TTM 04 ING ARANCIO.qxd:Layout 1 - Tube Tech Machinery

TTM 04 ING ARANCIO.qxd:Layout 1 - Tube Tech Machinery

TTM 04 ING ARANCIO.qxd:Layout 1 - Tube Tech Machinery

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Innovation<br />

& High<br />

<strong>Tech</strong>nology<br />

TUBE TECH MACHINERY<br />

<strong>TTM</strong>Magazine<br />

Issue no. 4 – October 2009 – Six-monthly magazine published by <strong>Tube</strong> <strong>Tech</strong> <strong>Machinery</strong><br />

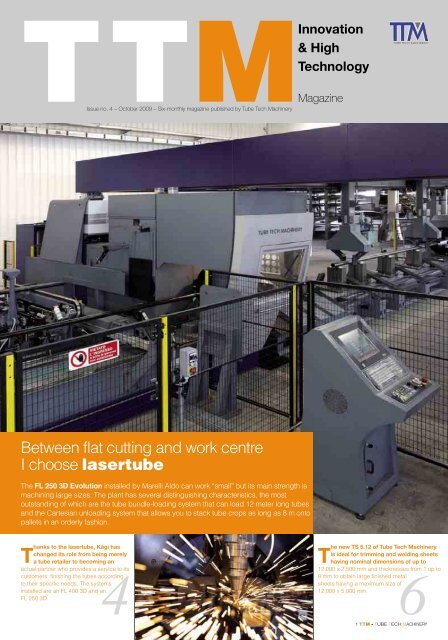

Between flat cutting and work centre<br />

I choose lasertube<br />

The FL 250 3D Evolution installed by Marelli Aldo can work “small” but its main strength is<br />

machining large sizes. The plant has several distinguishing characteristics, the most<br />

outstanding of which are the tube bundle-loading system that can load 12 meter long tubes<br />

and the Cartesian unloading system that allows you to stack tube crops as long as 8 m onto<br />

pallets in an orderly fashion.<br />

hanks to the lasertube, Kägi has<br />

Tchanged its role from being merely<br />

a tube retailer to becoming an<br />

actual partner who provides a service to its<br />

4<br />

customers: finishing the tubes according<br />

to their specific needs. The systems<br />

installed are an FL 400 3D and an<br />

FL 250 3D.<br />

new TS 5.12 of <strong>Tube</strong> <strong>Tech</strong> <strong>Machinery</strong><br />

is ideal for trimming and welding sheets<br />

having nominal dimensions of up to<br />

12,000 x 2,500 mm and thicknesses from 1 up to<br />

6<br />

8 mm to obtain large finished metal<br />

sheets having a maximum size of<br />

12,000 x 5,000 mm.<br />

T<br />

he<br />

1 <strong>TTM</strong> - TUBE TECH MACHINERY

[ APPLICATIONS ]<br />

Between flat<br />

cutting and work<br />

centre, I choose<br />

lasertube<br />

The FL250 3D Evolution with a 12 m load and an 8 m<br />

long Cartesian unloading system is the solution chosen<br />

by Marelli Aldo to expand and complete its offer in the<br />

field of third party realization of metallic carpentry.<br />

An important choice that "winks" to the structural tube<br />

sector.<br />

Established in 1979, Marelli Aldo is the<br />

marriage of professionalism, entrepreneurial<br />

skills, know-how and experience in the<br />

field of metal structural<br />

work. From single<br />

pieces to small and large production<br />

series, the company owned by Figino<br />

Serenza in the province of Como can meet<br />

any type of sheet metal or metal tube<br />

machining needs and<br />

supply a finished product<br />

of absolute, also<br />

aesthetic, quality. In its 30 years of business,<br />

Marelli Aldo has investigated and<br />

examined the production problems of<br />

every setting and sector – from simple<br />

metal fences to more complex structures<br />

and metal structural work for machine tools<br />

– and accordingly increased its capabilities<br />

to meet the urgent and sometimes<br />

extravagant production needs for interior<br />

furnishings. These challenges are a real<br />

proving ground for a third-party processing<br />

company. Design decisions, often remote<br />

from real technological possibilities, found<br />

a ready response in the mastery and<br />

production and engineering capabilities of<br />

the company as demonstrated by the futuristic<br />

reception of a hotel in Rimini and drawing<br />

tables made for prominent designers.<br />

Targeted investments policy<br />

The growth of the company went hand-inhand<br />

with the continuous and wise process<br />

of technological<br />

renewal of the<br />

machine fleet installed<br />

in a shed having a surface<br />

area of 3,200 m². And perhaps it<br />

was in this setting more than anything<br />

else in which the entrepreneurship of Aldo<br />

Marelli emerged brilliantly. Along with his<br />

son Stefano, he carried forward a policy of<br />

targeted investments aimed at continuously<br />

improving the service offered to its customers.<br />

“The goal of every investment is to<br />

be able to give something more”, says<br />

Aldo. “And thereby expand our range of<br />

action by starting to satisfy even the<br />

requests we previously could not accept”.<br />

Proof of this is the industrial thermosetting<br />

powder painting plant installed in 2001 to<br />

provide our customers with a truly “finished”<br />

product. “We set ourselves the goal<br />

to set up a painting plant that would guarantee<br />

high-level quality and service, to<br />

enable customers save time and avoid<br />

incurring additional costs” explains Marelli.<br />

“After conducting some analysis we<br />

believe that the best direction for today<br />

was a thermosetting powder painting plant,<br />

suitable for steel, sheet-metal and zinccoated<br />

parts. Moreover, thanks to the optimal<br />

quality/price ratio, this type of painting<br />

is suitable for a multitude of commodity<br />

sectors, from large-scale facilities to<br />

interior design and technical lighting<br />

2 <strong>TTM</strong> - TUBE TECH MACHINERY

[ APPLICAZIONI ]<br />

The “smart”<br />

Cartesian unloading<br />

system allows you to<br />

stack single tube<br />

crops up to 8 m long<br />

onto pallets in the<br />

adjacent area of the<br />

system.<br />

design and offer optimal resistance characteristics.”<br />

Therefore targeted investments are important<br />

but so is farsightedness, as in the<br />

case of the laser flat cutting system<br />

installed in early 20<strong>04</strong>. It provides a work<br />

space of 2,000 x 4,000 mm and laser<br />

power of 4,400 W. This allowed Marelli to<br />

start working right away, even on considerable<br />

thicknesses. And in doing so it<br />

distinguished itself on the market<br />

and rose above the conventional<br />

“price wars” typically found in thin<br />

sheet metal.<br />

“Small items” but mainly large<br />

sizes<br />

The same farsightedness and entrepreneurship<br />

in early 2009 led Marelli to install<br />

an innovative lasertube, by <strong>Tube</strong> <strong>Tech</strong><br />

<strong>Machinery</strong>, which allows it to process tubes<br />

having a diameter of 15-300 mm, as well<br />

as bars and profiles with a square section<br />

as large as 220 x 220 mm and rectangular<br />

sections as large as 250 x 100 mm.<br />

Therefore we are talking about a machine,<br />

the FL 250 3D Evolution, that can work<br />

“small” but its capability on large size is<br />

what distinguishes it, further proving the<br />

intention to stand out on the market in relation<br />

to those who Aldo prefers to consider,<br />

because of his philosophy, colleagues and<br />

not competitors.<br />

“The time had come to take another step<br />

forward and make another leap in quality<br />

for the company”, Marelli continues.<br />

“Having a 40% increase in turnover as the<br />

result of introducing the first flat laser, we<br />

were initially tempted to purchase a<br />

second system. However we quickly<br />

decided not to take that route because it<br />

would have added little in terms of “giving<br />

customers something new”. We thought<br />

about purchasing a work centre that would<br />

allow us to do in-house machining operations<br />

to remove the chips; however, currently<br />

we are still outsourcing this operation.<br />

So there you have it! We had been<br />

fascinated by the potentialities of applying<br />

laser technology to the three-dimensional<br />

cutting of tubes and bars. A lasertube<br />

would have allowed us to exploit the skills<br />

we had already acquired by using a laser<br />

and in so doing significantly expand market<br />

outlets. More importantly, we could<br />

pass on several advantages to our customers<br />

since we could now conceive and<br />

study the metal structural work in a new<br />

The Marelli FL<br />

250 3D Evolution<br />

is equipped with<br />

a max. 12 m long<br />

tube-bundle<br />

loading system.<br />

Marelli is able to<br />

process tubes<br />

with a diameter<br />

of 15 up to 300<br />

mm, but also<br />

square bars up<br />

to 220 x 220 mm<br />

and rectangular<br />

sections of 250 x<br />

100 mm.<br />

way. Building structures with tubes and<br />

bars cut in 3-D makes it possible to<br />

achieve “daps” that used to be unthinkable<br />

before. They would also be better and optimal<br />

in terms of performance and resistance.<br />

It would reduce the need to weld the<br />

structure which now can simply be “fastened”<br />

in a few spots. This means having<br />

even higher precision in the metal structural<br />

work with higher quality in the machining<br />

operation at a lower cost because it minimizes<br />

the worker-machining of residual<br />

material.<br />

Unloads tubes as long as 8 m<br />

in an orderly fashion<br />

The FL 250 3D Evolution installed at Marelli<br />

Aldo is the concrete expression of the<br />

capabilities of <strong>Tube</strong> <strong>Tech</strong> <strong>Machinery</strong> to personalize<br />

its systems according to specific<br />

production needs. “We chose this plant<br />

mainly for the purpose of the machining of<br />

medium large parts, though in the initial<br />

phase small diameters are more prevalent”<br />

Marelli explains. “It is our intent to emerge<br />

in the field of structural tubes and this is<br />

why we opted for a versatile and flexible<br />

plant, having a CO2 laser source of 3,200<br />

W. There is no doubt that we stand out<br />

from others because of the configuration<br />

chosen, because the machine has a 12 m<br />

tube-bundle loading system, a third<br />

spindle that makes it possible to pick up<br />

and machine even the last crop while<br />

another tube is being loaded. Moreover<br />

there is an innovative Cartesian system<br />

that unloads “intelligently” in the adjacent<br />

area for the stacking of each individual<br />

tube crop, up to 8 m long, onto pallets.<br />

This aspect is vital because it allows you to<br />

unload the tubes in an orderly fashion and<br />

find them practically ready for packing and<br />

shipping without having to go over them<br />

one by one. This translates to wasting less<br />

time, increasing productivity and lower<br />

processing costs which becomes a direct<br />

benefit to the final customer. This advantage<br />

is even more significant when handling<br />

large heavy tubes”.<br />

3 <strong>TTM</strong> - TUBE TECH MACHINERY

[ APPLICATIONS ]<br />

The lasertube has a revolutionized the way Kägi<br />

manages its work which increasingly uses lasers<br />

even for simply cutting tubes or sheets to size.<br />

3D CUTT<strong>ING</strong><br />

Semi-finished and finished tub<br />

Kägi is a Swiss company with a long history of selling tubes that – contrary to what one might think<br />

due to its over 100 years of company history – is an eminently dynamic business that is evolving all<br />

time. Several years ago it took the decision to reinvent itself and go beyond being merely a tube retailer<br />

to becoming an actual partner who could provide a service to its customers by finishing finished<br />

tubes according to specific requirements.<br />

K<br />

of the Brescia company”, We currently produce<br />

three plant sizes: the FL 250, the FL chining the piece which is such an expen-<br />

ically. It will no longer be required to re-ma-<br />

400 and the FL 600. The FL 400 3D chosen sive step of processing because it requires<br />

by Kägi is the intermediate size. A size that suitable locking equipment and machinery<br />

allows it to approach the small-tube market,<br />

i.e. approximately 40 mm, as well as less time is needed than in the past”.<br />

(different for each article). Moreover much<br />

large diameters of up to 406 mm, with any<br />

type of section: round, square, oval, modelled<br />

or an open profile that can be inscribed<br />

in the maximum diameter according to the<br />

initial intentions of Kägi. We are one of the<br />

few manufacturers who offer such a wide<br />

range of machinable diameters”.<br />

ägi has always worked in the sale and<br />

distribution of metal tubes and profiles.<br />

Being equipped only with conventional cutting<br />

lines (circular saws) for cropping and<br />

cutting tubes to the requested sizes – solutions<br />

that recluded to perform the finishing<br />

operations on the tubes – the<br />

company long ago intuited the possibility<br />

of being able to better<br />

“serve" its customers by supplying<br />

tubes that were already<br />

finished with notches and anything else required<br />

to improve and facilitate their use.<br />

Kägi is very familiar with the machining of<br />

tubes and therefore knows that it requires<br />

several specializations. The sectors and settings<br />

where it is used are vast and extremely<br />

diversified. This awareness suggested<br />

laser cutting as the most suitable technology<br />

for this purpose. So it found in the FL 400<br />

3D system made by <strong>Tube</strong> <strong>Tech</strong> <strong>Machinery</strong><br />

the ideal solution for its needs.<br />

A fundamental aspect that characterizes the<br />

strategic move made by Kägi was its willingness<br />

to process a certain size of tubes,<br />

while thinking about the possibilities of processing<br />

medium-to-large diameters to distinguish<br />

itself from to its competitors already<br />

present on the market. This is why they chose<br />

an “intermediate” plant from the <strong>Tube</strong> <strong>Tech</strong><br />

<strong>Machinery</strong> range. “Though still a work in<br />

progress, the FL 800 will bring lasertube performance<br />

up to levels never reached in the<br />

past", says Alessio Cadei, Sales Manager<br />

More rapid and higher precision<br />

assemblies<br />

“Kägi found in our technology a basic strong<br />

point”, states Cadei. “The use of the 3D cutting<br />

head mounted by <strong>Tube</strong> <strong>Tech</strong> <strong>Machinery</strong><br />

on all of its machine models, even the smallest,<br />

demonstrates this. Our “3D” is not an<br />

optional. In fact the machine is equipped<br />

right from the start with this type of head. I<br />

could almost say that the “2D” is the optional<br />

in this situation. Upstream of all it is an<br />

important awareness. The world of tubes is<br />

evolving and companies who embrace the<br />

lasertube will not be making an anachronistic<br />

decision but will be going beyond the<br />

immediate situation at hand. Bear in mind<br />

that tomorrow, companies might have the<br />

need to make bevels, partial cuts and even<br />

other machining operations that the 3D head<br />

will allow them to make safely and econom-<br />

One of the basic strategic elements in the<br />

continuous growth of the lasertube is precisely<br />

the possibility to make complex structures<br />

in the simplest possible manner thanks<br />

to the daps you can obtain by fully exploiting<br />

the potentialities of laser cutting. “The<br />

possibility to use the 3D cutting head”, adds<br />

Cadei, “allows the designer and engineer<br />

to come up with solutions that until now have<br />

been unconceivable, and that bring huge<br />

advantages in terms of assembly.<br />

Assemblies are quicker and more precise<br />

and, furthermore, sturdier and more economical”.<br />

4 <strong>TTM</strong> - TUBE TECH MACHINERY

[ APPLICATIONS ]<br />

Perfect alignment of tube under head<br />

The 3D head was certainly one of the<br />

aspects to which Kägi gave priority.<br />

Another decisive factor was the machine<br />

configuration with four mobile spindles that<br />

make it possible to “mask” all the dead<br />

times associated with handling the tube<br />

and as such they do not affect the<br />

production cycle. As the cutting operations<br />

are carried out the tube goes from spindle<br />

1 to spindle 2 and then to 3 and 4 and<br />

while the last machining operation of the<br />

tube end segment is being finished, the<br />

new tube can be loaded and prepared for<br />

cutting; the machine is immediately ready<br />

to cut without having to wait any time at all<br />

for unloading.<br />

“The technology of the four spindles<br />

contains multiple functionalities to avoid<br />

mechanical problems, or any kind of<br />

problem for that matter, especially in the<br />

handling of tubes with large diameters and<br />

thicknesses that, by their very nature, are<br />

never perfectly straight” explains Cadei.<br />

“Often they are subject to “bends” that<br />

must be managed properly to avoid<br />

damaging machine parts. This is why<br />

spindles have self-centering and selfloading<br />

systems designed to compensate<br />

for the geometric errors of the tubes and at<br />

the same time ensure the perfect<br />

alignment of the tube under the cutting<br />

twice as fast as the typical speeds for<br />

machining tubes of these dimensions.<br />

Personalized Lay-out<br />

Another aspect that should not be<br />

overlooked, and that in the case of Kägi<br />

was given extra care, was the<br />

personalization of the entire plant, even in<br />

terms of its layout. The optimal<br />

management of the handling of tubes,<br />

whether rough or cut, is only apparently<br />

secondary but it is essential when we are<br />

talking about tubes having lengths up to 14<br />

m that weigh a few tons and are extremely<br />

cumbersome to move around the shed. We<br />

therefore established with Kägi the ideal<br />

flow for rational machining of the tubes;<br />

this means that an incredible amount of<br />

care was given to the starting position of<br />

the rough tube and where it is more<br />

Finished semi-manufactured parts,<br />

even those with a small diameter<br />

The lasertube is becoming an increasingly<br />

strategic choice for companies who<br />

process sheets but want to expand their<br />

business to include similar sectors as well<br />

as for companies like Kägi who want to<br />

supply finished products in addition to<br />

cutting tubes to size. Therefore the<br />

decision to invest in an intermediate<br />

machine was the right decision because it<br />

allowed the Swiss company to position<br />

itself on a market segment that has not yet<br />

been covered, i.e. that of large tubes. And<br />

it also allowed them to see and experience<br />

the potentialities it provides for sectors that<br />

use small tubes.<br />

Currently, in spite of the number of<br />

competitors, the largest volume of work is<br />

for medium dimensions and medium-small<br />

dimensions. This is why Kägi, after<br />

purchasing the FL 400 3D, wanted to add<br />

a second lasertube and has even started<br />

talking about a third machine. “This would<br />

be an FL 250 3D and the clear goal would<br />

be to supply customers who need very<br />

small tube diameters, even smaller than 20<br />

mm, up to a maximum diameter of 300 mm<br />

with lengths of 8,500 mm” explains Cadei<br />

satisfied. “Consequently they chose a<br />

slightly smaller type of machine but again<br />

The four-spindle<br />

technology feature<br />

functions that are<br />

designed to avoid<br />

mechanical<br />

problems, or any<br />

type of problem for<br />

that matter,<br />

especially in the<br />

handling of large<br />

diameter tubes<br />

which, by their very<br />

nature, are never<br />

perfectly straight.<br />

e according to specifications<br />

head. The tube might be crooked but the<br />

machine can manage it without damaging<br />

itself and, more importantly, while<br />

maintaining the precision of the cut. The<br />

spindles can function independently or can<br />

be connected as a gantry function”.<br />

Summing up the three basic aspects in<br />

Kägi's decision, we need to firstly mention<br />

the possibility of covering an extremely<br />

wide range of machining operations, as the<br />

well-established possibility of making 3D<br />

cuts and, most importantly, the plant<br />

productivity and flexibility because in all<br />

handling operations of tubes while the<br />

machine is running, productivity becomes<br />

truly unrivalled. The increased productivity<br />

is also associated with the increased basic<br />

speed of the axes that move the machine.<br />

In fact we are talking about a machine<br />

equipped with linear motors that run on the<br />

main axes at 100 m/min, in other words<br />

convenient to “come out” with the<br />

processed tube to achieve an appropriate<br />

flow to the production cycle and ideal for<br />

positioning of the plant “utilities” (laser<br />

source, electrical board, etc.) that have<br />

been arranged in such a way as to not<br />

hinder the work process. “Kägi wanted a<br />

raised platform on which to position<br />

electrical boards, the suction plant and the<br />

laser source so that the space on the<br />

ground could be dedicated to other<br />

components of the plant” specifies Cadei.<br />

“We are talking about a total length of over<br />

40 m by 16 m, with a 14 m long “loading”<br />

and “unloading” stretch.<br />

Optimal suction of fumes<br />

The plant installed by Kägi respects the<br />

work environment and the workers. The<br />

automated handling of tubes significantly<br />

reduces the risks to human safety, as well<br />

as the cutting fumes suction system which<br />

is always present inside the tubes. There<br />

are two suction systems, one on the right<br />

edge and the other on the left. This<br />

guarantees optimal suction of the fumes<br />

produced by the cutting even during the<br />

final assembly of the last tube crop. A<br />

suction device alone would not make this<br />

possible and would significantly pollute the<br />

air in the workshop. <strong>Tube</strong> <strong>Tech</strong> <strong>Machinery</strong><br />

ensures maximum suction in a work<br />

situation, with noticeably positive effects on<br />

work safety and worker health.<br />

did not want to give into the “laws of the<br />

marketplace” that simply require the<br />

classic machine for 2D tubes having a<br />

diameter of 6 m. In these cases the 8,5 m<br />

3D tube with diameter up to 300 mm is<br />

machined in a flexible way, closed and<br />

opened profiles thanks to the chain<br />

operated front loading system. This new<br />

machine manages tubes having a linear<br />

weight of 45 kg/m, in other words its<br />

performance is decidedly high”. As we<br />

have seen, the lasertube has<br />

revolutionized Kägi's work management in<br />

a way that increasingly exploits the laser<br />

even for simple operations of cutting to<br />

size. The fact of also being able to use the<br />

lasertube for cropping operations, and<br />

program them easily and rapidly, certainly<br />

represents an additional opportunity<br />

though Kägi's primary reason for installing<br />

the <strong>Tube</strong> <strong>Tech</strong> system was to supply<br />

finished tubular semi-manufactured<br />

products.<br />

The 3-D cutting head<br />

was one of the<br />

decisive factors for<br />

choosing the FL 400<br />

and 250 cutting<br />

systems.<br />

The FL 400 3D<br />

cutting system is<br />

installed at the Kägi<br />

factory.<br />

5 <strong>TTM</strong> - TUBE TECH MACHINERY

[ SOLUTIONS ]<br />

<strong>Tube</strong> <strong>Tech</strong> <strong>Machinery</strong> has presented the new TS 5.12, the latest sheet metal welding<br />

plant developed by the company after its fortunate experiences with the<br />

TS4.20. The machine is capable of trimming and welding sheet metal with nominal<br />

dimensions of up to 12,000 x 2,500 mm and thicknesses ranging from 1 up to 8<br />

mm to obtain finished sheets having a large-size, with maximum dimensions of<br />

12,000 x 5,000 mm. This is a solution that makes it possible to think of welding different<br />

thicknesses of sheets to obtain “Tailored Blanks”.<br />

Tailored Blanks …<br />

… no problem<br />

T<br />

he TS 5.12 has a remarkable degree of automation<br />

that, starting with the rough sheet fed<br />

manually, allows you to align and centre the<br />

sheet by alternating longitudinal and transversal<br />

movements on rollers provided<br />

with a safety clutch. After centering<br />

the first sheet, it is locked with an automatic<br />

hydraulic blank holder stop and<br />

then trimmed using the laser cutting head.<br />

Simultaneously with the trimming of the first<br />

sheet, the machine brings the next sheet to<br />

the proper position, aligns it and centres it<br />

until the final trimming phase. After trimming<br />

the two adjacent edges of both sheets, the<br />

machine brings them closer to each other and<br />

welds the edges continuously with the laser<br />

head and without deposit metal. A US welding<br />

control system is provided during the entire<br />

process. These phases can be repeated<br />

in automatic mode until the formation of a<br />

sheet having maximum dimensions of 12,000<br />

x 5,000 mm.<br />

A fibre laser of 4 kW<br />

One of the most important new features of the<br />

TS 5.12 is certainly the use of the fibre laser.<br />

For the first time, <strong>Tube</strong> <strong>Tech</strong> <strong>Machinery</strong> is ready<br />

to use a fibre laser resonator (4 kW) made<br />

by IPG Photonics with the certainty that after<br />

conducting in-depth trials and multiple tests,<br />

is today the best solution for welding without<br />

deposit metal.<br />

Another point of interest of this new TS 5.12<br />

is the possibility to be able to start with<br />

sheets made from coils, appropriately prepared.<br />

This reduces costs of raw materials<br />

The TS 5.12 cutting and welding system will be<br />

ready for the first tests and inspection trials at the<br />

beginning of 2010.<br />

which benefit the cost of the final product.<br />

Moreover the possibility to make metal<br />

sheets to size (Tailored Blanks) allows them<br />

to “build” a metal sheet with variable thicknesses<br />

to reduce the weight of the sheet and<br />

provide the resistance capacities required.<br />

This factor also contributes significantly to<br />

cost reduction while improving the quality of<br />

the product.<br />

The machine will be ready for the inspection<br />

as early as January 2010.<br />

XXL LASER WELD<strong>ING</strong><br />

Producing large sizes from small standard<br />

sheets is the specialty of the<br />

transformation technique used by<br />

Göcke in Ahaus. Its TS 4.20 laser plant<br />

made by <strong>Tube</strong> <strong>Tech</strong> <strong>Machinery</strong> automatically<br />

welds sizes of up to 4 m<br />

wide and 20 m long. The beads are<br />

extremely thin and do not shrink.<br />

The TS 4.20 welds small sheets to<br />

make large-sized sheets; they purchase<br />

the sheet sizes found in regular<br />

stores – small, medium and large<br />

– and weld them to make them into<br />

small plates that can reach the abovementioned<br />

dimensions. Thanks to the<br />

laser technique, even very thin sheets<br />

can be joined without deforming them<br />

and this is a great advantage. The<br />

plant processes sheets that are 1,5 –<br />

8 mm thick.<br />

“We keep an individual solution ready<br />

for every request”, says Jörg Göcke,<br />

the director and son of the company's<br />

founder. “Since we are specialized<br />

in special productions, we offer<br />

the best possibilities for rapidly and<br />

impeccably welding the products according<br />

to size or unusual dimensions.<br />

One of our distinctive strong points<br />

is the large size which can be as much<br />

as 25 m long.<br />

These pieces are used in building<br />

bridges, vehicles or open air excavations”.<br />

So Göcke in Ahaus produces<br />

machined parts for the mining of lignite<br />

or half-octagonal shells for the<br />

construction of current or electricity<br />

poles for the procurement of energy.<br />

Another important application for<br />

Göcke is the construction of wagons<br />

for the metro trains, urban rail trains<br />

and regional railways; for the wagons<br />

of local traffic it produces whole<br />

sheets of stainless steel for the lateral<br />

walls that are solid, lightweight<br />

and trimmed.<br />

Growth has facilitated the decision<br />

Offering innovative solutions in all<br />

sizes means having to continuously<br />

update production. “We work with a<br />

modern fleet of machinery that is continuously<br />

reorganized and renovated<br />

in accordance with the latest technical<br />

standards,” says Göcke. “Our<br />

ongoing aim is to be increasingly innovative”.<br />

So, the growing demand<br />

for large welded sizes has confronted<br />

us with a choice: do we outsource<br />

a certain volume of the orders or keep<br />

them in-house and invest in a new<br />

laser welding plant?<br />

“The decision to install the TS 4.20<br />

was essentially the classic “Make or<br />

buy" decision. It was up to us to decide:<br />

should we outsource this work<br />

or do we want to provide this production<br />

in-house according to our high<br />

quality standards? The volume of orders<br />

increased so much that over time<br />

we decided to invest in this TS 4.20<br />

automatic laser welding plant.<br />

Another reason for our decision was<br />

the desire to embark on new ventures”.<br />

6 <strong>TTM</strong> - TUBE TECH MACHINERY

[ INFO... ]<br />

New<br />

The cutting operations<br />

are also automatic<br />

To complete the range of machines that cut and weld metal sheets,<br />

<strong>Tube</strong> <strong>Tech</strong> <strong>Machinery</strong> is developing new solutions that also integrate<br />

the laser cutting technology for the realization of finished pieces. In<br />

addition to the TS4.20 and TS5.12 lines, we are currently designing a<br />

solution that allows the preparation by welding the large sheet and later,<br />

on the same machine, subjecting it to all the laser cutting operations<br />

-- completely automatic -- to produce the finished product. These<br />

are usually specific customized plants, therefore designed to solve<br />

very specific problems. In particular this type of machinery has applications<br />

for situations where huge sizes need to be made, e.g. the edges<br />

of train wagons and metro cars. The goal of the new plant is to<br />

weld sheets using a laser head without deposit material and therefore<br />

to make the cuts that will constitute the windows and doors of<br />

the aforesaid wagons in automatic mode. One of the main advantages,<br />

besides the notable speed of the process, it is the remarkable<br />

savings in the handling of the sheet that in these cases can be as large<br />

as 4,000 x 25,000 mm for making double-decker carriages. The<br />

machine will be able to start with standard sized rough sheets and<br />

pre-assemble the large size and cut it. It will then use an integrated<br />

handler to unload the sheet directly from the machine into the position<br />

stipulated by the customer. The new plant will also have a system<br />

for automatically unloading the offcuts which are large since we are<br />

dealing with wagon windows (approximately 1,500 x 1,000 mm):<br />

these offcuts will automatically be stacked on pallets and then made<br />

easily available to be reused on other laser cutting machines.<br />

TECHNICAL DATA<br />

Maximum loadable tube length<br />

Maximum tube weight<br />

<strong>Tube</strong> sections<br />

Dimensions rally section maximum<br />

Dimensions square section (maximum)<br />

Dimensions rectangular section (maximum)<br />

Maximum unloadable tube crop<br />

FL 800 3D<br />

16,000 mm<br />

350 kg/m<br />

round, square,<br />

rectangular, oval<br />

815 mm<br />

550 x 550 mm<br />

600 x 400 mm<br />

16,000 mm<br />

FL 800 moves the challenge ...<br />

urrently <strong>Tube</strong> <strong>Tech</strong> <strong>Machinery</strong> already has the broadest<br />

Cand most complete range of lasertube plants and<br />

produces three different machine sizes: FL 250, FL 400<br />

and FL 600. However the new FL800 is currently being created,<br />

and is a solution that will raise the bar even higher in terms of<br />

maximum machinable diameter, the real “challenge” for<br />

lasertube manufacturers. In addition to being able to process<br />

large diameter tubes, this new machine will embrace a fresh<br />

concept for moving them. In fact the plant will have air portals for<br />

loading and unloading and therefore will enable the precise and<br />

rapid management of heavy tubes. The portals will be managed<br />

in a simple and intuitive manner by the CNC and<br />

will not require a change in set-up when<br />

changing the type of tubes.<br />

“We can also produce customized<br />

metal plates”, Göcke continues,<br />

“the so-called Tailored Blanks, to<br />

make a large sized sheet in various<br />

thicknesses and of different<br />

materials or types of steel. An important<br />

advantage of TS 4.20 is the<br />

automatic control of the welding<br />

bead. Here the machine controls<br />

the three values of pliability, temperature<br />

and luminosity of the<br />

product. From this we can figure<br />

out the quality of the welding bead.<br />

As long as these three values stay<br />

within the established tolerance<br />

field, the welding bead is considered<br />

good. If any defects occur,<br />

the plant continues to weld its initial<br />

program until the end. Then<br />

there is a visual control by the<br />

welding control unit. If the defects<br />

are found, such as pores or inclusions,<br />

the entire joining process<br />

is repeated, in other words the<br />

weld is cut and welded again.<br />

Synergy<br />

The visit of Alessio Cadei, the Sales Director<br />

of <strong>Tube</strong> <strong>Tech</strong> <strong>Machinery</strong> at the Trumpf location<br />

in Ditzingen confirmed and further strengthened<br />

the close collaboration between the<br />

two companies. The meeting made clear the<br />

organization and quality proposed by the<br />

German company with whom it was reinforced<br />

the strong partnership so that it is not unilateral,<br />

i.e. supplier-customer but it makes possible<br />

to engender more effective synergies<br />

developed jointly.<br />

Alessio Cadei, Sales Director of <strong>Tube</strong> <strong>Tech</strong> <strong>Machinery</strong> (to<br />

the right) and Costantino Pizzorno of Trumpf.<br />

IN PIACENZATO TALK<br />

ABOUT Lasers and<br />

Aluminium<br />

“The welding of aluminium: new prospects offered by modern<br />

laser technology”. This was the theme dealt with at<br />

the opening discussion at EXPOlaser 2009 (19 - 21<br />

November) with the contribution of <strong>Tube</strong> <strong>Tech</strong> <strong>Machinery</strong><br />

and IPG Photonics and major Italian universities such as<br />

the Milan Polytechnic and the University of Brescia. Welding<br />

aluminium with laser technology is a topical issue that is<br />

spreading widely through the world of light alloys, especially<br />

in light of the advent of innovative fibre laser resonators.<br />

Performance and operative flexibility are wedded<br />

with premium mechanical characteristics making possible<br />

the application of this technology even in fields that till<br />

now have been predominated by conventional welding<br />

methods. This is why the afternoon Conference of Thursday<br />

19 November is something you will not want to miss.<br />

7 <strong>TTM</strong> - TUBE TECH MACHINERY

[ PROSPECTS ]<br />

EVENTS<br />

EMO<br />

5.-10. October 2009 - Milan I<br />

Hall 18 - Stand B14<br />

EXPOlaser<br />

19.-21. November 2009 - Piacenza I<br />

Blechexpo<br />

1.-4. December 2009 - Stuttgart DE<br />

Hall 1 - Stand 1521<br />

<strong>Tube</strong> <strong>Tech</strong> <strong>Machinery</strong> will soon blow out the ten candles. It is celebrating<br />

its tenth anniversary during an extremely difficult and problematic macroeconomic<br />

context in which so many companies are floundering.<br />

Nonetheless T.T.M. increased its turnover by 5% in 2008 and the forecast for<br />

2009 allows to confirm the same turnover as the previous year. T.T.M. recently assembled<br />

a “Tailor made” brochure showing its range of machinery and plants,<br />

including the latest inventions. I really like the idea of “the smallest company with<br />

the broadest range of laser machines for processing tubes”.<br />

In this market segment we offer solutions that can machine tubes with diameters<br />

of 15 mm and even reach 800 mm, all using the 3-D cut. In these plants we have<br />

introduced (and once again, we are proud to be the first) “intelligent” unloading<br />

portals. This solution is achieved by using controlled axes and inventions that<br />

can generate significant increases in<br />

productivity estimated at around 20 -<br />

30%. All of this is done in absolute safety,<br />

bringing an improvement to the work environment which, as you know, is<br />

now an added value as well as a regulatory obligation. In December we will present<br />

the new TS 5.12, the plant for cutting and welding different sizes of sheet<br />

metal, whether it is carbon steel or stainless steel, with a work field of up to 5000<br />

x 12,000 mm. The generator will be Fibre Laser 5000 W made by IPG Photonics.<br />

We will concretely have a way to verify the performance and characteristics of<br />

the laser at a high brilliance level. This technology, highly anticipated on a market<br />

that has high expectations, will be tested by T.T.M. and compared with the CO 2<br />

laser. We believe it will represent an enormous step forward in the world of applications,<br />

even though, like all things that must be tested in all possible situations.<br />

Therefore, in spite of these difficult years for the economy, in 2008 and especially<br />

2009, T.T.M. continued to persevere undaunted in its process of growth and research<br />

of new applications.<br />

A constant growth<br />

<strong>Tube</strong> <strong>Tech</strong> <strong>Machinery</strong> S.r.l.<br />

Via Bonfadina, 33<br />

25<strong>04</strong>6 Cazzago San Martino (BS) Italy<br />

Tel. +39 030 7256311<br />

Fax +39 030 7256333<br />

info@tubetechmachinery.com<br />

www.tubetechmachinery.com<br />

associate UCIMU - SYSTEMS TO PRODUCE