The welding - Tube Tech Machinery

The welding - Tube Tech Machinery

The welding - Tube Tech Machinery

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

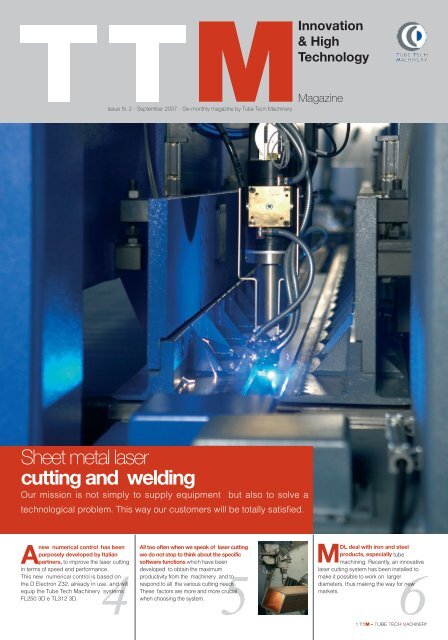

TTM 02 ING ROSSO 12-09-2007 15:15 Pagina 1Innovation& High<strong>Tech</strong>nologyMMagazineIssue N. 2 - September 2007 - Six-monthly magazine by <strong>Tube</strong> <strong>Tech</strong> <strong>Machinery</strong>Sheet metal lasercutting and <strong>welding</strong>Our mission is not simply to supply equipment but also to solve atechnological problem. This way our customers will be totally satisfied.Anew numerical control has beenpurposely developed by Italianpartners, to improve the laser cuttingin terms of speed and performance.This new numerical control is based onthe D.Electron Z32, already in use, and willequip the <strong>Tube</strong> <strong>Tech</strong> <strong>Machinery</strong> systemsFL250 3D e TL312 3D.All too often when we speak of laser cuttingwe do not stop to think about the specificsoftware functions which have beendeveloped to obtain the maximumproductivity from the machinery and torespond to all the various cutting needs.<strong>The</strong>se factors are more and more crucialwhen choosing the system.MDL deal with iron and steelproducts, especially tubemachining. Recently, an innovativelaser cutting system has been installed tomake it possible to work on largerdiameters, thus making the way for newmarkets.4 5 61 TTM - TUBE TECH MACHINERY

TTM 02 ING ROSSO 12-09-2007 15:15 Pagina 2[ APPLICATIONS ]TS 4.20 2D is the abbreviation for the brand new system developedby <strong>Tube</strong> <strong>Tech</strong> <strong>Machinery</strong> for the cutting and <strong>welding</strong> of sheet metal.<strong>The</strong> system is totally automatic and can trim and weld sheetmetal using a special head which both cuts and welds.This system has been designed and manufacturedby TTM together with Trumpf and Precitec, whohave supplied some of the parts.<strong>The</strong> system has been developed for avery important service centre whichthanks to this new <strong>Tube</strong> <strong>Tech</strong><strong>Machinery</strong> machine can improve itsproduction and begin new applicationswith much larger metal sheetsto offer to its customers. This newtechnique has been studied to meetthe customers’ specific needs, and, yetagain, TTM proves to be a supplier full ofnew ideas which means new, reliable andtechnologically advanced machinery.“We are convinced that it is important notto concentrate only on one kind of system”- says Fiorenzo Castellini, owner ofthe Castellini Group, to which <strong>Tube</strong> <strong>Tech</strong><strong>Machinery</strong> belongs – “since we canprovide practical solutions to our clients’problems by benefit of a long experienceTraction and bendingtest trials on the<strong>welding</strong> strips.in problem solving.This system is a clear demonstration ofthis.”We must remember that the core businessof TTM consists in laser cuttingequipment for working on large-dimensionaltubes, so, with the TS 4.20 2D, thecompany has tackled a new kind of production.“In fact, we are not here simplyto provide a piece of equipment, but alsoto find a solution to a technological problem,for the customer’s total and absolutesatisfaction.<strong>The</strong> objective is metal sheetsmeasuring 4 x 20 m<strong>The</strong> metal sheets go from a minimum of1.000 x 2.000 mm to amaximum of 2.050 x4.100 mm with thicknessesvarying from 1to 8 mm. <strong>The</strong> machinehas an automatic sheetloading system whichmeans a high level ofautomation.. “Actually, the client askedus for a highly automated machine systemcapable of trimming and <strong>welding</strong>highly resistant steel sheets of the above–mentioned size to obtain a finishedproduct measuring 4.000 x 20.000 mm”.From this came the initials “TS” ( taglio esaldatura- cutting and <strong>welding</strong>). “4.20” isthe size of the final product. It is importantto note the starting sizes of thesheets are the maximum possible, so, themachinery has to adapt automatically todifferent sizes, to a minimum of 1.000 x2.000 mm.<strong>The</strong> production stages<strong>The</strong> TS 4.20 2D production cycle is quitesimple and consists in the followingstages:• automatic loading of metal sheet on toa work surface by a vacuum system.• sheet is lined up and centred on worktable using fixed and mobile clampingdevices• metal sheet is moved across undercontrol of CNC;• blocking of side of sheet using ahydraulic system;• edges trimmed using a two- dimensionalheaded laser cutter.• positioning of a second metal sheet.After centring, it is brought to a distanceof about 30 mm from the first one andblocked on the first long edge by a2 TTM - TUBE TECH MACHINERY

TTM 02 ING ROSSO 12-09-2007 15:15 Pagina 3Construction design ofthe TS 4.20 2D:the initials “TS” standfor “taglio e saldatura”,“4.20” is the size of thefinal productmobile hydraulically controlled system;• second sheet trimmed by a laser cut• the two edges are perfectly aligned :only one of the sheets is moved;• the two sheets are pointed to avoidheat distortion between them;• continuous laser <strong>welding</strong> using thesame cutting head with the PrecitecLWM (Laser Welding Monitor) whichoperates as a joint runner and alsochecks and controls the <strong>welding</strong>• the two clamping devices are opened• the welded sheets are transferred.At this point the cycle repeats, adding anew sheet to those already welded. Whenthe <strong>welding</strong> operation is over, obtaininga sheet of the required size, themetal sheet is transferred, either manuallyor mechanically, to other lasercutters to be trimmed and machined, ifnecessary.<strong>The</strong> <strong>welding</strong>Naturally the quality of the final producthad to be guaranteed. Layers of sheetmetal made in sizes unavailable on themarket for use on railway lines had toprovide the same quality guaranteedand same mechanical characteristics asits components. Here is engineerCastellini’s comment on this : “This wasthe most difficult part of our work, not somuch for its intricacy as for the novelty ofwhat we had to guarantee. On the <strong>welding</strong>on the base sheets with a thicknessof 2, 4, 6 and 8 mm we carried out metallurgicdistinction tests from the strips(with tests for hardness) and mechanicaltests for traction and bending (in accordancewith the standard EN ISO 15614-11) to determine the best parametersand, the relative working limits. <strong>The</strong>n, byexploiting the LWM of the Precitec wemade sure that these limits could not besurpassed while the machinery in function.Thus, we could guarantee themachinery would work smoothly. It was along job but we loved every minute of itaswe always do, when faced with a newchallenge. We are also happy because,at the end, our client complimented us onour work.”Finally it is our duty to say that, as all themachines at TTM, the TS 4.20 2D wasalso designed with the help of FEM(Finite Elements Method) to ensure technicalperfection<strong>The</strong> TS 4.20 2D has anautomatic sheetloadingsystem, savingon labour costs3 TTM - TUBE TECH MACHINERY

TTM 02 ING ROSSO 12-09-2007 15:15 Pagina 4[ TECHNOLOGIC PARTNERSHIP ]NUMERICAL CONTROLA new numerical control has been studied and devised, by Italians, to speed up the laser cut. <strong>The</strong> new NCis based on the D.Electron Z32 control system which is already in use and will equip the <strong>Tube</strong> <strong>Tech</strong><strong>Machinery</strong> FL250 3D and TL312 3D.<strong>The</strong> control increases thework done by the laser<strong>Tube</strong> <strong>Tech</strong> <strong>Machinery</strong>, has many years’experience in the field of laser cuttingmachines designed to work on very largetubes and sheet metal. <strong>The</strong> company hasdecided to develop a new numeric controlsystem for use on their machinery. Thissystem derives from the collaboration withan Italian firm, the D.Electron inFlorence, renowned the world over for both itshardware and software in the construction ofnumerical controls.<strong>The</strong>refore, the new machines in the FL250 3Dseries, for the cutting of tubes with a diameterup to 254 mm and in the TL312 3D series, forthe cutting of large sized sheet metal (3.200 x12.000 mm and beyond), will be equipped withthe new, but well-tested control system basedon the D.Electron Z32. But let’s go back a stepand see what motivated such a strategic andsignificant choice.<strong>The</strong> open system favourspersonal design<strong>The</strong> need for this arose from the special type ofmarket TTM has always been up against, thatis the necessity to take its high precision performancesso typical of tube and sheet metalmachinery, to laser working on larger andheavier pieces where inertia can have a negativeinfluence on work and production.It is also necessary to personalize the functionsand applications to satisfy the customers’WE CHOSE TO START WITH A NUMERIC CONTROL WITHA MODULAR STRUCTURE WHICH CAN BE SCALED FOREXCELLENT CONFIGURATIONS FOR DIFFERENT USES.needs. <strong>The</strong>refore, the system must be flexibleand adaptable to the 3D laser cuttingmachines.This is why we chose to start with a numericcontrol which has a modular structurethat can be scaled, just like the Z32 ( PCbasedarchitecture), which gives optimalresults. Not only is the hardware excellent; the software is ready to include special,optional programs developed by the customersthemselves.<strong>The</strong> “common denominator” of flexibilityand research and development has givenrise to the collaboration between TTM andD.Electron. This certainly offers excellentmarket prospects for both companies.Thanks to the experience of the work teamTTM and D.Electron, the customer canreap the benefits of the most up to datemachinery.<strong>The</strong> modular structure,which can be scaled,for excellentconfigurations fordifferent uses.4 TTM - TUBE TECH MACHINERY

TTM 02 ING ROSSO 12-09-2007 15:15 Pagina 5CAD/ CAM 3D[ TECHNOLOGIC PARTNERSHIP ]Software:the strategic aspect<strong>The</strong> well established partnershipbetween Alma, production leader insoftware CAD/CAM for the working ofsheet metal, tubes and metal bars,and <strong>Tube</strong> <strong>Tech</strong> <strong>Machinery</strong>, worldleader in 3D laser cutting, gives usthe opportunity to talk about software.In fact, Alma’s flexibility inadapting its software at TTM’srequest for their customers showshow strategically important the softwareis to guarantee the required high level ofour products.We must immediately say that TTM and ALMAare helpful to one another in the field of innovation.For <strong>Tube</strong> <strong>Tech</strong> <strong>Machinery</strong> it is a realstrong point to have a partner which developsits software in correspondence to the problemswhich they are, from time to time, confrontedwith. We can widen our markets since wehave the possibility of offering software “onrequest”. On the other hand, the collaborationwith <strong>Tube</strong> <strong>Tech</strong> <strong>Machinery</strong> adds importantvalue to Alma, since TTM gives them opportunitiesto develop tools that give more use tothe environmental modules Act/, regarding the3D cutting of tubes and metal bars.All too often when speaking about laser cutting we seemto forget the function of the special software developedto make the machinery more productive and to resolvethe problem of individual cutting requests, fundamentalwhen choosing the kind of machinery for the job.<strong>The</strong> “light answer”<strong>The</strong> software range Act/, Alma meets therequirements of all machinery produced by<strong>Tube</strong> <strong>Tech</strong> <strong>Machinery</strong>, from production managementto the programming of the FL systemsfor tube and bar cutting with five interpolatedaxes, thanks to modules likeAct/<strong>Tube</strong>s and Act/Cut3D, or systems forworking the metal sheets for cutting, <strong>welding</strong>and 3D cutting of deep- drawn details with themodule Act/Cut Professional.<strong>The</strong> custom-made software for <strong>Tube</strong> <strong>Tech</strong><strong>Machinery</strong> regards all levels of machine productionstarting from the design, for which apotent instrument for a “light answer” reducingthe time needed to calculate and elaboratedata in cases where there is a lot of geometryto be done on the same piece, has beendeveloped. “Replica leggera” “Light answer”introduced by TTM enables a sequence ofmaster cuts to be established which is thenrepeated only in the post processor phase.This delays the duplication of information ofthe intersecting tubes and lightens the volumeof data to be elaborated. This caused no meanproblem to a Russian firm working on the productionof pipes for the oil industry. Here weare referring to tubes about 8 meters long onwhich, using the FL 250 system, 1.200 holesof different shapes and sizes are bored to filterthe crude oil. This is an isolated case butillustrates, in an excellent way, the concept ofcustomization.<strong>The</strong> dedicated interface<strong>The</strong>re are cases in which customized softwarehas gone further. For a Finnish producerof pipes and high pressure manifoldsa special interface of DIALOGUEwas developed with a Tribon 3m PipeModeler, CAD 3D system dedicated topiping, which the company uses to programall the machinery installed in theworkshop.With this interface you can reconstruct inAct/<strong>Tube</strong>s, using the information fromTribon, the designs of the tubes needed fornesting; Act/Cut 3D automatically convertsall the information, especially that neededfor chamfers and stoppers(distantial).Since they are high pressure manifolds, theintersections must be welded with completemetal penetration which calls forjointing and the above-.mentioned stopperswhich are used to maintain a fixeddistance so the <strong>welding</strong> is filled properly.Resource EditorStill on the subject of customized software,it is possible to create a resource editor, inother words a personalized databaseincluding all the technical parameters setfor each machine tool. For example, themain parameters of the <strong>Tube</strong> <strong>Tech</strong><strong>Machinery</strong> machines are defined accordingto machining, tooling, materials, theirquality and thickness to be worked.<strong>The</strong> materials and tubes/sections are putinto a database which is the same for allthe machines and the user can insert sectionsof the most commonly used tubesand code them. For TTM open data fileshave been installed, IP joists or C and, sothe cutting sequences for the moduleAct/Cut3D have been prepared.Other functions of Act/Cut3D have beencustomized to create the optimal schedulefor the <strong>Tube</strong> <strong>Tech</strong> <strong>Machinery</strong> machines.Parameters have been prepared for theFL600, FL400, FL250 and FL200 systemswhich make automatic calculations allowingalso a human intervention, whenrequired, to modify the final program.5 TTM - TUBE TECH MACHINERY

TTM 02 ING ROSSO 12-09-2007 15:15 Pagina 6[ APPLICATIONS ]LASER TUBES<strong>The</strong> 3D cutting of larghas been addedFor decades, la MDL of Capriano delColle in the province of Bresciahave been concerned with the tradingof iron and steel products. <strong>The</strong>company’s main activity is tube manufacturing.<strong>The</strong>y have the means toperform the following: tapering, boring,trimming, cutting to size andbending. <strong>The</strong>refore, the firm focuses on avariety of different client areas: cars manu-<strong>The</strong> MDL system canuse 3D tubes accordingto the customer’sneeds.facturers, plumbing, central heating, furnishing,components production, curtainaccessories. MDL are direct suppliers orwork on someone else’s behalf. <strong>The</strong>y manufacturesteel, copper, brass and aluminiumtubes. When you go round the firm’spremises you are impressed by the quantityof the material there is in the warehouseinfact they process about 50.000 t of tubingper year.“MDL certainly answers the needs of allcompanies requiring specialized servicesin the field of iron and steel machining,especially tubing” explains Marcello Zanini,one of the owners. “We supply semi- finishedtubes to all sectors, our work alsoincludes the <strong>welding</strong> or the bending oftubes and the making of drawn tubes,round, square or rectangular welded tubeswith burring/trimming on both sides. Wealso provide a cleaning service for both theinside and outside of tubes, made-tomeasureboring, machining of round, ovalor square tubes or just cutting tubes andmetal bars to the required measure.MDL are involved in the trading of iron and steel products,especially tube manufacturing. <strong>The</strong>y have recently installedan innovative laser cutting system to increase the diametersthey can work on and open up new markets.Increasing the range of workablethicknesses for market expansionRecently, MDL has installed a new lasercutting system, the FL250 3D of the <strong>Tube</strong><strong>Tech</strong> <strong>Machinery</strong> with the aim of completingthe services they can offer and thusexpanding their markets. “By investing inlaser technology - says Zanini – today wecan approach the market in a differentway, expanding into areas previouslyunknown to us. With the introduction of thelaser tube we can approach market areaswe had formerly avoided.”Actually, the general sensation is that thereis an increase in work opportunities in thefield of commissioned work for otherfirms, especially in mechanics. New projectsare replacing rounded sheet metalwith tubing sections. It is not just by purechance they have chosen the FL250 3Dsystem with a 2,700 W CO2 energysource, capable of working on small tubes,used typically in traditional laser technologyfor the furniture industry, or on largersections of tubing used in areas where thepotential of laser technology is still relativelyunknown.6 TTM - TUBE TECH MACHINERY

TTM 02 ING ROSSO 12-09-2007 15:15 Pagina 7ge tubes<strong>The</strong> quantity of tubesin the warehouse isstunning.MDL processabout 50.000 tof tubes per year.“Our aim was to increase the range ofworkable thicknesses to open up newmarkets for us - emphasizes Zanini –and we can progress to larger structuresas used in modern construction work forwarehouses and scaffolding.”One of the FL250 3D‘s main characteristicsis the solidity of the entire structure.It has been devised for the processing ofMDL have installed thetube laser cuttingsystem FL250 3Dproduced by <strong>Tube</strong><strong>Tech</strong> <strong>Machinery</strong>.3D cutting and added value<strong>The</strong> FL250 3D installed in MDL has anautomatic loading and unloading systemwhich can process tubes and metal barswith a maximum length of 7 m. A fundamentalaspect of the machine is its 3D cuttinghead which means MDL is a “cutabove” the rest of the market. “<strong>The</strong> 3D cut<strong>The</strong> 3D laser head cutter can be placedin any direction inside a semi -sphere. <strong>The</strong>head movements are made by direct-drivemotors without any mechanical transmission.<strong>The</strong> exact distance of the laser pointfrom the surface to be cut is controlled bya sensor which immediately automaticallycorrects the positioning of the machineaxis. <strong>The</strong> accuracy and integrated coolingcustom- madeangled tubes, chamferssystem guarantees high precision.and flares from 10 to 254 mm.Maximum speed is reached on the FL250“I would almost say - says Zanini – that3D using dynamic motors and exceptional-the FL250 3D shows its maximum poten-ly high quality transformers.tial in the cutting of very thick tubes.<strong>The</strong> machine is very solid, but it is equallyPerhaps this is conditioned by the factimportant to remember that the section ofthat there is no substantial differencethe tubes or the metal bars can be auto-from any other system available on themarket when it comes to cutting thinnertubes. I am convinced, though, that thethicker and, therefore, heavier, the tubegets, the solidity and reliability of themachine becomes more important, evenmore important than its laser technology”.Perhaps this is the reason why TTM haschosen to provide a machine which coversthe whole range of thicknesses thatMDL wanted to face in the best possibleway, even though, in some cases, thiswas superfluous.Sections of oval tubingthat MDL had to cutand for which <strong>Tube</strong><strong>Tech</strong> <strong>Machinery</strong> devisedand made a specialpiece of machinery,demonstratingcompetence and readinessto help understandand give theircustomers what theyreally want.is a kind of added value for our customersthat only we can give them, especiallywhen working on large structures, wherechamfer and caulking are absolutely vitalto the preparation for <strong>welding</strong>”, Marcellotells us. “ When talking about 3D cutting,we mean various kind of cuts which makejointing, <strong>welding</strong> and the assembly of thewhole structure much easier. <strong>The</strong> 3D cutteralso speeds up operations and consequentlyhas cost benefits for the customer.”matically changed: there is absolutely noneed to fix any setting of the machine; forexample, you can pass from a round tubeto a square one without having to changeanything. It was a different story in thecase of some sections of oval tubing thatMDL had to cut; <strong>Tube</strong> <strong>Tech</strong> <strong>Machinery</strong>devised and made a special piece ofmachinery for this. This is a demonstrationof how TTM, with their competence andreadiness to help and understand, givetheir customers what they really want7 TTM - TUBE TECH MACHINERY

TTM 02 ING ROSSO 12-09-2007 15:15 Pagina 8[ PROSPECTS ]EVENTSEMO HannoverHannover17 - 22 September 2007Pavilion 15 - Stand D42SCANDINAVIAN TECHNICAL FAIRStockholm16 - 19 October 2007Stand B05:21EXPOLASERPiacenza15 - 17 November 2007Stand C6-D5WIRE & TUBEDüsseldorf31 March - 4 April 2008Commitment, passion and willpower have enabled us tocomplete a whole range of products which were <strong>Tube</strong> <strong>Tech</strong><strong>Machinery</strong>’s target in the last few years. New ideas havemade it possible for us to produce high performance new machinery,flexible in use and made to meet our customers’ individual needs. Wehave managed to make our standards appreciated so much that othermachine constructors have used our ideas.With three models (the FL250 capable of machining 20 to 254 mm ofdiameter, the FL400 capable of machining 40 to 406 mm of diameterand our flagship the FL600 for tubes 80 to 610 mm) we think we arethe smallest manufacturer in the world offering the largest range oftubes in this sector. All our systemshave 3D cutting heads, now essentialto guarantee our customers total,unlimited flexibility.In the field of sheet metal working, the brand new and innovative TL312 3D has revolutionized the concept of large machinery for sheetmetal working with a size of 3.000 x 12.000 mm with a 3D headcutter. With the help of the double gantry we can do things withspeed and precision never reached before on such large sheets.<strong>The</strong> latest creation, now installed at Göeke in Germany, is the TS4.20where, after cutting we have ventured into <strong>welding</strong>. You can find outall about this project in the TTM Magazine.Our great feeling of satisfaction does not last for long, since we arealways trying to satisfy our customers’ demands and keep up with theirrequests. I am certain that <strong>Tube</strong> <strong>Tech</strong> <strong>Machinery</strong> has consolidated itsfoundations in becoming an important reference point in lasertechnology. Laser technology is constantly changing and there is notime to rest on our laurels. This is the reason why TTM will continue inits development and research of new solutions.Ambitious aims.FL 250 FL 400FL 600TP 3.12 TPD 3.12 TS 4.20<strong>Tube</strong> <strong>Tech</strong> <strong>Machinery</strong> S.r.l.Via Bonfadina, 3325046 Cazzago San Martino (BS) ItalyTel. +39 030 7256311Fax +39 030 7256333info@tubetechmachinery.comwww.tubetechmachinery.comAssociato UCIMU - Sistemi per Produrre