Nuclear Plant Journal - Digital Versions

Nuclear Plant Journal - Digital Versions

Nuclear Plant Journal - Digital Versions

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

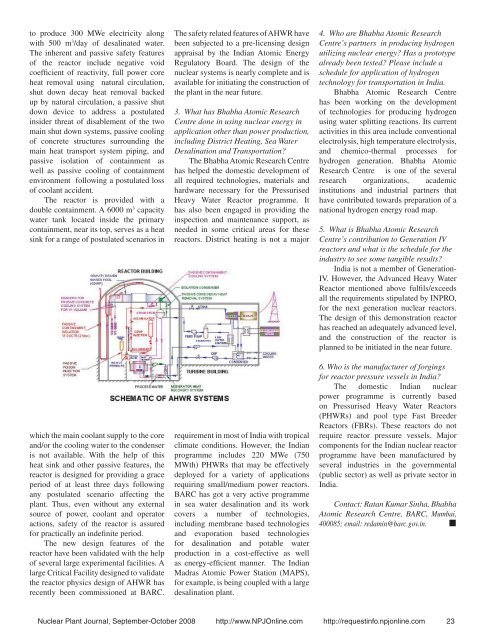

to produce 300 MWe electricity along<br />

with 500 m 3 /day of desalinated water.<br />

The inherent and passive safety features<br />

of the reactor include negative void<br />

coefficient of reactivity, full power core<br />

heat removal using natural circulation,<br />

shut down decay heat removal backed<br />

up by natural circulation, a passive shut<br />

down device to address a postulated<br />

insider threat of disablement of the two<br />

main shut down systems, passive cooling<br />

of concrete structures surrounding the<br />

main heat transport system piping, and<br />

passive isolation of containment as<br />

well as passive cooling of containment<br />

environment following a postulated loss<br />

of coolant accident.<br />

The reactor is provided with a<br />

double containment. A 6000 m 3 capacity<br />

water tank located inside the primary<br />

containment, near its top, serves as a heat<br />

sink for a range of postulated scenarios in<br />

which the main coolant supply to the core<br />

and/or the cooling water to the condenser<br />

is not available. With the help of this<br />

heat sink and other passive features, the<br />

reactor is designed for providing a grace<br />

period of at least three days following<br />

any postulated scenario affecting the<br />

plant. Thus, even without any external<br />

source of power, coolant and operator<br />

actions, safety of the reactor is assured<br />

for practically an indefinite period.<br />

The new design features of the<br />

reactor have been validated with the help<br />

of several large experimental facilities. A<br />

large Critical Facility designed to validate<br />

the reactor physics design of AHWR has<br />

recently been commissioned at BARC.<br />

The safety related features of AHWR have<br />

been subjected to a pre-licensing design<br />

appraisal by the Indian Atomic Energy<br />

Regulatory Board. The design of the<br />

nuclear systems is nearly complete and is<br />

available for initiating the construction of<br />

the plant in the near future.<br />

3. What has Bhabha Atomic Research<br />

Centre done in using nuclear energy in<br />

application other than power production,<br />

including District Heating, Sea Water<br />

Desalination and Transportation<br />

The Bhabha Atomic Research Centre<br />

has helped the domestic development of<br />

all required technologies, materials and<br />

hardware necessary for the Pressurised<br />

Heavy Water Reactor programme. It<br />

has also been engaged in providing the<br />

inspection and maintenance support, as<br />

needed in some critical areas for these<br />

reactors. District heating is not a major<br />

requirement in most of India with tropical<br />

climate conditions. However, the Indian<br />

programme includes 220 MWe (750<br />

MWth) PHWRs that may be effectively<br />

deployed for a variety of applications<br />

requiring small/medium power reactors.<br />

BARC has got a very active programme<br />

in sea water desalination and its work<br />

covers a number of technologies,<br />

including membrane based technologies<br />

and evaporation based technologies<br />

for desalination and potable water<br />

production in a cost-effective as well<br />

as energy-efficient manner. The Indian<br />

Madras Atomic Power Station (MAPS),<br />

for example, is being coupled with a large<br />

desalination plant.<br />

4. Who are Bhabha Atomic Research<br />

Centre’s partners in producing hydrogen<br />

utilizing nuclear energy Has a prototype<br />

already been tested Please include a<br />

schedule for application of hydrogen<br />

technology for transportation in India.<br />

Bhabha Atomic Research Centre<br />

has been working on the development<br />

of technologies for producing hydrogen<br />

using water splitting reactions. Its current<br />

activities in this area include conventional<br />

electrolysis, high temperature electrolysis,<br />

and chemico-thermal processes for<br />

hydrogen generation. Bhabha Atomic<br />

Research Centre is one of the several<br />

research organizations, academic<br />

institutions and industrial partners that<br />

have contributed towards preparation of a<br />

national hydrogen energy road map.<br />

5. What is Bhabha Atomic Research<br />

Centre’s contribution to Generation IV<br />

reactors and what is the schedule for the<br />

industry to see some tangible results<br />

India is not a member of Generation-<br />

IV. However, the Advanced Heavy Water<br />

Reactor mentioned above fulfils/exceeds<br />

all the requirements stipulated by INPRO,<br />

for the next generation nuclear reactors.<br />

The design of this demonstration reactor<br />

has reached an adequately advanced level,<br />

and the construction of the reactor is<br />

planned to be initiated in the near future.<br />

6. Who is the manufacturer of forgings<br />

for reactor pressure vessels in India<br />

The domestic Indian nuclear<br />

power programme is currently based<br />

on Pressurised Heavy Water Reactors<br />

(PHWRs) and pool type Fast Breeder<br />

Reactors (FBRs). These reactors do not<br />

require reactor pressure vessels. Major<br />

components for the Indian nuclear reactor<br />

programme have been manufactured by<br />

several industries in the governmental<br />

(public sector) as well as private sector in<br />

India.<br />

Contact: Ratan Kumar Sinha, Bhabha<br />

Atomic Research Centre, BARC, Mumbai,<br />

400085; email: redamin@barc.gov.in. <br />

<strong>Nuclear</strong> <strong>Plant</strong> <strong>Journal</strong>, September-October 2008 http://www.NPJOnline.com http://requestinfo.npjonline.com 23