1wMF53w

1wMF53w

1wMF53w

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

VALUE CHAIN AND TECHNOLOGIES<br />

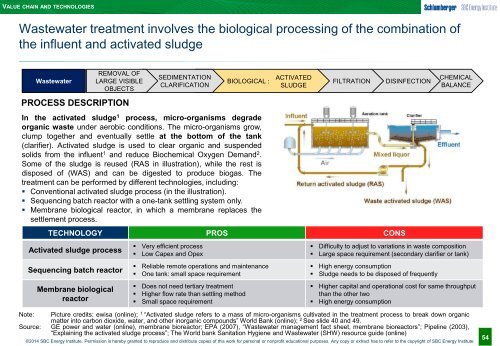

Wastewater treatment involves the biological processing of the combination of<br />

the influent and activated sludge<br />

Wastewater<br />

REMOVAL OF<br />

LARGE VISIBLE<br />

OBJECTS<br />

PROCESS DESCRIPTION<br />

SEDIMENTATION<br />

CLARIFICATION<br />

BIOLOGICAL :<br />

In the activated sludge 1 process, micro-organisms degrade<br />

organic waste under aerobic conditions. The micro-organisms grow,<br />

clump together and eventually settle at the bottom of the tank<br />

(clarifier). Activated sludge is used to clear organic and suspended<br />

solids from the influent 1 and reduce Biochemical Oxygen Demand 2 .<br />

Some of the sludge is reused (RAS in illustration), while the rest is<br />

disposed of (WAS) and can be digested to produce biogas. The<br />

treatment can be performed by different technologies, including:<br />

• Conventional activated sludge process (in the illustration).<br />

• Sequencing batch reactor with a one-tank settling system only.<br />

• Membrane biological reactor, in which a membrane replaces the<br />

settlement process.<br />

ACTIVATED<br />

SLUDGE<br />

FILTRATION<br />

TECHNOLOGY PROS CONS<br />

Activated sludge process<br />

Sequencing batch reactor<br />

Membrane biological<br />

reactor<br />

• Very efficient process<br />

• Low Capex and Opex<br />

• Reliable remote operations and maintenance<br />

• One tank: small space requirement<br />

• Does not need tertiary treatment<br />

• Higher flow rate than settling method<br />

• Small space requirement<br />

DISINFECTION<br />

CHEMICAL<br />

BALANCE<br />

• Difficulty to adjust to variations in waste composition<br />

• Large space requirement (secondary clarifier or tank)<br />

• High energy consumption<br />

• Sludge needs to be disposed of frequently<br />

• Higher capital and operational cost for same throughput<br />

than the other two<br />

• High energy consumption<br />

Note: Picture credits: ewisa (online); 1 “Activated sludge refers to a mass of micro-organisms cultivated in the treatment process to break down organic<br />

matter into carbon dioxide, water, and other inorganic compounds” World Bank (online); 2 See slide 40 and 49.<br />

Source: GE power and water (online), membrane bioreactor; EPA (2007), “Wastewater management fact sheet, membrane bioreactors”; Pipeline (2003),<br />

“Explaining the activated sludge process”; The World bank Sanitation Hygiene and Wastewater (SHW) resource guide (online)<br />

54<br />

©2014 SBC Energy Institute. Permission is hereby granted to reproduce and distribute copies of this work for personal or nonprofit educational purposes. Any copy or extract has to refer to the copyright of SBC Energy Institute<br />

54