Research & Development for Ceramic Tiles in the 21st ... - Infotile

Research & Development for Ceramic Tiles in the 21st ... - Infotile

Research & Development for Ceramic Tiles in the 21st ... - Infotile

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

TT market<br />

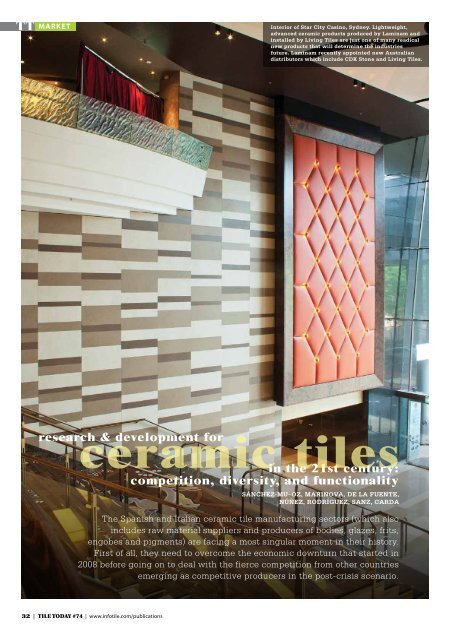

Interior of Star City Cas<strong>in</strong>o, Sydney. Lightweight,<br />

advanced ceramic products produced by Lam<strong>in</strong>am and<br />

<strong>in</strong>stalled by Liv<strong>in</strong>g <strong>Tiles</strong> are just one of many readical<br />

new products that will determ<strong>in</strong>e <strong>the</strong> <strong>in</strong>dustries<br />

future. Lam<strong>in</strong>am recently appo<strong>in</strong>ted new Australian<br />

distributors which <strong>in</strong>clude CDK Stone and Liv<strong>in</strong>g <strong>Tiles</strong>.<br />

ceramic tiles<br />

research & development <strong>for</strong><br />

<strong>in</strong> <strong>the</strong> <strong>21st</strong> century:<br />

competition, diversity, and functionality<br />

Sánchez-Mu–oz, Mar<strong>in</strong>ova, de la Fuente ,<br />

Núñez, Rodríguez, Sanz, Carda<br />

The Spanish and Italian ceramic tile manufactur<strong>in</strong>g sectors (which also<br />

<strong>in</strong>cludes raw material suppliers and producers of bodies, glazes, frits,<br />

engobes and pigments) are fac<strong>in</strong>g a most s<strong>in</strong>gular moment <strong>in</strong> <strong>the</strong>ir history.<br />

First of all, <strong>the</strong>y need to overcome <strong>the</strong> economic downturn that started <strong>in</strong><br />

2008 be<strong>for</strong>e go<strong>in</strong>g on to deal with <strong>the</strong> fierce competition from o<strong>the</strong>r countries<br />

emerg<strong>in</strong>g as competitive producers <strong>in</strong> <strong>the</strong> post-crisis scenario.<br />

32 | Tile Today #74 | www.<strong>in</strong>fotile.com/publications

nowadays, <strong>the</strong> sector has a<br />

more or less homogenous<br />

character <strong>in</strong> which <strong>the</strong><br />

different companies tend<br />

to produce very similar materials and<br />

<strong>the</strong>re<strong>for</strong>e compete <strong>for</strong> <strong>the</strong> same market.<br />

This paper proposes two alternative<br />

but compatible road maps that provide<br />

a possible future strategy to diversify<br />

<strong>the</strong> sector’s supply offer by plann<strong>in</strong>g<br />

its R&D+i to: i) achieve significant<br />

production cost sav<strong>in</strong>gs <strong>for</strong> standard<br />

ceramic products, and ii) to develop<br />

new specialised ceramic materials<br />

that meet <strong>the</strong> specific cultural and<br />

practical needs of each particular market<br />

environment. In <strong>the</strong> short term, <strong>the</strong><br />

ideal strategy would be to develop <strong>the</strong><br />

first alternative <strong>in</strong> order to produce<br />

ceramic bodies at significantly lower<br />

fir<strong>in</strong>g temperatures than at present,<br />

<strong>the</strong> immediate effect of which would<br />

be to reduce glaze thickness<br />

and <strong>the</strong> amount and size of<br />

pigment particles, <strong>the</strong>reby<br />

open<strong>in</strong>g <strong>the</strong> way to mass<br />

usage of th<strong>in</strong>-film decorat<strong>in</strong>g<br />

techniques (such as <strong>in</strong>k<br />

jets) and even laser techniques.<br />

In <strong>the</strong> medium and<br />

long term, <strong>the</strong> second alternative<br />

needs to be followed,<br />

to <strong>in</strong>crease <strong>the</strong> overall added<br />

value of ceramic tiles, which<br />

depends on <strong>the</strong> skills and <strong>in</strong>genuity<br />

of researchers and<br />

technicians alike to come up<br />

with a wide-rang<strong>in</strong>g diversity<br />

of ceramic products.<br />

<strong>in</strong>troduction<br />

When one analyses <strong>the</strong> relative significance<br />

of <strong>the</strong> role played by classic<br />

ceramic (CC) materials (traditional<br />

ceramics: floor and wall tiles, bricks,<br />

refractory materials, tableware and ceramic<br />

bathroom fitt<strong>in</strong>gs, etc. that basically<br />

attend primary human needs,<br />

especially home-build<strong>in</strong>g needs) and<br />

advanced ceramic (AC) materials (or<br />

technical ceramics, which apparently<br />

ma<strong>in</strong>ly refers to materials cover<strong>in</strong>g<br />

secondary human needs, e.g.<br />

<strong>in</strong> telecommunications), <strong>the</strong> world of<br />

ceramics seems to be “two headed”,<br />

“tw<strong>in</strong>-moded” and “asymmetrical”. It<br />

is tw<strong>in</strong>-headed <strong>in</strong> <strong>the</strong> sense that researchers<br />

tend to choose to devote<br />

<strong>the</strong>ir professional skills to ei<strong>the</strong>r CC<br />

or AC. It is “tw<strong>in</strong>-moded” <strong>in</strong> <strong>the</strong> sense<br />

that its manufactur<strong>in</strong>g companies, and<br />

even producer countries, also tend to<br />

opt <strong>for</strong> ei<strong>the</strong>r CC or AC. Never<strong>the</strong>less,<br />

<strong>the</strong> sector is also highly asymmetrical,<br />

<strong>in</strong> that <strong>the</strong> number of publications<br />

and concerted research devoted to CC<br />

is much lower than <strong>for</strong> AC, although<br />

turnover <strong>in</strong> economic terms is much<br />

higher worldwide <strong>for</strong> CC than <strong>for</strong> AC.<br />

Figure 1 shows turnover by sub-sectors<br />

throughout <strong>the</strong> world accord<strong>in</strong>g<br />

to a report by <strong>the</strong> Cookson company<br />

Floor and wall tiles<br />

Advanced ceramics<br />

Bricks adn roof tiles<br />

published <strong>in</strong> 2006, where AC can be<br />

seen to account <strong>for</strong> only 19 per cent.<br />

In Europe, a report by Ecorys, commissioned<br />

by <strong>the</strong> European Community,<br />

to study <strong>the</strong> competitiveness of <strong>the</strong><br />

European ceramics sector also revealed<br />

this same asymmetric character.<br />

Turnover <strong>in</strong> <strong>the</strong> sector <strong>in</strong> 2006 reached<br />

28,000 million euros, split as follows:<br />

floor and wall tiles 36 per cent, bricks<br />

and roof tiles 24 per cent, refractory<br />

materials 12 per cent, technical ceramics<br />

10 per cent, bathroom fitt<strong>in</strong>gs 8 per<br />

cent, and ceramic tableware 6 per cent<br />

(N.B. ~74 per cent is based on triaxial<br />

ceramics!!!). That same year, <strong>the</strong> sector<br />

had 221,000 employees, of which ~ 83<br />

per cent were dedicated to CC. France,<br />

Germany, Holland and <strong>the</strong> UK are <strong>the</strong><br />

ma<strong>in</strong> producers of AC, while Spa<strong>in</strong> and<br />

Italy head <strong>the</strong> list of CC producer countries.<br />

This asymmetry arises once aga<strong>in</strong><br />

Refractories<br />

Tableware<br />

Sanitary ware<br />

0 10 20 30 40 50 60 70<br />

BILLIONS OF DOLLARS<br />

Figure 1. Estimated world turnover <strong>in</strong> billion dollars <strong>for</strong> different<br />

ceramic materials, accord<strong>in</strong>g to a report published by Cookson’s<br />

<strong>in</strong> 2006.<br />

when world AC production figures are<br />

studied. The European Union provides<br />

only one tenth of total world supply, <strong>in</strong><br />

which <strong>the</strong> sum total of Japan and <strong>the</strong><br />

USA accounts <strong>for</strong> over 80 per cent 1 .<br />

Analysis of <strong>the</strong>se data, compar<strong>in</strong>g <strong>the</strong><br />

<strong>in</strong>tellectual ef<strong>for</strong>ts made <strong>in</strong> <strong>the</strong> ceramic<br />

<strong>in</strong>dustry with <strong>the</strong> social rewards<br />

reaped, reveals a paradox that defies<br />

<strong>in</strong>terpretation.<br />

This paper reflects on how R&D+i is<br />

applied to ceramic tiles (floor and wall<br />

F/W tiles) as well as to <strong>the</strong>ir <strong>in</strong>termediate<br />

products, i.e. spray-dried bodies,<br />

frits, glazes and pigments, and to<br />

its raw materials (<strong>in</strong>dustrial m<strong>in</strong>erals<br />

and chemical compounds), where <strong>the</strong>se<br />

<strong>in</strong>termediate products and raw materials<br />

are used <strong>in</strong> tile manufactur<strong>in</strong>g plants<br />

like assembly l<strong>in</strong>es. The leadership of<br />

<strong>the</strong> Spanish <strong>Ceramic</strong> Sector (SCS) <strong>in</strong><br />

tile production (which <strong>for</strong>ms a socioeconomic<br />

cluster situated ma<strong>in</strong>ly <strong>in</strong> <strong>the</strong><br />

Mediterranean coastal region) is based<br />

on a large number of factors. However,<br />

<strong>the</strong>re are three technical factors which<br />

af<strong>for</strong>d it a personality of its own, namely:<br />

i) <strong>the</strong> existence very close to <strong>the</strong> centres<br />

of production of top-quality red clay<br />

with which to make ceramic bodies, ii)<br />

<strong>the</strong> development of specific top-quality<br />

materials adapted <strong>for</strong> use with <strong>the</strong>se<br />

clays, and iii) <strong>the</strong> widespread support<br />

<strong>for</strong> <strong>the</strong> sector that comes from <strong>in</strong>stitutions<br />

with R&D+i capabilities <strong>in</strong> a<br />

wide range of collaboration projects<br />

that vary from <strong>the</strong> resolution of simple<br />

analytical issues to <strong>the</strong> development<br />

of specific materials and large scale<br />

projects entail<strong>in</strong>g changes <strong>in</strong> production<br />

technology. This paper looks at <strong>the</strong><br />

<strong>in</strong>ter-relationships between <strong>the</strong>se three<br />

factors <strong>in</strong> order to: i) review superficially<br />

<strong>the</strong> progress made to date and<br />

currently available <strong>in</strong>dustrial processes,<br />

ii) propose global measures that provide<br />

both economic and ecological or<br />

material cost sav<strong>in</strong>gs (susta<strong>in</strong>able development);<br />

and iii) establish possible<br />

ways to diversify production through<br />

research <strong>in</strong>to new materials and <strong>the</strong> use<br />

of new technologies applicable to <strong>the</strong><br />

sector (specialisation).<br />

Data: Cookson (2006)<br />

current ceramics<br />

<strong>Ceramic</strong> tile manufacturers<br />

are already familiar with <strong>the</strong><br />

results of <strong>the</strong> <strong>in</strong>-depth <strong>in</strong>novation<br />

process that took<br />

place <strong>in</strong> <strong>the</strong> 1980s, when dry<br />

route body process<strong>in</strong>g was<br />

replaced with wet route body<br />

process<strong>in</strong>g us<strong>in</strong>g clay spraydry<strong>in</strong>g<br />

technology. As a result<br />

of this change, a “ceramic tile<br />

revolution” took place, which<br />

completely changed <strong>the</strong> type<br />

of tiles manufactured prior to<br />

that date (see figure 2). The<br />

result was that traditional<br />

double-fired products almost<br />

disappeared to be replaced<br />

by porous s<strong>in</strong>gle fired tiles, while <strong>the</strong><br />

use of s<strong>in</strong>gle-fired floor<strong>in</strong>g (stoneware)<br />

also expanded significantly. Nowadays,<br />

red body tile output accounts <strong>for</strong> between<br />

70 and 80 per cent of <strong>the</strong> total,<br />

<strong>the</strong> rest be<strong>in</strong>g white body production<br />

(<strong>in</strong> which imported raw materials are<br />

used <strong>in</strong> most cases - between 60 and 85<br />

per cent of <strong>the</strong> total <strong>for</strong>mulation), while<br />

<strong>the</strong> production of porcela<strong>in</strong> stoneware<br />

is a m<strong>in</strong>ority (around 8.5 per cent). In<br />

o<strong>the</strong>r words, <strong>the</strong> current situation is still<br />

<strong>the</strong> result of <strong>the</strong> <strong>in</strong>heritance of <strong>the</strong> a<strong>for</strong>ementioned<br />

change <strong>in</strong> technology, based<br />

ma<strong>in</strong>ly on <strong>the</strong> use of local raw materials.<br />

It should be mentioned that remarkable<br />

ef<strong>for</strong>ts have been made to use national<br />

raw materials <strong>in</strong> white body <strong>for</strong>mulations<br />

<strong>for</strong> stoneware and porcela<strong>in</strong> tile 2-<br />

6 , where <strong>the</strong>ir <strong>in</strong>corporation <strong>in</strong>to white<br />

bodies has been enhanced by purify<strong>in</strong>g<br />

local clay us<strong>in</strong>g magnetic separation.<br />

However, <strong>the</strong> current trend shows<br />

that <strong>the</strong> stoneware/porcela<strong>in</strong> tile or<br />

white body/red body tandems are<br />

tend<strong>in</strong>g to disappear as synonyms of<br />

differ<strong>in</strong>g quality, and numerous bodies<br />

have arisen with ‘hybrid’ <strong>for</strong>mulations<br />

(<strong>in</strong>clud<strong>in</strong>g classic compositions,<br />

i.e. mixtures of red clays <strong>for</strong> stoneware<br />

and white clay-kaol<strong>in</strong> with feldspars<br />

www.<strong>in</strong>fotile.com/publications | Tile Today #74 | 33

TT market<br />

<strong>for</strong> porcela<strong>in</strong>, <strong>in</strong> some cases by add<strong>in</strong>g<br />

low proportions of carbonates) which<br />

have led to greyish and reddish hues<br />

with open porosity rates of less than<br />

0.5 per cent and mechanical properties<br />

comparable to white porcela<strong>in</strong> levels.<br />

However, traditional red body compositions<br />

(mixtures of flux and plastic clays<br />

with o<strong>the</strong>r compact<strong>in</strong>g and refractory<br />

materials which, when fired at 1140°C,<br />

provide an open porosity of 3-4 per cent<br />

and ~ 7 per cent of l<strong>in</strong>ear shr<strong>in</strong>kage) is<br />

still <strong>the</strong> dom<strong>in</strong>ant material and <strong>the</strong>re<strong>for</strong>e<br />

<strong>the</strong> one on which future research<br />

ef<strong>for</strong>ts should be based.<br />

<strong>Ceramic</strong> decoration is also undergo<strong>in</strong>g<br />

a significant transition from traditional<br />

(albeit modified) screen pr<strong>in</strong>t<strong>in</strong>g<br />

techniques us<strong>in</strong>g pigments with particle<br />

sizes of around 5 μm to o<strong>the</strong>r<br />

techniques based on <strong>in</strong>k technologies<br />

and pr<strong>in</strong>ters with different k<strong>in</strong>ds of<br />

heads, <strong>for</strong> which <strong>the</strong> ideal particle size<br />

is under 1 μm. This requires improved<br />

gr<strong>in</strong>d<strong>in</strong>g of <strong>the</strong> material on its exit<br />

from <strong>the</strong> kiln (once specific gr<strong>in</strong>d<strong>in</strong>g<br />

processes have been researched) and<br />

more stable (or less soluble) pigments<br />

at fir<strong>in</strong>g temperatures, a target which<br />

entails <strong>the</strong> greatest difficulty, especially<br />

to decorate porcela<strong>in</strong> tiles (Tc ~<br />

1170°C). Alternative manufactur<strong>in</strong>g<br />

procedures have also been researched<br />

<strong>for</strong> pigments that would produce <strong>the</strong><br />

required gra<strong>in</strong> size directly; such as<br />

<strong>the</strong> ‘sol-gel’ technique 7 , and <strong>for</strong> <strong>in</strong>ks<br />

conta<strong>in</strong><strong>in</strong>g dissolved chromophores.<br />

Ano<strong>the</strong>r directly related case is that of<br />

metallic glazes with significantly different<br />

decorat<strong>in</strong>g capabilities.<br />

competitive ceramics<br />

S<strong>in</strong>ce 1982, <strong>the</strong> sector has carried out<br />

widespread <strong>in</strong>vestment <strong>in</strong> plant and<br />

mach<strong>in</strong>ery, materials and human resources,<br />

<strong>in</strong> <strong>the</strong> same way as its counterparts<br />

<strong>in</strong> compet<strong>in</strong>g European countries<br />

or <strong>in</strong> o<strong>the</strong>r parts of <strong>the</strong> world s<strong>in</strong>ce <strong>the</strong><br />

1990s. These new producer countries<br />

have benefited from <strong>in</strong>herent advantages<br />

(whe<strong>the</strong>r <strong>in</strong> <strong>the</strong> use of local raw<br />

MANUFACTURING COSTS OF CERAMIC TILES<br />

Raw<br />

materials<br />

Glazes and<br />

colours<br />

S<strong>in</strong>gle fir<strong>in</strong>g<br />

(red body)<br />

S<strong>in</strong>gle fir<strong>in</strong>g<br />

(white body)<br />

Glazed stoneware<br />

Unglazed stoneware<br />

Electric<br />

energy<br />

Thermal<br />

energy<br />

(I)<br />

DRY<br />

PROCESSING<br />

MILLING OF<br />

RED BODIES<br />

PRESSING<br />

(small size)<br />

DECORATION<br />

(traditional methods)<br />

FIRING<br />

(about 1100°C)<br />

(slow cycles)<br />

present…<br />

”<br />

materials, labour costs or variable restrictions<br />

<strong>in</strong> environmental matters),<br />

although <strong>the</strong>y use identical production<br />

technologies, ma<strong>in</strong>ly of European orig<strong>in</strong>.<br />

There<strong>for</strong>e a change is required which<br />

will allow currently available technologies<br />

and materials to be used to produce<br />

ceramic tiles at a significantly lower<br />

overall cost than at present, regardless<br />

Figure 3. Diagram of approximate cost split <strong>for</strong> different types of ceramic tile,<br />

where, apart from employment, <strong>the</strong> greatest costs relate to raw materials, glazes and<br />

colours, which <strong>in</strong>dicates where cost sav<strong>in</strong>g strategies should be focused.<br />

1982 (II) ~2000<br />

WET<br />

PROCESSING<br />

MILLING OF<br />

(red and white bodies)<br />

(FLOOR/WALL TILES)<br />

SPRAY DRYING<br />

PRESSING<br />

(large sizes)<br />

DECORATION<br />

(bell waterfall,<br />

rollers, grits)<br />

FIRING<br />

1140°C–1220°C<br />

(short cycles)<br />

(III)<br />

FUNCTIONAL<br />

TILES<br />

MILLING OF<br />

(highly variable bodies)<br />

SPRAY DRYING<br />

PRESSING<br />

(highly variable<br />

sizes and shapes)<br />

b<br />

a<br />

FUNCTIONALIZATION<br />

(traditional, <strong>in</strong>kjet, laser)<br />

FIRING<br />

(highly variable<br />

cycles)<br />

Figure 2. Diagram of <strong>the</strong> technology change from dry route to wet route production <strong>in</strong><br />

1982 and <strong>the</strong> result<strong>in</strong>g upgrad<strong>in</strong>g of <strong>the</strong> type of ceramic tile production <strong>in</strong> Spa<strong>in</strong>.<br />

“<br />

… a change is required<br />

which will allow currently<br />

available technologies<br />

and materials to be used<br />

to produce ceramic tiles<br />

at a significantly lower<br />

overall cost than at<br />

Capital<br />

goods<br />

Production<br />

Labour<br />

0 10 20 30 40 50 60<br />

EUROS PER METRE SQUARE<br />

Source: G. Olivieri e Associati (<strong>Ceramic</strong>a In<strong>for</strong>mazione)<br />

of <strong>the</strong> <strong>in</strong>crease or reduction <strong>in</strong> <strong>the</strong> cost<br />

of <strong>in</strong>termediate products (see diagram<br />

<strong>in</strong> figure 3). The authors consider that<br />

such a change should commence with<br />

new ceramic bodies <strong>for</strong> fir<strong>in</strong>g at lower<br />

maximum temperatures (T c<br />

max<br />

), while<br />

still guarantee<strong>in</strong>g improved mechanical<br />

properties and current open porosity<br />

values (as obta<strong>in</strong>ed with water absorption<br />

trials). The technical existence of<br />

such a material would af<strong>for</strong>d numerous<br />

advantages, apart from energy cost sav<strong>in</strong>gs<br />

and reduced CO 2<br />

emissions, such<br />

as thickness reductions that would require<br />

fewer raw materials and enhance<br />

oxidisation of <strong>the</strong> organic matter to prevent<br />

‘black core’ issues.<br />

In <strong>the</strong> case of red bodies, lower fir<strong>in</strong>g<br />

temperatures would enable reduced<br />

opacify<strong>in</strong>g glaze thickness, <strong>the</strong>reby reduc<strong>in</strong>g<br />

<strong>the</strong> use of costly raw materials,<br />

whose market price fluctuates greatly<br />

(zircon). Likewise, this change would<br />

enable <strong>the</strong> use of smaller amounts of<br />

pigment (so competition would be<br />

centred on design) or pigments with<br />

smaller particle sizes (such as those<br />

required <strong>for</strong> <strong>in</strong>k-jet techniques) or less<br />

stable pigments that are more reactive<br />

with <strong>the</strong> flux materials at maximum fir<strong>in</strong>g<br />

temperature to <strong>in</strong>crease <strong>the</strong> colour<br />

range <strong>in</strong> <strong>the</strong> end product. Obviously,<br />

such a change calls <strong>for</strong> <strong>the</strong> development<br />

of new, low-temperature glazes<br />

that need to adapt to <strong>the</strong> new bodies’<br />

l<strong>in</strong>ear shr<strong>in</strong>kage and heat expansion/<br />

shr<strong>in</strong>kage values. In this respect, it<br />

should be remembered that tiles are<br />

used to cover surfaces and that any<br />

reduction <strong>in</strong> maximum fir<strong>in</strong>g temperature<br />

associated with reduced l<strong>in</strong>ear<br />

shr<strong>in</strong>kage would be most welcome,<br />

as that would enable production of an<br />

even wider range of sizes. Very similar<br />

benefits could be obta<strong>in</strong>ed when<br />

us<strong>in</strong>g white bodies. It is important<br />

to highlight <strong>the</strong> fact if <strong>the</strong> thickness<br />

of <strong>the</strong> cover<strong>in</strong>g layer can be reduced,<br />

b<br />

34 | Tile Today #74 | www.<strong>in</strong>fotile.com/publications

TT market<br />

more advanced (and relatively more<br />

costly) materials can be employed,<br />

which would <strong>the</strong>n extend <strong>the</strong> number<br />

of decorat<strong>in</strong>g techniques available <strong>for</strong><br />

use, such as th<strong>in</strong>-film pr<strong>in</strong>t<strong>in</strong>g or laser<strong>in</strong>duced<br />

crystallisation techniques 8<br />

and o<strong>the</strong>r such technologies 9-10 – see<br />

diagram summary <strong>in</strong> figure 4.<br />

Consequently, as maximum fir<strong>in</strong>g<br />

temperature (T c max ) comes down, <strong>the</strong><br />

overall competitive and cost-sav<strong>in</strong>g<br />

benefits would <strong>in</strong>crease <strong>in</strong> <strong>the</strong> same<br />

direction, like a positive feedback process.<br />

Never<strong>the</strong>less, from <strong>the</strong> technical<br />

po<strong>in</strong>t of view, reduc<strong>in</strong>g T c<br />

max<br />

<strong>in</strong> red<br />

bodies is not <strong>the</strong> same as reduc<strong>in</strong>g it <strong>in</strong><br />

white bodies, as s<strong>in</strong>ter<strong>in</strong>g <strong>in</strong> red bodies<br />

is ma<strong>in</strong>ly l<strong>in</strong>ked to surface phenomena<br />

affect<strong>in</strong>g compacted particles, while<br />

<strong>in</strong> <strong>the</strong> latter case, s<strong>in</strong>ter<strong>in</strong>g is a liquid<br />

stage that occurs when feldspars and<br />

o<strong>the</strong>r fluxes melt. There<strong>for</strong>e, re-<strong>for</strong>mulation<br />

<strong>in</strong> one case may be very different<br />

from <strong>the</strong> o<strong>the</strong>r. On <strong>the</strong> o<strong>the</strong>r hand, T c<br />

max<br />

<strong>in</strong> wall tiles could be reduced by us<strong>in</strong>g<br />

carbonates with lower decomposition<br />

temperatures. Obviously, under no circumstances<br />

should <strong>in</strong>creased fusibility<br />

be achieved <strong>in</strong> bodies by sacrific<strong>in</strong>g<br />

dimensional stability or fir<strong>in</strong>g heat<br />

ranges. Thus, low T c<br />

max<br />

bodies depend<br />

on <strong>the</strong> development of advanced fluxes<br />

and high-density spray powders, <strong>for</strong><br />

which <strong>the</strong> role of particle surface stress<br />

needs to be studied. In conclusion, to<br />

be competitive, ceramic products need<br />

to blend sav<strong>in</strong>gs on materials (many of<br />

which are now scarce) with reduced<br />

fuel and energy costs, <strong>the</strong>reby reduc<strong>in</strong>g<br />

emissions of pollutant gases – all of<br />

<strong>the</strong>se be<strong>in</strong>g ideas compatible with <strong>the</strong><br />

concept of “susta<strong>in</strong>able development”.<br />

smart ceramics<br />

Recent history shows that any plann<strong>in</strong>g<br />

carried out <strong>in</strong> <strong>the</strong> <strong>in</strong>dustrial world needs<br />

to take certa<strong>in</strong> issues <strong>in</strong>to account,<br />

such as energy (l<strong>in</strong>ked to raw materials<br />

from well-def<strong>in</strong>ed geographical locations)<br />

and super-population (<strong>the</strong>re<strong>for</strong>e,<br />

‘mega markets’ especially <strong>in</strong> Asia), and<br />

consequently to consider <strong>the</strong>m from <strong>the</strong><br />

viewpo<strong>in</strong>t of susta<strong>in</strong>able development.<br />

Companies manufactur<strong>in</strong>g CC cannot<br />

suddenly switch to produc<strong>in</strong>g advanced<br />

ceramics and compete <strong>in</strong> a market that<br />

is alien to <strong>the</strong>m and has very different<br />

characteristics 11 . They can, however,<br />

echo <strong>the</strong> social demands that such<br />

materials cover <strong>in</strong> order to gradually<br />

<strong>in</strong>corporate <strong>the</strong>m <strong>in</strong>to <strong>the</strong>ir products.<br />

In short, it is a question of transferr<strong>in</strong>g<br />

technological <strong>in</strong>novation to <strong>the</strong> ‘smart<br />

home’ – see diagram <strong>in</strong> figure 6 –<br />

where a house can be valued <strong>in</strong> terms<br />

of new capabilities and surfaces are not<br />

simply decorative items but ra<strong>the</strong>r active<br />

elements with specific functions.<br />

Fur<strong>the</strong>rmore, special attention can be<br />

given to <strong>the</strong> economic growth <strong>in</strong> different<br />

geographical, climatic and cultural<br />

areas of <strong>the</strong> planet, where <strong>in</strong>habitants’<br />

needs and priorities are, <strong>in</strong> many cases,<br />

identical to those of Western society<br />

and who are emerg<strong>in</strong>g as potential<br />

consumer markets if <strong>the</strong>ir expectations<br />

are met. The orig<strong>in</strong> of this new trend<br />

<strong>in</strong> tile functionality arose more or less<br />

at <strong>the</strong> turn of <strong>the</strong> century (see diagram<br />

<strong>in</strong> figure 2). With this premise, three<br />

fields can be dist<strong>in</strong>guished as <strong>the</strong> areas<br />

where smart and multi-purpose ceramics<br />

can ga<strong>in</strong> ground if <strong>the</strong> two ends of<br />

positive feedback between demand<br />

and practicality are made to meet 11-13 .<br />

This paper dist<strong>in</strong>guishes three groups:<br />

a) ceramics <strong>for</strong> healthcare; b) ceramics<br />

<strong>for</strong> energy; and c) ceramics <strong>for</strong> com<strong>for</strong>t.<br />

In such a context, outdoor products (<strong>for</strong><br />

façades and roofs) should cease to be<br />

regarded as separate items from <strong>in</strong>door<br />

articles.<br />

ceramics <strong>for</strong> healthcare<br />

This group <strong>in</strong>cludes <strong>in</strong>novations relat<strong>in</strong>g<br />

to health & safety, personal hygiene<br />

and quality of air. With regard to<br />

<strong>the</strong> first matter, a historical look at <strong>the</strong><br />

automobile <strong>in</strong>dustry shows that <strong>in</strong>vestment<br />

<strong>in</strong> health and safety has always<br />

had a social and market component<br />

which guarantees success. There exist<br />

numerous environments <strong>in</strong> which<br />

health and safety can be <strong>in</strong>stilled <strong>in</strong>to<br />

ceramic til<strong>in</strong>g, <strong>for</strong> example, <strong>in</strong> centres<br />

us<strong>in</strong>g ionis<strong>in</strong>g radiation such as hospitals,<br />

radio<strong>the</strong>rapy centres and research<br />

<strong>in</strong>stitutes. In <strong>the</strong>se cases, radiationproof<br />

wall plat<strong>in</strong>g could be supplied<br />

us<strong>in</strong>g ceramics with high density crystall<strong>in</strong>e<br />

phases with heavy, radiationpassivat<strong>in</strong>g<br />

chemicals.<br />

The questions of personal hygiene<br />

and air quality relate to <strong>the</strong> photocatalytic<br />

effect 14 of bactericide and<br />

air clean<strong>in</strong>g products. The first question<br />

stems from biocide materials that<br />

<strong>in</strong>itially used Ag particles and later<br />

Ag+TiO 2<br />

particles and is already be<strong>in</strong>g<br />

explored by several companies. The<br />

COMPETITIVE CERAMICS<br />

The best solution is based on sav<strong>in</strong>gs <strong>in</strong> materials (scarce) and energy, us<strong>in</strong>g<br />

new <strong>for</strong>mulas and adapt<strong>in</strong>g process<strong>in</strong>g (susta<strong>in</strong>able development)<br />

1. Develop<strong>in</strong>g low-temperature ceramic bodies (T

TT market<br />

Early generation photovoltaic<br />

energy is ma<strong>in</strong>ly<br />

based on <strong>the</strong> production of<br />

monocrystal or polycrystall<strong>in</strong>e<br />

silicon chips <strong>in</strong> cells to<br />

<strong>for</strong>m panels which, <strong>in</strong> turn,<br />

are fitted as totally <strong>for</strong>eign<br />

appendixes on build<strong>in</strong>gs.<br />

In this case, no ceramic or<br />

glass substrate is required<br />

<strong>for</strong> <strong>the</strong>se devices to work.<br />

However, second generation<br />

photovoltaic energy<br />

calls <strong>for</strong> sav<strong>in</strong>gs <strong>in</strong> raw materials<br />

(semiconductors),<br />

which at present means sacrific<strong>in</strong>g<br />

energy efficiency,<br />

and uses th<strong>in</strong> layers of different<br />

semiconductors <strong>in</strong> tandem<br />

(<strong>for</strong> selective absorption<br />

of different wavelengths) on<br />

glass, ceramic or even plastic<br />

substrates, giv<strong>in</strong>g rise to<br />

a technology now known as BiPV (built<strong>in</strong><br />

photovoltaics) 16 , i.e. <strong>the</strong>se devices<br />

<strong>for</strong>m an <strong>in</strong>tegral part of <strong>the</strong> build<strong>in</strong>g.<br />

In this generation, <strong>the</strong> substrate and<br />

<strong>the</strong> th<strong>in</strong> multilayer device are not two<br />

<strong>in</strong>dependent entities but ra<strong>the</strong>r build<strong>in</strong>g<br />

efficiency depends on <strong>the</strong> degree<br />

to which technically <strong>the</strong>y can be coupled<br />

toge<strong>the</strong>r, so <strong>the</strong>ir glass and/or ceramic<br />

character is essential. Although<br />

at present glass substrate panels have<br />

been much more widely implemented<br />

than ceramic-based panels, <strong>the</strong> latter<br />

possibly af<strong>for</strong>d greater <strong>in</strong>stallation opportunities.<br />

Consequently, certa<strong>in</strong> confidentiality<br />

exists regard<strong>in</strong>g <strong>the</strong> nature<br />

of <strong>the</strong>se ceramic bases when results<br />

are presented by specialist companies<br />

from <strong>the</strong> sector 17-18 ], although data is<br />

available about devices with mullite 19<br />

and zircon 20 substrates, among o<strong>the</strong>rs.<br />

F<strong>in</strong>ally, it should be mentioned that a<br />

third generation is currently be<strong>in</strong>g developed,<br />

although still at <strong>the</strong> research<br />

level, <strong>in</strong> which ceramic and glass materials<br />

may become an <strong>in</strong>tegral part of<br />

all <strong>the</strong> components <strong>in</strong> <strong>the</strong>se devices 21 .<br />

With regard to ceramics <strong>for</strong> energysav<strong>in</strong>g,<br />

an analysis of<br />

heat ga<strong>in</strong>s and losses<br />

<strong>in</strong> build<strong>in</strong>gs (efficiency)<br />

needs to be made from<br />

a climatic po<strong>in</strong>t of view,<br />

given that this affects<br />

potential markets with<br />

very different requirements.<br />

There<strong>for</strong>e, a<br />

first dist<strong>in</strong>ction should<br />

be made between two<br />

contrast<strong>in</strong>g situations:<br />

“daylight architecture”<br />

<strong>for</strong> cold climates and<br />

“sunlight architecture”<br />

<strong>for</strong> warm climates. In <strong>the</strong><br />

<strong>for</strong>mer case, emphasis<br />

is on <strong>the</strong> use of ceramic<br />

materials to absorb solar<br />

heat energy (dur<strong>in</strong>g<br />

<strong>the</strong> day), which is <strong>the</strong>n<br />

slowly released dur<strong>in</strong>g<br />

-<br />

O 2<br />

REDUCTION<br />

-<br />

OH<br />

REDUCTION<br />

H 2 O<br />

<strong>the</strong> night, while <strong>in</strong> <strong>the</strong> latter case, <strong>the</strong>se<br />

materials should not accumulate heat<br />

but ra<strong>the</strong>r enable night time ventilation<br />

of <strong>the</strong> build<strong>in</strong>g. In this sense, studies<br />

have been carried out on <strong>the</strong> near <strong>in</strong>frared<br />

reflectance of different <strong>in</strong>organic<br />

pigments 22 to obta<strong>in</strong> ceramics that help<br />

to prevent <strong>in</strong>door temperatures from<br />

ris<strong>in</strong>g, <strong>the</strong>reby provid<strong>in</strong>g energy sav<strong>in</strong>gs<br />

by reduc<strong>in</strong>g <strong>the</strong> time that air condition<strong>in</strong>g<br />

units need to be used.<br />

ceramics <strong>for</strong> com<strong>for</strong>t<br />

TiO 2<br />

(anatase)<br />

C.B.<br />

- “electron” e-<br />

O 2<br />

VB<br />

+ “hole” h-<br />

Figure 5. Simplified diagram of photocatalytic effect on TiO 2<br />

(anatase) surfaces. When ultraviolet radiation strikes <strong>the</strong> Ti-O<br />

b<strong>in</strong>d<strong>in</strong>g electrons, electronic transitions take place from <strong>the</strong><br />

valence band (VB) to <strong>the</strong> conduction band (CB), <strong>the</strong>reby enabl<strong>in</strong>g<br />

oxidisation and reduction reactions with <strong>the</strong> decomposition of<br />

certa<strong>in</strong> organic molecules <strong>in</strong> <strong>the</strong> atmosphere, NO x<br />

, etc.<br />

HEALTHCARE<br />

Safety<br />

Health<br />

Air quality<br />

(photocatalytic effect)<br />

Given that <strong>in</strong> many <strong>in</strong>dustrialised<br />

countries, we spend a large part of our<br />

time <strong>in</strong>doors (up to 90 per cent <strong>in</strong> <strong>the</strong><br />

so-called first world), it is easy to understand<br />

<strong>the</strong> importance of com<strong>for</strong>t,<br />

which <strong>in</strong> many cases is associated<br />

with productivity. This concept should<br />

be <strong>in</strong>terpreted <strong>in</strong> terms of:<br />

i) Noise and vibration: <strong>the</strong> importance<br />

and need <strong>for</strong> <strong>in</strong>sulation and<br />

especially noise <strong>in</strong>sulation and buffer<strong>in</strong>g<br />

is not limited to large-scale<br />

sports <strong>in</strong>stallations and swimm<strong>in</strong>g<br />

pools. These questions are of great<br />

importance <strong>in</strong> many <strong>in</strong>stances <strong>in</strong><br />

SMART CERAMICS<br />

ENERGY<br />

Production<br />

(photovoltaic,<br />

solar heat<strong>in</strong>g)<br />

Sav<strong>in</strong>g (climates)<br />

COMFORT<br />

Noise and vibrations<br />

Humidity<br />

Installation control<br />

Cultural diversity<br />

Figure 6. Diagram of <strong>the</strong> types of smart ceramics, separated <strong>in</strong>to three<br />

types of function: healthcare, energy and com<strong>for</strong>t.<br />

build<strong>in</strong>gs that have already<br />

been erected, especially <strong>for</strong><br />

economic solutions that do not<br />

entail large losses of space.<br />

ii) Humidity: humidity control<br />

by means of ceramic wall<br />

cover<strong>in</strong>gs is an <strong>in</strong>novative<br />

idea which is already be<strong>in</strong>g<br />

exploited by manufactur<strong>in</strong>g<br />

companies and consists<br />

of materials made of special<br />

bodies which absorb or emit<br />

water depend<strong>in</strong>g on <strong>the</strong> ambient<br />

moisture level.<br />

iii) Installation control: this<br />

is a field that has already been<br />

<strong>in</strong>itiated by certa<strong>in</strong> Spanish<br />

ceramic companies 23 and is<br />

based on <strong>the</strong> concept of “home<br />

automation”, which consists<br />

of <strong>in</strong>tegrat<strong>in</strong>g <strong>in</strong><strong>for</strong>mation<br />

technologies and telecommunications<br />

<strong>in</strong> <strong>the</strong> home. In this<br />

regard, automatic control systems<br />

have been developed <strong>for</strong> all <strong>the</strong> <strong>in</strong>stallations<br />

<strong>in</strong> a house, <strong>in</strong>clud<strong>in</strong>g<br />

tiles (by means of sensors and WiFi<br />

devices) which have <strong>the</strong> follow<strong>in</strong>g<br />

advantages: greater strength than<br />

current (plastic) devices, easier to<br />

clean, possibility of <strong>in</strong>corporat<strong>in</strong>g<br />

Braille codes, and versatility.<br />

iv) Cultural diversity: partially or<br />

totally subjective factors, preferred<br />

designs and/or particular<br />

beliefs. One particular aspect such<br />

as colour does not have <strong>the</strong> same<br />

mean<strong>in</strong>g or <strong>in</strong>fluence <strong>in</strong> <strong>the</strong> East<br />

as <strong>in</strong> <strong>the</strong> Western world. Although<br />

<strong>in</strong> Western Europe, it is possible<br />

that a sufficient number of houses<br />

already exist to cover <strong>the</strong> needs of<br />

<strong>the</strong> next generation, <strong>the</strong>re are numerous<br />

emerg<strong>in</strong>g markets where<br />

<strong>in</strong>dividual wooden build<strong>in</strong>gs are<br />

go<strong>in</strong>g to be replaced and/or extended<br />

by constructions where<br />

ceramics and glass will play a<br />

more prom<strong>in</strong>ent role. It should be<br />

noted <strong>in</strong> this respect that com<strong>for</strong>t<br />

is l<strong>in</strong>ked to daily issues -<strong>the</strong> natural<br />

stage <strong>for</strong> ceramics –<br />

which <strong>for</strong>tunately do not<br />

have <strong>the</strong> same relevance<br />

nor refer to <strong>the</strong> same daily<br />

rout<strong>in</strong>es <strong>in</strong> all cultures.<br />

conclusions<br />

Nowadays, <strong>the</strong> Spanish<br />

ceramic tile manufactur<strong>in</strong>g<br />

sector is highly homogenous<br />

with regard to<br />

<strong>the</strong> products it markets,<br />

<strong>the</strong> prom<strong>in</strong>ent features of<br />

which are surface decoration<br />

(glazes and pigments)<br />

and <strong>the</strong> colour<br />

of <strong>the</strong> fir<strong>in</strong>g body (<strong>the</strong><br />

substrate), when tiles<br />

with identical mechanical<br />

properties are compared.<br />

From a technical<br />

38 | Tile Today #74 | www.<strong>in</strong>fotile.com/publications

po<strong>in</strong>t of view, this is <strong>the</strong> result of <strong>the</strong><br />

transition from dry route to wet route<br />

technology dur<strong>in</strong>g <strong>the</strong> 1980s, as well<br />

as of <strong>the</strong> abundance of quality raw materials<br />

(clays) <strong>in</strong> <strong>the</strong> area surround<strong>in</strong>g<br />

<strong>the</strong>se production centres, and of <strong>the</strong><br />

R&D+i ef<strong>for</strong>ts made by its numerous<br />

ceramic technicians. With <strong>the</strong> turn of<br />

<strong>the</strong> century, competition from emerg<strong>in</strong>g<br />

countries has become evident and<br />

<strong>the</strong> onset of <strong>the</strong> present economic crisis<br />

may be an <strong>in</strong>dication that <strong>the</strong> current<br />

<strong>in</strong>dustrial model <strong>in</strong> countries such<br />

as Spa<strong>in</strong> is becom<strong>in</strong>g obsolete. In view<br />

of such a situation, this paper proposes<br />

one possible route to be followed <strong>in</strong> <strong>the</strong><br />

short term (competitive ceramics) and<br />

ano<strong>the</strong>r which can be taken <strong>in</strong> <strong>the</strong> medium<br />

and long-term (smart ceramics).<br />

ACKNOWLEDGEMENTS<br />

The authors would like to extend <strong>the</strong>ir<br />

gratitude to Tierra Atomizada SA, Invest<br />

Plasma SL and Microcolors SA, all companies<br />

located <strong>in</strong> Castellón, Spa<strong>in</strong> <strong>for</strong><br />

<strong>the</strong> <strong>in</strong>valuable collaboration and scientific<br />

discussion held with <strong>the</strong>ir technical<br />

teams, and to <strong>the</strong> Dávalos Fletcher<br />

Foundation, also <strong>in</strong> Castellón, <strong>for</strong> its f<strong>in</strong>ancial<br />

support. This modified paper<br />

appeared at Qualicer 2010.<br />

AUTHORS:<br />

L. Sánchez-Muñoz 1 , I.T. Mar<strong>in</strong>ova 2 ,<br />

G.F. de la Fuente 3 , I. Núñez 2 , M.A.<br />

Rodríguez 1 , J. Sanz 4 , J.B. Carda 2<br />

(1) Instituto de Cerámica y Vidrio, CSIC (Madrid,<br />

Spa<strong>in</strong>) (2) Inorganic and Organic Chemistry Dept.,<br />

Universidad Jaume I (Castellón, Spa<strong>in</strong>) (3) Instituto<br />

de Ciencia de Materiales de Aragón, CSIC, (Zaragoza,<br />

Spa<strong>in</strong>) (4) Instituto de Ciencia de Materiales de<br />

Madrid, CSIC (Madrid, Spa<strong>in</strong>)<br />

REFERENCES<br />

1 FWC Sector Competitiveness Studies –<br />

Competitiveness of <strong>the</strong> <strong>Ceramic</strong>s Sec tor.<br />

With<strong>in</strong> <strong>the</strong> Framework Contracto f Pectoral<br />

Competititveness Studies – ENTR/06/054. F<strong>in</strong>al<br />

report, 13 October 2008. ECORYS.<br />

2 Sánchez-Muñoz L, Nebot-D’az I, Carda JB, Tuduri<br />

F, Gracia A, Cerisuelo E (2001) Obtención de<br />

soportes cerámicos de baja porosidad a partir<br />

de materias primas nacionales. Ceram. Inf. 272:<br />

48-54.<br />

3 Sánchez-Muñoz L, Carda Castelló JB. Materias<br />

primas y aditivos cerámicos. Enciclopedia<br />

Cerámica. Tomo 2.1. cap. I a VII (2002) y Tomo 2.2.<br />

cap VIII a XVI (2003). Ed: Faenza Editrice Ibérica<br />

S.L. Castellón.<br />

4 Sánchez-Muñoz L, Cava S, Paskocimas CA,<br />

Cerisuelo E, Longo E, Carda Castelló JB (2002).<br />

Influ ncia da composi ao das matérias-primas no<br />

processo de gresifica ao de revestimentos cerâmicos.<br />

Cerâmica (Revista de la Asociación Brasileña<br />

de Cerámica) 48:137-145.<br />

5 Sánchez-Muñoz L, Cava S, Paskocimas CA,<br />

Cerisuelo E, Longo E, Carda Castelló JB (2002)<br />

Modelamento do processo de gresifica ao de<br />

massa cerâmicas de revestimento. Cerâmica<br />

(Revista de la Asociación Brasileña de Cerámica)<br />

48: 217-222.<br />

6 Sánchez-Muñoz L, Cava S, Paskocimas CA,<br />

Cerisuelo E, Longo E, Carda Castelló JB (2002)<br />

Sele ao de matérias-primas no desenvolvimento<br />

de <strong>for</strong>mula oes de massas cerâmicas. Cerâmica<br />

(Revista de la Asociación Brasileña de Cerámica)<br />

48: 108-113.<br />

7 Atk<strong>in</strong>son A, Doorbar J, Hudd A, Segal DL, White<br />

PJ (1997) Cont<strong>in</strong>uous <strong>in</strong>k-jet pr<strong>in</strong>t<strong>in</strong>g us<strong>in</strong>g solgel<br />

“ceramic” <strong>in</strong>ks. J Sol-Gel Sci. Technol. 8:<br />

1093-1097.<br />

8 Lennikov VV, Pedra JM, Gomez JJ, de la Fuente<br />

GF, Carda JB (2007) In situ syn<strong>the</strong>sis of composite<br />

MTiO 3 -Al 2 O 3 coat<strong>in</strong>gs via laser zone melt<strong>in</strong>g.<br />

Solid State Sciences 9: 404-409.<br />

9 Larrea A, de la Fuente GF, Mer<strong>in</strong>o RI, Orera VM<br />

(2002) ZrO 2 -Al 2 O 3 eutectic plates produced by<br />

laser zone melt<strong>in</strong>g. Journal of <strong>the</strong> European<br />

<strong>Ceramic</strong> Society 22: 191- 198.<br />

10 Bakali J, Fortanet E, de la Fuente X, Lahoz<br />

R, Estepa LC, Peris G, Mar<strong>in</strong>ova I, Pavlov R,<br />

Pedra JM, Carda JB (2004) Structural and<br />

Microstructural Characterisation of Refractory<br />

Oxides Syn<strong>the</strong>sised by Laser. Key Eng. Mater.<br />

264-268: 317-320.<br />

11 Ohmura A, Ouchi N, Morisaki S, Watanabe C<br />

(2003): Funcionality development as a survival<br />

strategy <strong>for</strong> f<strong>in</strong>e ceramics. Technovation 23:<br />

833-842.<br />

12 Moreno Berto AV (2006) <strong>Ceramic</strong> tiles: above and<br />

beyond traditional applications. Bol. Soc. Esp.<br />

Ceram. Vidr. 45(2):59-64.<br />

13 Jaquotot P, Campillo A, Re<strong>in</strong>osa JJ, Romero JJ,<br />

Bengochea MA, Esteban-Cubillo A, Santarén<br />

J, Aguilar E, P<strong>in</strong>a R, Pecharromán C, Moya JS,<br />

Fernández JF (2009) Desarrollo de esmaltes nanoestructurados<br />

multifuncionales. Bol. Soc. Es.<br />

Ceram Vidrio 48(2):95-98.<br />

14 Fujishima A, Honda K (1972): Electrochemical<br />

photolysis of water at a semiconductor electrode.<br />

Nature 238 (5358) 37-38.<br />

15 Groenendijk M, Meijer J (2006) Microstruc–tur<strong>in</strong>g<br />

us<strong>in</strong>g femtosecond pulsed laser ablation. J. Laser<br />

Appl. 18(3):227-232.<br />

16 Bahaj A (2005) Solar photovoltaics energy: generation<br />

<strong>in</strong> <strong>the</strong> built environment. Civil Eng<strong>in</strong>eer<strong>in</strong>g<br />

158: 45-51.<br />

17 Carnel L, Gordon I, Van Gestel D, Van<br />

Nieuwenhuysen K, Agost<strong>in</strong>elli G, Beaucarne G,<br />

Poortmans J (2006) Th<strong>in</strong>-film polycrystall<strong>in</strong>e silicon<br />

solar cell on ceramics substrates with a V oc<br />

above 500 mV. Th<strong>in</strong> Solid Films 511-512: 21-25.<br />

18 Barnett AM, Rand JA, Hall RB, Bisaillon JC,<br />

DelleDonne EJ, Feyock BW, Ford DH, Ingram<br />

AE, Mauk MG, Yaskoff JP, Sims PE (2001) High<br />

current, th<strong>in</strong> silicon-on-ceramic solar cell. Solar<br />

Energy Mater. Solar Cells 66: 45-50.<br />

19 Focsa A, Gordon I, Beaucarne G, Tuzun O, Slaoui<br />

A, Poortmans (2008) Heterojunction a-Si/poly-Si<br />

solar cells on mullita substrates. Th<strong>in</strong> Solid Films<br />

516: 6896-6901.<br />

20 Kieliba T, Bau S, Schober R, Oβwald D, Reber S,<br />

Eyer A, Willeke G (2002) Crystall<strong>in</strong>e silicon th<strong>in</strong>film<br />

solar cells on ZrSiO 4 ceramic substrates. Solar<br />

Energy mater. Solar Cells 74: 216-266.<br />

21 Conibeer G (2007) Third-generation photovoltaics.<br />

Nature Mater. 10 (11): 42-50.<br />

22 Lev<strong>in</strong>son R, Akbari H, Reilly JC (2007) Cooler tileroofed<br />

build<strong>in</strong>gs with near-<strong>in</strong>frared reflective nonwhite<br />

coat<strong>in</strong>gs. Build. Envir. 42: 2591-2605.<br />

23 www.tauceramica.net<br />

Lippage free, HassLe free<br />

The Tuscan Level<strong>in</strong>g System is <strong>the</strong> professional way to lay large tiles, fast.<br />

• The system is easy to learn and use, at any skill level<br />

• Makes <strong>in</strong>stallation twice as fast, and more profitable<br />

• Reduces <strong>in</strong>staller fatigue and stress<br />

• Prevents tiles from mov<strong>in</strong>g whilst dry<strong>in</strong>g<br />

• Drastically reduces <strong>the</strong> need <strong>for</strong> gr<strong>in</strong>d<strong>in</strong>g<br />

• For use with tiles 300mm or larger<br />

Position strap and cap Lay <strong>the</strong> tile Attach sett<strong>in</strong>g tool Tension until level Wait <strong>for</strong> glue to dry Remove strap and cap<br />

Tuscan Level<strong>in</strong>g System<br />

Sett<strong>in</strong>g Tool - Ergonomic 1 Unit<br />

Tuscan Level<strong>in</strong>g System Cap<br />

Box of 250pcs<br />

Tuscan Level<strong>in</strong>g System Strap<br />

Box of 1000pcs<br />

00 | Tile Today #74 | www.<strong>in</strong>fotile.com/publications<br />

pHone 03 8552 6000 to f<strong>in</strong>d YoUr nearest stoCKist, or <strong>for</strong> a demonstration, visit tUsCanLeveL<strong>in</strong>g.Com