Quantitative effects of composting state variables on ... - ResearchGate

Quantitative effects of composting state variables on ... - ResearchGate

Quantitative effects of composting state variables on ... - ResearchGate

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Science <str<strong>on</strong>g>of</str<strong>on</strong>g> the Total Envir<strong>on</strong>ment 409 (2011) 1243–1254<br />

C<strong>on</strong>tents lists available at ScienceDirect<br />

Science <str<strong>on</strong>g>of</str<strong>on</strong>g> the Total Envir<strong>on</strong>ment<br />

journal homepage: www.elsevier.com/locate/scitotenv<br />

<str<strong>on</strong>g>Quantitative</str<strong>on</strong>g> <str<strong>on</strong>g>effects</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>composting</str<strong>on</strong>g> <str<strong>on</strong>g>state</str<strong>on</strong>g> <str<strong>on</strong>g>variables</str<strong>on</strong>g> <strong>on</strong> C/N ratio through GA-aided<br />

multivariate analysis<br />

Wei Sun a , Guo H. Huang a,b, ⁎, Guangming Zeng c , Xiaosheng Qin d , Hui Yu a<br />

a Faculty <str<strong>on</strong>g>of</str<strong>on</strong>g> Engineering and Applied Science, University <str<strong>on</strong>g>of</str<strong>on</strong>g> Regina, Regina, Saskatchewan, Canada, S4S 0A2<br />

b MOE Key Laboratory <str<strong>on</strong>g>of</str<strong>on</strong>g> Regi<strong>on</strong>al Energy Systems Optimizati<strong>on</strong>, Sino-Canada Energy and Envir<strong>on</strong>mental Research Academy, North China Electric Power University, Beijing, 102206 China<br />

c MOE Key Laboratory <str<strong>on</strong>g>of</str<strong>on</strong>g> Envir<strong>on</strong>mental Biology and Polluti<strong>on</strong> C<strong>on</strong>trol, College <str<strong>on</strong>g>of</str<strong>on</strong>g> Envir<strong>on</strong>mental Science and Engineering, Hunan University, Changsha, Hunan, 410082, China<br />

d School <str<strong>on</strong>g>of</str<strong>on</strong>g> Civil and Envir<strong>on</strong>mental Engineering, Nanyang Technological University, 50 Nanyang Avenue, Singapore 639798, Singapore<br />

article<br />

info<br />

abstract<br />

Article history:<br />

Received 20 August 2010<br />

Received in revised form 1 December 2010<br />

Accepted 17 December 2010<br />

Available <strong>on</strong>line 22 January 2011<br />

Keywords:<br />

Food waste <str<strong>on</strong>g>composting</str<strong>on</strong>g><br />

Stepwise cluster analysis<br />

Genetic algorithm<br />

Variable selecti<strong>on</strong><br />

The C/N ratio<br />

It is widely known that variati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the C/N ratio is dependent <strong>on</strong> many <str<strong>on</strong>g>state</str<strong>on</strong>g> <str<strong>on</strong>g>variables</str<strong>on</strong>g> during <str<strong>on</strong>g>composting</str<strong>on</strong>g><br />

processes. This study attempted to develop a genetic algorithm aided stepwise cluster analysis (GASCA)<br />

method to describe the n<strong>on</strong>linear relati<strong>on</strong>ships between the selected <str<strong>on</strong>g>state</str<strong>on</strong>g> <str<strong>on</strong>g>variables</str<strong>on</strong>g> and the C/N ratio in food<br />

waste <str<strong>on</strong>g>composting</str<strong>on</strong>g>. The experimental data from six bench-scale <str<strong>on</strong>g>composting</str<strong>on</strong>g> reactors were used to<br />

dem<strong>on</strong>strate the applicability <str<strong>on</strong>g>of</str<strong>on</strong>g> GASCA. Within the GASCA framework, GA searched optimal sets <str<strong>on</strong>g>of</str<strong>on</strong>g> both<br />

specified <str<strong>on</strong>g>state</str<strong>on</strong>g> <str<strong>on</strong>g>variables</str<strong>on</strong>g> and SCA's internal parameters; SCA established statistical n<strong>on</strong>linear relati<strong>on</strong>ships<br />

between <str<strong>on</strong>g>state</str<strong>on</strong>g> <str<strong>on</strong>g>variables</str<strong>on</strong>g> and the C/N ratio; to avoid unnecessary and time-c<strong>on</strong>suming calculati<strong>on</strong>, a proxy<br />

table was introduced to save around 70% computati<strong>on</strong>al efforts. The obtained GASCA cluster trees had smaller<br />

sizes and higher predicti<strong>on</strong> accuracy than the c<strong>on</strong>venti<strong>on</strong>al SCA trees. Based <strong>on</strong> the optimal GASCA tree, the<br />

<str<strong>on</strong>g>effects</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> the GA-selected <str<strong>on</strong>g>state</str<strong>on</strong>g> <str<strong>on</strong>g>variables</str<strong>on</strong>g> <strong>on</strong> the C/N ratio were ranged in a descending order as: NH 4 + -N<br />

c<strong>on</strong>centrati<strong>on</strong> N Moisture c<strong>on</strong>tentNAsh C<strong>on</strong>tent NMean TemperatureNMesophilic bacteria biomass. Such a<br />

rank implied that the variati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> amm<strong>on</strong>ium nitrogen c<strong>on</strong>centrati<strong>on</strong>, the associated temperature and the<br />

moisture c<strong>on</strong>diti<strong>on</strong>s, the total loss <str<strong>on</strong>g>of</str<strong>on</strong>g> both organic matters and available mineral c<strong>on</strong>stituents, and the<br />

mesophilic bacteria activity, were critical factors affecting the C/N ratio during the investigated food waste<br />

<str<strong>on</strong>g>composting</str<strong>on</strong>g>. This first applicati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> GASCA to <str<strong>on</strong>g>composting</str<strong>on</strong>g> modelling indicated that more direct search<br />

algorithms could be coupled with SCA or other multivariate analysis methods to analyze complicated<br />

relati<strong>on</strong>ships during <str<strong>on</strong>g>composting</str<strong>on</strong>g> and many other envir<strong>on</strong>mental processes.<br />

© 2010 Elsevier B.V. All rights reserved.<br />

1. Introducti<strong>on</strong><br />

Efficient operati<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>composting</str<strong>on</strong>g> relies <strong>on</strong> insights <str<strong>on</strong>g>of</str<strong>on</strong>g> relati<strong>on</strong>ships<br />

between <str<strong>on</strong>g>state</str<strong>on</strong>g> <str<strong>on</strong>g>variables</str<strong>on</strong>g> (e.g. oxygen c<strong>on</strong>centrati<strong>on</strong>, ash c<strong>on</strong>tent,<br />

moisture c<strong>on</strong>tent, and pH) and specific characteristics (e.g. microbial<br />

activities, maturity, and stability). Previously, many experimental<br />

approaches were developed in analyzing these relati<strong>on</strong>ships (Chefetz<br />

et al., 1996; Tiquia et al., 1996; Herrmann and Shann, 1997; Hsu and Lo,<br />

1999; Sanchez-M<strong>on</strong>edero et al., 2001; Liang et al., 2003; Galvez-Sola<br />

et al., 2010). However, experiment-based evaluati<strong>on</strong>s could hardly help<br />

quantify the interacti<strong>on</strong>s am<strong>on</strong>g multiple <str<strong>on</strong>g>composting</str<strong>on</strong>g> <str<strong>on</strong>g>state</str<strong>on</strong>g> <str<strong>on</strong>g>variables</str<strong>on</strong>g>.<br />

In comparis<strong>on</strong>, a model-based analysis could help examine the inherent<br />

impacts <str<strong>on</strong>g>of</str<strong>on</strong>g> various factors <strong>on</strong> the biological and physiochemical<br />

processes and gain an in-depth insight into the related mechanisms<br />

(Hamoda et al., 1998; Turner et al., 2005; Mas<strong>on</strong>, 2006; Chikae et al.,<br />

2006, 2007; Lin et al., 2008; D'Imporzano et al., 2008; Khalil et al., 2008;<br />

Mudhoo and Mohee, 2008; Vlyssides et al., 2009; Giusti and Marsili-<br />

⁎ Corresp<strong>on</strong>ding author. Faculty <str<strong>on</strong>g>of</str<strong>on</strong>g> Engineering, University <str<strong>on</strong>g>of</str<strong>on</strong>g> Regina, Regina,<br />

Saskatchewan, Canada, S4S 0A2. Tel.: +1 306 585 5631; fax: +1 306 585 4855.<br />

E-mail address: huangg@iseis.org (G.H. Huang).<br />

Libelli, 2010). Nevertheless, dynamic, n<strong>on</strong>linear and interactive features<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> these physicochemical or biological properties in <str<strong>on</strong>g>composting</str<strong>on</strong>g><br />

inherently make the analysis as a challenge. C<strong>on</strong>venti<strong>on</strong>al c<strong>on</strong>tinuous<br />

and linear methods cannot efficiently reflect such complicated<br />

relati<strong>on</strong>ships.<br />

Stepwise cluster analysis (SCA) is an emerging n<strong>on</strong>-parameter<br />

regressi<strong>on</strong> technology. It includes a series <str<strong>on</strong>g>of</str<strong>on</strong>g> cut or merge operati<strong>on</strong>s<br />

according to given statistic criteria and finally generates a cluster tree in<br />

the sense <str<strong>on</strong>g>of</str<strong>on</strong>g> probability. SCA has been applied to predicting air quality<br />

in the urban envir<strong>on</strong>ment (Huang, 1992), supporting diagnosis <str<strong>on</strong>g>of</str<strong>on</strong>g> lung<br />

cancer (Ren et al., 1997), and optimizing groundwater bioremediati<strong>on</strong><br />

processes (Qin et al., 2007; He et al., 2008b). However, applicati<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

SCA in approximating the relati<strong>on</strong>ships between <str<strong>on</strong>g>state</str<strong>on</strong>g> <str<strong>on</strong>g>variables</str<strong>on</strong>g> and<br />

specific characteristics during <str<strong>on</strong>g>composting</str<strong>on</strong>g> processes were relatively<br />

limited (Sun et al., 2009). Meanwhile, <strong>on</strong>e weakness <str<strong>on</strong>g>of</str<strong>on</strong>g> SCA is that its<br />

performance is sensitive to both input <str<strong>on</strong>g>variables</str<strong>on</strong>g> and internal parameters.<br />

Effective identificati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> these <str<strong>on</strong>g>variables</str<strong>on</strong>g> and parameters will<br />

be beneficial for improving the accuracy <str<strong>on</strong>g>of</str<strong>on</strong>g> SCA predictability. The<br />

identificati<strong>on</strong> process essentially involves soluti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> a n<strong>on</strong>linear,<br />

discrete optimizati<strong>on</strong> model with the objective functi<strong>on</strong> being the<br />

performance <str<strong>on</strong>g>of</str<strong>on</strong>g> SCA; this could hardly be handled by c<strong>on</strong>venti<strong>on</strong>al<br />

0048-9697/$ – see fr<strong>on</strong>t matter © 2010 Elsevier B.V. All rights reserved.<br />

doi:10.1016/j.scitotenv.2010.12.023

1244 W. Sun et al. / Science <str<strong>on</strong>g>of</str<strong>on</strong>g> the Total Envir<strong>on</strong>ment 409 (2011) 1243–1254<br />

gradient-based methods. Genetic algorithm (GA) is a powerful<br />

searching technique in seeking optimal soluti<strong>on</strong>s in large and complex<br />

decisi<strong>on</strong> spaces through imitating the principle <str<strong>on</strong>g>of</str<strong>on</strong>g> natural evoluti<strong>on</strong>. It<br />

has been successfully applied to variable or factor selecti<strong>on</strong> in various<br />

statistical predicti<strong>on</strong>s or machine learning studies (Depczynski et al.,<br />

2000; Cavill et al., 2009), as well as detecti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the most relevant<br />

spectral regi<strong>on</strong> related to the <str<strong>on</strong>g>composting</str<strong>on</strong>g> process (Martinez-Sabater<br />

et al., 2009).<br />

Therefore, the objective <str<strong>on</strong>g>of</str<strong>on</strong>g> this study is to develop a GA-aided<br />

stepwise-cluster analysis model (GASCA) through integrating GA and<br />

SCA within a general framework to quantify the n<strong>on</strong>linear relati<strong>on</strong>ships<br />

between <str<strong>on</strong>g>state</str<strong>on</strong>g> <str<strong>on</strong>g>variables</str<strong>on</strong>g> (time, temperatures, pH, moisture<br />

c<strong>on</strong>tent, ash c<strong>on</strong>tent, organic c<strong>on</strong>tent, NH 4 + -N c<strong>on</strong>centrati<strong>on</strong>, cumulative<br />

NH 3 emissi<strong>on</strong>s and bacterial biomass) and the C/N ratio in food<br />

waste <str<strong>on</strong>g>composting</str<strong>on</strong>g>. It entails: screening <str<strong>on</strong>g>of</str<strong>on</strong>g> significant <str<strong>on</strong>g>state</str<strong>on</strong>g> <str<strong>on</strong>g>variables</str<strong>on</strong>g><br />

and system parameters in virtue <str<strong>on</strong>g>of</str<strong>on</strong>g> the powerful search ability <str<strong>on</strong>g>of</str<strong>on</strong>g> GA;<br />

development <str<strong>on</strong>g>of</str<strong>on</strong>g> a GA-aided stepwise-cluster model for analyzing the<br />

<str<strong>on</strong>g>effects</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> multiple <str<strong>on</strong>g>state</str<strong>on</strong>g> <str<strong>on</strong>g>variables</str<strong>on</strong>g> <strong>on</strong> the C/N ratio; and dem<strong>on</strong>strati<strong>on</strong><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> the proposed method based <strong>on</strong> the data from bench-scale<br />

<str<strong>on</strong>g>composting</str<strong>on</strong>g> experimental systems.<br />

2. Materials and methods<br />

2.1. Feedstock and reactors<br />

We chose synthetic food waste as the <str<strong>on</strong>g>composting</str<strong>on</strong>g> feedstock and<br />

used six runs <str<strong>on</strong>g>of</str<strong>on</strong>g> designed <str<strong>on</strong>g>composting</str<strong>on</strong>g> experiments (bench-scale<br />

reactors) in our laboratory to describe various representative<br />

operati<strong>on</strong> c<strong>on</strong>diti<strong>on</strong>s. The synthetic food waste was produced using<br />

potato, carrot, ground pork, steamed rice (food products from a local<br />

grocery store) and American Elm leaves. Cooked soybean was added<br />

in Runs 1 and 2 to lower the C/N ratio. Baking soda (Sodium hydrogen<br />

carb<strong>on</strong>ate) was added in Runs 3 and 4 to adjust the pH value. Coal ash<br />

was added in Run 6 as a bulking agent. These materials were cut into<br />

pieces <str<strong>on</strong>g>of</str<strong>on</strong>g> approximately 5 mm in size and mixed thoroughly. The<br />

<str<strong>on</strong>g>composting</str<strong>on</strong>g> mixtures were manually turned over with a shovel <strong>on</strong>ce a<br />

day, and three samples (less than 50 g in total) from three locati<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

each reactor were collected for analyzing pH, moisture c<strong>on</strong>tent, ash<br />

c<strong>on</strong>tent, organic c<strong>on</strong>tent, NH 4 + -N c<strong>on</strong>centrati<strong>on</strong>s, bacterial biomass<br />

and C/N ratio. The weights <str<strong>on</strong>g>of</str<strong>on</strong>g> samples were kept minimal to avoid<br />

their <str<strong>on</strong>g>effects</str<strong>on</strong>g> <strong>on</strong> the <str<strong>on</strong>g>composting</str<strong>on</strong>g> process. The compositi<strong>on</strong>s and<br />

physiochemical characteristics <str<strong>on</strong>g>of</str<strong>on</strong>g> initial <str<strong>on</strong>g>composting</str<strong>on</strong>g> mixtures for the<br />

six runs are listed in Table 1.<br />

Each reactor is a cylindrical PVC tube (40.64 cm high and an<br />

effective volume <str<strong>on</strong>g>of</str<strong>on</strong>g> approximately 30 l) with three layers <str<strong>on</strong>g>of</str<strong>on</strong>g> heatinsulating<br />

materials preventing heat loss. On the bottom, an air inlet<br />

and a leachate outlet were c<strong>on</strong>nected. The inlet air, blown in by a<br />

vacuum pump, was distributed flowing upward through a holed<br />

vinyl pipe in the aerati<strong>on</strong> distributi<strong>on</strong> chamber near the bottom <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

the reactor. The aerati<strong>on</strong> rate was m<strong>on</strong>itored by a flow-meter. On the<br />

top, an air outlet, a thermometer point and a sampling port were<br />

distributed. The outlet air was discharged through a vinyl tube into a<br />

wide mouth flask c<strong>on</strong>taining H 2 SO 4 soluti<strong>on</strong> (100 ml 0.1 M) to absorb<br />

NH 3 . The final gas passing through a c<strong>on</strong>densati<strong>on</strong> bottle was<br />

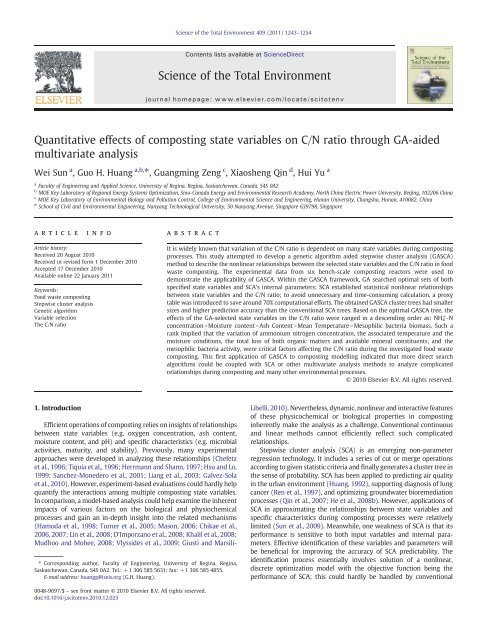

discharged to the lab ventilati<strong>on</strong> system. A flow diagram <str<strong>on</strong>g>of</str<strong>on</strong>g> the<br />

<str<strong>on</strong>g>composting</str<strong>on</strong>g> reactor is shown in Fig. 1.<br />

2.2. State <str<strong>on</strong>g>variables</str<strong>on</strong>g> and C/N ratio<br />

With the ambient temperature being maintained at 20±1 °C for<br />

all experimental runs, we placed a stainless steel rod with two<br />

thermometers (Traceable 15-077-9E, C<strong>on</strong>trol Company, TX, USA) at<br />

different depths <str<strong>on</strong>g>of</str<strong>on</strong>g> the compost matrix. The lower thermometer was<br />

fixed at a locati<strong>on</strong> 2.54 cm away from the segmentati<strong>on</strong> plate to obtain<br />

the surface's temperature. The upper <strong>on</strong>e was placed in the centre <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

the compost matrix and adjusted everyday with the change <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

compost height to acquire the core's temperature. The pH in a soluti<strong>on</strong><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> compost and water (weight ratio: 1:2) was measured through a<br />

bench top pH/Temperature Meter (Thermo Ori<strong>on</strong>, 410A Plus)<br />

(Thomas, 1996). The moisture c<strong>on</strong>tent by weight loss <str<strong>on</strong>g>of</str<strong>on</strong>g> compost<br />

sample was determined by the gravimetric method (Gardner, 1986);<br />

the ash c<strong>on</strong>tent and the organic c<strong>on</strong>tent were measured by the<br />

igniti<strong>on</strong> method (Nels<strong>on</strong> and Sommers, 1982). In additi<strong>on</strong>, NH 4 + -N<br />

c<strong>on</strong>centrati<strong>on</strong>s (mg/kg, wet Sample) and cumulative NH 3 emissi<strong>on</strong>s<br />

(μg/day) were analyzed through the FIAstar 5000 Analyzer (Foss<br />

analytic AB, Sweden) equipped with 5027 Sampler, interference<br />

filters (540 and 720 nm), and reducti<strong>on</strong> columns (Foss Analytical AB,<br />

2001). The col<strong>on</strong>y numbers <str<strong>on</strong>g>of</str<strong>on</strong>g> thermophilic and mesophilic bacteria<br />

were counted by the spread plate counting method (Wollum, 1982;<br />

Germida, 1993). The oxygen c<strong>on</strong>centrati<strong>on</strong>s in the surrounding air<br />

and the exhaust gas <str<strong>on</strong>g>of</str<strong>on</strong>g> the reactor were m<strong>on</strong>itored every 3 h by a M40<br />

Multi-Gas M<strong>on</strong>itor (Industrial Scientific Corp., Oakdale, PA, USA), and<br />

the C/N ratio (the ratio <str<strong>on</strong>g>of</str<strong>on</strong>g> total carb<strong>on</strong> and total nitrogen) was<br />

measured by the LECO TruSpec CN Determinator (LECO Corporati<strong>on</strong>,<br />

St. Joseph, MI, USA). More experimental details can be found in the<br />

work <str<strong>on</strong>g>of</str<strong>on</strong>g> An (2006).<br />

Table 1<br />

Initial <str<strong>on</strong>g>state</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> raw <str<strong>on</strong>g>composting</str<strong>on</strong>g> mixtures for six barrels.<br />

Barrel Unit 1 2 3 4 5 6<br />

Substrate Potato kg 2 2 2.2 2.2 2.0 1.7<br />

Steamed rice kg 3.1 3.1 3.5 3.5 3.2 2.8<br />

Carrot kg 3 3 3.4 3.4 3.1 2.7<br />

Leaves kg 0.7 0.7 0.8 0.8 0.7 0.6<br />

Meat kg 0.5 0.5 0.6 0.6 0.5 0.5<br />

Soy bean kg 3 6 – – – –<br />

Starting culture kg 0.5 0.5 0.5 0.5 0.5 0.5<br />

Coal ash kg – – – – – 4.0<br />

Baking soda kg – – 0.2 0.3 – –<br />

Total weight kg 12.8 15.8 11.2 11.3 12.8 15.8<br />

Chemical compositi<strong>on</strong> pH – 5.86 5.96 8.85 8.77 5.89 5.97<br />

Moisture c<strong>on</strong>tent % 56.98 56.38 62.55 66.65 64.27 50.09<br />

Ash c<strong>on</strong>tent % 1.88 2.08 2.90 2.38 1.48 29.73<br />

Organic c<strong>on</strong>tent % 41.14 41.54 34.55 30.97 34.25 20.18<br />

Carb<strong>on</strong> (dry) % 47.93 47.77 43.67 44.37 45.88 19.70<br />

Nitrogen (dry) % 3.25 3.17 1.34 1.48 1.44 0.56<br />

C/N ratio – 14.75 15.08 32.63 29.89 31.9 34.99<br />

Microorganism Thermophilic bacteria log CFU/g (dry) 4.667 7.146 4.728 4.477 6.080 5.478<br />

Mesophilic bacteria log CFU/g (dry) 12.366 11.341 12.284 11.322 8.447 13.068

W. Sun et al. / Science <str<strong>on</strong>g>of</str<strong>on</strong>g> the Total Envir<strong>on</strong>ment 409 (2011) 1243–1254<br />

1245<br />

Fig. 1. Schematic diagram <str<strong>on</strong>g>of</str<strong>on</strong>g> the <str<strong>on</strong>g>composting</str<strong>on</strong>g> system.<br />

3. Theoretical<br />

3.1. Framework <str<strong>on</strong>g>of</str<strong>on</strong>g> GASCA<br />

A GA-aided stepwise cluster analysis for describing the relati<strong>on</strong>ship<br />

between <str<strong>on</strong>g>state</str<strong>on</strong>g> <str<strong>on</strong>g>variables</str<strong>on</strong>g> and the C/N ratio during food waste<br />

<str<strong>on</strong>g>composting</str<strong>on</strong>g> c<strong>on</strong>sists <str<strong>on</strong>g>of</str<strong>on</strong>g> several major steps (Fig. 2). Firstly, all the<br />

observed <str<strong>on</strong>g>variables</str<strong>on</strong>g> during the six runs <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>composting</str<strong>on</strong>g> experiments<br />

are collected as the dataset for the GASCA model, since the sample<br />

numbers from a single experimental run are not enough for<br />

c<strong>on</strong>structing GASCA models. Then, GA searches optimal sets <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

specified <str<strong>on</strong>g>state</str<strong>on</strong>g> <str<strong>on</strong>g>variables</str<strong>on</strong>g> and SCA parameters through a number <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

standard procedures such as initiati<strong>on</strong>, crossover, and mutati<strong>on</strong>. An<br />

index based <strong>on</strong> both the normalized root mean squared error<br />

(RMSE) <str<strong>on</strong>g>of</str<strong>on</strong>g> the training set and the SCA tree's size is used as fitness<br />

functi<strong>on</strong> for evaluating the performance <str<strong>on</strong>g>of</str<strong>on</strong>g> each potential set <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

parameters (i.e. chromosomes). Meanwhile, a proxy table will be<br />

introduced to store the SCA characteristics (the chromosome<br />

informati<strong>on</strong> and its corresp<strong>on</strong>ding fitness) so as to avoid unnecessary<br />

and repetitive training <str<strong>on</strong>g>of</str<strong>on</strong>g> SCA. GA will c<strong>on</strong>tinue searching until<br />

the terminati<strong>on</strong> criteria are satisfied. Finally, the optimal combinati<strong>on</strong><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> parameters is identified and further used in SCA for<br />

approximating the relati<strong>on</strong>ship between the selected <str<strong>on</strong>g>state</str<strong>on</strong>g> <str<strong>on</strong>g>variables</str<strong>on</strong>g><br />

and the C/N ratio.<br />

Start<br />

Yes<br />

Gen=Gen+1<br />

Selecti<strong>on</strong>/Crossover/<br />

Mutati<strong>on</strong><br />

fitness functi<strong>on</strong><br />

Reserve Elitists<br />

fitness<br />

functi<strong>on</strong><br />

In Proxy<br />

table<br />

Yes<br />

No<br />

Data initializati<strong>on</strong><br />

Layer i=i+1<br />

Cut or Merge<br />

each Cluster<br />

Yes<br />

Gen ≤ max <br />

Still Cut or Merge<br />

No<br />

No<br />

Display Results<br />

end<br />

Save the<br />

Cluster Tree<br />

in Proxy table<br />

Fig. 2. Flow chart <str<strong>on</strong>g>of</str<strong>on</strong>g> GASCA.

1246 W. Sun et al. / Science <str<strong>on</strong>g>of</str<strong>on</strong>g> the Total Envir<strong>on</strong>ment 409 (2011) 1243–1254<br />

3.2. Dataset<br />

All the observed data from the six runs <str<strong>on</strong>g>of</str<strong>on</strong>g> food waste <str<strong>on</strong>g>composting</str<strong>on</strong>g><br />

were collected (198 samples) and combined to form the whole<br />

dataset. Each sample was a combinati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> inputs (i.e. <str<strong>on</strong>g>state</str<strong>on</strong>g> <str<strong>on</strong>g>variables</str<strong>on</strong>g><br />

and SCA's inherent parameters) and the C/N ratio. The <str<strong>on</strong>g>state</str<strong>on</strong>g> <str<strong>on</strong>g>variables</str<strong>on</strong>g><br />

had potential <str<strong>on</strong>g>effects</str<strong>on</strong>g> <strong>on</strong> C/N ratio variati<strong>on</strong>; they included time (X 1 ),<br />

mean temperature (X 2 ), pH (X 3 ), moisture c<strong>on</strong>tent (X 4 ), ash c<strong>on</strong>tent<br />

(X 5 ), organic c<strong>on</strong>tent (X 6 ), NH + 4 -N c<strong>on</strong>centrati<strong>on</strong> (X 7 ), cumulative NH 3<br />

emissi<strong>on</strong>s (X 8 ), log col<strong>on</strong>y count <str<strong>on</strong>g>of</str<strong>on</strong>g> thermophilic bacteria (X 9 ), log<br />

col<strong>on</strong>y count <str<strong>on</strong>g>of</str<strong>on</strong>g> mesophilic bacteria (X 10 ), upper temperature (X 11 ),<br />

and lower temperature (X 12 ). Although the sum <str<strong>on</strong>g>of</str<strong>on</strong>g> X 4 ,X 5 and X 6 was<br />

<strong>on</strong>e, the three <str<strong>on</strong>g>state</str<strong>on</strong>g> <str<strong>on</strong>g>variables</str<strong>on</strong>g> were still included since it was difficult to<br />

exclude <strong>on</strong>e <str<strong>on</strong>g>of</str<strong>on</strong>g> them from the candidates subjectively; The SCA's<br />

inherent parameters were α cut (significance level for cutting clusters),<br />

α merge (significance level for merging clusters), and N min (the<br />

minimum number <str<strong>on</strong>g>of</str<strong>on</strong>g> samples within tip clusters). The C/N ratio was<br />

the c<strong>on</strong>cerned output. The entire dataset was randomly divided into a<br />

training set (167 samples, 84%) and a test set (31 samples, 16%). The<br />

training set was used for calibrating the GASCA (or SCA) forecasting<br />

trees and the test <strong>on</strong>e was for verificati<strong>on</strong> in independent samples<br />

from different reactors. Since the magnitudes <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>state</str<strong>on</strong>g> <str<strong>on</strong>g>variables</str<strong>on</strong>g> were<br />

significantly different from each other, we firstly c<strong>on</strong>verted all input<br />

datasets into the range <str<strong>on</strong>g>of</str<strong>on</strong>g> [−1, 1] before the training process and then<br />

transformed the values <str<strong>on</strong>g>of</str<strong>on</strong>g> the predicted dependent <str<strong>on</strong>g>variables</str<strong>on</strong>g> back to<br />

their original ranges after the training was completed.<br />

3.3. Principle <str<strong>on</strong>g>of</str<strong>on</strong>g> stepwise cluster analysis (SCA)<br />

SCA is based <strong>on</strong> the theory <str<strong>on</strong>g>of</str<strong>on</strong>g> multivariate analysis <str<strong>on</strong>g>of</str<strong>on</strong>g> variance.<br />

Generally, two phases are involved in its implementati<strong>on</strong>: training<br />

and test. In the training phase, the sample dataset is cut into two<br />

subsets (clusters) and then two are merged into <strong>on</strong>e during the<br />

iterative training process. According to Wilks' likelihood-ratio<br />

criteri<strong>on</strong>, the cutting point is optimal <strong>on</strong>ly if the value <str<strong>on</strong>g>of</str<strong>on</strong>g> Wilks' Λ is<br />

minimum (Wilks, 1962). Since the Λ is directly related to the F<br />

statistic, the sample means <str<strong>on</strong>g>of</str<strong>on</strong>g> the two sub-clusters can be compared<br />

for significant differences through F test (Rao, 1952). Thus, the criteria<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> cutting (or merging or not) clusters rely <strong>on</strong> a set <str<strong>on</strong>g>of</str<strong>on</strong>g> F tests (Rao,<br />

1965; Tatsuoka, 1971). Based <strong>on</strong> the F tests, a tree is shaped step by<br />

step until no subsets could be cut or merged any more. In the test<br />

phase, the values <str<strong>on</strong>g>of</str<strong>on</strong>g> the new independent <str<strong>on</strong>g>variables</str<strong>on</strong>g> in the test samples<br />

will be used as references to determine which child cluster a sample in<br />

the parent cluster will enter. Thus, the sample would gradually enter<br />

<strong>on</strong>e tip cluster. The mean <str<strong>on</strong>g>of</str<strong>on</strong>g> dependent <str<strong>on</strong>g>variables</str<strong>on</strong>g> from the training set<br />

at the tip cluster that the sample finally enters becomes the predicted<br />

value <str<strong>on</strong>g>of</str<strong>on</strong>g> the sample's dependent variable. A more detailed descripti<strong>on</strong><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> SCA can be referred to our previous work (Qin et al., 2008).<br />

3.4. Variable/parameter selecti<strong>on</strong> using GA<br />

An integrated GASCA model combining GA with SCA would possess<br />

abilities in both variable searching and n<strong>on</strong>linear fitting. GA transfers<br />

chromosome informati<strong>on</strong> (certain independent <str<strong>on</strong>g>variables</str<strong>on</strong>g> and inherent<br />

parameters) to SCA and then SCA returned the fitness (an index reflecting<br />

both structure and performance <str<strong>on</strong>g>of</str<strong>on</strong>g> the SCA tree) to the corresp<strong>on</strong>ding<br />

chromosome in GA. In detail, the chromosome is a 19-bit binary string.<br />

The first twelve binary strings encode all the SCA's candidate independent<br />

<str<strong>on</strong>g>variables</str<strong>on</strong>g>, where the ‘1’ represents that its corresp<strong>on</strong>ding independent<br />

variable is selected while the ‘0’ means not. The last seven binary<br />

strings represent inherent parameters <str<strong>on</strong>g>of</str<strong>on</strong>g> SCA (α cut , α merge and N min ). In<br />

order to unify the calculati<strong>on</strong>, we chosen several representative values<br />

within the appropriate ranges <str<strong>on</strong>g>of</str<strong>on</strong>g> the three parameters respectively and<br />

used binary strings to represent the locati<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> each value in the ranges.<br />

Thus the binary strings are capable <str<strong>on</strong>g>of</str<strong>on</strong>g> describing real-number values <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

SCA's inherent parameters. The mapping relati<strong>on</strong>ships between the<br />

binary string and the <str<strong>on</strong>g>variables</str<strong>on</strong>g>/parameters are illustrated in Fig. 3.<br />

An index based <strong>on</strong> both the SCA's fitting accuracy and the SCA tree's<br />

complexity was developed as the fitness functi<strong>on</strong>. The accuracy <str<strong>on</strong>g>of</str<strong>on</strong>g> SCA's<br />

fitting is defined as RMSE <str<strong>on</strong>g>of</str<strong>on</strong>g> the training set. The complexity <str<strong>on</strong>g>of</str<strong>on</strong>g> SCA tree<br />

is depicted as the sum <str<strong>on</strong>g>of</str<strong>on</strong>g> normalized layer number <str<strong>on</strong>g>of</str<strong>on</strong>g> the SCA (N s,layer ),<br />

the normalized node number <str<strong>on</strong>g>of</str<strong>on</strong>g> the SCA (N s,node ) and the normalized<br />

number <str<strong>on</strong>g>of</str<strong>on</strong>g> independent <str<strong>on</strong>g>variables</str<strong>on</strong>g> (N s,x ). Four weighting coefficients<br />

(μ 1 , μ 2 , μ 3 , and μ 4 ) were introduced to balance the accuracy and the<br />

complexity. Thus the fitness functi<strong>on</strong> has the following definiti<strong>on</strong>:<br />

Fitness = μ 1 RMSE s + μ 2 N s;layer + μ 3 N s;node + μ 4 N s;x<br />

vffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffiffi<br />

n<br />

u∑<br />

ðy j −y training; j Þ 2<br />

tj =1<br />

−RMSE<br />

n−1<br />

min<br />

RMSE s =<br />

RMSE max −RMSE min<br />

N layer−N layer; min<br />

N s;layer =<br />

N layer; max −N layer; min<br />

N node−N node; min<br />

N s;node =<br />

N node; max −N node; min<br />

N s;x =<br />

N x−N x; min<br />

N x; max −N x; min<br />

where RMSE min and RMSE max are ideal minimum and maximum values <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

RMSE, respectively; n is the number <str<strong>on</strong>g>of</str<strong>on</strong>g> samples in the training set; y j and<br />

y training,j are the predicted and observed values for C/N in the jth sample in<br />

the training set, respectively; N layer is the layer number <str<strong>on</strong>g>of</str<strong>on</strong>g> the SCA tree.<br />

N layer,min and N layer,max are ideal minimum and maximum values <str<strong>on</strong>g>of</str<strong>on</strong>g> N layer ,<br />

ð1Þ<br />

ð2Þ<br />

ð3Þ<br />

ð4Þ<br />

ð5Þ<br />

X1<br />

Input Variables <str<strong>on</strong>g>of</str<strong>on</strong>g> SCA<br />

Internal Parameters <str<strong>on</strong>g>of</str<strong>on</strong>g> SCA<br />

State Variables<br />

α cut α merge N min<br />

X2 X3 X4 X5 X6 X7 X8 X9 X10 X11 X12 C1 C2 C3 M1 M2 N1 N2<br />

Populati<strong>on</strong><br />

1 0 ... 1 0 1 ... 0 1 1 ... 0 1 1 1<br />

1 1 ... 0 1 0 ... 0 1 0 ... 0 0 1 0<br />

1 0 ... 1 1 1 ... 0 1 1 ... 0 1 1 0<br />

0 0 ... 1 1 1 ... 0 1 1 ... 0 1 1 0<br />

… … ...<br />

0 1 ... 1 0 1 ... 0 1 0 ... 0 1 0 1<br />

1 0 ... 1 0 1 ... 0 1 0 ... 0 1 1 0<br />

Detailed form<br />

1 0 1 1 0 1 1 1 0 0 1 1 1 0 1 1 0 1 0<br />

Vector 1 1 1 0 1 0 1 0 1 0 1 0 1 0 1 0 1 0 1<br />

1 0 0 0 1 1 0 1 1 0 1 0 0 0 1 0 1 1 0<br />

1 0 1 0 0 1 1 1 0 0 1 0 1 0 1 0 0 1 0<br />

mutati<strong>on</strong> mutati<strong>on</strong><br />

mutati<strong>on</strong><br />

1 0 1 0 1 1 1 0 0 0 1 0 1 0 1 1 0 1 0<br />

crossover<br />

Fig. 3. Principle <str<strong>on</strong>g>of</str<strong>on</strong>g> GASCA.

W. Sun et al. / Science <str<strong>on</strong>g>of</str<strong>on</strong>g> the Total Envir<strong>on</strong>ment 409 (2011) 1243–1254<br />

1247<br />

respectively; N node is the node number <str<strong>on</strong>g>of</str<strong>on</strong>g> the SCA tree; N node,min and<br />

N node,max are ideal minimum and maximum values <str<strong>on</strong>g>of</str<strong>on</strong>g> N node ,respectively;<br />

N x is the number <str<strong>on</strong>g>of</str<strong>on</strong>g> independent <str<strong>on</strong>g>variables</str<strong>on</strong>g>; N x,min and N x,max are ideal<br />

minimum and maximum values <str<strong>on</strong>g>of</str<strong>on</strong>g> N x , respectively.<br />

Similar to the c<strong>on</strong>structi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> a single chromosome, a populati<strong>on</strong><br />

with a group <str<strong>on</strong>g>of</str<strong>on</strong>g> chromosomes in GA would be randomly generated.<br />

Parents would be selected based <strong>on</strong> individuals' fitness values using<br />

the stochastic uniform method, then further intercrossed to exchange<br />

their genetic informati<strong>on</strong> by the scattered crossover method, and<br />

mutated through changing their informati<strong>on</strong> randomly by the<br />

Gaussian mutati<strong>on</strong> method (The MathWorks, 2008). Generati<strong>on</strong> by<br />

generati<strong>on</strong>, parents with worse fitness would be replaced by children<br />

with better fitness in the evaluated populati<strong>on</strong>. Once the stopping<br />

criteri<strong>on</strong> was satisfied; the chromosome with the lowest fitness value<br />

would represent the informati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the final optimal combinati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

<str<strong>on</strong>g>variables</str<strong>on</strong>g>/parameters for SCA.<br />

3.5. Program implementati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> GASCA<br />

A flow diagram <str<strong>on</strong>g>of</str<strong>on</strong>g> GASCA is presented in Fig. 2. All programs were<br />

written in Matlab R2008a (The MathWorks, 2008). The main program<br />

for coupling GA and SCA is clarified as follows:<br />

Step 1: Before SCA training, the entire dataset (the <str<strong>on</strong>g>state</str<strong>on</strong>g> <str<strong>on</strong>g>variables</str<strong>on</strong>g><br />

and C/N) is scaled to fall within the range <str<strong>on</strong>g>of</str<strong>on</strong>g> −1 to1;<br />

Step 2: A number (the default is 100) <str<strong>on</strong>g>of</str<strong>on</strong>g> randomly generated<br />

chromosomes (<str<strong>on</strong>g>of</str<strong>on</strong>g> a bit length equal to the number <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>state</str<strong>on</strong>g><br />

<str<strong>on</strong>g>variables</str<strong>on</strong>g> and inherent parameters chosen) form a populati<strong>on</strong>;<br />

Step 3: GA invokes the SCA functi<strong>on</strong> to evaluate fitness <str<strong>on</strong>g>of</str<strong>on</strong>g> every<br />

chromosome in the populati<strong>on</strong>:<br />

Step 4: New chromosomes are generated through selecti<strong>on</strong>,<br />

crossover, and mutati<strong>on</strong> operati<strong>on</strong>s; GA invokes the SCA functi<strong>on</strong><br />

to calculate fitness values <str<strong>on</strong>g>of</str<strong>on</strong>g> new chromosomes.<br />

Step 5: Replace the old chromosomes with new chromosomes;<br />

Step 6: After all operati<strong>on</strong>s, the chromosome with the worst fitness<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> the entire populati<strong>on</strong> is replaced with the current elitist;<br />

Step 7: Return to Step 4 to begin the evoluti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the next<br />

generati<strong>on</strong>; if the generati<strong>on</strong> number exceeds a certain value (e.g.<br />

25), the program will end.<br />

The computati<strong>on</strong>al procedures <str<strong>on</strong>g>of</str<strong>on</strong>g> the SCA functi<strong>on</strong> are described as<br />

follows:<br />

Step 1: GA will search the proxy table to find out whether the same<br />

chromosome is calculated already or not; if yes, the corresp<strong>on</strong>ding<br />

fitness will be assigned to the chromosome directly and the<br />

program goes to Step 12, and if no, goes to Step 2;<br />

Step 2: GA invokes SCA to evaluate the fitness <str<strong>on</strong>g>of</str<strong>on</strong>g> every<br />

chromosome: the entire training dataset will be cut into a smaller<br />

<strong>on</strong>e based <strong>on</strong> the independent variable informati<strong>on</strong> embedded in<br />

the chromosome; such a dataset is treated as a leaf cluster (i.e. a<br />

cluster without sub-clusters); the parameter informati<strong>on</strong> (α cutting ,<br />

α merging and N min ) will be used in Steps 9, 11 and 12;<br />

Step 3: For every leaf cluster, each <str<strong>on</strong>g>state</str<strong>on</strong>g> variable X id (i.e.<br />

independent <str<strong>on</strong>g>variables</str<strong>on</strong>g>, id=1, 2, …, m) is chosen in the order <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

X 1 to X m ; the samples (including both independent and dependent<br />

<str<strong>on</strong>g>variables</str<strong>on</strong>g>) in cluster σ (matrix) are sequenced to σ(X id )inan<br />

ascending order according to the value <str<strong>on</strong>g>of</str<strong>on</strong>g> X id ;<br />

Step 4: For the matrix σ(X id ), every cutting line nr (between row i<br />

to row i+1, nr=1, 2, …, n−1) is chosen in the order from 1 to n<br />

−1; n is the number <str<strong>on</strong>g>of</str<strong>on</strong>g> samples for cluster σ(X id ); the cluster<br />

σ(X id ) will be divided into two sub Clusters β and γ according to<br />

the cutting line;<br />

Step 5 The Wilks' Λ based <strong>on</strong> the dependent <str<strong>on</strong>g>variables</str<strong>on</strong>g> (Y β and Y γ )is<br />

calculated; by comparing all m*(n−1) values <str<strong>on</strong>g>of</str<strong>on</strong>g> Wilks' Λ, the<br />

minimal value <str<strong>on</strong>g>of</str<strong>on</strong>g> Λ(id*, nr*) can be obtained;<br />

Step 6: Calculate the F cal value; if F cal ≥F α-cuting , the parent cluster<br />

can be cut into two sub-clusters;<br />

Step 7: The independent variable and the value in the cutting point<br />

(x id *, nr*) becomes a judging criteri<strong>on</strong>; all samples in this cluster<br />

with x id*, nr ≤x id*, nr* are allocated to <strong>on</strong>e sub-cluster, with the rest<br />

to the other;<br />

Step 8: Repeat Steps 3 to 7 until all clusters are tested for possible<br />

cutting in the present layer;<br />

Step 9: When the cutting operati<strong>on</strong> in the present layer is d<strong>on</strong>e, the<br />

merging operati<strong>on</strong>s begin; if other old leaf clusters exist, these new<br />

leaf clusters will be tested al<strong>on</strong>g with all other leaf clusters to<br />

dem<strong>on</strong>strate whether pairs <str<strong>on</strong>g>of</str<strong>on</strong>g> them could be merged into <strong>on</strong>e<br />

cluster; the Wilks' Λ and F cal values will be calculated for each pair<br />

clusters; if F cal ≥F α-merging , the two clusters will be c<strong>on</strong>sidered<br />

having no significant difference and can be merged;<br />

Step 10: If there are no other old leaf clusters or no merged<br />

operati<strong>on</strong>s are needed, the new leaf clusters will be treated as new<br />

clusters and tested for further cutting or merging operati<strong>on</strong>s<br />

according to Steps 3 to 9;<br />

Step 11: If no leaf cluster can be cut or merged or the number <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

samples in every cluster is less than N min , the training process is<br />

completed with the SCA tree being shaped; then, the fitness <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

chromosome is calculated based <strong>on</strong> Eqs. (1)–(5);<br />

Step 12: Return to Step 1 for evaluating the next chromosome; if<br />

the fitness <str<strong>on</strong>g>of</str<strong>on</strong>g> each existing chromosome has been evaluated,<br />

return to the main program.<br />

4. Results<br />

4.1. Structure <str<strong>on</strong>g>of</str<strong>on</strong>g> GA<br />

In general, GA's fitness functi<strong>on</strong> and operati<strong>on</strong> (selecti<strong>on</strong>, crossover,<br />

and mutati<strong>on</strong>) c<strong>on</strong>figurati<strong>on</strong>s have significant impacts <strong>on</strong> its performance.<br />

The fitness functi<strong>on</strong> is always problem-oriented; determinati<strong>on</strong><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> its value (Eqs. (1)–(5)) depends <strong>on</strong> the relevant coefficients selecti<strong>on</strong>,<br />

according to the datasets <str<strong>on</strong>g>of</str<strong>on</strong>g> food waste <str<strong>on</strong>g>composting</str<strong>on</strong>g>. Through error and<br />

test, four weighting coefficients (i.e. μ 1 , μ 2 , μ 3 ,andμ 4 )forbalancingthe<br />

accuracy and the complexity <str<strong>on</strong>g>of</str<strong>on</strong>g> SCA were determined as 1.04, 0.35, 0.37<br />

and 0.024. The coefficients for normalizing SCA' complexity calculati<strong>on</strong><br />

(i.e. RMSE min ,RMSE max ,N layer,min ,N layer,max ,N node,min, N node,max, N x,min<br />

and N x,max ) were c<strong>on</strong>figured as 0, 10, 3, 150, 3, 1500, 2 and 12,<br />

respectively. GA's standard operati<strong>on</strong>s are c<strong>on</strong>trolled by the relevant<br />

parameters, including the populati<strong>on</strong> size (PS), the selecti<strong>on</strong> rate (SR),<br />

the crossover fracti<strong>on</strong> (CF, or crossover rate), and the mutati<strong>on</strong> rate<br />

(MR). Usually, the larger the PS, the higher the CF; the higher the MR, the<br />

more diversified the chromosomes. However, a larger PS and a higher<br />

MR may lead to the requirement <str<strong>on</strong>g>of</str<strong>on</strong>g> more computati<strong>on</strong>al efforts.<br />

To obtain a relative optimal c<strong>on</strong>figurati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> GA for supporting<br />

SCA's variable selecti<strong>on</strong>, PS and CF (MR=1–CF in our GA program)<br />

were chosen to examine their <str<strong>on</strong>g>effects</str<strong>on</strong>g> <strong>on</strong> fitness. We changed <strong>on</strong>e <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

them in its possible range and kept the other at its default value<br />

during each observati<strong>on</strong>. The results indicated that, when the PS<br />

increased from 20 to 110 by every 10 units, the obtained optimal<br />

fitness value would fluctuate and keep as a c<strong>on</strong>stant after the PS<br />

exceeds 100. Similarly, the obtained optimal fitness value would keep<br />

the same when CF was greater than 0.8 (in the range from 0 to 1 by<br />

every 0.05). Thus, the optimal setting <str<strong>on</strong>g>of</str<strong>on</strong>g> GA for SCA was set as:<br />

populati<strong>on</strong> size=100, crossover fracti<strong>on</strong>=0.8 and maximum allowable<br />

generati<strong>on</strong>=25. The operati<strong>on</strong> processes <str<strong>on</strong>g>of</str<strong>on</strong>g> GA under such a<br />

setting are illustrated in Fig. 4. Over the entire GA iterati<strong>on</strong>, the best,

1248 W. Sun et al. / Science <str<strong>on</strong>g>of</str<strong>on</strong>g> the Total Envir<strong>on</strong>ment 409 (2011) 1243–1254<br />

Best, Worst, and Mean Scores<br />

Average Distance<br />

Times Calling Proxy Table<br />

0.9<br />

0.8<br />

0.7<br />

0.6<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

3.5<br />

3<br />

2.5<br />

2<br />

1.5<br />

1<br />

0.5<br />

0<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

worse and the average fitness value (the vertical bars in Fig. 4a) would<br />

decrease gradually with the increase <str<strong>on</strong>g>of</str<strong>on</strong>g> generati<strong>on</strong> number. There<br />

were always significant differences between the best and the average<br />

fitness values at each generati<strong>on</strong>; the average distance would<br />

decrease instantly but automatically keep fluctuating during the<br />

process <str<strong>on</strong>g>of</str<strong>on</strong>g> GA operati<strong>on</strong> (Fig. 4b). This dem<strong>on</strong>strated that the<br />

populati<strong>on</strong> diversity could be maintained and the undesired prematurity<br />

could be avoided during GA operati<strong>on</strong>s.<br />

4.2. Interacti<strong>on</strong>s between SCA and GA<br />

5 10 15 20 25<br />

5 10 15 20 25<br />

5 10 15 20 25<br />

Generati<strong>on</strong><br />

(a)<br />

(b)<br />

(c)<br />

Fig. 4. Representative operati<strong>on</strong> processes <str<strong>on</strong>g>of</str<strong>on</strong>g> GASCA 2 .<br />

Within the GASCA framework, reducti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> SCA's computati<strong>on</strong>al<br />

efforts is critical for improving GASCA's efficiency. This is due to: (i) the<br />

SCA's calculati<strong>on</strong> amount increases significantly with the increase <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

dataset volume, and (ii) SCA is frequently invoked to calculate the<br />

fitness functi<strong>on</strong> during the GA operati<strong>on</strong>. Thus, effective use <str<strong>on</strong>g>of</str<strong>on</strong>g> SCA's<br />

results that have been calculated during the former generati<strong>on</strong>s would<br />

greatly improve the entire efficiency <str<strong>on</strong>g>of</str<strong>on</strong>g> GASCA. To this end, a proxy table<br />

are introduced to realize this mechanism. During GA operati<strong>on</strong>s, when<br />

GASCA needs to evaluate the fitness <str<strong>on</strong>g>of</str<strong>on</strong>g> a new chromosome, a proxy table<br />

can be used to find out whether the same chromosome has been<br />

calculated in the previous generati<strong>on</strong>s. Fig. 4c shows that the time to<br />

invoke the proxy table gradually increase to its maximum value with the<br />

increase <str<strong>on</strong>g>of</str<strong>on</strong>g> generati<strong>on</strong> numbers. During the early stage <str<strong>on</strong>g>of</str<strong>on</strong>g> GASCA, the<br />

invoking time was relatively limited. It implied that most <str<strong>on</strong>g>of</str<strong>on</strong>g> the SCAs<br />

needed to be trained since there were few chromosome records in the<br />

proxy table. At later stages, the invoking time kept increasing since more<br />

and more chromosome records were saved in the proxy table.<br />

Therefore, the corresp<strong>on</strong>ding fitness values <str<strong>on</strong>g>of</str<strong>on</strong>g> many SCAs could be<br />

obtained directly from the proxy table since these chromosomes and<br />

their fitness values had already been recorded. In Fig. 4c, the sum <str<strong>on</strong>g>of</str<strong>on</strong>g> time<br />

invoking the proxy table was 1879 while that required for calculating<br />

the fitness was 2600; about 72% efforts for fitness calculati<strong>on</strong> had been<br />

saved. It thus dem<strong>on</strong>strated that the introducti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> a proxy table could<br />

effectively reduce the chance <str<strong>on</strong>g>of</str<strong>on</strong>g> repetitive training and thus significantly<br />

improve the efficiency <str<strong>on</strong>g>of</str<strong>on</strong>g> GASCA iterati<strong>on</strong>.<br />

In additi<strong>on</strong> to efficiency, the accuracy <str<strong>on</strong>g>of</str<strong>on</strong>g> the final result <str<strong>on</strong>g>of</str<strong>on</strong>g> GASCA is<br />

also critical. The manner that GA affects the c<strong>on</strong>structi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> a SCA tree<br />

largely determines the performance <str<strong>on</strong>g>of</str<strong>on</strong>g> a GASCA tree. The factors for<br />

c<strong>on</strong>trolling SCA's performance c<strong>on</strong>sist <str<strong>on</strong>g>of</str<strong>on</strong>g> dataset quality, dataset<br />

partiti<strong>on</strong> strategy, SCA's internal parameters (α cut , α merge and N min ),<br />

and the combinati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> candidate independent <str<strong>on</strong>g>variables</str<strong>on</strong>g> (Qin et al.,<br />

2007). In this study, the candidate independent <str<strong>on</strong>g>variables</str<strong>on</strong>g> and<br />

inherent parameters <str<strong>on</strong>g>of</str<strong>on</strong>g> SCA are c<strong>on</strong>sidered as the major factors that<br />

GA would affect a SCA tree. In our practice for the current dataset <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

food waste <str<strong>on</strong>g>composting</str<strong>on</strong>g>, it is found that the SCA would tend to be overfitting<br />

(i.e. the RMSE for the test set is much worse than the <strong>on</strong>e for the<br />

training set) in <strong>on</strong>e <str<strong>on</strong>g>of</str<strong>on</strong>g> following settings: 1) when the α cut is less than<br />

0.03 or greater than 0.065; 2) when the α merge is less than 0.05 or<br />

greater than 0.065; 3) when the α cut is greater than α merge ; 4) and<br />

when N min is less than 7 and greater than 10. Thus, the variati<strong>on</strong> range<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> inherent parameters are set as: α cut ∈ [0.03, 0.065], α merge ∈ [0.05,<br />

0.065], and N min ∈ integer in [7, 10]. Since α cut and α merge are real<br />

numbers, it is difficult to incorporate them into binary-bit chromosomes.<br />

Alternatively, a set <str<strong>on</strong>g>of</str<strong>on</strong>g> representative values for these inherent<br />

parameters are chosen as: α cut ∈{0.03, 0.035, 0.04, 0.045, 0.05, 0.055,<br />

0.06, 0.065}, α merge ∈{0.05, 0.055, 0.06, 0.065}, and N min ∈ {7, 8, 9, 10}.<br />

Meanwhile, 3, 2 and 2 binary-bits are used to represent 2 3 ,2 2 , and 2 2<br />

numbers <str<strong>on</strong>g>of</str<strong>on</strong>g> representative values, respectively. For example, the last<br />

seven bit <str<strong>on</strong>g>of</str<strong>on</strong>g> chromosome (1010110) includes three parts 101 (No.6 in<br />

α cut 's representative values), 01 (No.2 for α merge ) and 10 (No.3 for<br />

N min ), which means the corresp<strong>on</strong>ding values were chosen as:<br />

α cut =0.055, α merge =0.055, and N min =9. In this manner, the values<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> chromosomes in GA represent the locati<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> parameters in the<br />

given ranges. Al<strong>on</strong>g with the evoluti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> GA, the performance <str<strong>on</strong>g>of</str<strong>on</strong>g> the<br />

chromosomes will be improved and the related parameters will be<br />

transferred to SCA.<br />

4.3. GASCA vs. SCA<br />

To compare GASCA with SCA, four opti<strong>on</strong>al SCA/GASCA models<br />

were calculated (Table 2). SCA 1 has all <str<strong>on</strong>g>of</str<strong>on</strong>g> the candidate independent<br />

<str<strong>on</strong>g>variables</str<strong>on</strong>g> and uses each internal parameter at its default value; SCA 2<br />

selects these <str<strong>on</strong>g>variables</str<strong>on</strong>g>/parameters through the trial and error<br />

method; GASCA 1 uses GA to select <strong>on</strong>ly independent <str<strong>on</strong>g>variables</str<strong>on</strong>g> for<br />

SCA and employs default SCA's inherent parameters; GASCA 2 uses GA<br />

to select both independent <str<strong>on</strong>g>variables</str<strong>on</strong>g> and SCA's inherent parameters.<br />

The results indicated that the R 2 for training sets <str<strong>on</strong>g>of</str<strong>on</strong>g> GASCA were much<br />

higher than those <str<strong>on</strong>g>of</str<strong>on</strong>g> SCA [R 2 -train: GASCA 2 (0.990)≈ GASCA 1

W. Sun et al. / Science <str<strong>on</strong>g>of</str<strong>on</strong>g> the Total Envir<strong>on</strong>ment 409 (2011) 1243–1254<br />

1249<br />

Table 2<br />

Performance <str<strong>on</strong>g>of</str<strong>on</strong>g> different SCA/GASCA trees.<br />

Model SCA 1 SCA 2 GASCA 1 GASCA 2<br />

Selcti<strong>on</strong>s X <str<strong>on</strong>g>variables</str<strong>on</strong>g> All Xs Trial and error GA-aided GA-aided<br />

SCA internal parameters Default Trial and error Default GA-aided<br />

X 1,2,3,4,5,6,7,8,9,10,11,12 1,3,4,5,6,7,9,10,12 2,4,5,7,10,11 2,4,5,7,10<br />

Y C/N C/N C/N C/N<br />

α cut 0.05 0.04 0.05 0.04<br />

α merge 0.05 0.06 0.05 0.06<br />

N min 10 10 10 9<br />

Layer 25 21 20 17<br />

Node 165 128 123 100<br />

Training set R 2 0.985 0.977 0.991 0.990<br />

RMSE 0.770 0.949 0.582 0.615<br />

Test set R 2 0.946 0.958 0.946 0.945<br />

RMSE 1.614 1.454 1.566 1.560<br />

Fitness 0.19647 0.18920 0.14024 0.12851<br />

(0.991)NSCA 1 (0.985)NSCA 2 (0.977)]; the R 2 for test sets <str<strong>on</strong>g>of</str<strong>on</strong>g> GASCA<br />

were almost the same as those <str<strong>on</strong>g>of</str<strong>on</strong>g> SCA 1 while SCA 2 had the highest<br />

value [R 2 -test: SCA 2 (0.958)NGASCA 2 (0.945)≈GASCA 1 (0.946)=<br />

SCA 1 (0.946)]; the RMSEs for training sets <str<strong>on</strong>g>of</str<strong>on</strong>g> GASCA were lower than<br />

those <str<strong>on</strong>g>of</str<strong>on</strong>g> SCA [RMSEs-train: GASCA 1 (0.582)bGASCA 2 (0.615)bSCA 2<br />

(0.949)bSCA 1 (0.770)]; the RMSEs for test sets <str<strong>on</strong>g>of</str<strong>on</strong>g> GASCA were lower<br />

than those <str<strong>on</strong>g>of</str<strong>on</strong>g> SCA 1 while SCA 2 had the lowest value [RMSEs-test: SCA 2<br />

(1.454)bGASCA 2 (1.560)bGASCA 1 (1.566)bSCA 1 (1.614)]. As for the<br />

c<strong>on</strong>figurati<strong>on</strong>, the number <str<strong>on</strong>g>of</str<strong>on</strong>g> independent <str<strong>on</strong>g>variables</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> GASCA were<br />

much less than those <str<strong>on</strong>g>of</str<strong>on</strong>g> SCA [GASCA 2 (5)bGASCA 1 (6)bSCA 2 (9)b<br />

SCA 1 (12)]; the layer number <str<strong>on</strong>g>of</str<strong>on</strong>g> GASCA were less than those <str<strong>on</strong>g>of</str<strong>on</strong>g> SCA<br />

[GASCA 2 (17)bGASCA 1 (20)bSCA 2 (21)bSCA 1 (25)]; and the node<br />

number <str<strong>on</strong>g>of</str<strong>on</strong>g> GASCA were much less than those <str<strong>on</strong>g>of</str<strong>on</strong>g> SCA [GASCA 2 (100)b<br />

GASCA 1 (123)bSCA 2 (128)bSCA 1 (165)]. Thus, the fitness <str<strong>on</strong>g>of</str<strong>on</strong>g> the four<br />

models could be ranged in a descending order as: GASCA 2 (0.12851)b<br />

GASCA 1 (0.14024) bSCA 2 (0.18920)bSCA 1 (0.19647).<br />

The results indicated that the predictive capability <str<strong>on</strong>g>of</str<strong>on</strong>g> SCA 2 for the<br />

test set was better than GASCA 2 while SCA 2 's other performances were<br />

worse . This implied that the trial and error method might improve the<br />

SCA's performance to some degree. The comparis<strong>on</strong> between GASCA 2<br />

and SCA 1 was further illustrated in Figs. 5 to 7. It showed that the size <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

GASCA 2 was much smaller than that <str<strong>on</strong>g>of</str<strong>on</strong>g> SCA 1 while the performance <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

GASCA 2 was better. Thus, the GASCA trees have better fitting and<br />

predictive ability in performance and higher efficiency in computati<strong>on</strong><br />

than the SCA trees when building n<strong>on</strong>linear relati<strong>on</strong>ships between the<br />

<str<strong>on</strong>g>state</str<strong>on</strong>g> <str<strong>on</strong>g>variables</str<strong>on</strong>g> and the C/N ratio during food waste <str<strong>on</strong>g>composting</str<strong>on</strong>g>. The<br />

strength <str<strong>on</strong>g>of</str<strong>on</strong>g> GASCA is derived from the mutual compensati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> GA and<br />

SCA. Their integrati<strong>on</strong> brings about not <strong>on</strong>ly a better GASCA tree but<br />

also intense calculati<strong>on</strong> for searching the optimal SCA tree in GA's<br />

evoluti<strong>on</strong> envir<strong>on</strong>ment. SCA <strong>on</strong>ly needs to calculate all possible Wilks'<br />

Λ values in the corresp<strong>on</strong>ding dataset; in comparis<strong>on</strong>, GASCA would<br />

have to invoke the SCA functi<strong>on</strong> to compare all possible Wilks' Λ values<br />

in the GA-selected dataset when GASCA needs to evaluate fitness. The<br />

computati<strong>on</strong>al effort would inevitably increase but the problem could<br />

be mitigated by the use <str<strong>on</strong>g>of</str<strong>on</strong>g> a proxy table. The final GASCA tree was<br />

smaller in size but better in performance, which implied its excellent<br />

ability to avoid over-fitting, since the models with bigger size would<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g>ten over-fit the dataset.<br />

The optimal GASCA 2 tree was finally generated to reflect the<br />

relati<strong>on</strong>ships between the <str<strong>on</strong>g>state</str<strong>on</strong>g> <str<strong>on</strong>g>variables</str<strong>on</strong>g> and the C/N ratio (Table 3;<br />

Fig. 5). The optimal combinati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> input <str<strong>on</strong>g>variables</str<strong>on</strong>g> include mean<br />

temperature (X 2 ), moisture c<strong>on</strong>tent (X 4 ), ash c<strong>on</strong>tent (X 5 ), NH 4 + -N<br />

c<strong>on</strong>centrati<strong>on</strong> (X 7 ), and log col<strong>on</strong>y count <str<strong>on</strong>g>of</str<strong>on</strong>g> mesophilic bacteria (X 10 );<br />

the internal c<strong>on</strong>figurati<strong>on</strong> parameters are: α cut =0.04, α merge =0.06<br />

and N min =9. The GASCA tree is a forecasting system flexible to reflect<br />

C/N variati<strong>on</strong> during food waste <str<strong>on</strong>g>composting</str<strong>on</strong>g> based <strong>on</strong> the relati<strong>on</strong>ship<br />

between the C/N ratio and <str<strong>on</strong>g>state</str<strong>on</strong>g> <str<strong>on</strong>g>variables</str<strong>on</strong>g>. For example, let X 2 =47.85,<br />

X 4 =0.6554, X 5 =0.0186, X 7 =666.92, and X 10 =8.4627 as a new<br />

sample for the GASCA tree. To predict the C/N ratio, we have:<br />

X 7 N87.51 for the first branch knot so that the sample enters cluster 3<br />

(Fig. 5); X 5 ≤0.04, so that it enters cluster 6 and then merges into<br />

cluster 8; X 7 N273.78, so that it enters cluster 12; X 7 N624.22, so that it<br />

enters cluster 19; X 2 N28.25, so that it enters cluster 30; X 10 ≤8.49 so<br />

that it enters cluster 38 and then merges into cluster 46; X 4 N0.63, so<br />

that it enters cluster 57 and then finally merges into cluster 68 with a<br />

predicti<strong>on</strong> value <str<strong>on</strong>g>of</str<strong>on</strong>g> 11.11±0.26.<br />

1<br />

x7≤87.51<br />

x5≤0.39 2<br />

3 x5≤0.04<br />

4 5<br />

6 7<br />

x2≤48.90<br />

10<br />

9<br />

8<br />

x7≤20.89<br />

(18.29,1.39)<br />

x4≤0.61<br />

x7≤273.78<br />

16 15<br />

14<br />

13<br />

11 12<br />

x10≤10.87<br />

x4≤0.69<br />

x7≤624.22<br />

22 23<br />

20<br />

21<br />

18<br />

19<br />

x4≤0.72<br />

17<br />

24<br />

31<br />

32<br />

x10≤7.01 x2≤28.25<br />

x4≤0.67<br />

x4≤0.62<br />

x7≤31.20<br />

27 28 29<br />

30<br />

(37.44,0.00)<br />

x7≤38.14<br />

41 40<br />

26 25<br />

34 35<br />

42 43<br />

x5≤0.02<br />

x10≤8.49<br />

x4≤0.43<br />

x2≤34.90<br />

53 52<br />

37 36 38 39<br />

49 48<br />

33<br />

x4≤0.71 47<br />

46<br />

x7≤5.81<br />

45 44<br />

61 62<br />

65 66<br />

x10≤10.60<br />

x4≤0.63<br />

x2≤27.85<br />

58 57 51 50<br />

54<br />

(20.77,0.72)<br />

x2≤33.90<br />

73 74<br />

59 60<br />

x7≤1118.24<br />

56 55<br />

88<br />

x10≤10.42 79<br />

63 64<br />

69<br />

70<br />

71 72<br />

(10.79,0.22)<br />

(27.29,1.23)<br />

68<br />

x4≤0.65<br />

x10≤6.19<br />

(20.06,0.53)<br />

x10≤13.25<br />

75<br />

76<br />

77<br />

82 83 67<br />

(11.11,0.26)<br />

x10≤13.42<br />

93 94<br />

x2≤47.55<br />

89 90<br />

87<br />

x7≤5684.52<br />

84<br />

85<br />

78<br />

(30.30,2.05) x7≤74.77<br />

(13.94,0.54)<br />

81 80<br />

95 96<br />

(19.55,0.37)<br />

(9.83,0.24)<br />

91<br />

97<br />

98<br />

92<br />

86<br />

x10≤8.51 (23.31,0.08) (21.97,1.24)<br />

(12.10,0.81)<br />

99 100<br />

(15.73,1.53) (13.07,1.07)<br />

(10.42,0.55)<br />

(25.78,1.25)(24.59,0.84)<br />

Fig. 5. GASCA 2 tree for the C/N ratio.

1250 W. Sun et al. / Science <str<strong>on</strong>g>of</str<strong>on</strong>g> the Total Envir<strong>on</strong>ment 409 (2011) 1243–1254<br />

1<br />

x7≤87.51<br />

2<br />

3<br />

x1≤11.00<br />

x6≤0.28<br />

4 5<br />

6 7<br />

x6≤0.36<br />

x6≤0.15 x5≤0.07 x7≤527.91<br />

12<br />

8 9<br />

10 11 13 14 15<br />

17 x1≤3.00 x1≤15.00<br />

x4≤0.72 x6≤0.19 x4≤0.66<br />

x12≤28.90<br />

19 20 22 21 24 23 26 25 27 28<br />

18 16<br />

x4≤0.71 x4≤0.72 x1≤9.00 x9≤11.54<br />

x1≤6.00<br />

33 34 35 36<br />

30<br />

37 38 39 40<br />

x3≤6.13<br />

31<br />

32<br />

x1≤24.00 x10≤7.69<br />

x3≤9.05<br />

x9≤11.80<br />

x8≤99.11<br />

47 46 48 49 50 51<br />

42 43<br />

x6≤0.29<br />

44 45<br />

x5≤0.01<br />

90<br />

57<br />

55<br />

58 59<br />

52 x3≤5.90<br />

53<br />

29 x10≤10.60<br />

63<br />

69 70<br />

56 60 61(9.55,0.01)<br />

x6≤0.32<br />

68 67 62<br />

75 76<br />

x9≤12.12 (19.83,0.20) x6≤0.18<br />

64<br />

84 83 81 82 73<br />

x3≤4.50<br />

(26.72,0.74)<br />

x4≤0.75<br />

91 92<br />

89 x12≤30.80 (18.02,0.56) (16.71,0.58)<br />

71 72<br />

98 97<br />

(19.42,0.39) (18.69,0.05)<br />

x10≤8.96<br />

41<br />

87<br />

104<br />

86 85 74<br />

(20.16,0.39)<br />

x10≤10.87<br />

109<br />

54<br />

x10≤13.42<br />

x2≤33.90<br />

101 102<br />

(10.38,0.15)<br />

x1≤13.00<br />

94 93<br />

65 66<br />

x11≤68.40<br />

118 119<br />

x5≤0.03 x7≤237.80<br />

x1≤15.00<br />

(9.88,0.19)<br />

107 108<br />

130<br />

78 77 79 80<br />

111<br />

x12≤30.60<br />

125 126<br />

x5≤0.02<br />

110<br />

95 96<br />

135 136 (21.42,0.11) (20.88,0.38)<br />

88<br />

(22.96,0.77)<br />

100<br />

137<br />

99<br />

x8≤46.18<br />

106 105<br />

103<br />

142<br />

x11≤57.20<br />

x5≤0.02<br />

x10≤10.87<br />

114 115<br />

113 112<br />

148 149<br />

x10≤14.12<br />

x6≤0.22<br />

117 121<br />

120<br />

123 122<br />

x6≤0.23<br />

x2≤31.00<br />

116<br />

124 127 128<br />

154 155<br />

x5≤0.02<br />

x11≤68.40<br />

129 132 131<br />

(10.68,0.30)<br />

160 161<br />

133<br />

x7≤273.78<br />

(12.41,0.24)<br />

(29.41,1.08) 163<br />

134<br />

138 139<br />

x12≤24.30<br />

(33.90,3.10)<br />

x12≤54.60<br />

141 140<br />

158<br />

(13.36,0.58) x10≤7.44<br />

x1≤8.00<br />

143 144<br />

145 146<br />

164 165<br />

x10≤13.94<br />

147<br />

150 151<br />

(12.15,0.17) (11.96,0.12) x7≤624.22<br />

(25.58,0.44) (24.77,0.64)<br />

x9≤6.40<br />

152 153<br />

157 156<br />

(11.55,0.13) (11.06,0.29)<br />

(13.79,0.23) 159<br />

162<br />

(14.73,0.60)<br />

Fig. 6. SCA 1 tree for the C/N ratio.<br />

Based <strong>on</strong> the c<strong>on</strong>figurati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the optimal GASCA tree (Fig. 5 and<br />

Table 3), the effect <str<strong>on</strong>g>of</str<strong>on</strong>g> input (X k ) <strong>on</strong> the output (Y) in GASCA is<br />

quantified using the following equati<strong>on</strong>:<br />

NN<br />

EffectðX k ; YÞ = ∑ N Xk<br />

ðiÞ<br />

i =1<br />

where NN is the number <str<strong>on</strong>g>of</str<strong>on</strong>g> total nodes in the GASCA tree; N Xk (i) is the<br />

number <str<strong>on</strong>g>of</str<strong>on</strong>g> patterns (samples) at node i <str<strong>on</strong>g>of</str<strong>on</strong>g> the GASCA tree where the<br />

corresp<strong>on</strong>ding X k variable is used as the cutting criteria at node i. N Xk<br />

(i) represents the number <str<strong>on</strong>g>of</str<strong>on</strong>g> samples <strong>on</strong> which X k variable has <str<strong>on</strong>g>effects</str<strong>on</strong>g><br />

at node i. According to our previous work (Sun et al., 2009), the <str<strong>on</strong>g>effects</str<strong>on</strong>g><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> the <str<strong>on</strong>g>state</str<strong>on</strong>g> <str<strong>on</strong>g>variables</str<strong>on</strong>g> <strong>on</strong> the C/N ratio could be ranged in a descending<br />

order as: NH 4 + -NNMoisture c<strong>on</strong>tentNAsh C<strong>on</strong>tentNMean TemperatureNMesophilic<br />

bacteria biomass. The result might imply that the<br />

variati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> NH 4 + -N c<strong>on</strong>centrati<strong>on</strong>, the associated temperature and<br />

moisture c<strong>on</strong>diti<strong>on</strong>s, the total loss <str<strong>on</strong>g>of</str<strong>on</strong>g> both organic matters and<br />

available mineral c<strong>on</strong>stituents, and mesophilic bacteria activity, might<br />

be the important factors affecting C/N ratio during the food waste<br />

<str<strong>on</strong>g>composting</str<strong>on</strong>g>.<br />

4.4. Effect <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>state</str<strong>on</strong>g> <str<strong>on</strong>g>variables</str<strong>on</strong>g> <strong>on</strong> the C/N ratio<br />

Dynamic variati<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> the C/N ratios during the six runs <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

<str<strong>on</strong>g>composting</str<strong>on</strong>g> experiments follow different patterns (Fig. 8). In Runs 1<br />

and 2, the initial C/N ratios drop to 14.75 and 15.08 due to the additi<strong>on</strong><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> soybean. This is c<strong>on</strong>sistent with the c<strong>on</strong>clusi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> W<strong>on</strong>g et al.<br />

(2001) where adding soybean residues could lower the C/N ratio<br />

because <str<strong>on</strong>g>of</str<strong>on</strong>g> its relatively high nitrogen c<strong>on</strong>tent (W<strong>on</strong>g et al., 2001). The<br />

C/N ratios in these two runs gradually drop to the minimum (9.57 and<br />

9.38) in Day 28 and Day 30, respectively, possibly due to the carb<strong>on</strong><br />

loss by CO 2 emissi<strong>on</strong>. The two C/N ratios then gradually rise to 13.70<br />

until Day 37 and to 12.70 until Day 42; then both keep fluctuating or<br />

stable, individually. This is possibly due to the decrease <str<strong>on</strong>g>of</str<strong>on</strong>g> total<br />

ð6Þ<br />

nitrogen c<strong>on</strong>tent caused by NH 3 emissi<strong>on</strong>. In Runs 3 and 4, the initial<br />

C/N ratios are adjusted to about 32.63 and 29.89. The C/N ratio in Run<br />

3 keeps decreasing to 17.46 until Day 33 and slowly increases to 19.43<br />

until the last day. The C/N ratio in Run 4 keeps decreasing to 19.85<br />

until Day 18, keeps fluctuating to 20.92 until Day 33, and then slowly<br />

drops to 17.15 until Day 43. In Run 5, the initial C/N ratio <str<strong>on</strong>g>of</str<strong>on</strong>g> the<br />

<str<strong>on</strong>g>composting</str<strong>on</strong>g> material is 31.9. The C/N ratio keeps decreasing until Day<br />

35 and become stable (11.79) until Day 39. The decrease <str<strong>on</strong>g>of</str<strong>on</strong>g> C/N ratio<br />

may be associated with the mass loss <str<strong>on</strong>g>of</str<strong>on</strong>g> organic materials by CO 2<br />

emissi<strong>on</strong> (maturating processes). In Runs 6, the initial C/N ratio is<br />

raised to 34.99 after adding coal ash amendment. The C/N ratio<br />

decreases to 11.88 until Day 15 and fluctuates in a small range<br />

between 11.41 and 12.84 in the latter stage. The final composts<br />

obtained in all <str<strong>on</strong>g>of</str<strong>on</strong>g> the six runs are c<strong>on</strong>sidered mature, since the C/N<br />

ratio should be less than 20 for growing plant (Lin, 2008). The good<br />

agreement between the predicted and the experimental values <str<strong>on</strong>g>of</str<strong>on</strong>g> the<br />

C/N ratios in Fig. 8 further verifies the good performance <str<strong>on</strong>g>of</str<strong>on</strong>g> the GASCA<br />

tree.<br />

As the base run (without additi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> cooked soybean, baking soda<br />