Rally with Delphi - Delphi Aftermarket

Rally with Delphi - Delphi Aftermarket

Rally with Delphi - Delphi Aftermarket

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Delphi</strong>’s Magazine for Automotive Technicians // Issue 2<br />

THIS MONTH<br />

WE TALK:<br />

<strong>Rally</strong> <strong>with</strong> <strong>Delphi</strong><br />

MAF Step-by-Step Guide<br />

Common Rail<br />

Injector Technology<br />

<strong>Delphi</strong> Service Centre<br />

ABS Speed Sensors<br />

New Diagnostic Tool<br />

Webinar Training<br />

Replacing Receiver Driers<br />

Brake Pad Development<br />

and Testing<br />

<strong>Delphi</strong> Sponsors the WRC<br />

How To Diagnose Common<br />

Rail Injector Faults<br />

New Vehicle Electronics<br />

Air Conditioning<br />

Shock Absorbers<br />

Filters and Chassis<br />

High Standards.<br />

Below the Surface.<br />

Partnering <strong>with</strong> Peugeot<br />

Winning Relationship <strong>with</strong><br />

Hendrick Motorsports<br />

<strong>Delphi</strong> Technologies Featured<br />

on Ferrari<br />

P2<br />

P4<br />

P6<br />

P8<br />

P9<br />

P10<br />

P11<br />

P12<br />

P14<br />

P16<br />

P18<br />

P18<br />

P19<br />

P20<br />

P21<br />

P21<br />

P21<br />

P22<br />

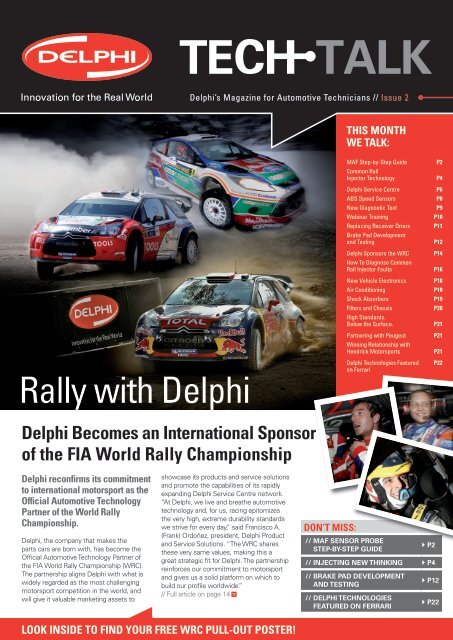

<strong>Delphi</strong> Becomes an International Sponsor<br />

of the FIA World <strong>Rally</strong> Championship<br />

<strong>Delphi</strong> reconfirms its commitment<br />

to international motorsport as the<br />

Official Automotive Technology<br />

Partner of the World <strong>Rally</strong><br />

Championship.<br />

<strong>Delphi</strong>, the company that makes the<br />

parts cars are born <strong>with</strong>, has become the<br />

Official Automotive Technology Partner of<br />

the FIA World <strong>Rally</strong> Championship (WRC).<br />

The partnership aligns <strong>Delphi</strong> <strong>with</strong> what is<br />

widely regarded as the most challenging<br />

motorsport competition in the world, and<br />

will give it valuable marketing assets to<br />

showcase its products and service solutions<br />

and promote the capabilities of its rapidly<br />

expanding <strong>Delphi</strong> Service Centre network.<br />

“At <strong>Delphi</strong>, we live and breathe automotive<br />

technology and, for us, racing epitomizes<br />

the very high, extreme durability standards<br />

we strive for every day,” said Francisco A.<br />

(Frank) Ordoñez, president, <strong>Delphi</strong> Product<br />

and Service Solutions. “The WRC shares<br />

these very same values, making this a<br />

great strategic fit for <strong>Delphi</strong>. The partnership<br />

reinforces our commitment to motorsport<br />

and gives us a solid platform on which to<br />

build our profile worldwide.”<br />

// Full article on page 14 TT<br />

DON’T MISS:<br />

// MAF SENSOR PROBE<br />

STEP-BY-STEP GUIDE<br />

P2<br />

// INJECTING NEW THINKING P4<br />

// BRAKE PAD DEVELOPMENT<br />

AND TESTING<br />

// DELPHI TECHNOLOGIES<br />

FEATURED ON FERRARI<br />

P12<br />

P22<br />

LOOK INSIDE TO FIND YOUR FREE WRC PULL-OUT POSTER!

<strong>Delphi</strong> MAF Sensor Probe<br />

1. Using a torque wrench and the correct socket,<br />

remove the bolts securing the MAF air box.<br />

Carefully unscrew the jubilee clip and detach<br />

the hose connected to the MAF air box.<br />

5. Remove the faulty MAF sensor probe from the MAF<br />

assembly by holding the flow tube in one hand and the probe<br />

connector in the other. Gently pull the two away from each<br />

other until the sensor probe is completely removed.<br />

1<br />

5<br />

2. Carefully remove the air box from the vehicle<br />

and place on a clean work surface.<br />

2<br />

6. Open the sealed new sensor package. Handle the sensor<br />

connector only (NEVER touch electronics as this may damage<br />

sensor probe). Slide new sensor probe into flow tube.<br />

6<br />

Interested in<br />

Learning More<br />

Check out our detailed<br />

product information on<br />

www.delphi.com/am<br />

Why <strong>Delphi</strong> MAF<br />

Sensor Probe<br />

• Stock one <strong>Delphi</strong> part to fit almost 12 million<br />

European passenger cars. The <strong>Delphi</strong> MAF<br />

sensor probe combines 23 OE Service MAF<br />

sensor references into one <strong>Delphi</strong><br />

MAF sensor probe for reduced inventory.<br />

• Replace OE <strong>with</strong> OE. The <strong>Delphi</strong> MAF<br />

sensor probe is not remanufactured<br />

and boasts all new components.<br />

• Save money by eliminating the need<br />

to replace the plastic housing.<br />

• It’s a greener repair solution; eliminates<br />

replacement of plastic housing.<br />

Follow these stepby-step<br />

instructions<br />

on how to repair<br />

and replace the<br />

MAF sensor probe…<br />

Once it’s determined the mass air flow sensor<br />

requires replacement, the same servicing<br />

procedures are followed to remove the failed<br />

sensor assembly. Inspect the flow tube to<br />

ensure there are no cracks in the plastic<br />

housing. If there are, you will need to replace<br />

the entire unit – not just the probe.<br />

Is the flow tube free from cracks Then, follow<br />

this step-by-step guide to learn how to replace<br />

the MAF sensor probe. Once the sensor probe<br />

is replaced, continue re-installing the completed<br />

MAF sensor assembly into the vehicle as you<br />

would normally.<br />

3. Remove the MAF flow tube assembly from the<br />

air box using a torque wrench and the correct socket.<br />

3<br />

4. Place the flow tube assembly on a clean work surface <strong>with</strong><br />

the sensor probe connector facing up. Following this, you<br />

must remove the screws using the correct security torx bit.<br />

4<br />

7. Using both hands, firmly grip the flow tube and press the<br />

probe into the flow tube using your thumbs.<br />

7<br />

P2 <strong>Delphi</strong>’s Magazine for Automotive Technicians // Issue 2 <strong>Delphi</strong>.com/am<br />

P3

Injecting New Thinking<br />

Philippe Bercher, deputy director of engineering,<br />

<strong>Delphi</strong> Diesel Systems, talks <strong>with</strong> Ian Adcock<br />

about improvements in injection technology<br />

From the<br />

beginning, our<br />

target was to<br />

meet emissions<br />

legislation, and<br />

reduce CO 2<br />

,<br />

which is another<br />

driver for us;<br />

so increasing<br />

injection<br />

pressures and<br />

the number of<br />

injections were<br />

the priorities.<br />

At the recent SIA International Congress in Rouen,<br />

<strong>Delphi</strong> presented a paper on new developments in<br />

fuel injection equipment and engine control systems<br />

that help to reduce substantially overall diesel engine<br />

emissions, including CO 2<br />

. These latest technologies<br />

will simplify compliance <strong>with</strong> increasingly demanding<br />

emissions standards in Europe, such as Euro6, and<br />

in other markets worldwide where high-efficiency<br />

diesel engines are increasingly recognised as an<br />

effective means of cutting CO 2<br />

.<br />

The upgrades include an increase in maximum<br />

operating pressure from 2000 bar up to 2400<br />

bar, <strong>with</strong> improved high-pressure atomisation,<br />

enhancements to <strong>Delphi</strong>’s closed-loop control<br />

system, improved hydraulic efficiency and reduced<br />

engine starting time to provide seamless stop-start.<br />

The main research activities carried out over the last<br />

five years were largely dedicated to the investigation<br />

of potential performance upgrades of the injection<br />

system and the electronic engine control strategies.<br />

The objective was to fulfil Euro6 emission<br />

regulations, implement CO 2<br />

emission reduction<br />

functionality – stop-start, reduced hydraulic energy<br />

losses – and to optimise costs.<br />

Clear priorities<br />

“From the beginning, our target was to meet<br />

emissions legislation, and reduce CO 2<br />

, which<br />

is another driver for us; so increasing injection<br />

pressures and the number of injections were the<br />

priorities,” states <strong>Delphi</strong>’s Philippe Bercher. “When<br />

we started production in early 2000, we were at<br />

1400 bar and today we’re at 2000 bar.” However, the<br />

process doesn’t stop there he says: “We’re already<br />

targeting 2400 bar for passenger cars; but, for heavy<br />

duty engines, they’re one step ahead, because<br />

they’re already in production <strong>with</strong> 2500 bar and<br />

they’re going up to 2700 or even 3000 bar.<br />

For passenger cars and light diesels maybe,<br />

yes, we can increase the injection pressure<br />

beyond 2400 bar. But I am not sure the<br />

cost and complexity would be acceptable in<br />

light duty diesels.”<br />

However, it’s not just about <strong>Delphi</strong>’s desire<br />

or capability of achieving such high injection<br />

pressures, but whether there would then be<br />

a demand for this from the OEMs as Bercher<br />

explains: “Looking to the future, we see two<br />

distinct strategies, so we have to talk a bit about<br />

the OEMs plans, because we see different<br />

directions. One major vehicle manufacturer, for<br />

example, is focusing on NOx after-treatment for<br />

Euro6, so they’re probably not going to demand<br />

increased pressures and they will stay at 2000 bar,<br />

even for the next generation of engines.<br />

But some other customers want to be sure that<br />

the engine gives the lowest emissions, as they<br />

don’t want to use NOx after-treatment and they<br />

are looking for increased pressure.”<br />

As <strong>with</strong> most technologies, there are<br />

manufacturing/materials/cost trade-offs. This is<br />

particularly so <strong>with</strong> diesel systems attempting to<br />

meet Euro6, and especially Euro7, in small cars,<br />

where the on-cost of additional diesel technology<br />

might outweigh the fuel consumption and exhaust<br />

emissions gains.<br />

As Bercher points out, there is a balance to be<br />

achieved between injection pressures and the<br />

number of nozzle holes employed in the injector for<br />

a fixed nozzle flow: “If we increase the pressure,<br />

it’s because we want to improve the air-fuel mix<br />

<strong>with</strong>in the combustion chamber using smaller<br />

diameter nozzle holes. We know that the limitation<br />

we have today is nozzle hole diameter, because,<br />

if we go below 90 microns, we have some coking<br />

effect and it’s also a question of manufacturing.<br />

However, if we can decrease the hole diameter,<br />

we don’t need to increase the pressure so much,<br />

because then we wouldn’t get the emissions<br />

benefit of the nozzle hole reduction.<br />

Republished <strong>with</strong> the kind permission of<br />

Findlay Media and Automotive Design<br />

Technology challenges<br />

“Furthermore, there’s a limit to the number of<br />

holes, because the limit today is the hole diameter<br />

and, therefore, the number of holes you can put on<br />

the nozzle body. Currently, we are at eight to nine; if<br />

we go above that, you will not have enough material<br />

between the holes to <strong>with</strong>stand the pressure.” He<br />

admits that <strong>Delphi</strong> has tested a nozzle <strong>with</strong> more<br />

holes, but claims: “There’s no benefit so far.”<br />

The request for reduced tailpipe emissions<br />

is leading OEMs to develop ever more<br />

complex powertrain systems embracing<br />

combinations of technologies, such as<br />

electric assist motors and stop-start, both<br />

of which present Bercher and his team<br />

<strong>with</strong> their own challenges:<br />

“For stop-start, there are three main difficulties:<br />

the first concerns the pump, as it will have to<br />

tolerate more stop-starts than the conventional<br />

system. A customer may have a target of<br />

300,000-500,000 stop-starts in a vehicle’s<br />

lifetime; for a standard<br />

vehicle, <strong>with</strong>out stop-start,<br />

it’s maybe half of that. That<br />

means the pump has to be<br />

improved and be capable<br />

of doubling its normal<br />

service life, so that impacts<br />

the bearings in the pump.<br />

Secondly, as the injectors<br />

back leak time is needed to<br />

regenerate pressure.<br />

You could be forgiven for thinking that increasing rail<br />

pressure beyond 2000 bar would have a knock-on<br />

effect for other parts of the fuel delivery system –<br />

not so, says Bercher. “The big step was to move<br />

from the rotary pump at 500 bar and go to 1400-<br />

1500 bar; but today we know the manufacturing<br />

improvements we have to make, so we don’t see<br />

the same challenges“.<br />

For example, injectors on direct actuation,<br />

where there isn’t a return flow to the tank,<br />

when you stop the engine, pressure is<br />

maintained in the system, so it’s available to<br />

inject and fire the engine.<br />

“Finally, in terms of the engine<br />

management system (EMS), we<br />

can develop a strategy to ensure<br />

the engine is in a given position<br />

when it is stopped, so that, when<br />

it restarts, the EMS knows what<br />

state the engine is in, in order to<br />

quickly manage the injection. For<br />

the electric-diesel hybrids, it’s a bit<br />

different as the ratio of stop-starts<br />

is something like three times<br />

greater,” he adds. TT<br />

<strong>Delphi</strong>’s global network of highly equipped, highly skilled diesel specialists offers professional,<br />

cost-effective diagnostics, test and repair of today’s and tomorrow’s most advanced diesel fuel<br />

injection technology. They have invested in the very latest test equipment, tooling, standards,<br />

skills and knowledge and are backed by a leading OE manufacturer. To locate your nearest<br />

<strong>Delphi</strong> Diesel Centre, visit delphi.com/am.<br />

If we increase<br />

the pressure, it’s<br />

because we want<br />

to improve the<br />

air-fuel mix <strong>with</strong>in<br />

the combustion<br />

chamber using<br />

smaller diameter<br />

nozzle holes.<br />

P4 <strong>Delphi</strong>’s Magazine for Automotive Technicians // Issue 2 <strong>Delphi</strong>.com/am<br />

P5

Partnering for Success<br />

With <strong>Delphi</strong> Service Centre<br />

DSC membership<br />

offers benefits<br />

such as...<br />

• Association <strong>with</strong> a leading supplier<br />

of original equipment car parts<br />

• Access to OE parts and professionally<br />

repaired Common Rail units<br />

• Specialist diagnostic equipment and tooling<br />

to service today’s advanced vehicles<br />

• Technical hotline for system diagnosis<br />

help and guidance<br />

• Web based database of workshop manuals<br />

and technical bulletins<br />

• In-depth training on the very latest<br />

automotive systems<br />

• Regular communications on new vehicle<br />

technologies and diagnostic equipment<br />

In speaking of his decision to partner <strong>with</strong><br />

<strong>Delphi</strong> and CFI, Michael Shaikly, managing<br />

director, said “Without the link we wouldn’t<br />

be able to do what we do…we as a company<br />

were struggling <strong>with</strong> diesel. If we had a diesel<br />

problem come in, we were out. In becoming<br />

a <strong>Delphi</strong> Service Centre garage we had the<br />

opportunity to purchase well-priced diagnostic<br />

tools and the door was opened to helpful<br />

technical support and information. Diesel is a<br />

really profitable area and <strong>Delphi</strong> Service Centre<br />

has allowed us to tap into this opportunity.<br />

It adds real kudos to our business.”<br />

By developing a local <strong>Delphi</strong> Service<br />

Centre network, we are able to offer<br />

professional, reliable diesel car<br />

servicing, maintenance and repair<br />

across the region.<br />

• National promotion through a website<br />

and network locator: delphi.com/am<br />

In becoming a<br />

<strong>Delphi</strong> Service<br />

Centre garage<br />

we had the<br />

opportunity<br />

to purchase<br />

well-priced<br />

diagnostic tools<br />

and the door<br />

was opened to<br />

helpful technical<br />

support and<br />

information.<br />

With the current expansion of diesel cars<br />

worldwide, garages <strong>with</strong> the expertise, knowledge<br />

and support to service these vehicles are well<br />

placed to watch their business go from strength<br />

to strength. <strong>Delphi</strong>’s Service Centre program<br />

provides independent garages <strong>with</strong> this support,<br />

partnering them <strong>with</strong> a local diesel repair specialist,<br />

as well as the backing of a leading OE automotive<br />

manufacturer. Garages joining the network can<br />

access <strong>Delphi</strong>’s OE parts offering, OE-based<br />

training, technical support and equipment and can<br />

choose among four modules: diesel, as well as<br />

air conditioning, petrol engine management and<br />

braking, steering and suspension.<br />

Frank Shaikly & Son based in Colchester, UK is just<br />

one example of the success of this programme.<br />

Shaikly has been in business for over 30 years;<br />

however, it was not until their appointment<br />

as a <strong>Delphi</strong> Service Centre – Diesel garage,<br />

and subsequent partnership <strong>with</strong> Colchester<br />

Fuel Injection (CFI), an authorised diesel repair<br />

workshop, that they were able to work <strong>with</strong> modern<br />

diesel powered cars. Before joining the Europewide<br />

network, they had to outsource all diesel<br />

engine work that came into their garage, as they<br />

did not have the relevant knowledge and tooling.<br />

Through their partnership <strong>with</strong> CFI, they now have<br />

access to a range of diagnostic equipment and<br />

tools, OE parts, in depth knowledge, and critically,<br />

support from a professional diesel repair specialist.<br />

Diesel is a really<br />

profitable area<br />

and <strong>Delphi</strong><br />

Service Centre<br />

has allowed us<br />

to tap into this<br />

opportunity.<br />

It adds real<br />

kudos to our<br />

business.<br />

And as their technical partner, the benefits<br />

are clear for CFI too. “By developing a local<br />

<strong>Delphi</strong> Service Centre network, we are able to<br />

offer professional, reliable diesel car servicing,<br />

maintenance and repair across the region,”<br />

comments Paul Goldsmith, general manager.<br />

“These garages have all been trained by <strong>Delphi</strong>,<br />

and we have supplied them <strong>with</strong> the relevant<br />

tools and equipment, so we are confident that<br />

diagnostic interrogation can be performed<br />

successfully at a local level. The result;<br />

we are now able to concentrate on our<br />

core business – the repair of fuel injection<br />

equipment. But the real bonus is that this<br />

repair work is also increasing. As their technical<br />

partner, the garage refers their repair work to us.<br />

A real win-win for both companies.” TT<br />

To learn more about <strong>Delphi</strong> Service Centre<br />

and the benefits for your business, visit<br />

delphi.com/dsc.<br />

P6 <strong>Delphi</strong>’s Magazine for Automotive Technicians // Issue 2 <strong>Delphi</strong>.com/am<br />

P7

Bringing OE<br />

Braking Safety Expertise to the <strong>Aftermarket</strong><br />

<strong>Delphi</strong> Launches<br />

First Durable Convertible PC Diagnostic Tool<br />

<strong>Delphi</strong> has extended its braking portfolio <strong>with</strong> the introduction of 65 new OE quality ABS speed<br />

sensors fitted to popular vehicle applications such as Audi, BMW, VW, Peugeot, Citroën, Seat,<br />

Ford and Opel. The range provides coverage of more than 42 million vehicles, <strong>with</strong> only 30<br />

part numbers representing 80% of a typical distributor’s ABS speed sensor sales.<br />

<strong>Delphi</strong> brands<br />

every part <strong>with</strong><br />

the <strong>Delphi</strong> logo<br />

and part number,<br />

ensuring easy<br />

identification,<br />

cutting down<br />

on technician’s<br />

labour and part<br />

sourcing.<br />

Did You Know<br />

The most commonly<br />

failing ABS speed<br />

sensor is an<br />

Audi application,<br />

part number<br />

SS10307.<br />

Today <strong>Delphi</strong> offers an industry leading range<br />

of braking products <strong>with</strong> over 8,500 references<br />

covering all major vehicle manufacturers.<br />

Leveraging its braking expertise, and knowledge<br />

of vehicle electronics, <strong>Delphi</strong> has recently<br />

introduced a new ABS speed sensor range.<br />

<strong>Delphi</strong>’s ABS speed sensors are 100% tested for<br />

quality and performance, and all backed by a two<br />

year warranty. They tolerate engine oil, transmission<br />

fluids, anti-freeze and car washing detergents<br />

<strong>with</strong> no adverse reactions in performance, and<br />

can <strong>with</strong>stand extreme weather conditions.<br />

Furthermore, all <strong>Delphi</strong> ABS speed sensor<br />

connectors are plated, which is extremely important<br />

in preventing corrosion and premature failure.<br />

What does this mean to the garage It means that<br />

you know when you install a <strong>Delphi</strong> ABS speed<br />

sensor, you are fitting a product that has been<br />

designed, engineered and manufactured to provide<br />

the performance you would expect from such a<br />

critical safety component. TT<br />

DELPHI PART # KEY APPLICATIONS AXLE FITMENT<br />

SS10305 BMW 520, 523, 525, 528, 540 Front LH / RH<br />

SS10306 BMW 520, 523, 525, 528, 540 Rear LH / RH<br />

SS10307 AUDI TT / SEAT Arosa, Cordoba, Ibiza, Inca, Leon, Toledo /<br />

SKODA Octavia / VW Bora, Caddy, Corrado, Golf, Lupo,<br />

New Beetle, Passat, Polo, Vento<br />

SS10308 AUDI TT / SEAT Arosa, Cordoba, Ibiza, Inca, Leon, Toledo /<br />

SKODA Octavia / VW Bora, Caddy, Corrado, Golf, Lupo,<br />

New Beetle, Passat, Polo, Vento<br />

SS20000<br />

AUDI A3,TT / SEAT Arosa, Toledo / SKODA Octavia / VW Bora,<br />

Golf, Lupo, New Beetle<br />

SS20001 AUDI A2 / SEAT Cordoba, Ibiza / SKODA Fabia, Roomster /<br />

VW Fox, Polo<br />

SS20002 AUDI A2 / SEAT Cordoba, Ibiza / SKODA Fabia / VW Fox, Polo Front RH<br />

Front<br />

Front<br />

Rear<br />

LH<br />

RH<br />

LH / RH<br />

SS20003 SEAT Toledo / VW Corrado, Golf, Jetta, Passat Rear LH / RH<br />

SS20004 AUDI A4 / VW Passat Front LH / RH<br />

SS20005 BMW 316, 318, 320, 323, 325, 328, M3 Front LH / RH<br />

SS20006 BMW 316, 318, 320, 323, 325, 328, M3 Rear LH / RH<br />

SS20007 BMW 520, 523, 525, 528, 530, 535, 540, M5 Front LH / RH<br />

SS20008 BMW 520, 523, 525, 528, 530, 535, 540, M5 Rear LH / RH<br />

SS20009 BMW 520, 523, 525, 528, 530, 540 Rear LH / RH<br />

SS20010 BMW X5 Front LH / RH<br />

SS20011 CITROËN Xantia Front LH / RH<br />

SS20012 CITROËN Xantia Front LH / RH<br />

SS20013 CITROËN Xantia Rear LH / RH<br />

SS20014 CITROËN Xantia Rear LH / RH<br />

SS20015 CITROËN Berlingo / PEUGEOT Partner Rear LH / RH<br />

SS20016 FORD Escort Front LH / RH<br />

SS20017 FORD Focus Front LH / RH<br />

SS20018 FORD Ka Front LH / RH<br />

SS20019 FORD Fiesta, Fiesta Van, Puma / MAZDA 121 Front LH / RH<br />

SS20020 FORD Galaxy / SEAT Alhambra / VW Sharan Front LH / RH<br />

SS20021 OPEL Astra / VAUXHALL Astra Front LH / RH<br />

SS20022 PEUGEOT 206 Front LH / RH<br />

SS20023 PEUGEOT 206 Rear LH / RH<br />

Front<br />

LH<br />

<strong>Delphi</strong> is leveraging its knowledge of each vehicle’s<br />

DNA to introduce a new semi-rugged, convertible<br />

PC diagnostic tool, giving technicians faster, more<br />

affordable access to on board diagnostics, technical<br />

support, and service information. Designed for<br />

garages, including its rapidly expanding network of<br />

<strong>Delphi</strong> Service Centres, the tool features a rotating<br />

10“ screen, which is both water and scratch<br />

resistant. This allows the technician to use the tool<br />

in tablet mode to diagnose a vehicle <strong>with</strong> one hand<br />

on the handle and the other hand <strong>with</strong> the stylus on<br />

touch screen. Then by simply rotating the screen,<br />

the technician instantly converts it back to a regular<br />

laptop <strong>with</strong> the benefit of a true keyboard to search<br />

through technical data.<br />

Other features include a built-in webcam, useful<br />

for technical support and online training sessions.<br />

A stylus provides touch screen control while also<br />

offering handwriting recognition. The user-friendly<br />

PC has a battery life of up to 8.5 hours, enough to<br />

last a full working day.<br />

“<strong>Delphi</strong> believes this is the first durable convertible<br />

PC for garages,” said Mike Rayne, vice president,<br />

Diesel <strong>Aftermarket</strong>, <strong>Delphi</strong> Product & Service<br />

Solutions. “This is a cost-effective diagnostic tool<br />

designed <strong>with</strong> the demands of workshop operation<br />

in mind. As it runs on Windows, technicians will find<br />

the device intuitive and it is even possible to add<br />

their own software programmes such as Word and<br />

Excel to fully exploit the power of this new system.”<br />

Rayne continues, “We are pleased to say we are<br />

seeing extremely positive initial market feedback on<br />

all aspects of the tool – including value for money,<br />

portability, ruggedness and compliance <strong>with</strong> the<br />

automotive workshop’s harsh environment.”<br />

Incorporating <strong>Delphi</strong>’s diagnostics software, the PC<br />

allows the technician to view, save and print live<br />

data parameters in both text and graphical format,<br />

interrogate fault code information and perform a<br />

range of configuration and adaption functions.<br />

Full vehicle scans and intelligent system scans are<br />

supported for the vast majority of vehicles.<br />

The PC can link directly to <strong>Delphi</strong>‘s<br />

Technical Data software, enabling the<br />

user to view OE service information,<br />

a quotation system, repair times and<br />

wiring diagrams. To further increase<br />

the user friendliness and save time,<br />

the PC will automatically select<br />

the vehicle being diagnosed when<br />

opening the Technical Data software.<br />

The new convertible PC joins<br />

<strong>Delphi</strong>’s wide range of diagnostics<br />

tools, from the compact and<br />

portable PDA to this new PC<br />

based solution… solutions to<br />

meet all your garage needs! TT<br />

Did You Know<br />

<strong>Delphi</strong>’s car diagnostics<br />

software covers 48<br />

vehicle manufacturers,<br />

over 4,000 vehicle<br />

models and<br />

approximately 54,000<br />

vehicle systems.<br />

Its truck software<br />

covers 31 vehicle<br />

manufacturers, 1,400<br />

vehicle models and<br />

over 22,000 vehicle<br />

systems, including<br />

trailer diagnostics.<br />

P8 <strong>Delphi</strong>’s Magazine for Automotive Technicians // Issue 2 <strong>Delphi</strong>.com/am<br />

P9

<strong>Delphi</strong>’s Best Practice<br />

Training Goes Digital<br />

Receiver Driers:<br />

Why and When Should They be Replaced<br />

Receiver driers are there to absorb<br />

corrosion causing moisture and to filter<br />

any particulates that are circulating<br />

around the system, such as:<br />

• Rust: If moisture has been present in a system for a period<br />

of time, rust could form on any metal parts. This rust can flake<br />

and be transported around the system by the refrigerant.<br />

• Metallic particles: If the compressor seizes and fails it could<br />

start to break up internally, and these bits could find their<br />

way around the system.<br />

• Silica gel granules: Once totally saturated, the drying agent<br />

in the drier turns to mush and circulates around the system.<br />

• Grease and general debris: If a system has been opened<br />

for a repair and the drier has not been replaced, general<br />

workshop debris could enter the system.<br />

Did You Know<br />

Contrary to<br />

popular opinion, air<br />

conditioning systems<br />

are sealed, but not for<br />

life. Like any system on<br />

a car <strong>with</strong> moving parts<br />

it must be serviced.<br />

The drier must be<br />

replaced every<br />

two years.<br />

Did You Know<br />

<strong>Delphi</strong> offers an<br />

extensive program<br />

of webinars covering<br />

all major systems<br />

such as GDI, diesel<br />

Common Rail, hybrid,<br />

vehicle electronics,<br />

braking, steering<br />

and suspension, air<br />

conditioning and<br />

diagnostics.<br />

Being able to access high quality training at the touch of a button<br />

is a highly valuable tool for busy garages, keen to stay up-to-date<br />

<strong>with</strong> new technology and the best practices in service and repair.<br />

Through <strong>Delphi</strong>’s recently introduced webinar<br />

programme, short for web-based seminar,<br />

technicians now have access to industry leading<br />

training, technical support and technical assistance<br />

from the comfort of their own desk. The online<br />

training is available globally – all you need is an<br />

internet connection, a PC and a telephone line.<br />

The webinars are taught live in 45-minute sessions<br />

by <strong>Delphi</strong>’s experienced trainers, and can be<br />

conducted at convenient times to minimise time<br />

spent away from the workshop. Designed to be<br />

interactive and user friendly, delegates are able<br />

to view the trainer live, ask questions as if in<br />

conventional training, simultaneously view the<br />

training materials and “virtually” raise their hand to<br />

ask questions through the programme’s conference<br />

line or text chat. If the training is on a diagnostic<br />

tool, such as the <strong>Delphi</strong> DS150, the trainer is able<br />

to share his PC, giving delegates the ability to<br />

experience the application first hand.<br />

The online training<br />

is available globally –<br />

all you need is an internet<br />

connection, a PC<br />

and a telephone line.<br />

All material, including Powerpoint, video, voice,<br />

Q&A and application sharing are recorded, and<br />

a streaming link is sent to all attendees who<br />

complete the training so that they may refer<br />

back to the key points at any time.<br />

To book a course, simply view the training<br />

schedule online, apply to attend the course<br />

electronically, and log in to the system for the<br />

scheduled course – it is as simple as that! TT<br />

To reduce the above,<br />

the following precautions<br />

should be observed:<br />

• The receiver drier should be changed every<br />

two years as part of a routine service.<br />

• If any component is replaced due to damage,<br />

the drier should also be replaced.<br />

• When working on an air conditioning system<br />

a clean work practice should be observed.<br />

• If the system is open for any length of time,<br />

waiting for parts etc, plug any open pipes,<br />

to avoid dirt and debris from entering the system.<br />

• The new receiver drier should be un-plugged<br />

and connected at the last possible moment<br />

before evacuation.<br />

Designed and manufactured to<br />

OE specifications, <strong>Delphi</strong> offers an<br />

extensive range of receiver driers.<br />

Its OE-designed internal<br />

components provide improved<br />

separation of liquid and vapour,<br />

while a molecular sieve desiccant<br />

effectively controls moisture and<br />

helps protect the entire system<br />

against corrosion. They also feature<br />

lightweight aluminium construction<br />

and a calibrated oil return in the<br />

outlet tube for enhanced lubrication.<br />

<strong>Delphi</strong> Service Centre<br />

garages are trained in the<br />

very latest air conditioning<br />

technology. They have<br />

access to a wide range<br />

of OE quality parts, as<br />

well as the tools and<br />

knowledge to service<br />

these systems. TT<br />

You may be able<br />

to extract most of<br />

the moisture, but<br />

evacuating a system<br />

will not remove<br />

particulates and will<br />

not reform silica gel<br />

mush into granules.<br />

P10 <strong>Delphi</strong>’s Magazine for Automotive Technicians // Issue 2 <strong>Delphi</strong>.com/am<br />

P11

Brake Pad<br />

Development and Testing:<br />

A rigorous approach to<br />

achieving OE-quality products<br />

Did You Know<br />

<strong>Delphi</strong> brake pads<br />

excelled in ‘AK Master’<br />

brake pad performance<br />

tests on the BMW 3<br />

Series (E46), Z3, Z4<br />

and Nissan Primera,<br />

outperforming<br />

key aftermarket<br />

competitors.<br />

Only products<br />

that meet <strong>with</strong><br />

the stringent<br />

testing are<br />

released to<br />

the market.<br />

As the company that makes the parts cars are born <strong>with</strong> for 25 of the world’s vehicle<br />

manufacturers, <strong>Delphi</strong> understands a vehicle’s DNA and the strict OE standards and performance<br />

requirements. <strong>Delphi</strong> applies these same standards to the aftermarket, ensuring that its range<br />

of braking products for European, Asian and German vehicles delivers OE-quality performance.<br />

First-to-market strategy requires<br />

robust testing procedures<br />

Since <strong>Delphi</strong> aims to supply brake discs and<br />

pads <strong>with</strong>in six months from vehicle launch, it<br />

is imperative that its development and testing<br />

processes are highly robust. The company’s<br />

product development engineers carry out<br />

clearly defined, exhaustive quality tests on<br />

<strong>Delphi</strong>’s aftermarket brake pads. This ensures<br />

that the pads’ performance is fully tested to<br />

the extreme road conditions found worldwide.<br />

Only products that meet <strong>with</strong> the stringent<br />

testing are released to the market.<br />

Product development:<br />

accurate application engineering is key<br />

A team of <strong>Delphi</strong> product development engineers<br />

application engineer approximately 150 brake pads<br />

per year covering up to 600 vehicle models.<br />

With an emphasis on being first to market on brakes,<br />

this extensive process is typically completed in three<br />

months. A full deconstruction analysis is carried<br />

out on every brake pad <strong>with</strong> a particular focus on:<br />

• type and quality of shimming<br />

• backplate construction and steel type<br />

• friction material design and type<br />

• accessory type and quality<br />

<strong>Delphi</strong>’s engineers also need to balance durability<br />

against performance. Typical EU materials focus<br />

on high speed performance to ensure safety,<br />

while other markets may put priority on wear<br />

(or wheel dust). Ultimately, all designs feature<br />

an element of compromise. For instance, it’s<br />

not possible for a pad to offer a constant friction<br />

level and last indefinitely <strong>with</strong> zero noise.<br />

The main aim is to reduce the friction variation<br />

but keep gradual change <strong>with</strong> temperature<br />

to feedback to the driver that he/she is using<br />

the brakes and getting nearer to the limit.<br />

<strong>Delphi</strong>’s existing range of friction materials is reassessed<br />

on an ongoing basis. Approximately 200<br />

materials are tested and evaluated each year, and the<br />

results are compared against materials used in its<br />

existing product range. The main areas for comparison<br />

include friction level, friction stability and wear (at<br />

certain temperatures or in certain conditions).<br />

From analysis to development<br />

Having carried out a full analysis of the OE product,<br />

<strong>Delphi</strong>’s product development engineers can<br />

then proceed to production drawings. They also<br />

select the type of friction materials to be used<br />

for each vehicle model, which is determined by a<br />

variety of factors: vehicle use, market, front or rear<br />

fitment and the balance of weight in the vehicle.<br />

Development samples are produced and undergo<br />

comprehensive validation and durability testing in<br />

laboratories, on dynos and via vehicle testing. Once<br />

the products have been internally approved by<br />

<strong>Delphi</strong>’s development engineering department, the<br />

tooling for the products is ordered and <strong>Delphi</strong> can<br />

then seek R90 approval for the finished product, a<br />

quality standard required by European legislation.<br />

Rigorous product testing<br />

All parts released for the aftermarket undergo the<br />

same rigorous product development processes,<br />

including Production Part Verification (PPV), to confirm<br />

the part being produced performs exactly as the<br />

prototype was designed, and Production Part Approval<br />

Process (PPAP) to ensure every part meets all of the<br />

requirements defined in the engineering samples.<br />

Laboratory testing:<br />

<strong>Delphi</strong>’s laboratory tests include:<br />

• Shear: a safety test to ensure the friction<br />

material does not detach from the backplate.<br />

• Compressibility: ensures equivalent pedal<br />

feel and ABS operation to the OE<br />

under normal conditions.<br />

Vehicle and dynamometer testing<br />

<strong>Delphi</strong> brake pads undergo a number of real-world<br />

tests. Among these are: the AK Master European<br />

standard test, the Auto Motor und Sport (AMS)<br />

test, noise dyno analysis, Alpine testing, high<br />

speed autobahn testing, the FMVSS as well as<br />

Ameca testing (to fulfill US testing requirements).<br />

The dynamometer is calibrated to match the exact<br />

characteristics of a specific vehicle application.<br />

The vehicle weight and rolling radius (taken from<br />

the vehicle’s tyres) is used to calculate a specific<br />

inertia to replicate the forces involved. Hydraulic<br />

parts and discs from the vehicle application are<br />

also used, and the speed of the test can be<br />

set according to the application’s capability.<br />

<strong>Delphi</strong> adopts the same rigorous approach to the<br />

development and engineering of its entire brake<br />

pads range. Workshops selecting <strong>Delphi</strong> can<br />

therefore be confident that they are investing in<br />

high quality, durable products that will satisfy their<br />

customers and keep them safe on the roads. TT<br />

• Hot compressibility: avoids increasing<br />

pedal travel at high temperatures.<br />

• Heat transfer: ensures that the pad<br />

will not transfer too much heat into the<br />

brake fluid, helping to avoid fluid boiling.<br />

• Swell: avoids brake drag when hot.<br />

<strong>Delphi</strong> adopts<br />

the same rigorous<br />

approach to the<br />

development<br />

and engineering<br />

of its entire<br />

brake pads<br />

range.<br />

P12 <strong>Delphi</strong>’s Magazine for Automotive Technicians // Issue 2 <strong>Delphi</strong>.com/am<br />

P13

<strong>Rally</strong> <strong>with</strong> <strong>Delphi</strong><br />

<strong>Delphi</strong> Becomes an International<br />

Sponsor of the FIA World<br />

<strong>Rally</strong> Championship<br />

<strong>Delphi</strong> reconfirms its commitment to international<br />

motorsport as the Official Automotive Technology<br />

Partner of the World <strong>Rally</strong> Championship.<br />

<strong>Delphi</strong>, the company that makes the parts cars are<br />

born <strong>with</strong>, has become the Official Automotive<br />

Technology Partner of the FIA World <strong>Rally</strong><br />

Championship (WRC). The partnership aligns <strong>Delphi</strong><br />

<strong>with</strong> what is widely regarded as the most challenging<br />

motorsport competition in the world, and will give it<br />

valuable marketing assets to showcase its products<br />

and service solutions and promote the capabilities of<br />

its rapidly expanding <strong>Delphi</strong> Service Centre network.<br />

As an official partner, <strong>Delphi</strong> will have access to<br />

valuable branding and marketing rights at races<br />

throughout the season. This includes the <strong>Delphi</strong><br />

logo on Championship marketing material and<br />

documentation, as well as race infrastructure such as<br />

stage and service park banners and arches. This will<br />

provide extensive global TV exposure for <strong>Delphi</strong>, <strong>with</strong><br />

the WRC consistently recording a cumulative audience<br />

of over 550 million in over 140 territories. <strong>Delphi</strong> will<br />

also feature prominently, on the Championship's<br />

official website; wrc.com, and in the WRC’s rapidly<br />

expanding social media channels.<br />

This is an exciting<br />

partnership for DPSS<br />

said Carrie Wright, vice president, global brand<br />

and communications, <strong>Delphi</strong> Product and Service<br />

Solutions. “The sponsorship will provide a solid,<br />

high visibility platform to increase our global<br />

awareness, while helping to drive sales through<br />

the distribution chain. We know that our customers<br />

are passionate about motorsport, and in particular<br />

the WRC, and this will form the basis of our<br />

marketing efforts in Europe in 2011, including<br />

promotions, and hospitality at key races.”<br />

“At <strong>Delphi</strong>, we live and breathe automotive<br />

technology and, for us, racing epitomizes the very<br />

high, extreme durability standards we strive for every<br />

day,” said Francisco A. (Frank) Ordoñez, president,<br />

<strong>Delphi</strong> Product and Service Solutions. “The WRC<br />

shares these very same values, making this a great<br />

strategic fit for <strong>Delphi</strong>. The partnership reinforces<br />

our commitment to motorsport and gives us a solid<br />

platform on which to build our profile worldwide.”<br />

Simon Long, CEO of North One Sport, the<br />

Championship Promoter, said "<strong>Delphi</strong>’s commitment<br />

to delivering real world innovations that make vehicles<br />

smarter and safer, as well as more powerful and<br />

efficient is a natural fit <strong>with</strong> the Championship. With<br />

their OE technology and service expertise,<br />

the association <strong>with</strong> <strong>Delphi</strong> is very important to us.<br />

We are delighted to welcome <strong>Delphi</strong> to our family<br />

of sponsors." TT<br />

Sanctioned by the Federation Internationale de<br />

l’Automobile (FIA), the Championship pits cars<br />

and drivers in a series of multi day events through<br />

some of the toughest, and most varied, conditions<br />

on the planet. In 2011 drivers and the likes of<br />

Citroën, Ford and MINI, will compete in rallies in<br />

13 countries across Europe, Central and South<br />

America, Australasia and the Middle East.<br />

“At <strong>Delphi</strong>, we live and breathe automotive technology and, for us, racing epitomizes the very high, extreme durability<br />

standards we strive for every day” Francisco A. (Frank) Ordoñez, president, <strong>Delphi</strong> Product and Service Solutions.<br />

For more information about the WRC,<br />

please visit www.wrc.com<br />

P14 <strong>Delphi</strong>’s Magazine for Automotive Technicians // Issue 2 <strong>Delphi</strong>.com/am<br />

P15

Go To <strong>Delphi</strong> for How To!<br />

<strong>Delphi</strong>. The ‘Go-To’ Company for Technical Information<br />

The vehicle:<br />

Ford Mondeo<br />

2.0 TDCi<br />

The symptoms:<br />

The engine is running<br />

erratically, resulting in low<br />

power and poor emissions.<br />

The fault:<br />

The Common Rail injectors<br />

show the following fault codes:<br />

F2336 Injector 1 fault<br />

F2337 Injector 2 fault<br />

F2338 Injector 3 fault<br />

F2339 Injector 4 fault<br />

The fault is accompanied <strong>with</strong> a<br />

descriptor “Accelerometer out<br />

of range”. This typically means<br />

that the tolerance window of<br />

80 micro seconds has been<br />

exceeded and therefore the<br />

system cannot modify the<br />

drive to the injector to maintain<br />

stability.<br />

If the fault code is accompanied<br />

by a rail pressure fault code it is<br />

likely that the whole system has<br />

been contaminated. In all cases<br />

a hydraulic diagnostic check,<br />

using the <strong>Delphi</strong> Sealed Rail Kit,<br />

should confirm which parts are<br />

at fault.<br />

A step-by-step guide to<br />

diagnosing Common Rail<br />

injector faults on Ford Mondeo<br />

The resolution:<br />

The fault codes should first be<br />

confirmed, and if the code is one or<br />

all of those to the left, the following<br />

procedure is recommended:<br />

Step 1:<br />

Remove the fuel filter and<br />

empty the contents into<br />

a clean container.<br />

If the content is not clear, full of<br />

particulates, or has high water<br />

content, then the system must be<br />

cleaned out from the tank to the filter.<br />

If the sample is clear and the amount<br />

of particulates in the sample covers<br />

less than one square centimetre then<br />

proceed to the hydraulic test. More<br />

than one square centimetre suggests<br />

heavy contamination, and if the<br />

particles are of a metallic nature, a full<br />

system overhaul will be required.<br />

Tip! Ferrous metallic particles can<br />

be identified by using a magnet<br />

under the base of the container.<br />

At this stage it is also advised to<br />

check for damage to the other<br />

mechanical components in the<br />

system using a hydraulic or “wet<br />

side” diagnostic on the pump,<br />

injectors and rail. A biodiesel check<br />

can be performed using <strong>Delphi</strong>’s fuel<br />

analyser to confirm if the sample<br />

meets European EN590 fuel standard.<br />

Step 2:<br />

Hydraulically test the pump<br />

and injectors for max<br />

pressure and backleakage<br />

using the <strong>Delphi</strong> Sealed<br />

Rail Diagnostic Kit.<br />

If the pump pressure is lower than the<br />

recommended spec stated in the kit<br />

instructions, this indicates that the pump<br />

is worn and requires attention. Further<br />

testing <strong>with</strong> the False Actuator Kit will<br />

determine whether the damage is internal<br />

or to the external IMV.<br />

Note: Any contamination in the high<br />

pressure pump will also be in the<br />

rail and injectors and will result in a<br />

system replacement.<br />

If the pressure can be recovered by a new<br />

IMV proceed to the next step. The injector<br />

backleakage is critical and must be <strong>with</strong>in<br />

the parameters outlined in the test kit<br />

manual. If the backleakage is not uniform<br />

between the cylinders then the highest<br />

backleak injectors should be serviced in<br />

accordance <strong>with</strong> <strong>Delphi</strong> service standards,<br />

or replaced <strong>with</strong> new injectors.<br />

Note: The high backleak injectors<br />

should align <strong>with</strong> the fault codes<br />

present for the relevant injector<br />

number. If all of the injectors have<br />

high backleakage this is probably due<br />

to fuel contamination and will indicate<br />

further intervention is required and<br />

that all of the injectors require service.<br />

Note: If contamination is present<br />

in the system, changing injectors<br />

alone will run a high risk of repeat<br />

failure, thus increasing the cost of<br />

repair to the customer.<br />

Step 3:<br />

Replace the fuel filter<br />

When replacing the filter ensure a<br />

genuine <strong>Delphi</strong> or Ford part is used.<br />

The filter screen is 2 microns which is<br />

necessary for system protection.<br />

Non-genuine filters may have a larger<br />

filter screen, typically 5 to 10 microns –<br />

this is inadequate for this application.<br />

To learn what <strong>Delphi</strong> Service Centre can do<br />

for your business, and to find out how you can<br />

access similar technical information on an<br />

ongoing basis, visit: www.delphi.com/dsc<br />

Step 4:<br />

Ensure the correct<br />

torque setting<br />

Ensure all pipes are tightened to the<br />

correct torque setting to prevent distortion<br />

of the pipe and/or injector and that the<br />

injector mountings are also torqued in<br />

accordance <strong>with</strong> the specification.<br />

Step 5:<br />

Re-programme the ECU<br />

Every <strong>Delphi</strong> Common Rail injector, be it<br />

new or repaired, should have a label <strong>with</strong><br />

a characterisation code applied to it. It is<br />

essential that the ECU is re-programmed<br />

<strong>with</strong> this code when the injector is fitted<br />

to the vehicle. This will ensure that the<br />

adjustment to the pulse times is made<br />

and that the correct fuel delivery is<br />

maintained.<br />

Step 6:<br />

Final check<br />

And finally, clear all fault codes,<br />

road test the vehicle and recheck<br />

for codes after the road test.<br />

By joining an established network such<br />

as <strong>Delphi</strong> Service Centre, independent<br />

garages are paired <strong>with</strong> technical partners<br />

who can provide extensive technical<br />

support and training. <strong>Delphi</strong> Service Centre<br />

members also have access to an extensive<br />

library of technical bulletins, such as the<br />

above, giving detailed technical guidance<br />

on key system and vehicle issues, helping<br />

them to overcome any challenging<br />

technical issues. TT<br />

P16 <strong>Delphi</strong>’s Magazine for Automotive Technicians // Issue 2 <strong>Delphi</strong>.com/am<br />

P17

<strong>Delphi</strong> Extends its Global Portfolio<br />

Making Vehicle<br />

Electronics a reality<br />

<strong>Delphi</strong> is reinforcing its position as one of the only manufacturers to offer a complete service<br />

solution for a vehicle’s entire engine and fuel management system, <strong>with</strong> the introduction of 49<br />

new OE specification parts, helping technicians to service increasingly complex systems.<br />

<strong>Delphi</strong> MAF Sensors: <strong>Delphi</strong> MAF sensors are<br />

designed <strong>with</strong> a green approach allowing the<br />

technician to reuse the OE part’s plastic housing<br />

and replace only the sensor. In fact, 98% of Mass<br />

Air Flow failures are caused by the sensor alone.<br />

DELPHI PART #<br />

AF10055-11B1<br />

AF10056-11B1<br />

AF10058-11B1<br />

AF10059-11B1<br />

KEY APPLICATIONS<br />

ACURA, BUICK, CHEVROLET, GMC,<br />

HONDA, ISUZU, OLDSMOBILE,<br />

and PONTIAC<br />

CADILLAC, CHEVROLET, GMC,<br />

and PONTIAC<br />

BUICK, CADILLAC, CHEVROLET,<br />

HYUNDAI, KIA, PONTIAC,<br />

and SATURN<br />

CHEVROLET and GMC<br />

Oxygen Sensors: Incorporating the very latest<br />

planar technology, <strong>Delphi</strong>’s oxygen sensors<br />

deliver the industry’s fastest light-off time to<br />

reduce cold-start emissions and improve fuel<br />

economy. The extended range of 40 part numbers<br />

supports an additional 18 million applications,<br />

including popular models for Ford, Kia, Hyundai,<br />

Mazda, Nissan, Seat, Toyota and Volkswagen.<br />

Fuel Pumps: The five newly launched fuel<br />

pumps provide coverage for a further 1.3<br />

million applications. <strong>Delphi</strong> fuel pumps deliver<br />

fast-pressure rise for quick engine starts<br />

and feature internal springs, an integrated<br />

OE fuel vapour pressure sensor and twostrainer<br />

system for long-lasting durability. TT<br />

DELPHI PART #<br />

FE0429-12B1<br />

HP10071-11B1<br />

HP10089-11B1<br />

HP10098-11B1<br />

HP10114-11B1<br />

KEY APPLICATIONS<br />

LADA, ALFA ROMEO, CHRYSLER,<br />

FIAT, FORD, HONDA, HYUNDAI,<br />

INFINITI, JEEP, KIA, MAZDA,<br />

MITSUBISHI, NISSAN, RENAULT,<br />

SUBARU, and SUZUKI<br />

2003-1999 FORD F-150 BI-FUEL,<br />

F-150 GAS, 2004 F-150 HERITAGE,<br />

BI-FUEL<br />

2003-1999 FORD F-150 BI-FUEL,<br />

F-150 GAS, 2004 F-150 HERITAGE,<br />

BI-FUEL, F-150 HERITAGE CNG,<br />

1999 F-250 BI-FUEL, F-250 GAS<br />

1998-97 FORD F-150 GAS, F-250 GAS<br />

2003-1999 FORD F-150 GAS, 2004<br />

F-150 HERITAGE GAS<br />

At the same time, <strong>Delphi</strong> has introduced a<br />

new air conditioning catalogue.<br />

The new catalogue contains a deeper level of content than other<br />

catalogues, <strong>with</strong> a detailed buyers guide including product pictures,<br />

allowing for quicker identification of parts, while still providing a clear<br />

and easy-to-understand description of the application, and a dedicated<br />

OE cross reference section. All new parts are also included on other<br />

leading European electronic catalogues such as TecDoc, ALDOC etc.<br />

Extended<br />

shocks range<br />

<strong>Delphi</strong> has substantially increased its shock<br />

absorber range <strong>with</strong> the addition of 142 new<br />

part numbers, comprising 37 shock absorbers,<br />

102 coil springs and 3 top mount kits.<br />

Did You Know<br />

<strong>Delphi</strong>’s air<br />

conditioning<br />

product offering<br />

is one of the most<br />

comprehensive in<br />

Europe, <strong>with</strong> 94%<br />

car parc coverage<br />

for compressors,<br />

condensers and<br />

receiver driers,<br />

and 97% car parc<br />

coverage for cabin<br />

air filters.<br />

Cooling down for the summer<br />

<strong>with</strong> <strong>Delphi</strong> OE product<br />

<strong>Delphi</strong> is launching 75 new part numbers<br />

for vehicle air conditioning systems,<br />

including 17 additions to both its compressor<br />

and cabin filter range, and 22 OE heat<br />

exchangers (condensers, radiators and<br />

charge air coolers), providing a wider range<br />

of the most common crash repair parts.<br />

The range extension features new <strong>Delphi</strong> OE<br />

Compact Variable Compressors (CVC), the latest<br />

generation of air conditioning technology, and<br />

covers popular European applications including<br />

the new Alfa Romeo Giulietta, Chevrolet Volt,<br />

Orlando and Cruze, Fiat Panda, Lada Kalina and<br />

Chevy Nina, Mini Countryman, Nissan Qashqai,<br />

Opel/Vauxhall Astra, Insignia and Meriva, Peugeot<br />

508 and VW Caddy, Sharan and Touran.<br />

To help drive your sales, <strong>Delphi</strong> has also<br />

launched a new thermal campaign.<br />

The comprehensive programme, available now, includes a<br />

totem, a counter display, 50 winter leaflets highlighting the three<br />

different market activities: crash, maintenance and repair, and<br />

50 summer leaflets giving handy tips on replacing parts. TT<br />

Popular applications include Audi A6, Citroën C3<br />

and DS3, Hyundai i30, Mazda 3, Mercedes A,<br />

B and E Class, Opel/Vauxhall Astra H, Signum<br />

and Vectra C, Peugeot 308 and VW Passat.<br />

Available now, these new parts increase<br />

<strong>Delphi</strong>’s vehicle parc coverage to more than<br />

95%. The extensions are all featured in <strong>Delphi</strong>’s<br />

new 2011 shock absorber catalogue, which<br />

contains a greater level of content than other<br />

catalogues, including product pictures and<br />

Buyers’ Guide information in the same section.<br />

This enables parts to be identified more<br />

speedily whilst still providing a clear and easyto-understand<br />

description of the application.<br />

The catalogue is also supported by a<br />

comprehensive range of marketing material<br />

including a product leaflet, an outside banner<br />

and a display case for sales representatives<br />

highlighting <strong>Delphi</strong>’s OE quality standards. TT<br />

P18 <strong>Delphi</strong>’s Magazine for Automotive Technicians // Issue 2 <strong>Delphi</strong>.com/am<br />

P19

Driving Sales<br />

Building the Brand:<br />

<strong>Delphi</strong> is adding to its recently extended filtration<br />

portfolio, <strong>with</strong> the addition of six new OE quality<br />

filters, including the popular HDF610 fitted to<br />

2.4 million European applications on Citroën,<br />

Ford, Peugeot and Toyota.<br />

DELPHI PART #<br />

HDF610<br />

KEY APPLICATIONS<br />

CITROËN, FORD, PEUGEOT &<br />

TOYOTA 1.4l<br />

HDF612 FORD, VOLVO 2.1l & 2.4l<br />

HDF613 FORD S-MAX, KUGA, MONDEO 2.0l<br />

HDF614 HYUNDAI, KIA 1.1l, 1.6l, 2.0l<br />

In 2011, <strong>Delphi</strong> will be investing heavily in the brand to keep <strong>Delphi</strong> top-of-mind<br />

<strong>with</strong> customers. Here are just a few examples of the communication and promotional<br />

efforts... watch this space for more exciting initiatives coming soon.<br />

High Standards.<br />

Below the Surface.<br />

During 2010 <strong>Delphi</strong> conducted research <strong>with</strong> technicians, counter<br />

staff and distributors across the world to gather honest and constructive<br />

feedback on <strong>Delphi</strong>'s brand perception in the market, as well as the<br />

current and proposed advertising creative and messaging.<br />

New catalogue<br />

for friction,<br />

discs and drums<br />

<strong>Delphi</strong> has launched the latest edition friction, discs and drums catalogue<br />

to meet the increasing demand for its OE quality replacement components.<br />

The catalogue contains 414 new part numbers including 152 brake discs<br />

and 112 brake pads covering some of Europe’s most important and latest<br />

applications: Ford C-Max 2010, Focus 2011,Mini Countryman 2011,<br />

Nissan Juke 2010 , Micra 2011, Opel/Vauxhall Astra 10/2009, Meriva<br />

2010, Peugeot 3008 & 5008 2009, Skoda Roomster 2010, Yeti 2009,<br />

Toyota Auris 2010, VW Touareg 2010, Touran 2010.<br />

HDF615 VAG 1.9l & 2.0l<br />

HDF616 VAG, PORSCHE 3.0l & 4.2l<br />

To support the sales of its newly extended<br />

filter portfolio, <strong>Delphi</strong> has launched a<br />

comprehensive range of marketing material<br />

including a sales brochure, brochure<br />

holder, key application chart, A2 poster and<br />

countermat. Leveraging <strong>Delphi</strong>'s new 'High<br />

Standards, Below the Surface' advertising<br />

campaign, the point of sale material<br />

addresses the critical question of why buy<br />

<strong>Delphi</strong> filters and is available in 17 languages.<br />

The results are the foundation for our 'High Standards, Below<br />

the Surface' campaign. The professionals said that it's what's<br />

underneath the surface of the parts that differentiates <strong>Delphi</strong> from<br />

the competition. So <strong>Delphi</strong> is opening the door for you, and your<br />

customers, to see what's inside our parts, demonstrating our<br />

understanding of vehicles and their DNA, as the company that<br />

makes the parts cars are born <strong>with</strong>.<br />

The new advertising campaign will be featured in both print<br />

and digital, and will run in Europe <strong>with</strong> more than 300 inserts.<br />

Partnering <strong>with</strong><br />

Peugeot in the ultimate<br />

durability test<br />

For the second year running, <strong>Delphi</strong> has partnered <strong>with</strong> Peugeot<br />

to run two Peugeot RCZs in the 24h Nürburgring a gruelling<br />

endurance race which will take place on June 25/26. In addition,<br />

the cars will also compete in the VLN championship, a series of<br />

10 races at the Nürburgring Nordschleife. As a technical partner,<br />

<strong>Delphi</strong>'s brand appears on the two cars. <strong>Delphi</strong> will also feature<br />

in their communications.<br />

10 year winning<br />

relationship <strong>with</strong><br />

Hendrick motorsports<br />

The new catalogue features thumbnail images of pads and shoes, along<br />

<strong>with</strong> a measurement rule feature on the application pages, illustrations and<br />

dimensions in the buyers guide, and improved fitting kit and wear indicator<br />

guides, all designed to make it much more user friendly.<br />

Speak to your local <strong>Delphi</strong> distributor for more<br />

information on any of these programmes.<br />

<strong>Delphi</strong> will continue its sponsorship of Hendrick<br />

Motorsport during the 2011 NASCAR Sprint Cup Series<br />

season. "This will be our 10th year <strong>with</strong> Hendrick<br />

Motorsports, one of NASCAR’s most successful teams,<br />

and we look forward to another winning season," says<br />

Francisco A. (Frank) Ordoñez, president, <strong>Delphi</strong> Product &<br />

Service Solutions, and vice president, <strong>Delphi</strong> Corp. “For<br />

us it is about giving technicians access to the drivers<br />

and crew chiefs they look up to. We are partnering <strong>with</strong><br />

the best, so we can give our customers the best.”<br />

P20 <strong>Delphi</strong>’s Magazine for Automotive Technicians // Issue 2 <strong>Delphi</strong>.com/am<br />

P21

<strong>Delphi</strong> Technologies:<br />

Making Ferrari Safe,<br />

Green and Connected<br />

<strong>Delphi</strong>, the company that makes the parts cars<br />

are born <strong>with</strong>, has a long history of developing<br />

innovative real-world products for high-end<br />

luxury vehicles and sports cars. As a key<br />

partner, <strong>Delphi</strong> is supplying its OE technologies<br />

including optimised air conditioning and<br />

advanced wiring systems to Ferrari, one<br />

of the world’s leading luxury brands.<br />

Innovative technologies helping to<br />

make Ferrari safe, green and connected<br />

<strong>Delphi</strong> has been supplying innovative climate control<br />

technology to Ferrari since 1992. Its energy efficient and high<br />

performance heating ventilation and air conditioning systems<br />

(HVAC), help to increase the vehicle’s fuel economy <strong>with</strong>out<br />

sacrificing passenger comfort. <strong>Delphi</strong> designed the HVAC<br />

modules for several Ferrari models, including the new Ferrari FF which was<br />

recently unveiled at the Geneva motor show. <strong>Delphi</strong>'s Compact Variable<br />

Compressors feature an energy-saving six or seven piston continuously<br />

variable mechanism allied to the A/C system’s control software which also<br />

allows for optimised fuel efficiency and engine power availability.<br />

Since the early 1990’s, <strong>Delphi</strong> has worked <strong>with</strong> Ferrari co-developing and<br />

co-designing electrical/electronic architecture systems and components<br />

to meet Ferrari's very high performance and quality demands.<br />

Recently launched vehicles<br />

featuring <strong>Delphi</strong> technology<br />

include:<br />

• Audi Q5 Hybrid – ultrasonic alarm<br />

• Audi RS3 Sportback – ultrasonic alarm,<br />

immobilizer<br />

• BMW 6er Cabrio – antenna system,<br />

TV receiver, roof module, seat switches,<br />

steering wheel switches<br />

• Chevrolet Cruze – diesel Common Rail<br />

• Fiat Freemont – steering switches,<br />

wiring harnesses, fuel vapor sensors<br />

• Kia Picanto – diesel Common Rail<br />

• Kia Rio – diesel Common Rail<br />

• Lancia Thema – engine wiring<br />

• Lancia Ypsilon – body computer,<br />

remote keyless entry, antenna immobilizer,<br />

electrical/electronic architecture, wiring<br />

harness, data connectivity<br />

• Mercedes-Benz C Coupé – DAB Tuner,<br />

satellite digital audio reception system,<br />

passive occupant detection system, head<br />

lamp levelling control, ultrasonic alarm,<br />

integrated antenna, complete wiring,<br />

diesel Common Rail<br />

• Mercedes-Benz SLK – DAB Tuner, satellite<br />

digital audio reception system, passive<br />

occupant detection system, head lamp<br />

levelling control, diesel Common Rail<br />

• Opel Antara – diesel Common Rail, radio,<br />

graphical info display, universal handsfree<br />

phone, allowing for cellular phone use in<br />

the car using Bluetooth technology<br />

• Saab 9-5 station wagon – complete wiring<br />

• Volvo V60 station wagon plug-in hybrid –<br />

active safety technologies: adaptive<br />

cruise control and electronically scanning<br />

radar (ESR sensor), lane departure warning,<br />

head-up display<br />

• Volkswagen Golf Cabrio –<br />

ultrasonic alarm, immobilizer<br />

The Ferrari line-up fitted <strong>with</strong><br />

<strong>Delphi</strong> technologies:<br />

Ferrari California: connection systems, dual-zone HVAC module <strong>with</strong> Stop &<br />

Start function, condenser <strong>with</strong> integrated receiver drier, latest generation of compact<br />

variable compressor, control head and software; and additional system components<br />

(including lines & hoses, filters and all pressure and temperature sensors).<br />

FF: electrical/electronic architecture, wiring harness, data<br />

connectivity, HVAC module, condenser, compressor, control head, sensors.<br />

Ferrari 458 Italia: HVAC module, wiring harness.<br />

P22 <strong>Delphi</strong>’s Magazine for Automotive Technicians // Issue 2 <strong>Delphi</strong>.com/am<br />

P23

AIR-CONDITIONING CHASSIS DIAGNOSTICS DIESEL VEHICLE ELECTRONICS<br />

<strong>Delphi</strong> Service Centre.<br />

High standards.<br />

Below the surface.<br />

The <strong>Delphi</strong> Service Centre program is designed to ensure that independent garages<br />

benefit from <strong>Delphi</strong>’s knowledge and experience as a leading supplier to the top<br />

25 global vehicle manufacturers. By joining the program, you can access OE-based<br />

training, technical support and equipment. What does that mean The right tools<br />

to help you make the right repair for your customers. You can trust <strong>Delphi</strong>, the<br />

company who makes the parts cars are born <strong>with</strong>.<br />

IT’S WHAT’S UNDERNEATH<br />

THAT SETS DELPHI APART<br />

<strong>Delphi</strong> Service Centres // ❚ Industry<br />

leading training to keep you upto-date<br />

<strong>with</strong> the latest automotive<br />

technology including air conditioning,<br />

braking, steering and suspension and<br />

diesel and petrol engine management;<br />

❚ Technical support and information to<br />

provide expert back-up when you need<br />

it – from a hotline staffed by experts to<br />

detailed diagnostic manuals and infield<br />

support from our service operations<br />

team; ❚ OE-approved diagnostic tools<br />

giving you extensive vehicle and system<br />

coverage and the ability to program<br />

key components such as Common<br />

Rail injectors, quickly and effectively;<br />

❚ Access to OE parts and tooling for<br />

high-quality repairs and fewer comebacks;<br />

❚ Professional marketing support to help<br />

drive business to your garage.<br />

Find out how your garage can<br />

benefi t from <strong>Delphi</strong>’s Service<br />

Centre program by visiting:<br />

delphi.com/dsc<br />

©2011 <strong>Delphi</strong> Automotive Systems, LLC. All rights reserved.<br />

We want to hear from you! Let us know what you think about <strong>Delphi</strong>’s magazine for automotive technicians.<br />

If you have any questions or comments, please contact us at: <strong>Delphi</strong> Product & Service Solutions, Spartan Close,<br />

Warwick, CV34 6AG, UK / Tel: 01926 470000 / www.delphi.com/am.<br />

DDSX552(EN)<br />

DEL277 HS_ad_DSC_A4_EN.indd 1 22/02/2011 12:09