cnc milling for model and mold making - imes-icore Webseite

cnc milling for model and mold making - imes-icore Webseite

cnc milling for model and mold making - imes-icore Webseite

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

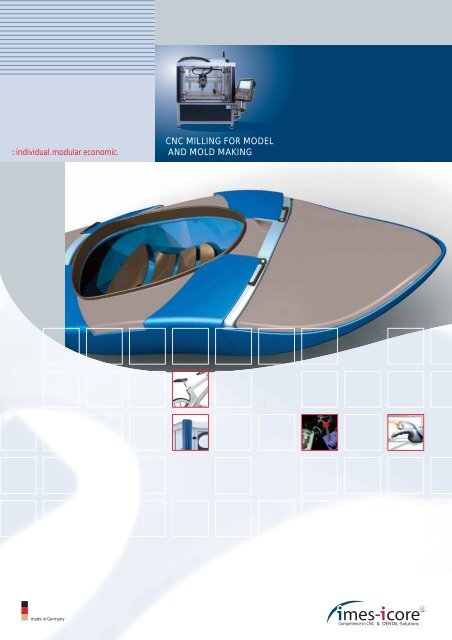

:: individual. modular. economic.<br />

CNC MILLING FOR MODEL<br />

AND MOLD MAKING<br />

made in Germany

Welcome to the world of <strong>imes</strong>-<strong>icore</strong>.<br />

Individuality <strong>and</strong> economy redefined!<br />

THE EXPANSION MODULE:<br />

<strong>imes</strong>-<strong>icore</strong> is specialized<br />

in the development,<br />

the production,<br />

the selling <strong>and</strong> the ser-<br />

<strong>milling</strong> systems.<br />

vice of complete CNC<br />

Dust removal<br />

units<br />

CAD software<br />

Rotary axis<br />

Electronic<br />

h<strong>and</strong>wheel<br />

Milling tools<br />

By our intelligent modular system with all<br />

sides open technology interfaces we are<br />

able to exceed your specific requirements.<br />

Complex ones, time or cost-intensive adaptions<br />

are no matter at <strong>imes</strong>-<strong>icore</strong>.<br />

Far from it: <strong>imes</strong>-<strong>icore</strong> module technology<br />

provides <strong>for</strong> a price-per<strong>for</strong>mance ratio, that<br />

will convince you of.<br />

Cool / Spray<br />

system<br />

3D Lasersensor<br />

Clamping<br />

technique<br />

Tool check<br />

Touch probe<br />

The i-mes series <strong>for</strong> <strong>model</strong> <strong>and</strong> tool<strong>making</strong><br />

can be developed to complete systems<br />

with an automation which are unrivalled<br />

economical.<br />

Large travel strokes <strong>and</strong> big table surfaces<br />

with concurrent compact machine dimensions<br />

are no contradiction <strong>for</strong> us.<br />

Easy operability, simple menu guidance <strong>and</strong><br />

control systems as well as the durable industry<br />

st<strong>and</strong>ard of our machines make <strong>imes</strong><strong>icore</strong><br />

singular at the market.<br />

It does not surprise that all considerable<br />

customers of the <strong>model</strong> <strong>and</strong> tool<strong>making</strong>,<br />

designer, engineering companies, architect's<br />

office, development departments as<br />

well as universities <strong>and</strong> technical<br />

colleges trust in <strong>imes</strong>-<strong>icore</strong>.<br />

Tool clamps<br />

Advantages<br />

Main spindle<br />

drives<br />

CAM software<br />

Tool clamping<br />

systems<br />

FROM THE IDEA TO PROTOTYP, MODEL AND SERIES:<br />

Vacuum clamping<br />

systems<br />

Outst<strong>and</strong>ing price-per<strong>for</strong>mance ratio<br />

Economical complete CNC solutions<br />

Technological expansion modules <strong>for</strong> complete individualizing<br />

Large travel strokes <strong>and</strong> table surfaces<br />

High-efficient automation up to robot connection<br />

Customized CAD/CAM/CNC software solutions<br />

Easy underst<strong>and</strong>able user interfaces <strong>and</strong> control systems<br />

Manufacturing, installation, training, service <strong>and</strong> technical advice of all<br />

technologies from one competent source<br />

Have a conversation: It's time <strong>for</strong> a new thinking!<br />

1. CAD construction,<br />

CAM generation<br />

2. High-efficient, precise mil<br />

ling of a <strong>model</strong>.<br />

3. Milling all single parts with<br />

'fixing bars' technique.<br />

2/3

competence in CNC & Dental solutions.<br />

AREAS OF APPLICATION<br />

MODEL MAKING HANDCRAFT<br />

ARCHITECTURAL MODEL MAKING<br />

MODEL AND TOOLMAKING<br />

RAPID PROTOTYPING<br />

MILLING OF UREOL (CIBATOOL, OBUMODULAN)<br />

:: Milling of 3D display <strong>model</strong>s<br />

:: Milling of deep drawing parts<br />

:: 5-axis <strong>milling</strong><br />

MILLING OF WOOD<br />

:: Milling of 3D wood <strong>model</strong>s (plywood)<br />

:: 5-axis machining<br />

MILLING OF GYPSUM<br />

:: Milling of plaster moulds <strong>for</strong> casting <strong>model</strong>s (ceramics industry)<br />

MILLING OF ALUMINUM<br />

:: Milling of 3D display <strong>model</strong>s<br />

:: Milling of deep drawing parts<br />

MILLING OF PLASTICS<br />

:: Milling of 3D display parts<br />

:: 5-axis machining<br />

RANGE OF APPLICATIONS<br />

:: Design <strong>model</strong>s<br />

:: Styling <strong>and</strong> architectural <strong>model</strong>s<br />

:: Data control <strong>model</strong>s<br />

:: Operational <strong>model</strong>s<br />

:: Flow patterns<br />

:: Original <strong>and</strong> master mod<br />

:: Foundry patterns<br />

:: Checking fixtures<br />

:: Test units<br />

:: Laminating <strong>model</strong>s<br />

:: Pressing tools<br />

4. Assembly to a complete mo<br />

del.<br />

5. Display <strong>model</strong>s, sample<br />

parts, small series.

<strong>imes</strong>-<strong>icore</strong> FLATCOM – Large travel strokes at low price!<br />

SPECIFIED FOR THE<br />

MILLING OF PLASTIC<br />

FLATCOM St<strong>and</strong>ard features<br />

:: Large travel strokes<br />

:: Safety cover as dust protection <strong>and</strong> sound insulation<br />

:: Powerful DC Servo-technique<br />

:: PC control under windows (network connection possible)<br />

:: control software WIN-Remote integrated<br />

TECHNISCHE DATEN FLATCOM 20 FLATCOM 30 FLATCOM 40 FLATCOM 50<br />

travel stroke (X/Y/Z) in mm* 700/600/150 700/900/150 1200/900/150 1200/1400/150<br />

coordinate table (L x B) in mm 750 x 750 750 x 1000 1250 x 1000 1250 x1500<br />

Z gantry clearance in mm<br />

Dimensions with control<br />

cabinet<strong>and</strong> covergen<br />

LxBxH) in mm<br />

drive system<br />

linear guides<br />

controlling system<br />

software<br />

200 (300) optional<br />

1420 x 1150 x 1870 1420 x 1450 x 1870 1920 x 1450 x 1870 1920 x 1950 x1870<br />

DC-Servo<br />

ball screw 16 x 5 mm<br />

CAN BUS<br />

WIN-Remote<br />

The FLATCOM machine series is supplied in four<br />

sizes with travel strokes from 700 x 600 mm to<br />

1200 x 1400 mm in rack construction with protection<br />

cover.<br />

The aluminum profiles used with the construction<br />

are special profiles, which make a good rigidity<br />

possible at simultaneous low weight. The<br />

gantry clearance amounts 200 mm (optinal<br />

300 mm).<br />

As axis actuation ball screws with DC servo motors<br />

are used. The units are according to st<strong>and</strong>ard<br />

equipped with CAN CNC control on Windows<br />

2000/XP basis with look-ahead path<br />

control.<br />

*specifications without ball screw spindle<br />

3 axis system<br />

exp<strong>and</strong>able to 4th axis<br />

DC servo technique<br />

Interpreter software WIN-Remote<br />

4/5

competence in CNC & Dental solutions.<br />

<strong>imes</strong>-<strong>icore</strong> GFV/GFY – Maximum Flexibility <strong>and</strong> Economy!<br />

SPECIFIED FOR MO-<br />

DEL AND MOLD<br />

MILLING<br />

GVF/GFY CHARACTERISTICS:<br />

:: Protection cover: protection against rotary tools, noise level<br />

reduction <strong>and</strong> protection against splinters<br />

:: Portal passage: variable passage height between clamping sur<br />

face <strong>and</strong> lower edge Z-axis of 235 mm up to 435 mm<br />

:: Propulsion technology: DC or AC servo<br />

:: Stable structure of the units by torsionally stiff linear units<br />

with i-mes-LF 5/6 guidance, aluminum underframe <strong>and</strong> <strong>milling</strong><br />

bed with excellent mechanical characteristics<br />

:: The electronics boards are located in cabinet systems<br />

Technical Data GFx 44/48 GFx 98/68 GFx 98/108 GFx 138/108 GFx 138/158 GFx 138/248<br />

travel stroke (X/Y/Z) in mm 440/480/ 980/680/ 980/1080/ 1380/1080/ 1380/1580/ 1380/2480/<br />

200 (280*) 200 (280*) 200 (280*) 200 (280*) 200 (280*) 200 (280*)<br />

travel feed rate<br />

st<strong>and</strong>ard 8 m/min, optional up to 25 m/min (dependent upon drive system <strong>and</strong> application)<br />

gantry clearance (table -> Z-axis)<br />

235 (435*) mm<br />

dimensions<br />

(LxBxH) in mm 1440 x 1320 x 1890 2084 x 1584 x 1890 2084 x 1984 x 1890 2459 x 1984 x1890 2459 x 2484 x1890 1459 x 3384 x 1890<br />

drive system<br />

controlling system<br />

repeating accuracy<br />

resolution<br />

safety cover<br />

linear guides<br />

software<br />

DC: DC-Controller CVC-496 or AC: power amplifier Multi-F<br />

DC: CAN BUS / IMD or AC: Heidenhain TNC320<br />

~ ± 0,02 mm: dependent upon the mechanical configuration<br />

0,01 mm<br />

sliding door with safety circuit module<br />

a ball screw 16x5 mm in all axis (optional 16x10 mm)<br />

WIN-Remote or Heidenhain<br />

* with raised gantry clearance<br />

The CNC controlled processing machines of the<br />

GFV/GFY series guarantee a maximum of economy<br />

by most varied application ranges up to series<br />

production.<br />

Unique at the market: The same if st<strong>and</strong>ard unit or<br />

extended unit. As a result of modular <strong>and</strong> flexible<br />

structure of the individual components unbelievable<br />

combination options arise. There<strong>for</strong>e a selected<br />

CNC system is literally suit to the needs of the customer<br />

<strong>and</strong> to respective application.<br />

By own manufacturing oft he most important mechanical<br />

<strong>and</strong> electronic components the flat bed<br />

systems provide an unusual cost-per<strong>for</strong>mance ratio<br />

<strong>for</strong> <strong>milling</strong>, engraving, drilling, processing with<br />

the rotational axis <strong>and</strong> laser digitization. Due to<br />

theit design they provide highest precision in the<br />

materials aluminium, brass, <strong>milling</strong> plastics (Ureol,<br />

CibaTool), plastics <strong>and</strong> wood <strong>and</strong> much more.<br />

GFV:<br />

3 axis system<br />

exp<strong>and</strong>able to 4th axis<br />

DC servo technique<br />

Interpreter software WIN-Remote<br />

GFY:<br />

AC servo technique<br />

Interpreter software WIN-Remote<br />

Interpreter software Heidenhain

<strong>imes</strong>-<strong>icore</strong> GPY – Capacity with high gantry clearance!<br />

SPECIFIED FOR MIL-<br />

LING OF HIGH COM-<br />

PONENTS<br />

GPY CHARACTERISTICS:<br />

:: protective cover con<strong>for</strong>ms to CE safety st<strong>and</strong>ard with lateral sliding<br />

door<br />

:: gantry clearance: 720 mm<br />

:: exclusively AC servo drives in all axis<br />

:: robust mechanical construction in industrial execution<br />

:: X/Z: linear guide LF5;Y: linear guide LF6 spindle pitch of ball<br />

screw 16 x 5 mm in X/Y/Z-axis<br />

:: exp<strong>and</strong>able with the high per<strong>for</strong>mance spindle drive ES 915:<br />

3,8 kW/ 24.000 rpm<br />

TECHNICAL DATA GPY 98/68 GPY 98/108 GPY 138/108 GPY 138/158 GPY 138/248<br />

travel stroke (X/Y/Z) in mm<br />

without tool changer<br />

980/680/580 980/1080/580 1380/1080/5801380/1580/580 1380/2480/580<br />

travel feed rate<br />

st<strong>and</strong>ard 8m/min, optional up to 25 m/min(dependent upon application)<br />

gantry clearance (table -> Z-axis)<br />

640 mm<br />

coordinate table (XxY) in mm 1250 x1300 1125 x1700 1500 x1700 1500 x 2200 1500 x3050<br />

dimensions (LxBxH) in mm 2084 x 1584 x 1890 2084 x1984 x1890 2459 x1984 x1890 2459 x 2484 x1890 2459 x 3384 x1890<br />

drive system<br />

controlling system<br />

repeating accuracy<br />

resolution<br />

safety cover<br />

linear guides<br />

software<br />

3 axis system<br />

exp<strong>and</strong>able to 4th axis (rotary axis)<br />

exp<strong>and</strong>able to 4th / 5th axis<br />

AC servo technique<br />

AC power amplifier<br />

Heidenhain TNC320 or NumCAD<br />

± 0,02 mm: dependent upon mechanical configuration<br />

0,01 mm<br />

sliding door with safety circuit module<br />

axis with ball screws 16x5 mm<br />

WIN-Remote<br />

Many applications require a machine concept<br />

which on one side is versatile in application <strong>and</strong><br />

on the other side offers large surfaces respectively<br />

large travel strokes.Beyond that the system should<br />

be economical <strong>and</strong> inexpensive in acquisition. Nothing<br />

easier than that: By the unique design innumerable<br />

combination options of the machine<br />

frame <strong>and</strong> the linear axis could be realised. The interesting<br />

at the CNC machine series GPY is the<br />

double Z-axis with very high gantry clearance.<br />

The application area <strong>and</strong> the materials which<br />

should be milles are like the GFV / GFY units <strong>and</strong><br />

the GPY system is available with the same auxiliary<br />

modules.<br />

The very high per<strong>for</strong>mance main spindle drive<br />

ES915 with 3,8 kW / 24.000 rpm or the new rotary<br />

/ swiveling (4th / 5th axis) can be used by very solid<br />

cross rail.<br />

6/7

competence in CNC solutions.<br />

<strong>imes</strong>-<strong>icore</strong> SFY/SPY – Granite <strong>and</strong> steel <strong>for</strong> highest stability up to 5-axis!<br />

SPECIFIED FOR HSC<br />

MILLING, ALUMI-<br />

NIUM MACHINING<br />

With Heidenhain<br />

controlling system<br />

TNC 320<br />

SFY/ SPY CHARACTERISTICS:<br />

:: protective cover con<strong>for</strong>ms to CE safety st<strong>and</strong>ard with lateral<br />

sliding door<br />

:: portal- or gantry design alternatively(SFY-/SPY-series)<br />

:: gantry clearance up to 720 mm<br />

:: high per<strong>for</strong>mance AC servo technique in all axis<br />

:: robust mechanical construction (granite/steel)<br />

:: ball screw spindles 16 x 5 mm; Z: 16 x 2,5 mm<br />

:: different <strong>milling</strong> spindles up to 3,8 kW / 24.000 rpm possible<br />

GRANITE<br />

STEEL<br />

TECHNICAL DATA SFY 68/78 SFY 98/108<br />

SPY 68/78 SPY 98/108<br />

travel stroke (X/Y/Z) in mm 680/780/200 980/1080/200<br />

SPY: Z = 580 SPY: Z = 580<br />

travel feed rate<br />

st<strong>and</strong>ard 8m/min, optional up to 25 m/min(dependent upon application)<br />

gantry clearance<br />

SFY: 235 (optional: 435 mm)<br />

(table -> Z-axis) SPY: 700<br />

coordinate table (Lx B) in mm 1000 x 1200 1250 x 1500<br />

dimensions (LxBxH) in mm 1450 x 1350 x 1950 1800 x 1650 x 1950<br />

drive system<br />

AC power amplifier<br />

controlling system Heidenhain TNC 320<br />

repeating accuracy<br />

± 0,02 mm: dependent upon mechanical configuration<br />

resolution<br />

0,01 mm<br />

safety cover<br />

sliding door with safety circuit module<br />

linear guides<br />

Achsen mit Kugelgewindetrieben 16 x 5 mm; Z: 16 x 2,5 mm<br />

3 axis system<br />

exp<strong>and</strong>able to 4th axis (rotary axis)<br />

exp<strong>and</strong>able to 4th / 5th axis<br />

AC servo technique<br />

Unique in the <strong>model</strong> <strong>and</strong> mould <strong>making</strong>! Very high<br />

stability, absolute quiet running, exp<strong>and</strong>able up to<br />

5-axis treatment. These are the outst<strong>and</strong>ing characteristics<br />

of the SFY/SPY machine series.<br />

Decisive <strong>for</strong> this is the solid machine table which<br />

consists of a steel underframe <strong>and</strong> a granite table.<br />

Combined with a new double led X-axis <strong>for</strong> the<br />

stabilization of the Z-axis.<br />

By the interaction of the solid basic structure a<br />

high frequency spindle <strong>and</strong> a quick control technique<br />

one can use the advantages of the High speed<br />

Cutting fully <strong>and</strong> thus improves better surface<br />

qualities as well as production t<strong>imes</strong> drastically<br />

sink!<br />

3+2 or 5-axis-simultaneous! All of this is possible<br />

by the various options of the high precision rotary<br />

units as rotary- 7 swiveling units installed at the<br />

machine table or as a swiveling main spindle.

<strong>imes</strong>-<strong>icore</strong> MMF – Generous portal machine up to 5 axis <strong>for</strong> a large spectrum of use!<br />

MMF Characteristics:<br />

:: Steel welded structure of the two long Y gantry axis<br />

:: Webbed side portals made of aluminium-welded structure<br />

:: High-load steel profile guides with 8 linear slides per X- <strong>and</strong> Z-axis<br />

:: Z-axis centrically mounted on the X-axis<br />

:: Milling spindle ES 915<br />

:: riding along 5 t<strong>imes</strong> tool changer<br />

TECHNICAL DATA<br />

travel stroke (X/Y/Z/C/A)<br />

max. travel stroke (X/Y/Z)<br />

Cube dimension (X/Y/Z)<br />

Travel feed rate<br />

Clamping surface (T-nut profile)<br />

dimensions (LxBxH)<br />

drive system<br />

controlling system<br />

repeatability accuracy<br />

resolution<br />

Guide system<br />

option<br />

other sizes /travel stroke on request<br />

MMF<br />

2000/2500/800 mm/±200°/±95°<br />

3000/6000/1000 mm<br />

1000/1500/650 mm<br />

20 m/min<br />

1600 x 1200 mm<br />

3000 x 3500 x 3000 mm<br />

AC power amplifier<br />

numCAD CNC<br />

±0.02 mm<br />

0.01mm<br />

linear guides<br />

electronic h<strong>and</strong> wheel, Teach-in application,<br />

tactile touch probe<br />

The machine series MMF was developed particularly<br />

<strong>for</strong> the <strong>model</strong>, prototype <strong>and</strong> mould <strong>making</strong>.<br />

High structure rigidity was the centre of attention<br />

thereby - this results from the solid<br />

structure. Equipped with a rotary swivelling unit as<br />

4th <strong>and</strong> 5th axis the MMF is suitable optimally <strong>for</strong><br />

the five-axis-treatment <strong>and</strong> <strong>milling</strong> large volume<br />

work pieces.<br />

The combination of functions like e.g. jerk control,<br />

speed <strong>and</strong> acceleration pilot control, Look ahead<br />

path control <strong>and</strong> carrying of tool orientation, permits<br />

best technology utilization <strong>and</strong> adjustment<br />

to changing requirements, to speed, accuracy <strong>and</strong><br />

surface quality.<br />

3 axis system<br />

exp<strong>and</strong>able to 4th axis (rotary axis)<br />

exp<strong>and</strong>able to 4th / 5th axis<br />

AC servo technique<br />

isy CAM 3.2 software<br />

num CAD controlling system<br />

8/9

competence in CNC solutions.<br />

i-mes Special Machines –<br />

individual, customized units!<br />

SPECIAL MACHINE:<br />

Pneumatic front safety door coupled with NC<br />

program.<br />

SPECIAL MACHINE:<br />

With integrated loading table <strong>and</strong> safety light<br />

barrier.<br />

By the singular, modular <strong>and</strong> flexible building method<br />

of the machine systems we can plan <strong>and</strong> convert<br />

customized CNC automation solutions <strong>for</strong> the<br />

industrial manufacturing within shortest time to<br />

your desires <strong>and</strong> conceptions.<br />

The basic machine can get <strong>for</strong> example completely<br />

different dimensions like a series machine, e.g. different<br />

travel strokes <strong>and</strong> gantry clearance, table<br />

outbreaks, front clamping ranges (<strong>for</strong> extremely<br />

tall parts), alternating loading tables or axis combinations<br />

<strong>for</strong> the inline process.<br />

SPECIAL MACHINE:<br />

With integrated loading table <strong>and</strong> bar code<br />

binding

<strong>imes</strong>-<strong>icore</strong> – Application competency <strong>for</strong> the tool <strong>and</strong> mould <strong>making</strong>!<br />

isy CAM 3.2: The ultimate CAD / CAM package <strong>for</strong> <strong>model</strong> <strong>and</strong> mould <strong>making</strong><br />

isy CAM 3.2 ist die einmalige CAD/CAM-Software, bestehend aus einem<br />

universellen 2D/3D-CAD-und Modellierprogamm und einem umfangreichen<br />

CAM-Modul für die Technologien: 2D/3D-Fräsen, Bohren und Gravieren.<br />

isy CAM 3.2 bietet für Designer, Konstrukteure und CNC-Fachleute den<br />

neuesten St<strong>and</strong> der Technik auf dem Gebiet des Konstruierens, 3isy-CAM<br />

3.2 is the unique CAD/CAM software, consisting of an universal 2D/3D CAD<br />

<strong>and</strong> <strong>model</strong>ling program <strong>and</strong> a comprehensive CAD module <strong>for</strong> the technologies<br />

2D/3D <strong>milling</strong>, drilling <strong>and</strong> engraving. isy CAM 3,2 offers <strong>for</strong> designers,<br />

technical designers <strong>and</strong> CNC specialists newest state of the art in the<br />

area of construction, 3D <strong>model</strong>ling <strong>and</strong> manufacturing. isy CAM 3,2 has fastidious<br />

functions during simultaneous simple operation: volume <strong>model</strong>ler,<br />

conceptional design, hybrid 3D <strong>model</strong>ler, special tool <strong>and</strong> mould<br />

<strong>making</strong> functions (undercut recognition, hole recognition on planar<br />

<strong>and</strong> free <strong>for</strong>ming surfaces, automatic separation along the silhouette<br />

curve <strong>and</strong> negative/positive parts).<br />

In order to accelerate <strong>and</strong> optimize the CNC manufacturing process, isy<br />

CAM 3,2 offers feature recognition, drilling automatisms, CAM know how<br />

data bank <strong>and</strong> HSC strategies.<br />

With this integrated software package you receive a CNC machine system<br />

from one competent source - <strong>and</strong> there<strong>for</strong>e a contact person<strong>for</strong> CAD/CAM<br />

programming <strong>and</strong> CNC mechanical engineering! And to a noteworthy, by<br />

this extensive power spectrum, unusual <strong>and</strong> probably singular low price!<br />

THE ULTIMATE<br />

CAD/CAM PACKAGE<br />

Advance by 5 axis technology<br />

Special in the <strong>model</strong> <strong>and</strong> mould <strong>making</strong> 5 axis <strong>milling</strong> is on everyone's<br />

lip - manufacturing processes could be clearly optimized by<br />

this technology. One could archieve these advantages however<br />

only if both the CNC machine <strong>and</strong> the control know higher path<br />

feed motions.<br />

Furthermore the machine system consisting of cartesian linear axis<br />

<strong>and</strong> rotary axis has to be adapted to the respective application.<br />

By our well-known flexible <strong>and</strong> modular axis combinations <strong>and</strong> our<br />

special rotary units, based on highly precise Harmonic DRIVE gear,<br />

various applications can be realized. Many combinations are conceivably:<br />

if rotary / swiveling axis at the machine table or units with<br />

engaged tool axis.<br />

The powerful software functions of isy CAM 3,2 support beyond<br />

that all possible multi-side working on, 3+2 axis applications or 5<br />

axis simultaneous <strong>milling</strong>.<br />

5 axis <strong>milling</strong> technology <strong>for</strong> highest requirements!<br />

10/11

competence in CNC solutions.<br />

3D laser digitalization at the same machine<br />

Measuring technique at the machine increases your productivity<br />

By the extension of the CNC machine with the two 3D scanners<br />

CONOPROBE <strong>and</strong> ShapeTracer you trans<strong>for</strong>m your CNC system<br />

into a contactless digitizing / measuring machine.<br />

With these highly precise measuring instruments free <strong>for</strong>ming surfaces<br />

with most different surfaces in impressive quality could be collected<br />

.And by the smoothly merging into surface feedback software<br />

PointMaster , even complex geometry <strong>for</strong>ms with newest 3D reconstruction<br />

functions will be generated. This High end solution is the ideal<br />

addition <strong>for</strong> the scopes reverse engineering, prototyping, mould <strong>making</strong>,<br />

design <strong>model</strong> <strong>making</strong> <strong>and</strong> 3D measurement.<br />

All users, who have to create a CAD data<br />

set from a master <strong>for</strong>m or a h<strong>and</strong> sample, will<br />

be supported by the combination CNC machine,<br />

laser <strong>and</strong> PointMaster with the necessary<br />

tools.<br />

APPLICATIONS::<br />

:: 3D <strong>for</strong>m scanning <strong>and</strong> CAD subsequent treatment<br />

:: Registration (3D co-ordinates arrangement from scanning to CAD<br />

<strong>model</strong>)<br />

:: Surface feedback (IGES data generation)<br />

:: 3D measuring <strong>and</strong> analysis technology (target/actual<br />

comparison)<br />

Measuring technique at the machine increases your productivity<br />

Mit den schaltenden 3D-Messtastern TS20 von ReniShaw<br />

und dem kabellosen Infrarotsystem OP32<br />

von MARPOSS bestimmen Sie schnell und exakt<br />

With the tactile 3D probes TS20 from ReniShaw<br />

<strong>and</strong> the cordless infrared system OP32 from MAR-<br />

POSS you can determine fast <strong>and</strong> accurately the<br />

workpiece zero point. There<strong>for</strong>e set-up t<strong>imes</strong> <strong>and</strong><br />

service lives shorten <strong>and</strong> the accuracy increase.<br />

Beyond that you can use the 3D measurment probes<br />

<strong>for</strong> an ef<strong>for</strong>tless <strong>and</strong> exact trace of reference<br />

edges at work pieces <strong>and</strong> devices or <strong>for</strong> the measurement<br />

of streched work pieces.<br />

For the non-contact tool check the MIDA LASER<br />

system from MARPOSS is also be available.It makes<br />

the automatic measuring possible of rotary tools<br />

<strong>for</strong> the following check routines of the tools:<br />

:: break control of a tool<br />

:: calibration of tools<br />

:: measurement of length <strong>and</strong> diameter of a tool<br />

Teaching of the workpiece zero point with part situation<br />

compensation (rotation of the NC program<br />

at the control).

Our company positioned itself with a clear target at the market <strong>for</strong> CNC <strong>milling</strong><br />

machines: Plug an play system solutions are co-ordinated accurately to<br />

the individual customer requirements <strong>and</strong> offered <strong>for</strong> a outst<strong>and</strong>ing costper<strong>for</strong>mance<br />

ratio.<br />

This triad of technology, individuality <strong>and</strong> economy becomes possible by the<br />

integration of mechanics, electronics <strong>and</strong> software to modular variable components.<br />

With this passion <strong>for</strong> CNC solutions with maximum customer orientation<br />

we develop <strong>imes</strong>-<strong>icore</strong> to a br<strong>and</strong> with capacity <strong>and</strong> target group<br />

competence. Our concentration applies thereby to the following six sectors:<br />

Für die Bereitstellung von Bildmaterial danken wir der FH Joanneum Gesellschaft mbH / Graz,<br />

besonders den Studenten: Stefan Oberrauner, Georg Haslinger, Rol<strong>and</strong> Kaufmann, Sebastian<br />

Vonderau, Markus Klug, Paul Grader<br />

:: Plastic <strong>and</strong> foam industry<br />

:: Precision mechanics <strong>and</strong> micro machining<br />

:: Graphite machining<br />

:: Advertising <strong>and</strong> Engraving technique<br />

:: Model <strong>and</strong> mould <strong>making</strong><br />

:: Jeweler <strong>and</strong> goldsmith h<strong>and</strong>craft<br />

Owing to our modular system technology we are open to all sides <strong>for</strong> further<br />

challenges.<br />

Challenge us. Welcome at <strong>imes</strong>-<strong>icore</strong>!<br />

www.<strong>imes</strong>-<strong>icore</strong>.de<br />

<strong>imes</strong>-<strong>icore</strong> GmbH<br />

Im Leibolzgraben 16<br />

D- 36132 Eiterfeld<br />

Fon: +49 (0) 66 72 - 89 8 228<br />

Fax: +49 (0) 66 72 - 89 8 222<br />

eMail: info@<strong>imes</strong>-<strong>icore</strong>.de<br />

www.<strong>imes</strong>-<strong>icore</strong>.de