KRYOCLIM gb janvier 2004 - Glynwed A/S

KRYOCLIM gb janvier 2004 - Glynwed A/S

KRYOCLIM gb janvier 2004 - Glynwed A/S

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>KRYOCLIM</strong> ® SYSTEM<br />

<strong>2004</strong><br />

LAGGING PROCEDURES<br />

ELEMENTARY RULES<br />

Technical Sheet<br />

5.3.2<br />

The lagging must be done according to the DTU 61.1 (thermal insulation of refrigerating pipeworks) and to the DTU 65.20.<br />

The <strong>KRYOCLIM</strong> ® system does not need any anti-corrosion treatment before insulation.<br />

The fire resistance of the insulating products must comply the security standard against fire in the public buildings.<br />

It is better not to glue directly the insulating materials on the <strong>KRYOCLIM</strong> ® pipes and fittings.<br />

It is necessary to use cold brackets in order to avoid the crushing of the insulator on the supports.<br />

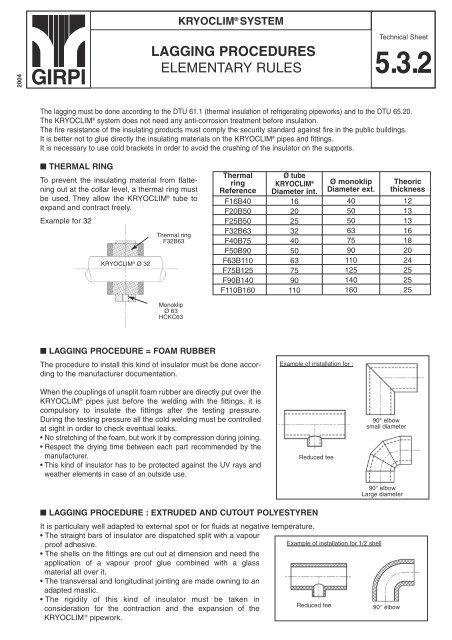

■ THERMAL RING<br />

To prevent the insulating material from flattening<br />

out at the collar level, a thermal ring must<br />

be used. They allow the <strong>KRYOCLIM</strong> ® tube to<br />

expand and contract freely.<br />

Example for 32<br />

<strong>KRYOCLIM</strong> ® Ø 32<br />

Thermal ring<br />

F32B63<br />

Thermal<br />

ring<br />

Reference<br />

F16B40<br />

F20B50<br />

F25B50<br />

F32B63<br />

F40B75<br />

F50B90<br />

F63B110<br />

F75B125<br />

F90B140<br />

F110B160<br />

Ø tube<br />

<strong>KRYOCLIM</strong> ®<br />

Diameter int.<br />

16<br />

20<br />

25<br />

32<br />

40<br />

50<br />

63<br />

75<br />

90<br />

110<br />

Ø monoklip<br />

Diameter ext.<br />

40<br />

50<br />

50<br />

63<br />

75<br />

90<br />

110<br />

125<br />

140<br />

160<br />

Theoric<br />

thickness<br />

12<br />

13<br />

13<br />

16<br />

18<br />

20<br />

24<br />

25<br />

25<br />

25<br />

Monoklip<br />

Ø 63<br />

HCKC63<br />

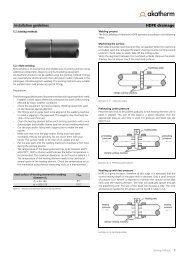

■ LAGGING PROCEDURE = FOAM RUBBER<br />

The procedure to install this kind of insulator must be done according<br />

to the manufacturer documentation.<br />

When the couplings of unsplit foam rubber are directly put over the<br />

<strong>KRYOCLIM</strong> ® pipes just before the welding with the fittings, it is<br />

compulsory to insulate the fittings after the testing pressure.<br />

During the testing pressure all the cold welding must be controlled<br />

at sight in order to check eventual leaks.<br />

• No stretching of the foam, but work it by compression during joining.<br />

• Respect the drying time between each part recommended by the<br />

manufacturer.<br />

• This kind of insulator has to be protected against the UV rays and<br />

weather elements in case of an outside use.<br />

Example of installation for :<br />

Reduced tee<br />

90° elbow<br />

small diameter<br />

90° elbow<br />

Large diameter<br />

■ LAGGING PROCEDURE : EXTRUDED AND CUTOUT POLYESTYREN<br />

It is particulary well adapted to external spot or for fluids at negative temperature.<br />

• The straight bars of insulator are dispatched split with a vapour<br />

proof adhesive.<br />

Example of installation for 1/2 shell<br />

• The shells on the fittings are cut out at dimension and need the<br />

application of a vapour proof glue combined with a glass<br />

material all over it.<br />

• The transversal and longitudinal jointing are made owning to an<br />

adapted mastic.<br />

• The rigidity of this kind of insulator must be taken in<br />

consideration for the contraction and the expansion of the<br />

<strong>KRYOCLIM</strong> ® pipework.<br />

Reduced tee<br />

90° elbow