Polyurethane raw materials and sys - PUR-Internet - Bayer

Polyurethane raw materials and sys - PUR-Internet - Bayer

Polyurethane raw materials and sys - PUR-Internet - Bayer

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

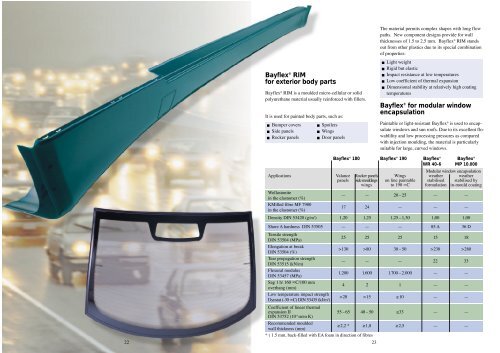

Bayflex ® RIM<br />

for exterior body parts<br />

Bayflex ® RIM is a moulded micro-cellular or solid<br />

polyurethane material usually reinforced with fillers.<br />

It is used for painted body parts, such as:<br />

� Bumper covers � Spoilers<br />

� Side panels � Wings<br />

� Rocker panels � Door panels<br />

22 23<br />

The material permits complex shapes with long flow<br />

paths. New component designs provide for wall<br />

thicknesses of 1.5 to 2.5 mm. Bayflex ® RIM st<strong>and</strong>s<br />

out from other plastics due to its special combination<br />

of properties:<br />

� Light weight<br />

� Rigid but elastic<br />

� Impact resistance at low temperatures<br />

� Low coefficient of thermal expansion<br />

� Dimensional stability at relatively high coating<br />

temperatures<br />

Bayflex ® for modular window<br />

encapsulation<br />

Paintable or light-resistant Bayflex ® is used to encapsulate<br />

windows <strong>and</strong> sun roofs. Due to its excellent flowablility<br />

<strong>and</strong> low processing pressures as compared<br />

with injection moulding, the material is particularly<br />

suitable for large, curved windows.<br />

Bayflex<br />

Modular window encapsulation<br />

Applications Valance<br />

panels<br />

Rocker panels<br />

side mouldings<br />

wings<br />

weather<br />

stabilised<br />

formulation<br />

weather<br />

stabilised by<br />

in-mould coating<br />

® 180 Bayflex ® 190 Bayflex ® Bayflex ®<br />

WR 40-6 MP 10.000<br />

Wings<br />

on line paintable<br />

to 190 ∞C<br />

Wollastonite<br />

in the elastomer (%)<br />

KMilled fibre MF 7980<br />

in the elastomer (%)<br />

— — 20–25 — —<br />

17 24 — — —<br />

Density DIN 53420 (g/m 3 ) 1,20 1,25 1,25 – 1,30 1,00 1,00<br />

Shore A hardness DIN 53505 — — — 85 A 36 D<br />

Tensile strength<br />

DIN 53504 (MPa)<br />

Elongation at break<br />

DIN 53504 (%)<br />

Flexural modulus<br />

DIN 53457 (MPa)<br />

Sag 1 h/ 160 ∞C/100 mm<br />

overhang (mm)<br />

Low temperature impact strength<br />

Dynstat (-30 ∞C) DIN 53435 (kJ/m2 Tear propagation strength<br />

DIN 53515 (kN/m)<br />

)<br />

25 25 25 15 18<br />

>130 >80 30 – 50 >230 >280<br />

— — — 22 33<br />

1.200 1.600 1.700 – 2.000 — —<br />

4 2 1 — —<br />

>20 >15 ≥10 — —<br />

Coefficient of linear thermal<br />

expansion II<br />

DIN 53752 (10<br />

55 – 65 40 – 50 ≥33 — —<br />

-6 m/m K)<br />

Recommended moulded<br />

wall thickness (mm)<br />

≥2,2 * ≥1,8 ≥2,5 — —<br />

* ( 1.5 mm, back-filled with EA foam in direction of fibres