International Dyestuff Industry - ColorantsHistory.Org

International Dyestuff Industry - ColorantsHistory.Org

International Dyestuff Industry - ColorantsHistory.Org

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Japan, previously totally dependent on Germany for synthetic dyestuffs (6,000 tons alone in<br />

1913), also began their manufacture during the war. Several firms set up in business, and<br />

the largest company, Japanese <strong>Dyestuff</strong>s Manufacturing Co. (Nippon Senryo Seizo<br />

Kabushiki Kaisha), of Osaka, received considerable government assistance. Mitsui Mining<br />

and Tokyo Gas extracted coal tar hydrocarbons in 1914. Sulfur blacks and azo dyes were<br />

produced, as well as triphenylmethane dyes, and Mitsui (at Omuda, Qushu) and the<br />

Japanese <strong>Dyestuff</strong>s Manufacturing Co. attempted the production of indigo. After the war,<br />

Japanese <strong>Dyestuff</strong>s specialized in basic colors, direct cotton dyes, acid and sulfur colorants,<br />

and mordants. Mitsui continued with indigo and alizarin production. By 1920 Japanese dye<br />

exports to China were competing effectively against the products of Switzerland, Germany<br />

and the United States. The government-owned iron works and the Manchurian Railway coke<br />

works set about increasing the availability of coal tar products.<br />

The British <strong>Dyestuff</strong> Corporation (BDC) opened an agency in Japan during the time that<br />

German imports were interrupted after the war, and United States-made dyes were not<br />

well received. BDC also created the <strong>Dyestuff</strong>s Corporation of America by absorbing<br />

Levinstein's transatlantic sales outfit and the Read Holliday interests in America. It became<br />

an important sales outlet, and also offered dyes from Du Pont.<br />

The revival of confidence in Britain was demonstrated in 1922 at the British Industries Fair,<br />

held at the White City, London, where new and old dye-makers displayed their colorful<br />

wares. The major participants were: BDC, British Alizarine Co. Ltd., L.B. Holliday & Co. Ltd.,<br />

Scottish Dyes, John W. Leitch & Co. Ltd., Hickson & Partners, Ltd., John C. Oxley's Dyes &<br />

Chemicals Ltd., James Robinson & Co. Ltd., Gray's Dyes & Chemicals Ltd., J.B. & W.R.<br />

Sharp Ltd., Williams Bros. & Co., Alliance Colour & Chemical Co. Ltd., and the Ajax Aniline<br />

Dye Manufacturing Co. Within a decade the number was to fall, mainly as the result of<br />

mergers within the chemical industry that were associated with the formation of a major<br />

national producer.<br />

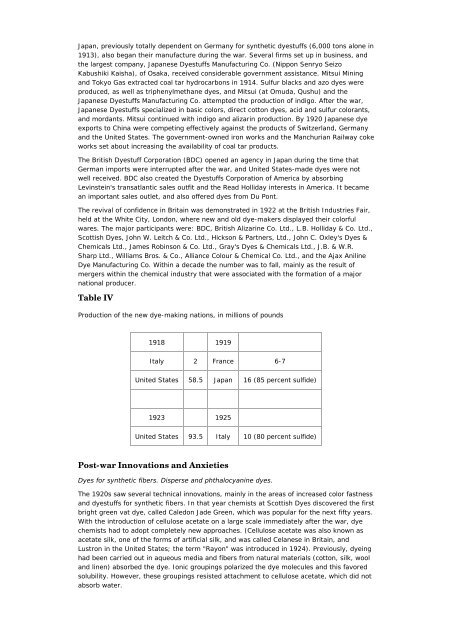

Table IV<br />

Production of the new dye-making nations, in millions of pounds<br />

1918 1919<br />

Italy 2 France 6-7<br />

United States 58.5 Japan 16 (85 percent sulfide)<br />

1923 1925<br />

United States 93.5 Italy 10 (80 percent sulfide)<br />

Post-war Innovations and Anxieties<br />

Dyes for synthetic fibers. Disperse and phthalocyanine dyes.<br />

The 1920s saw several technical innovations, mainly in the areas of increased color fastness<br />

and dyestuffs for synthetic fibers. In that year chemists at Scottish Dyes discovered the first<br />

bright green vat dye, called Caledon Jade Green, which was popular for the next fifty years.<br />

With the introduction of cellulose acetate on a large scale immediately after the war, dye<br />

chemists had to adopt completely new approaches. (Cellulose acetate was also known as<br />

acetate silk, one of the forms of artificial silk, and was called Celanese in Britain, and<br />

Lustron in the United States; the term "Rayon" was introduced in 1924). Previously, dyeing<br />

had been carried out in aqueous media and fibers from natural materials (cotton, silk, wool<br />

and linen) absorbed the dye. Ionic groupings polarized the dye molecules and this favored<br />

solubility. However, these groupings resisted attachment to cellulose acetate, which did not<br />

absorb water.