gantry clearance! - imes-icore GmbH

gantry clearance! - imes-icore GmbH

gantry clearance! - imes-icore GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

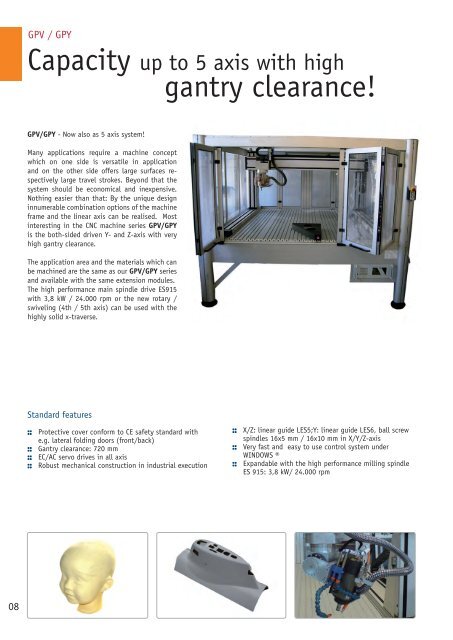

GPV / GPY<br />

Capacity up to 5 axis with high<br />

<strong>gantry</strong> <strong>clearance</strong>!<br />

GPV/GPY - Now also as 5 axis system!<br />

Many applications require a machine concept<br />

which on one side is versatile in application<br />

and on the other side offers large surfaces respectively<br />

large travel strokes. Beyond that the<br />

system should be economical and inexpensive.<br />

Nothing easier than that: By the unique design<br />

innumerable combination options of the machine<br />

frame and the linear axis can be realised. Most<br />

interesting in the CNC machine series GPV/GPY<br />

is the both-sided driven Y- and Z-axis with very<br />

high <strong>gantry</strong> <strong>clearance</strong>.<br />

The application area and the materials which can<br />

be machined are the same as our GPV/GPY series<br />

and available with the same extension modules.<br />

The high performance main spindle drive ES915<br />

with 3,8 kW / 24.000 rpm or the new rotary /<br />

swiveling (4th / 5th axis) can be used with the<br />

highly solid x-traverse.<br />

Standard features<br />

Protective cover conform to CE safety standard with<br />

e.g. lateral folding doors (front/back)<br />

Gantry <strong>clearance</strong>: 720 mm<br />

EC/AC servo drives in all axis<br />

Robust mechanical construction in industrial execution<br />

X/Z: linear guide LES5;Y: linear guide LES6, ball screw<br />

spindles 16x5 mm / 16x10 mm in X/Y/Z-axis<br />

Very fast and easy to use control system under<br />

WINDOWS ®<br />

Expandable with the high performance milling spindle<br />

ES 915: 3,8 kW/ 24.000 rpm<br />

08

Specifications<br />

travel stroke (X/Y/Z) in<br />

mm (base machine)<br />

travel feed rate (X/Y/Z)<br />

<strong>gantry</strong> <strong>clearance</strong> (table<br />

-> z-axis)<br />

coordinate table (XxY)<br />

in mm<br />

GPV/GPY<br />

98/68<br />

980/680/<br />

580<br />

GPV/GPY<br />

98/108<br />

980/1080/<br />

580<br />

GPV/GPY<br />

138/108<br />

1380/1080/<br />

580<br />

GPV/GPY<br />

138/158<br />

1380/1580/<br />

580<br />

standard 8m/min, optional up to 25 m/min<br />

(dependent upon drive system and application, Controller, design)<br />

640 mm<br />

GPV/GPY<br />

138/248<br />

1380/2480/<br />

580<br />

1250 x 1300 1125 x 1700 1500 x 1700 1500 x 2200 1500 x 3050<br />

dimensions (LxBxH) in<br />

mm<br />

2084/1584/<br />

1890<br />

2084/1984/<br />

1890<br />

2459/1984/<br />

2050<br />

2459/2484/<br />

2050<br />

2459/3384/<br />

2050<br />

drive system AC servo with ball screw spindles<br />

controlling system<br />

optional i-CAN / B&R / Heidenhain®<br />

repeating accuracy ± 0,01 mm: dependent upon the mechanical configuration and machine size<br />

resolution 0,01 mm<br />

safety cover<br />

folding doors with safety circuit module (standard)<br />

linear drives ball srew in all axis 16x5 mm / 16x10 mm<br />

software<br />

WIN®-REMOTE / isy CAM 2.5 plus<br />

Dimensions [mm]<br />

2050<br />

max. 700mm<br />

820<br />

240<br />

F<br />

A<br />

B<br />

D<br />

A B C D E F<br />

GPY 98/68 980 680 1250 2084 1584 1890<br />

GPY 98/108 980 1080 1125 2084 1984 1890<br />

GPY 138/108 1380 1080 1500 2459 1984 1890<br />

GPY 138/158 1380 1580 1500 2459 2484 1890<br />

GPY 138/248 1380 1580 1500 2459 3384 1890<br />

Applications<br />

series production of housings<br />

rapid prototyping<br />

model making<br />

design model making<br />

electronic industry<br />

wood working /<br />

wood industry<br />

multi-side working with rotary axis<br />

or 4th/5th axis head<br />

applied tool axis (Z-axis)<br />

laser digitisation<br />

copy-milling<br />

rework of big plastic parts<br />

thermoforming components<br />

machining foam machining<br />

Typical materials for<br />

machining<br />

aluminium<br />

plastics<br />

milling plastics<br />

wood<br />

foam<br />

styro foam<br />

ABS<br />

gypsum<br />

green ceramics<br />

09

GPY 5-axis-simultaneous-milling<br />

High-Tech-control and 7 drives provide<br />

an excellent machine dynamic !<br />

Especially in the field of model and mould making, everyone<br />

is talking about 5-axis milling – production processes can be<br />

optimized significantly<br />

One can reach this advantages only provided the CNC-machine-system<br />

has features like 5-axis transformation, jerk limitation<br />

on track, online tool length compensation,<br />

RTCP function (Rotation Tool Center Point), clamping position<br />

correction and the perfect interaction of all those features<br />

To be up to this, we together with technology partners further<br />

developed our GPY machine series.<br />

The control technology is PC based. Supporting dual core cycle<br />

t<strong>imes</strong> less 1/1000 sec. are possible.<br />

The CNC control works with G-code syntax according to<br />

DIN 66025 plus machine related commands.<br />

With the 4th and 5th axis, jerk free 5-axis simultaneously<br />

machining is possible, in which the tool-tip cuts with constant<br />

speed controlled by the function RTCP (Rotation Tool<br />

Center Point).<br />

To enable this feature the linear axis moving speed is tripled<br />

compare to standard. Without angle gears the <strong>gantry</strong> construction<br />

reaches much higher dynamic and quietness.<br />

The complete machine geometry is spatially determined and<br />

is known by the control. Therefore the compensation matrix<br />

provide an accuracy of ± 0,03 mm.<br />

The electronic hand wheel improves the operation friendliness,<br />

spindle speed and feed rate can be adjusted infinitely.<br />

Moreover this machine system is suitable for 3+2 machining<br />

(milling with angled tool spindle).<br />

Due to these features the GPY is an integrated machine<br />

concept for many 5-axis milling applications:<br />

FAST-PRECISE-EFFICIENT!<br />

10

The PLC environment is fully integrated in the control system.<br />

Hereby remote servicing for exact analyzing is ensured.<br />

The complete data library is available to inform about the<br />

system state.<br />

Embedding of automated running works trough continuous<br />

extension of the PLC programming according to IEC 61131-3,<br />

CFC (Continuous Function Chart), FUP (Function Plan),<br />

KOP (Kontakt Plan) and AWL (Anweisungs Liste).<br />

The programming blocks of this PLC system are used by<br />

designated manufacturers around the globe and guarantee<br />

continuity and innovation force.<br />

More information about it you may gather in a personal talk<br />

with our technical sales team.<br />

AC-servo motors with absolute encoders for rotating/swivel<br />

axis are used.<br />

This guarantees long term, reliable use of the CNC machine<br />

system.<br />

Technology highlights<br />

Rotation Tool Center Point (RTCP)<br />

tool length compensation (TLC)<br />

tool adjustment<br />

clamping position correction<br />

axle kinematic compensation<br />

RTCP off RTCP on Online adjustment of generated freeform<br />

surfaces to different tool-lenghts<br />

11