FD and DFD Curtain Fire Dampers with Integral Sleeves - Greenheck

FD and DFD Curtain Fire Dampers with Integral Sleeves - Greenheck

FD and DFD Curtain Fire Dampers with Integral Sleeves - Greenheck

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Document Number 453946<br />

<strong>FD</strong> & D<strong>FD</strong> 150X Models<br />

®<br />

1 1 ⁄2 Hour<br />

<strong>Curtain</strong> <strong>Fire</strong> <strong>Dampers</strong><br />

Vertical or Horizontal Mount<br />

Installation, Operation <strong>and</strong> Maintenance Instructions<br />

<strong>FD</strong> <strong>and</strong> D<strong>FD</strong> 150X Series models are intended for<br />

installation in accordance <strong>with</strong> fire damper<br />

requirements<br />

established by:<br />

National <strong>Fire</strong> Protection Association<br />

NFPA St<strong>and</strong>ard 80, 90A, & 101<br />

IBC International Building Codes<br />

CSFM California State <strong>Fire</strong> Marshal<br />

<strong>Fire</strong> Damper Listing (#3225-0981:102)<br />

New York City (BSA/MEA listing #260-91-M)<br />

L<br />

S TATE<br />

S<br />

I S<br />

T<br />

STATE OF CALIFORNIA<br />

FIR E MAR S HALL<br />

E R V<br />

I N G<br />

E<br />

I C<br />

Installation Supplements<br />

Refer to the appropriate <strong>Greenheck</strong> installation<br />

supplements for special requirements:<br />

• Support Mullions<br />

• Shaftwall Supplement<br />

• Drywall Supplement<br />

• Grille Installation Supplement<br />

• Drive Slip Supplement<br />

• Sealant Supplement<br />

• Sleeve Extension Supplement<br />

• Single side Retaining Angles Supplement<br />

Note: Refer to <strong>Greenheck</strong> IOM, Part #461335, for<br />

CFSD models to be installed in corridor ceiling<br />

applications.<br />

Refer to <strong>Greenheck</strong> IOM, Part # 452763 for<br />

st<strong>and</strong>ard D<strong>FD</strong> <strong>and</strong> <strong>FD</strong> models.<br />

“UL CLASSIFIED (see complete marking on product)”<br />

“UL CLASSIFIED to Canadian safety st<strong>and</strong>ards (see<br />

complete marking on product)”<br />

UL St<strong>and</strong>ard 555 (Listing #R13317)<br />

Safety WARNING:<br />

Improper installation, adjustment, alteration, service<br />

or maintenance can cause property damage, injury<br />

or death. Read the installation, operating, <strong>and</strong><br />

maintenance instructions thoroughly before installing<br />

or servicing this equipment.<br />

Receiving <strong>and</strong> H<strong>and</strong>ling<br />

Upon receiving dampers, check for both obvious <strong>and</strong><br />

hidden damage. If damage is found, record all necessary<br />

information on the bill of lading <strong>and</strong> file a claim <strong>with</strong><br />

the final carrier. Check to be sure that all parts of the<br />

shipment, including accessories, are accounted for.<br />

<strong>Dampers</strong> must be kept dry <strong>and</strong> clean. Indoor storage<br />

<strong>and</strong> protection from dirt, dust <strong>and</strong> the weather is highly<br />

recommended. Do not store at temperatures in excess of<br />

100°F.<br />

Warranty<br />

<strong>Greenheck</strong> warrants this equipment to be free from<br />

defects in material <strong>and</strong> workmanship for a period of one<br />

year from the shipment date. Any units or parts which<br />

prove to be defective during the warranty period will be<br />

repaired or replaced at our option. <strong>Greenheck</strong> shall not<br />

be liable for damages resulting from misapplication or<br />

misuse of its products. <strong>Greenheck</strong> will not be responsible<br />

for any installation or removal costs. <strong>Greenheck</strong> will not be<br />

responsible for any service work or backcharges <strong>with</strong>out<br />

prior written authorization.<br />

This manual is the property of the owner, <strong>and</strong> is required for future maintenance. Please leave it <strong>with</strong> the owner when the<br />

job is complete.<br />

Due to continuing research, <strong>Greenheck</strong> reserves the right to change specifications <strong>with</strong>out notice.

Table of Contents<br />

Pre-Installation Guidelines.......................................................................................................................................... 2<br />

Installation................................................................................................................................................................3-5<br />

Breakaway Connections............................................................................................................................................. 6<br />

Installation for Steel Stud Connection Option........................................................................................................... 7<br />

Damper Maintenance.................................................................................................................................................. 8<br />

Damper Troubleshooting............................................................................................................................................. 8<br />

Pre-Installation Guidelines<br />

The basic intent of a proper installation is to secure the fire damper in, not to, the opening in such a manner as to<br />

prevent distortion <strong>and</strong> disruption of damper operation. This is accomplished by allowing the fire damper in rated<br />

separation openings to exp<strong>and</strong> <strong>and</strong> for the connecting duct to separate in the event of the collapse of the hanging<br />

system. The following items will aid in completing the damper installation in a timely <strong>and</strong> effective manner.<br />

1. Check the schedules for proper damper locations <strong>with</strong>in the building. Visually inspect the damper for damage <strong>and</strong><br />

verify that the fusible link is in place or has not separated. If fusible link is not present or has separated, replace<br />

link. Never install a fire damper <strong>with</strong>out the proper UL approved fusible link in place. (Fusible link is st<strong>and</strong>ard<br />

control option. An electric link may have been provided.)<br />

2. Lift or h<strong>and</strong>le damper using sleeve or frame.<br />

3. Install damper accordingly to comply <strong>with</strong> manufacturer’s appropriate UL procedure file number.<br />

4. Damper must be installed into duct or opening square <strong>and</strong> free of twist or other misalignment. Damper must not be<br />

squeezed or stretched into duct or opening.<br />

5. Damper must be kept clean <strong>and</strong> protected from dirt, dust <strong>and</strong> other foreign materials prior to <strong>and</strong> after installation.<br />

Examples of such foreign materials include, but are not limited to:<br />

a. Mortar dust<br />

b. Drywall dust<br />

c. <strong>Fire</strong>safing materials<br />

d. Wall texture<br />

e. Paint overspray<br />

6. Damper should be sufficiently covered as to prevent overspray of spray-on insulating, wall texturing, or spray<br />

painting when performed <strong>with</strong>in 5 feet of the damper. Excessive dirt or foreign material deposits can cause damper<br />

to bind <strong>and</strong> not operate properly.<br />

7. Caulking is not necessary, nor is it allowed, between the damper sleeve <strong>and</strong> the wall or floor opening (annular<br />

space). However, caulking may be applied to the retaining angles.<br />

8. ACCESS: Suitable access (such that fusible links can be changed) must be provided for damper inspection <strong>and</strong><br />

servicing. Where it is not possible to achieve sufficient size access, it will be necessary to install a removable<br />

section of duct. (Refer to NFPA 90A).<br />

9. The Code Authority Having Jurisdiction (AHJ) must evaluate <strong>and</strong> provide approval of final installation where<br />

variations to these instructions are necessary.<br />

2

Installation - Failure to follow these instructions will void all warranties.<br />

These instructions apply to 11/2 hour rated fire dampers<br />

mounted in masonry, block or stud walls <strong>and</strong> concrete<br />

floors. Specific requirements in these instructions are<br />

m<strong>and</strong>atory. These instructions meet the requirements of<br />

UL 555. Installation shall comply <strong>with</strong> the requirements<br />

of NFPA 90A St<strong>and</strong>ard for the Installation of Air<br />

Conditioning <strong>and</strong> Ventilating Systems. U.L. listing<br />

R13317, California State <strong>Fire</strong> Marshal listings 3225-<br />

981:102, <strong>and</strong> New York City BSA/MEA listing 260-91-M<br />

as they apply to these dampers.<br />

Note: <strong>Fire</strong> dampers are manufactured <strong>and</strong> labelled for<br />

either vertical or horizontal installation. The dampers<br />

must be installed in accordance <strong>with</strong> the labelling.<br />

Retaining<br />

Angle<br />

2 in. Max.<br />

Min. 1 in.<br />

Overlap*<br />

Wall or<br />

Floor<br />

Retaining<br />

Angle<br />

Sleeve<br />

Duct<br />

6 in. Max.<br />

Damper<br />

1. NO ADDITIONAL SLEEVES ARE REQUIRED<br />

The fire damper extended frame is an approved<br />

sleeve <strong>and</strong> can be properly installed <strong>with</strong>out the need<br />

for a supplemental field installed sleeve. Damper<br />

frame shall extend a maximum of 6 in. (152mm)<br />

beyond the wall or floor opening on each side.<br />

2. CLEARANCES REQUIRED BETWEEN FIRE<br />

DAMPER SLEEVES AND WALL/FLOOR<br />

OPENINGS<br />

<strong>Fire</strong> damper assemblies exp<strong>and</strong> during periods of<br />

intense heat. Therefore, it is essential that openings<br />

in walls or floors be larger than the fire damper<br />

assembly to allow for this expansion. Minimum<br />

clearances required between the outside of fire<br />

damper sleeve assemblies <strong>and</strong> wall/floor openings<br />

are:<br />

• Galvanized steel fire dampers <strong>and</strong> sleeves: 1/8<br />

in. (3mm) per linear foot of damper width <strong>and</strong><br />

height <strong>with</strong> a minimum clearance of 1/4 in. (6mm)<br />

.Recommended clearances, for width <strong>and</strong>/or height<br />

dimensions of:<br />

1) 48 in. (1219mm) or less: 1/2 in. (13mm) clearance<br />

2) More than 48 in. (1219mm) <strong>and</strong> 96 in. (2438mm)<br />

or less: 1 in. (25mm) clearance<br />

3) More than 96 in. (2438mm): 11/2 in. (38mm)<br />

clearance<br />

These are total clearances (ignoring fastener heads)<br />

<strong>and</strong> do not need to be equally spaced around<br />

the damper. Refer to Section 3 <strong>and</strong> Figure 1 for<br />

additional installation considerations.<br />

Example:<br />

A 12 in. x 12 in. (305mm x 305mm) damper would<br />

require a minimum clearance of 1/4 in. (6mm).<br />

A 48 in. x 12 in. (1219mm x 305mm) damper<br />

would require a minimum clearance of 1/2 in.<br />

(13mm) on width <strong>and</strong> 1/4 in. (6mm) on height.<br />

6 in. Max.<br />

2 in. Max.<br />

*only applicable for damper sizes above 36 in. x 36 in.<br />

Figure 1: Retaining angle installation.<br />

3. SECURING THE FIRE DAMPER TO WALL AND<br />

FLOOR OPENINGS<br />

<strong>Fire</strong> damper assemblies must be installed in wall <strong>and</strong><br />

floor openings using retaining angles on each side of<br />

the wall or floor as described below:<br />

• Retaining angles for 11/2 hour rated dampers <strong>with</strong><br />

a width <strong>and</strong> height 48 in. (1219mm) or less must be<br />

a minimum of 20 ga. (1mm). Retaining angles for<br />

all 3 hour rated dampers <strong>and</strong> all dampers <strong>with</strong> a<br />

width or height greater than 48 in. (1219mm) must<br />

be a minimum of 16 gauge (1.5mm). The leg of the<br />

retaining angle on the damper sleeve shall be a<br />

minimum of 11/4 in. (32mm). The leg of the retaining<br />

angle on the wall/floor shall be long enough to cover<br />

the annular space <strong>and</strong> overlap the wall/floor by a<br />

minimum of 1 in. (25mm).<br />

• Retaining angles must be attached to the damper<br />

using one or more of the following methods of<br />

attachment:<br />

• tack or spot welds<br />

• #10 sheetmetal screws<br />

• 1/4 in. (6mm) bolts <strong>and</strong> nuts<br />

• 3/16 in. (4.7mm) steel pop rivets<br />

Attachments must be spaced a maximum of 6 in.<br />

(152mm) on center <strong>and</strong> a maximum of 2 in. (51mm)<br />

from corners. The angles must be attached to all 4<br />

sides of the sleeve <strong>with</strong> butt joints at each corner.<br />

A minimum of two attachments are required on<br />

each side, top <strong>and</strong> bottom. The angles need not be<br />

attached to each other at the corners.<br />

• Retaining angles should not be fastened to the wall/<br />

floor material. The angles should only s<strong>and</strong>wich the<br />

wall/floor <strong>and</strong> allow for damper expansion during<br />

periods of intense heat.<br />

3

4. CONNECTING DUCTS TO THE FIRE DAMPER<br />

All duct connections to <strong>FD</strong> & D<strong>FD</strong> 150X series extended frame dampers must be “breakaway” type connections. All<br />

connections shown 1/4 on in. minimum page 5 & 6 are considered breakaway. Factory furnished duct collars on types R & CR fire<br />

total clearance<br />

dampers are also considered breakaway(see Figure 2 & 3).<br />

1/4 in. minimum<br />

total clearance<br />

1/4 in. minimum<br />

total clearance<br />

Retaining Angles<br />

(See Section 4)<br />

Wall or Floor<br />

See Section 2<br />

Maximum<br />

6 in.<br />

Maximum<br />

6 in.<br />

Maximum<br />

6 in.<br />

Maximum Wall or Floor<br />

6 in.<br />

Wall or Floor<br />

Maximum<br />

6 in.<br />

Maximum<br />

6 in.<br />

“K” side<br />

Wall or Floor<br />

Sleeve<br />

(see sections 2 & 3)<br />

See Section 2<br />

Damper<br />

Duct<br />

Duct<br />

Duct<br />

Retaining Angles<br />

Retaining Angles<br />

(See Retaining Section Angles 3)<br />

(See Section 3)<br />

(See Section 3)<br />

Damper<br />

Damper Damper<br />

Type A<br />

Type A<br />

Wall Wall or Floor or Floor<br />

Wall or Floor<br />

Type A<br />

Retaining Angles<br />

(See Section 4)<br />

See Section 2<br />

Damper<br />

Damper<br />

Damper<br />

“K” side<br />

Wall or<br />

Floor<br />

See Section 2<br />

Damper<br />

Sleeve<br />

(see sections 2 & 3)<br />

Duct<br />

Duct<br />

Duct<br />

Duct<br />

Type B<br />

Wall or Floor<br />

On types R & CR factory<br />

furnished duct collar<br />

qualifies as breakaway<br />

connection.<br />

On types R & CR factory<br />

On types furnished R & duct CR factory collar<br />

furnished qualifies duct as breakaway collar<br />

qualifies connection. as breakaway<br />

connection.<br />

Type B<br />

Type B<br />

Wall or Floor<br />

Wall or Floor<br />

Type B<br />

Duct<br />

Duct<br />

Damper<br />

“K” side<br />

Wall or<br />

floor<br />

Type C, CO, CR, & R<br />

Sleeve<br />

Duct<br />

Damper<br />

Duct<br />

Type C, CO, CR, & R<br />

Damper<br />

On types R & CR factory<br />

furnished duct collar qualifies<br />

as breakaway connection, see<br />

Section 5<br />

Type C, CO, CR, & R<br />

Figure 2: Vertical Mount Type A, Type B, <strong>and</strong> Type C,<br />

CO, CR, R damper installation diagrams.<br />

Type C, CO, CR, & R<br />

Figure 3: Horizontal Mount Type A, Type B, <strong>and</strong> Type C,<br />

CO, CR, R damper installation diagrams.<br />

When dampers installed horizontally, the ramp must be<br />

positioned up as shown in above drawings.<br />

4<br />

Table 1<br />

Damper Model<br />

Maximum Sizes for Single<br />

Section <strong>Dampers</strong>*<br />

in. (mm)<br />

<strong>FD</strong>-150X (H or V) 48 x 48 (1219 x 1219)<br />

D<strong>FD</strong>-150X (V) 36 x 36 (914 x 914)<br />

D<strong>FD</strong>-150X (H) 30 x 30 (762 x 762)<br />

Note: V = Vertical mount & H = Horizontal<br />

* Sizes are based on damper <strong>with</strong> no transitions.

Recommended Preparation of Openings in Wood <strong>and</strong> Metal Stud Walls<br />

• Frame wall openings as shown in Figure 4 <strong>and</strong> 4A.<br />

• Gypsum wall board must be fastened 12 in. on center to all stud <strong>and</strong> runner flanges surrounding opening (see<br />

Figure 4 <strong>and</strong> 4A).<br />

• Prepare opening between studs <strong>and</strong> sleeve assembly as shown below (see Figure 5).<br />

• All construction <strong>and</strong> fasteners must meet then requirements of the appropriate wall design.<br />

(See UL <strong>Fire</strong> Resistance Directory)<br />

24 in. o.c.<br />

Maximum<br />

(metal studs)<br />

24 in. o.c.<br />

Maximum<br />

(metal studs)<br />

Ceiling Runner<br />

12 in.<br />

24 in. o.c.<br />

Maximum<br />

2 Panhead<br />

Screws<br />

2 in. (51mm)<br />

2 in. (51mm)<br />

16 in. o.c.<br />

Maximum<br />

(wood studs)<br />

16 in. o.c.<br />

Maximum<br />

(wood studs)<br />

Floor Runner<br />

Figure 4: Preparation detail for opening in stud wall.<br />

Second set of studs are not required on openings<br />

36 in. x 36 in. (914mm x 914mm) or smaller.<br />

Metal Stud Construction<br />

Gypsum Wallboard<br />

Stud or Runner<br />

Retaining<br />

Angle<br />

1 in. Min.<br />

Damper<br />

Sleeve<br />

In metal stud construction,<br />

exposed steel surfaces need<br />

not be covered <strong>with</strong> gypsum<br />

wallboard.<br />

Figure 4A<br />

Metal Stud Construction<br />

Metal stud only<br />

Wooden Stud Construction<br />

Gypsum Wallboard<br />

Gypsum Wa llboard<br />

Stud or Runner<br />

Stud or Runner<br />

Retaining<br />

Angle<br />

Retaining<br />

Angl e<br />

1 in. Min.<br />

1 in. Min.<br />

Damper<br />

Sleeve<br />

In metal stud construction,<br />

exposed steel surfaces need<br />

not be covered <strong>with</strong> gypsum<br />

wallboard.<br />

Wooden Stud Construction<br />

Damper<br />

Sleeve<br />

In wood stud construction,<br />

gypsum wallboard must cover<br />

all wood stud surfaces.<br />

Figure 5: Detail of retaining angles <strong>and</strong> gypsum board application for metal <strong>and</strong> wooden stud construction.<br />

5

Duct-Sleeve Connections<br />

Traditional Breakaway Style Transverse Joints<br />

Transverse joints illustrated in Figure 6 have always<br />

been approved as breakaway connections. SMACNA<br />

testing has also approved the following variations as<br />

breakaway connections.<br />

• The breakaway connections shown to the right can<br />

be applied <strong>with</strong> maximum of (2) #10 sheet metal<br />

screws on each side <strong>and</strong> on the bottom located in<br />

the center of the slip pocket <strong>and</strong> penetrating both<br />

sides of the slip pocket.<br />

• Transverse joints illustrated can<br />

be applied as top <strong>and</strong> bottom<br />

joints <strong>with</strong> Drive Slip - side<br />

Drive Slip Joint<br />

joints in duct heights up to 20<br />

in. (508mm).<br />

Round <strong>and</strong> Oval Duct Breakaway Connections<br />

Round or flat oval ducts connected to factory supplied<br />

Type R, CR, or CO damper collars may use #10 sheet<br />

metal screws as follows:<br />

• Ducts 22 in. (559mm) wide (or dia.) <strong>and</strong> smaller may<br />

use 3 screws.<br />

• Ducts larger than 22 in. (559mm) wide (or dia.) may<br />

use 5 screws.<br />

Plain “S” Slip Hemmed “S” Slip Double “S” Slip<br />

Inside Slip Joint St<strong>and</strong>ing “S” St<strong>and</strong>ing “S” (Alt.)<br />

St<strong>and</strong>ing “S” (Alt.) St<strong>and</strong>ing “S” St<strong>and</strong>ing “S”<br />

(Bar Reinforced) (Angle Reinforced)<br />

Figure 6: Traditional breakaway style transverse joints.<br />

NOTE: All breakaway connections described may have<br />

duct sealant, PA2084T duct sealant adhesive manufactured<br />

by Precision, DP1010 water base duct sealant by Design<br />

Polymetrics, Grey Pookie, Ductmate PROseal ® , or<br />

CL Ward S Seal applied in accordance <strong>with</strong> SMACNA<br />

recommendations.<br />

Proprietary Flange System Breakaway Connections<br />

(Ductmate, Ward, Nexus)<br />

Flanged connection systems manufactured by<br />

Ductmate, Ward, <strong>and</strong> Nexus are approved as breakaway<br />

connections when installed as illustrated in Figure 7.<br />

6 in. long 1/16 in. max.<br />

thickness plastic cleats;<br />

12 in. c-c (min. 1 per side)<br />

Flanged system angles<br />

<strong>Fire</strong> Damper Sleeve<br />

(TDC by Lockformer, TDF by Engle)<br />

TDC <strong>and</strong> TDF systems are approved as breakaway<br />

connections when installed as described in the SMACNA<br />

Duct Construction St<strong>and</strong>ards. St<strong>and</strong>ard 6 in. metal clips<br />

may be used <strong>with</strong> spacing (see Figure 8). Three-eighth<br />

in. metal bolts <strong>and</strong> nuts may be used to fasten together<br />

corner pieces (see Figure 9).<br />

(Attach per<br />

manufacturer’s<br />

instructions)<br />

Duct<br />

Figure 7:<br />

Neoprene gasket<br />

between all angles<br />

Detail of manufactured flanged system<br />

breakaway connections.<br />

Do not bolt corners<br />

60 in. Duct<br />

4 Req’d.<br />

Clip Spacing<br />

6 in.<br />

7 in.<br />

Std. Clip<br />

Length<br />

9 in.<br />

6 in. 6 in.<br />

7 in.<br />

Duct End<br />

Flange<br />

Corner Piece<br />

Sleeve<br />

Typical TDC/TDF joint<br />

Duct<br />

48 in. Duct<br />

3 Req’d.<br />

36 in. Duct<br />

3 Req’d.<br />

24 in. Duct<br />

2 Req’d.<br />

18 in. Duct &<br />

Smaller<br />

1 Req’d.<br />

5 in. 5 in.<br />

5 in.<br />

CL<br />

Duct<br />

5 in.<br />

3/8 in. bolt<br />

(optional)<br />

Figure 8:<br />

6<br />

Detail of proprietary flanged system breakaway<br />

connections.<br />

Figure 9: Detail of bolted corner.

Installation for Steel Stud Connection (SSC) Option<br />

These instructions apply to 11/2 hour rated fire dampers mounted in steel stud walls. Specific requirements in these<br />

instructions are m<strong>and</strong>atory. These instructions meet the requirements of UL555. Installation shall comply <strong>with</strong> the<br />

requirements of NFPA 90A St<strong>and</strong>ard for the Installation of Air Conditioning <strong>and</strong> Ventilating Systems. U.L. listings<br />

R13317 <strong>and</strong> R13743, California State <strong>Fire</strong> Marshal listings 3225-981:102 <strong>and</strong> 3225-1241:101, <strong>and</strong> New York City BSA/<br />

MEA listing 260-91-M as they apply to these dampers.<br />

1. NO ADDITIONAL SLEEVES OR ANGLES ARE<br />

REQUIRED<br />

The fire damper extended frame is an approved<br />

sleeve <strong>and</strong> the Steel Stud Connection (SSC) Option<br />

allows fastening of the fire damper sleeve directly<br />

to the wall's steel stud framing. Damper frame shall<br />

extend a maximum of 6 in. (152mm) beyond the wall<br />

opening on either side. Maximum size fire damper<br />

that may be installed using this SSC option is 36 in. W<br />

x 36 in. H (914mm x 914mm).<br />

2. INSTALLATION<br />

<strong>Fire</strong> damper <strong>with</strong> SSC option must be in place before<br />

the wall is constructed or it can be installed as the<br />

wall is being constructed. Wall opening is framed<br />

around the fire damper before sheet rock or other<br />

wall board material is applied to the steel studs. This<br />

installation provides appropriate protection for duct<br />

penetrations in fire resistant wall construction using<br />

steel studs <strong>with</strong> a fire resistance rating less than 3<br />

hours. The following wall design 3 numbers (as detailed<br />

in the UL <strong>Fire</strong> Resistance Directory) are appropriate<br />

for fire damper installations using this SSC option:<br />

1 Hour Design: U405, U406, U422, U434, U448, U451,<br />

U456, U457, U465, U468, U469, U485, U494<br />

11/2 Hour Design: U449, U452, U470, U471<br />

2<br />

2<br />

2 Hour Design: U403, U411, U412, U421, U425, U428,<br />

U429, U443, U453, U474, U475, U477, U484, U491,<br />

U495<br />

3. FRAMING OF WALL OPENING<br />

Form a wall opening 1/8 in. (3mm) to 1/4 in. (6mm)<br />

larger than the OD of the fire damper's extended<br />

frame (sleeve) using the same metal studs <strong>and</strong><br />

techniques required by the wall design per the UL<br />

<strong>Fire</strong> Resistance Directory. Open side of the steel stud<br />

channels shall face the fire damper <strong>and</strong> encompass<br />

the damper's retaining bar.<br />

4. APPLY WALLBOARD AFTER DAMPER<br />

INSTALLATION<br />

After damper is installed, wallboard shall be applied<br />

to steel stud framework in the manner required by<br />

the wall design per the UL <strong>Fire</strong> Resistance Directory<br />

listing. Around the damper perimeter use a minimum<br />

of 2 connections per side, spaced 12 in. (305mm)<br />

maximum <strong>and</strong> located a maximum of 2 in. (51mm)<br />

from each corner. No additional retaining angles are<br />

required to complete the installation.<br />

5. CONNECTING DUCTS TO THE FIRE DAMPER<br />

3<br />

All duct connections to <strong>FD</strong> & D<strong>FD</strong> 150X series<br />

extended frame dampers must be “breakaway” type<br />

connections. All connections shown on page 5 & 6<br />

are considered breakaway. Factory furnished duct<br />

collars on types R, CR, & CO fire dampers are also<br />

considered breakaway.<br />

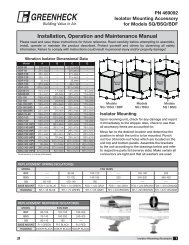

Item<br />

3 Description<br />

3<br />

1 <strong>FD</strong>150X fire damper <strong>with</strong> SSC option<br />

2 Steel stud wall (see UL <strong>Fire</strong> Resistance Directory for specific<br />

details)<br />

3 Steel stud frame around opening in wall<br />

4 Duct connection (see section 6)<br />

5 Wallboard (see UL <strong>Fire</strong> Resistance Directory for specific<br />

details)<br />

6 Fasteners (see UL <strong>Fire</strong> Resistance Directory <strong>and</strong> Section 5)<br />

2<br />

3<br />

3<br />

3<br />

6<br />

3<br />

6<br />

3<br />

5<br />

3<br />

5<br />

1<br />

1<br />

Retaining<br />

Bar<br />

1<br />

Retaining<br />

Bar<br />

1<br />

4<br />

4<br />

Top Cross-section View<br />

4 2<br />

Top Cross-section ViewSide Cross-Section View<br />

of Damper in Wall<br />

3<br />

5<br />

4 2<br />

Side Cross-Section View<br />

of Damper in Wall<br />

3<br />

6<br />

7<br />

1<br />

Retaining<br />

1<br />

4

Damper Maintenance<br />

<strong>Dampers</strong> shall be maintained, cycled, <strong>and</strong> tested in intervals as stated in the latest editions of NFPA 90A, 92A, <strong>and</strong> UL<br />

864 unless local codes require more frequent inspections.<br />

<strong>Dampers</strong> do not typically require maintenance as long as they are kept dry <strong>and</strong> clean. If cleaning is necessary, use<br />

mild detergents or solvents. If lubrication is desired, do not use oil-based lubricants or any other lubricants that attract<br />

contaminant’s such as dust.<br />

Damper Trouble Shooting<br />

The following is a cause <strong>and</strong> correction list for common concerns <strong>with</strong> the dampers.<br />

Symptom Possible Cause Corrective Action<br />

Damper does not fully open <strong>and</strong>/or<br />

fully close<br />

Frame is 'racked' causing blades to<br />

bind on jamb<br />

Screws in damper linkage<br />

Contaminant's on damper<br />

Link separated Heat Replace link<br />

Adjust frame such that it is square<br />

<strong>and</strong> plumb<br />

Locate screws <strong>and</strong> remove<br />

Clean <strong>with</strong> a non-oil based solvent<br />

(see Damper Maintenance)<br />

Our Commitment<br />

As a result of our commitment to continuous improvement, <strong>Greenheck</strong> reserves the right to change specifications<br />

<strong>with</strong>out notice.<br />

Specific <strong>Greenheck</strong> product warranties are located on greenheck.com <strong>with</strong>in the product area tabs <strong>and</strong> in<br />

the Library under Warranties.<br />

®<br />

Phone: (715) 359-6171 • Fax: (715) 355-2399 • E-mail: gfcinfo@greenheck.com • Website: www.greenheck.com<br />

453946• D<strong>FD</strong> & <strong>FD</strong> 150X Series Rev. 15, August 2013 Copyright 2013 © <strong>Greenheck</strong> Fan Corporation<br />

8