SLUDGE THICKENER - Operation Manual - Stone Food Machinery

SLUDGE THICKENER - Operation Manual - Stone Food Machinery

SLUDGE THICKENER - Operation Manual - Stone Food Machinery

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Mariestad 20061109<br />

<strong>Operation</strong> <strong>Manual</strong><br />

MEVA <strong>SLUDGE</strong> <strong>THICKENER</strong> MST15<br />

Function<br />

• The special LOW-PITCHED screen in the Sludge Thickener will lift the sludge flocs<br />

from the water and this is achieved using a LOW water level in the incoming sludge<br />

water.<br />

• Next there is a gentle dewatering, by gravity, as the sludge flocs are lifted upwards by<br />

the screen.<br />

• By varying the Screen`s speed it is possible to adjust the solids contents of the<br />

thickened sludge.<br />

• We keep a constant and LOW water level to guarantee that no sludge particles go into<br />

the reject/waste water.<br />

• A HIGH water level in the <strong>SLUDGE</strong> <strong>THICKENER</strong> simply means that sludge particles<br />

can be pressed through the bars by the Hydraulic Pressure and results in excessive<br />

suspended solids in the reject/waste water.<br />

• This is the significant difference in function from the Monoscreen that needs a high<br />

water level to work as a FineScreen in a Normal Waste Water Treatment Plant or<br />

Industrial Effluent Plant.<br />

<strong>Operation</strong><br />

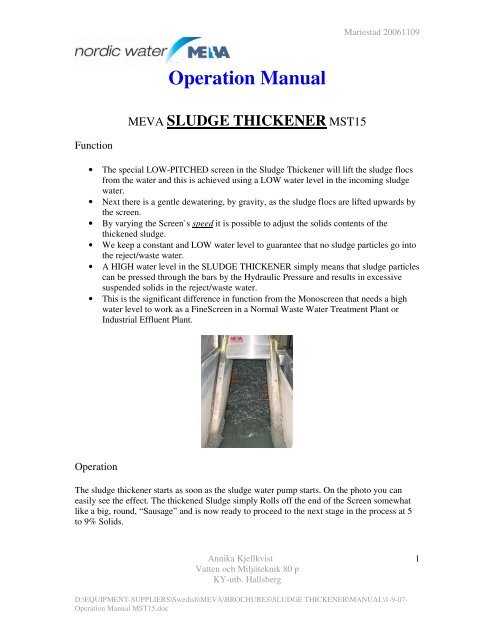

The sludge thickener starts as soon as the sludge water pump starts. On the photo you can<br />

easily see the effect. The thickened Sludge simply Rolls off the end of the Screen somewhat<br />

like a big, round, “Sausage” and is now ready to proceed to the next stage in the process at 5<br />

to 9% Solids.<br />

Annika Kjellkvist<br />

Vatten och Miljöteknik 80 p<br />

KY-utb. Hallsberg<br />

1<br />

D:\EQUIPMENT-SUPPLIERS\Swedish\MEVA\BROCHURES\<strong>SLUDGE</strong> <strong>THICKENER</strong>\MANUAL\1-9-07-<br />

<strong>Operation</strong> <strong>Manual</strong> MST15.doc

Mariestad 20061109<br />

Level Controls for Sludge Water<br />

A level meter is placed in a pipe in the incoming sludge water and set at a level about 25 cm.<br />

The Exact level has to be adjusted, from experience, later. The level meter is used to interlock<br />

the sludge water pump to ensure the reject/waste water quality remains optimal in terms of<br />

Suspended Solids.<br />

As the pump is interlocked, the screen will continue to lift up the sludge and the pump will<br />

start when the right water level has been reached.<br />

Frequency Inverter<br />

The <strong>SLUDGE</strong> <strong>THICKENER</strong> is controlled by a Frequency Inverter with the ability to adjust<br />

the screen speed and therefore the Sludge Solids.<br />

Regulation of Dry Solids content<br />

• The variation of the Screen`s speed is used to adjust the content of dry solids in the<br />

thickened sludge.<br />

• High volumes of incoming sludge water and high speed gives a LOWER content of<br />

dry solids.<br />

• LOWER volumes of sludge water and LOW Screen speed gives a HIGHER content of<br />

solids.<br />

• The same polymer dosing can be used.<br />

• The regulation can also be done by advance knowledge of the solid contents and the<br />

quality of the incoming sludge water. Less solids gives a higher frequency and a<br />

higher speed and vice versa.<br />

<strong>Operation</strong> time<br />

<strong>Operation</strong> time depends on the load on the screen, the amount of suspended solids in the<br />

incoming sludge water and desired content of solids in the final thickened sludge. Effective<br />

use is reached with an even covering of flocculated sludge over the entire screen surface.<br />

Polymer<br />

The polymer dose is best set by eye. Clear water should be seen between the sludge flocs. If<br />

the polymer is added before the sludge pump there is enough flocculation in the pump and the<br />

Annika Kjellkvist<br />

Vatten och Miljöteknik 80 p<br />

KY-utb. Hallsberg<br />

2<br />

D:\EQUIPMENT-SUPPLIERS\Swedish\MEVA\BROCHURES\<strong>SLUDGE</strong> <strong>THICKENER</strong>\MANUAL\1-9-07-<br />

<strong>Operation</strong> <strong>Manual</strong> MST15.doc

Mariestad 20061109<br />

following pipe. To increase the flocculation effect, two rubber cloths with a cross-cut, can be<br />

mounted in flanges along the pipe run to the <strong>SLUDGE</strong> <strong>THICKENER</strong> TANK.<br />

Reject water quality<br />

• A suspended solids meter in the reject water is set to alarm at a pre-set solids content.<br />

• This alarm is used to indicate that a manual inspection of the <strong>SLUDGE</strong> <strong>THICKENER</strong><br />

and an adjustment of the polymer dose may well be required.<br />

• The suspended solids meter will not regulate the polymer dose as it can give the<br />

opposite effect than that required !<br />

• Both under and over dose of polymer can give suspended solids in the reject/waste<br />

water so care and attention is required.<br />

• A maintenance technician needs to check if and when the alarm is triggered.<br />

• The Suspended Solids meter will ensure that there is not too much suspended solids in<br />

the reject/waste water.<br />

• We expect a solids content in reject/waste water to be < 100 mg/l.<br />

Loading of the <strong>SLUDGE</strong> <strong>THICKENER</strong><br />

• The loading of the sludge thickener will be calculated by the amount of sludge as kg<br />

solids/h.<br />

• Recommended load is 125 kg solids/h for model MST 15-50-1.Maximum load is 150<br />

kg solids/h for model MST 15-50-1.<br />

• Loading will vary with the size of each particular Sludge Thickener Model<br />

Example:<br />

• 10 m 3 sludge water with 1% solids contains about 120 kg solids.<br />

• 20 m 3 sludge water with 2% solids contains about 480 kg solids<br />

• One client loads the waste water with 90 gram solids/day !!<br />

• Industrial waste water can give different loads and has to be calculated.<br />

Maintenance<br />

Regular inspection – On a monthly basis.<br />

Check that:<br />

• The screen goes freely and quietly<br />

• The screen’s electric controls are working properly.<br />

Annika Kjellkvist<br />

Vatten och Miljöteknik 80 p<br />

KY-utb. Hallsberg<br />

3<br />

D:\EQUIPMENT-SUPPLIERS\Swedish\MEVA\BROCHURES\<strong>SLUDGE</strong> <strong>THICKENER</strong>\MANUAL\1-9-07-<br />

<strong>Operation</strong> <strong>Manual</strong> MST15.doc

Mariestad 20061109<br />

• Rinse the pipe to the level meter and the edges at the incoming sludge water area.<br />

• The bar screen is clear so that no screenings can build up and cause blockage between<br />

the bars. This is especially important for the section closest to the bottom of the<br />

thickener.<br />

• There is no sand or gravel in front of the bars.<br />

• Power Hose the face of the Screen at least once every two weeks<br />

Lubrication:<br />

• The machine is equipped with a bearing lubrication system and should be greased<br />

manually every month. Be careful as over greasing is not good for the bearings. The<br />

opposite is also true !!<br />

• The worn gear transmission oil should be changed once every one/two years<br />

depending on use.<br />

• Use SHELL OMALA 680 or equivalent.<br />

Thorough inspection – Once a year:<br />

• Wear components should be inspected and replaced if necessary. Wear<br />

components have a lifetime between one and seven years.<br />

• The following parts are considered as wear components:<br />

• Connecting rod bearings and axel bearing.<br />

• Slide pad and lower cross member slide plate.<br />

• Intermediate bar spacers.<br />

• The inlet and blade spacer and the discharge end blade spacer.<br />

Also check:<br />

• The bar units, their position and if they are straight.<br />

• The worm gear transmission.<br />

• That the screen can work freely and without noise.<br />

After inspection and service, re-fit, close and lock all covers!<br />

Annika Kjellkvist<br />

Vatten och Miljöteknik 80 p<br />

KY-utb. Hallsberg<br />

4<br />

D:\EQUIPMENT-SUPPLIERS\Swedish\MEVA\BROCHURES\<strong>SLUDGE</strong> <strong>THICKENER</strong>\MANUAL\1-9-07-<br />

<strong>Operation</strong> <strong>Manual</strong> MST15.doc

Mariestad 20061109<br />

Annika Kjellkvist<br />

Vatten och Miljöteknik 80 p<br />

KY-utb. Hallsberg<br />

5<br />

D:\EQUIPMENT-SUPPLIERS\Swedish\MEVA\BROCHURES\<strong>SLUDGE</strong> <strong>THICKENER</strong>\MANUAL\1-9-07-<br />

<strong>Operation</strong> <strong>Manual</strong> MST15.doc

Mariestad 20061109<br />

Annika Kjellkvist<br />

Vatten och Miljöteknik 80 p<br />

KY-utb. Hallsberg<br />

6<br />

D:\EQUIPMENT-SUPPLIERS\Swedish\MEVA\BROCHURES\<strong>SLUDGE</strong> <strong>THICKENER</strong>\MANUAL\1-9-07-<br />

<strong>Operation</strong> <strong>Manual</strong> MST15.doc