Overcurrent Protection and Devices, Short-Circuit Calculations ...

Overcurrent Protection and Devices, Short-Circuit Calculations ...

Overcurrent Protection and Devices, Short-Circuit Calculations ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Electrical Plan Review<br />

Series Ratings<br />

Most electrical distribution systems are fully rated as required by<br />

NEC ® 110.9. A fully rated system is a system where every overcurrent<br />

protective device has an interrupting rating equal to or greater<br />

than the available fault. Fully rated systems are typically preferred<br />

<strong>and</strong> recommended, but electrical distribution systems are permitted<br />

to incorporate series ratings, provided all the requirements of NEC ®<br />

240.86 <strong>and</strong> 110.22 are met. However, the actual application of<br />

series ratings is typically limited.<br />

Series rating is a combination of circuit breakers, or fuses <strong>and</strong> circuit<br />

breakers, that can be applied at available short-circuit levels above<br />

the interrupting rating of the load side circuit breakers, but not above<br />

that of the main or line-side device. Series ratings can consist of<br />

fuses protecting circuit breakers, or circuit breakers protecting circuit<br />

breakers.<br />

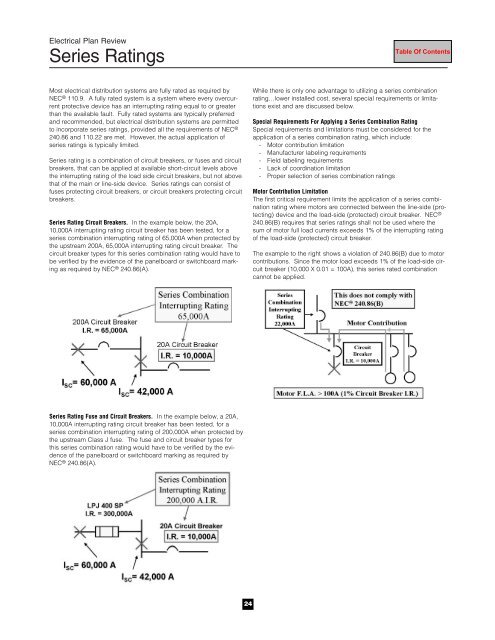

Series Rating <strong>Circuit</strong> Breakers. In the example below, the 20A,<br />

10,000A interrupting rating circuit breaker has been tested, for a<br />

series combination interrupting rating of 65,000A when protected by<br />

the upstream 200A, 65,000A interrupting rating circuit breaker. The<br />

circuit breaker types for this series combination rating would have to<br />

be verified by the evidence of the panelboard or switchboard marking<br />

as required by NEC ® 240.86(A).<br />

While there is only one advantage to utilizing a series combination<br />

rating…lower installed cost, several special requirements or limitations<br />

exist <strong>and</strong> are discussed below.<br />

Special Requirements For Applying a Series Combination Rating<br />

Special requirements <strong>and</strong> limitations must be considered for the<br />

application of a series combination rating, which include:<br />

- Motor contribution limitation<br />

- Manufacturer labeling requirements<br />

- Field labeling requirements<br />

- Lack of coordination limitation<br />

- Proper selection of series combination ratings<br />

Motor Contribution Limitation<br />

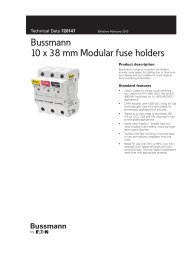

The first critical requirement limits the application of a series combination<br />

rating where motors are connected between the line-side (protecting)<br />

device <strong>and</strong> the load-side (protected) circuit breaker. NEC ®<br />

240.86(B) requires that series ratings shall not be used where the<br />

sum of motor full load currents exceeds 1% of the interrupting rating<br />

of the load-side (protected) circuit breaker.<br />

The example to the right shows a violation of 240.86(B) due to motor<br />

contributions. Since the motor load exceeds 1% of the load-side circuit<br />

breaker (10,000 X 0.01 = 100A), this series rated combination<br />

cannot be applied.<br />

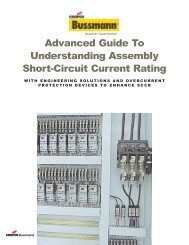

Series Rating Fuse <strong>and</strong> <strong>Circuit</strong> Breakers. In the example below, a 20A,<br />

10,000A interrupting rating circuit breaker has been tested, for a<br />

series combination interrupting rating of 200,000A when protected by<br />

the upstream Class J fuse. The fuse <strong>and</strong> circuit breaker types for<br />

this series combination rating would have to be verified by the evidence<br />

of the panelboard or switchboard marking as required by<br />

NEC ® 240.86(A).<br />

24