Watertight Doors in Passenger ship design - Gard

Watertight Doors in Passenger ship design - Gard

Watertight Doors in Passenger ship design - Gard

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

1<br />

<strong>Watertight</strong> <strong>Doors</strong> <strong>in</strong><br />

<strong>Passenger</strong> <strong>ship</strong> <strong>design</strong><br />

ty<br />

29 May 2013<br />

Henn<strong>in</strong>g Luhmann<br />

WTD Workshop Arendal<br />

29 May 2013

Meyer Werft<br />

2<br />

• Founded <strong>in</strong> 1795<br />

• 100% family owned<br />

• 2 locations – 1 <strong>ship</strong>yard<br />

• Meyer Werft <strong>in</strong> Papenburg<br />

• Neptun Werft <strong>in</strong> Rostock<br />

– 11 production halls<br />

• 2 covered build<strong>in</strong>g docks<br />

• 4 halls for unit and pipe<br />

production<br />

• 5 halls for laser weld<strong>in</strong>g and<br />

flow l<strong>in</strong>e for block production<br />

– Largest covered<br />

<strong>ship</strong>build<strong>in</strong>g hall <strong>in</strong><br />

the world (504 m x 125 m)<br />

– Europe's largest laser<br />

centre<br />

– Crane capacity of up to<br />

800 t per crane<br />

– Own cab<strong>in</strong> production

Product Portfolio 3<br />

Cruise <strong>ship</strong>s<br />

River cruise <strong>ship</strong>s<br />

Research <strong>ship</strong>s<br />

Ships: 36 (+5) Ships: 27 (+15) Ships: 0 (+1)<br />

Gas tankers<br />

Island ferries<br />

Ferries / Cruise ferries<br />

Ships: 56 Ships: 29 Ships : 32<br />

<strong>Passenger</strong> <strong>ship</strong>s<br />

Livestock carriers<br />

Conta<strong>in</strong>er <strong>ship</strong>s<br />

Ships: 24 Ships: 27 Ships: 4

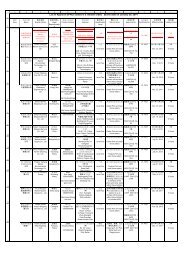

Orderbook<br />

Meyer Werft, Papenburg<br />

Neptun Werft, Rostock<br />

4<br />

Norwegian Cruise L<strong>in</strong>e<br />

Norwegian Getaway<br />

2014<br />

Royal Carribean<br />

International<br />

Quantum of the Seas 2014<br />

Anthem of the Seas 2015<br />

Research <strong>ship</strong><br />

Sonne delivery 2015<br />

© 2008 Meyer Werft GmbH<br />

Norwegian Cruise L<strong>in</strong>e<br />

S. 693 delivery 2015<br />

S. 694 delivery 2017<br />

16 River cruise vessels<br />

delivery until 2014

15 years – 11 prototypes 5<br />

2000 – Aurora 76,000 GT Purpose-built for British market<br />

2001 – Radiance o/t Seas 90,000 GT Gas turb<strong>in</strong>e & pod propulsion<br />

2001 – Norwegian Star 92,000 GT Freestyle <strong>design</strong><br />

2004 – Pont-Aven 41,000 GT High-speed cruise ferry<br />

2005 – Norwegian Jewel 93,500 GT Largest panmax <strong>design</strong><br />

2007 – AIDAdiva 68,500 GT Compact „Club“ <strong>design</strong><br />

2008 – Celebrity Solstice 122,000 GT 1 st <strong>ship</strong> with 1000+ balcony cab<strong>in</strong>s<br />

2010 – Disney Dream 130,000 GT Surprise for the <strong>in</strong>dustry<br />

2013 – NCL Breakaway 146,600 GT Optimized <strong>in</strong>dustrialized <strong>design</strong><br />

2014 – Quantum o/t Seas 167,000 GT Energy sav<strong>in</strong>g as a key element<br />

2015 – NCL Breakaway Plus 163,000 GT Evolution of Breakaway

Introduction<br />

6<br />

• To achieve a good safety level a careful balance is needed<br />

Regulations<br />

Safety<br />

Design<br />

Operation<br />

WTD Workshop Arendal<br />

29 May 2013

Damage Stability<br />

7<br />

• Internal watertight <strong>in</strong>tegrity requires high attention<br />

• Operation of water tight doors<br />

• Rout<strong>in</strong>g of pipes and ducts<br />

• Bulkhead penetrations<br />

• Up to 100 different systems need to be controlled<br />

dur<strong>in</strong>g <strong>design</strong> and production<br />

WTD Workshop Arendal<br />

29 May 2013

Types of watertight doors<br />

8<br />

• Different type of doors used<br />

– Normal WTD below bulkhead deck<br />

– Light WTD with reduced scantl<strong>in</strong>gs, otherwise like normal WTD<br />

– Semi-watertight doors: to be used with GZ range only, not below<br />

immersion l<strong>in</strong>e<br />

– Fire doors<br />

• Use of doors dur<strong>in</strong>g navigation may be different<br />

– WTD always closed<br />

– Semi-WTD and fire doors may be kept open<br />

WTD Workshop Arendal<br />

29 May 2013<br />

7 February 2012 Public Workshop Hels<strong>in</strong>ki 8

Design assumption<br />

9<br />

• All damage stability calculations are based on closed water tight doors<br />

• Operational needs are not considered carefully dur<strong>in</strong>g <strong>design</strong> <strong>in</strong> the past<br />

• Layout of the vessel may be <strong>in</strong> conflict with operational needs<br />

• Many <strong>ship</strong>s have exemptions to have WTDs open dur<strong>in</strong>g navigation<br />

Many 3-zone<br />

damages<br />

are not<br />

survivable<br />

WTD Workshop Arendal<br />

29 May 2013

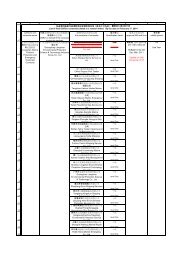

GA with marked WTD<br />

10<br />

WTD Workshop Arendal<br />

29 May 2013<br />

7 February 2012 Public Workshop Hels<strong>in</strong>ki 10

Purpose of WTD<br />

11<br />

• Why are <strong>ship</strong>s built with watertight doors<br />

effective use of the available space<br />

• 2 nd means of escape<br />

• Avoid<strong>in</strong>g dead-end corridors<br />

• Used for transport of goods<br />

• Ma<strong>in</strong>tenance and transport of spare parts<br />

WTD Workshop Arendal<br />

29 May 2013

Examples of use of WTD<br />

12<br />

2 nd means of escape<br />

Dead-end<br />

Avoid<strong>in</strong>g dead-end corridors<br />

Staircase<br />

Used for transport of goods<br />

2nd escape<br />

Cold rooms<br />

Service lift<br />

Laundry<br />

L<strong>in</strong>en stores<br />

WTD Workshop Arendal<br />

29 May 2013

Examples of use of WTD<br />

13<br />

Ma<strong>in</strong>tenance and transport of spare parts<br />

easy connection of eng<strong>in</strong>e rooms is desired by many chief eng<strong>in</strong>eers<br />

Ships have been <strong>design</strong>ed <strong>in</strong> the past without the right balance between daily<br />

operation and damage stability<br />

WTD Workshop Arendal<br />

29 May 2013

Evacuation<br />

14<br />

• Evacuation has a high priority <strong>in</strong> <strong>ship</strong> <strong>design</strong><br />

• Each ma<strong>in</strong> vertical zone has a well protected staircase<br />

lead<strong>in</strong>g to the life boat deck and assembly stations<br />

• Each watertight compartment has a vertical escape to<br />

the boat deck <strong>in</strong>side a protected stair case<br />

• Each space requires 2 <strong>in</strong>dependent means of escape<br />

evacuation deck<br />

WTD Workshop Arendal<br />

29 May 2013

Design to keep WTD closed<br />

15<br />

• Design can be adapted to keep WTDs closed<br />

• To be considered at an early <strong>design</strong> stage<br />

• Survivability (atta<strong>in</strong>ed <strong>in</strong>dex A) may be reduced<br />

• Example “Laundry” <strong>in</strong> larger compartment:<br />

WTD Workshop Arendal<br />

29 May 2013

Design to keep WTD closed<br />

16<br />

• Other examples<br />

Laundry arrangement on<br />

two decks<br />

In one compartment<br />

Workshops <strong>in</strong> one compartment<br />

Multiple lifts to access provision rooms<br />

WTD Workshop Arendal<br />

29 May 2013

Design to m<strong>in</strong>imize WTD<br />

17<br />

• Optimized cab<strong>in</strong> arrangement to m<strong>in</strong>imize the number of doors<br />

Six WTD <strong>in</strong> 2 compartments<br />

One WTD <strong>in</strong> 2 compartments<br />

WTD Workshop Arendal<br />

29 May 2013

<strong>Doors</strong> on bulkhead deck<br />

18<br />

• Layout of bulkhead deck to meet many different requirements<br />

– Subdivision with partial bulkheads<br />

– Escape from watertight compartments<br />

– Longitud<strong>in</strong>al corridor for crew and goods<br />

– Control stations<br />

WTD Workshop Arendal<br />

29 May 2013

<strong>Doors</strong> on bulkhead deck<br />

19<br />

• Use of fire doors <strong>in</strong> way of central corridor<br />

• Fire doors susta<strong>in</strong> 2.5m water level with only small<br />

leakage<br />

• May be used to restrict progressive flood<strong>in</strong>g on bulkhead<br />

deck<br />

• Improves subdivision without the underm<strong>in</strong><strong>in</strong>g overall risk<br />

– Fire doors may be used <strong>in</strong> escape ways<br />

– No risk for <strong>in</strong>juries like for WTD<br />

WTD Workshop Arendal<br />

29 May 2013

Categories of doors<br />

20<br />

• MSC Circ 1380 def<strong>in</strong>es different categories of doors<br />

• The categories need to be discussed, but<br />

• <strong>Doors</strong> may have significantly different <strong>in</strong>fluence on<br />

survivability<br />

• Acceptance to use water tight doors should reflect the<br />

<strong>in</strong>fluence on survivability<br />

Influence of a s<strong>in</strong>gle open<br />

WTD on A-<strong>in</strong>dex<br />

WTD Workshop Arendal<br />

29 May 2013

Categories of doors<br />

21<br />

• Design should be optimized to m<strong>in</strong>imize the <strong>in</strong>fluence of open water tight<br />

doors<br />

• Number of doors to be further reduced<br />

• Latest <strong>design</strong>s show equal vulnerability for open water tight doors<br />

Influence of a s<strong>in</strong>gle<br />

open WTD on A-<strong>in</strong>dex<br />

Influence of open WTD on vulnerability<br />

WTD Workshop Arendal<br />

29 May 2013

Operation<br />

22<br />

• Design and operation need to be aligned from early <strong>design</strong><br />

• All damage stability calculations assume all WTD closed<br />

• Operation may require the connection between certa<strong>in</strong> spaces<br />

• Risk for <strong>in</strong>juries for crew and passengers is very high dur<strong>in</strong>g clos<strong>in</strong>g of WTD<br />

• Good example for a possible balanced approach between stakeholders<br />

• Designers: <strong>design</strong> subdivision follow<strong>in</strong>g operational needs<br />

• Operators. Cooperate <strong>in</strong> early <strong>design</strong> stage, change traditional procedures to<br />

ma<strong>in</strong>ta<strong>in</strong> watertight <strong>in</strong>tegrity<br />

• Academia: provide methods and tools to keep crew alerted<br />

• Regulators: force all <strong>design</strong>ers and operators to keep doors closed for new <strong>ship</strong>s<br />

WTD Workshop Arendal<br />

29 May 2013

Conclusion<br />

23<br />

• Safety is one of the key objectives of passenger <strong>ship</strong> <strong>design</strong><br />

• <strong>Watertight</strong> doors are a vital component to achieve the desired<br />

survivability<br />

• The cruise <strong>ship</strong> <strong>in</strong>dustry works pro-active<br />

• Safety levels need to be cont<strong>in</strong>uously reviewed and adjusted if needed<br />

• Only with close cooperation between operators, <strong>ship</strong>yards and<br />

adm<strong>in</strong>istrations the good safety record can be further improved<br />

WTD Workshop Arendal<br />

29 May 2013