Condition Monitoring from GEA Westfalia Separator (wewatch®)

Condition Monitoring from GEA Westfalia Separator (wewatch®)

Condition Monitoring from GEA Westfalia Separator (wewatch®)

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

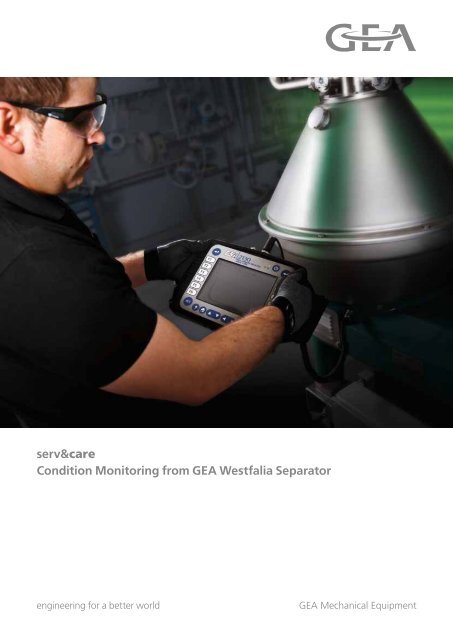

serv&care<br />

<strong>Condition</strong> <strong>Monitoring</strong> <strong>from</strong> <strong>GEA</strong> <strong>Westfalia</strong> <strong>Separator</strong><br />

engineering for a better world<br />

<strong>GEA</strong> Mechanical Equipment

Continuous <strong>Condition</strong> <strong>Monitoring</strong> Ensures Higher<br />

Reliability and Availability of Your Machines<br />

<strong>GEA</strong> <strong>Westfalia</strong> <strong>Separator</strong> wewatch ® permits ongoing condition<br />

monitoring and diagnosis. With minimum personnel input,<br />

this provides you with reliable information for optimizing the<br />

installation availability and avoiding unscheduled downtime.<br />

Vibration analysis – by handheld device:<br />

• Temporary status evaluation carried out by an<br />

experienced specialist<br />

• One time analysis of measuring results and<br />

recommendations<br />

<strong>Condition</strong> monitoring with wewatch ® is available in<br />

two versions – offline and online.<br />

Offline monitoring – <strong>GEA</strong> <strong>Westfalia</strong> <strong>Separator</strong> WatchMaster:<br />

The WatchMaster offline version monitors the actual machine<br />

condition permanently and shows it on a local traffic light LED<br />

display.<br />

• Instrument for constant measurements of the equipment<br />

• Measurement via on site installation<br />

• Downloadable database of historical measurements<br />

• Complete analysis and evaluation of historical<br />

measuring results<br />

Online monitoring –<br />

<strong>GEA</strong> <strong>Westfalia</strong> <strong>Separator</strong> WatchMaster plus:<br />

The “online” Version WatchMaster plus allows addition-<br />

ally the monitoring und evaluation through specialists of<br />

<strong>GEA</strong> <strong>Westfalia</strong> <strong>Separator</strong> Group in the subsidiaries and<br />

headquarter in Oelde. Any servicing which has to be carried<br />

<strong>GEA</strong> Mechanical Equipment<br />

<strong>GEA</strong> <strong>Westfalia</strong> <strong>Separator</strong> Group GmbH<br />

Werner-Habig-Straße 1, 59302 Oelde, Germany<br />

Phone: +49 2522 77-0, Fax: +49 2522 77-2488<br />

www.westfalia-separator.com<br />

out can be scheduled in good time to maximize reliability and<br />

productivity. With WatchMaster plus it is possible to step into<br />

a condition based, predictive service level agreement.<br />

• Instrument for constant measurements of the equipment<br />

• Measurement via on site installation<br />

• Constant data transfer via internet<br />

• Permanent condition monitoring of the machines and alarm<br />

handling<br />

• Worldwide online access to the installed systems<br />

• Only in conjunction with a service level agreement,<br />

including:<br />

• Regular reports concerning the condition of the machine<br />

• Early recognition of arising issues of the machine<br />

• Plannable repair work on the basis of the condition<br />

• Recording of key control parameters<br />

• Historical review of measured values and current values<br />

Advantages<br />

Offline:<br />

• Clearly visible status information<br />

• Minimized unscheduled downtimes<br />

• Enhanced plant availability and productivity<br />

• Additional plant safety<br />

• Structured analysis possible<br />

Online:<br />

• Optimized maintenance interval scheduling<br />

• Preventive and status-oriented service<br />

• Minimized unscheduled downtimes<br />

• Constant and simultaneous communication<br />

• Additional plant safety and optimized plant availability<br />

and productivity<br />

• Simplify Root Cause Analysis evaluation<br />

The information contained in this brochure merely serves as a non-binding description of our products and is without guarantee. Binding information, in particular relating to capacity data and suitability for specific applications, can only be provided within the framework of concrete<br />

inquiries. Printed on chlorine-free bleached paper · Printed in Germany · Subject to modification · <strong>Westfalia</strong> ® , <strong>Westfalia</strong> <strong>Separator</strong> ® and wewatch ® are registered trademarks of <strong>GEA</strong> Mechanical Equipment GmbH. B_SE-12-02-0002 EN