - N67 CEN TC 144/WG4 - PREN 836/92 - EN 294.<br />

THE PRESIDENT<br />

TEST AND RESULT<br />

TYPE: CULTIVATOR MODEL RT 80<br />

Noise lev el at operator’s ear : LAeq = 87,1 dB (A)<br />

Test condition: 1,6 Mt at the center of the handlebar<br />

Handlebar v ibration according to ISO.5349 : 5,7 m/sec 2<br />

S.Matteo della Decima li 20 -12 - 1994<br />

9

SpA RT 80<br />

S.p.A.<br />

Via Lampedusa, 1 - 40010 S. MATTEO DELLA DECIMA (BO) - ITALY<br />

TEL. 0039/051/82.05.34 TELEFAX 0039/051/682.61.64<br />

10