KRYOCLIM gb janvier 2004 - Glynwed A/S

KRYOCLIM gb janvier 2004 - Glynwed A/S

KRYOCLIM gb janvier 2004 - Glynwed A/S

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

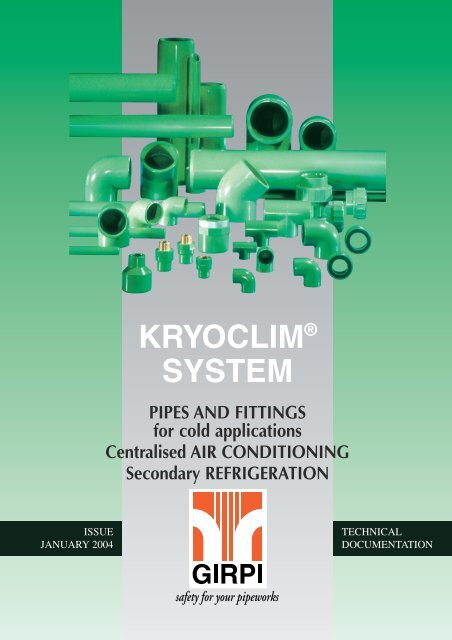

<strong>KRYOCLIM</strong> ®<br />

SYSTEM<br />

PIPES AND FITTINGS<br />

for cold applications<br />

Centralised AIR CONDITIONING<br />

Secondary REFRIGERATION<br />

ISSUE<br />

JANUARY <strong>2004</strong><br />

TECHNICAL<br />

DOCUMENTATION<br />

safety for your pipeworks

<strong>KRYOCLIM</strong> ® SYSTEM<br />

<strong>2004</strong><br />

TECHNICAL DOCUMENTATION<br />

SUMMARY<br />

Technical Sheet<br />

0.0<br />

Titles<br />

• Summary 0.0<br />

General characteristics<br />

• Applications 1.1<br />

• Benefits 1.2<br />

• Characteristics 1.3<br />

• Operating conditions 1.4<br />

n° Technical Sheets<br />

Range<br />

• Descriptive 2.1<br />

Works on pipes and fittings<br />

• Tools 3.1<br />

• Cold welding method 3.2<br />

• Recommendations 3.3<br />

• Control, testing and implementation 3.4<br />

Contraction Expansion<br />

• Phenomenon - calculations 4.1<br />

• Consequences 4.2<br />

• Remedies 4.3<br />

• Determining of leg B 4.4<br />

• Expansion joints 4.5<br />

Environnement<br />

• MONOKLIP brackets 5.1<br />

• Basket tray for insulated pipes 5.2<br />

• Insulation 5.3<br />

• Antifreeze fluids 5.4<br />

Pressure losses<br />

• Calculation rules 6.1<br />

• Diagram at 7°C 6.2<br />

Dimensional sheets<br />

• Usual pipes and fittings 7.1 to 7.5<br />

Compatible fluids<br />

• Antifreeze fluids 8.0<br />

• Chemical resistance tables 8.1 to 8.7<br />

IMPORTANT DETAIL : The date on cach page of this documentation is not a printing date but an updating date.

<strong>KRYOCLIM</strong> ® SYSTEM<br />

GENERAL CHARACTERISTICS<br />

APPLICATIONS<br />

Technical Sheet<br />

1.1<br />

<strong>2004</strong><br />

GIRPI is a part of an international group present in many countries (Aliaxis).<br />

Thanks to its long experience in the fields of refrigeration and air conditioning with its different<br />

products, GIRPI developed a complete system which answers the needs of the following applications<br />

:<br />

• Centralised Air conditioning applications :<br />

- chilled water<br />

• Industrial applications :<br />

- cooling<br />

- process<br />

• Food industry<br />

- refrigerated warehouses<br />

- industrial kitchens<br />

<strong>KRYOCLIM</strong> ® benefits from the low temperature performance of its main component called HPF.<br />

The system is particulary suitable for commercial and industrial secondary refrigeration and indirect<br />

air conditioning applications.<br />

Thanks to its wide range of pipes (diameter 20 to 160), fittings and accessories especially developed<br />

to be adapted to existing networks, <strong>KRYOCLIM</strong> ® enables the installation of every kind of commercial<br />

and industrial refrigeration and indirect air conditioning networks from -30° to +40° C based<br />

on the following secondary fluids : chilled water, gylcols...<br />

The practice, which is well known in centralised air conditioning applications is being chosen<br />

more and more for complete commercial and industrial refrigeration applications.

<strong>KRYOCLIM</strong> ® SYSTEM<br />

2000<br />

GENERAL CHARACTERISTICS<br />

BENEFITS<br />

Technical Sheet<br />

1.2<br />

The <strong>KRYOCLIM</strong> ® system offers a lot of benefits against traditional materials :<br />

❏ Corrosion resistant :<br />

❏ Strength-Impact Resistant :<br />

❏ Fire classification :<br />

❏ Non-permeability :<br />

❏ Hydraulicity :<br />

❏ Thermal conductivity<br />

cœfficient :<br />

❏ Condensation :<br />

❏ Chemical resistance :<br />

❏ Installation :<br />

<strong>KRYOCLIM</strong> ® is non-corrodible and allows to avoid<br />

expensive film-forming treatments. The networks<br />

remained perfectly sealed.<br />

The <strong>KRYOCLIM</strong> ® manufactured of HPF ® alloy withstands<br />

impact even at low temperature.<br />

The <strong>KRYOCLIM</strong> ® system is non-flammable and is<br />

being classified M1<br />

<strong>KRYOCLIM</strong> ® is non-permeable to oxygen, thus eliminating<br />

the formation of sludge inside the pipes.<br />

The smooth internal surface of <strong>KRYOCLIM</strong> ® products<br />

reduces frictional losses.<br />

Energy savings.<br />

Fall of the heat losses up to 30 % in comparison with<br />

steel.<br />

Reduced problems against traditional materials. The<br />

external temperature of <strong>KRYOCLIM</strong> ® pipes is several<br />

degrees higher.<br />

<strong>KRYOCLIM</strong> ® has been developed to have a perfect<br />

compatibility with the fluids presented in the sheet<br />

8.0.<br />

Easy- to-install system<br />

- Light weight.<br />

- Simple tools.<br />

- No flame.<br />

The <strong>KRYOCLIM</strong> ® system can be built-in, embedded<br />

or buried.

<strong>KRYOCLIM</strong> ® SYSTEM<br />

GENERAL CHARACTERISTICS<br />

Technical Sheet<br />

1.3<br />

2000<br />

1. PHYSICAL CHARACTERISTICS<br />

Characteristics Standards Units Values<br />

Physical aspect NF T 54-029 - ISO 7686 — —<br />

Fire classification<br />

M1-being classified<br />

Volumic mass NF T 54-022 - ISO 1183/3514 kg/m 3 ≈ 1350<br />

Linear expansion dilation ASTM D 696-70 mm/m °C 0,09<br />

Transversal vesistivity (under 1000 V) ASTM D 257/76 Ohm.cm 10 15<br />

Termal conductivity λ ASTM C 177-76 W/m°C 0,17<br />

Shrinkage at 150°C NF T 54.021 - ISO 2505 % ≤ 4<br />

2. MECHANICAL CHARACTERISTICS<br />

Characteristics Standards Units Values<br />

Bending under load NF T 51-005/méth.A - ISO 877<br />

temperature<br />

°C ≈ 55<br />

VICAT softening temperature NF T 51-021/méth.B - ISO R 306<br />

(5 daN load) NF T 54-034 - ISO 2056/2507<br />

°C ≥ 75<br />

Resistance to static pressure NF T 54 035 - ISO 2035 —<br />

• at 20°C time ≥ 1 h NF T 54-016 — 4,2 x PN<br />

Resistance to alternating pressure NF T 54-094<br />

(on fittings and glued jointings) NF T 54-016<br />

Pressure : min 20 bar/max. 60 bar<br />

• ø 20 to 90 : frequency 1Hz Cycles ≥ 5000<br />

• ø 110 : frequency 0,42 Hz Cycles ≥ 2500<br />

1 MPa = 10 bars<br />

3. QUALITY CONTROLS<br />

To provide a normal quality level for ist products and to guarantee its users that the stated performances are respected,<br />

GIRPI has implemented the control regulations imposed by the different French and international standards.<br />

The controls concern the physical and mechanical characteristics of the couplings.<br />

However in addition to the above verifications and to guarantee the maximum reliability level in actual operating<br />

conditions, GIRPI has developed and carries out additional tests one of which is currently undergoing standardization<br />

(NF T 54-094 standard).<br />

Thus, a crushing operation on the couplings associated with an alternate pressure test (on solvent cement fittings<br />

assemblies) is regulary carried out. The couplings are subjected to fluid hammer cycles (20/60 bar) at 3600<br />

cycles/hour for diameters 20 to 90 and 1500 cycles/hour for diameters 110 and 160.<br />

Furthermore, operational test are constantly carried out on our laboratory’s testing rigs. This enables us to guarantee<br />

the adaption of each component in the pipework to its own function.<br />

The ISO 9001 Version 2000 certified procedures at all stages (production, quality, control etc...) guarantee globally<br />

the quality of GIRPI’s products.

<strong>KRYOCLIM</strong> ® SYSTEM<br />

2000<br />

GENERAL CHARACTERISTICS<br />

OPERATIONS CONDITIONS<br />

Technical Sheet<br />

1.4<br />

WORKING PRESSURE AND TEMPERATURE<br />

10 bar from - 30°C to + 20°C<br />

(PMS)<br />

10 bars<br />

MAXIMUM WORKING<br />

PRESSURE<br />

The flow temperature of some networks (such as process or<br />

defreezing of convection fans) can reach more than 20°C.<br />

<strong>KRYOCLIM</strong> ® allows a maximum temperature of 40°C with a<br />

maximum pressure of 7 bar.<br />

7 bars<br />

Fluid Température<br />

temperature<br />

du fluide<br />

■ WORKING LIFETIME :<br />

-30 -20 -10 0 10 20 30 40 (°C)<br />

The working pressure and temperature indicated in the following tables are determined for a working life of 50<br />

years without interruption.<br />

Working pressures according to working temperatures are figured out by using regression curves as per standard<br />

NF T 54-091.<br />

■ TESTING PRESSURE<br />

PN<br />

Testing pressure<br />

1 hour (20°C)<br />

4,2 PN<br />

10 42 bars<br />

2,5 PN<br />

1 heure 100 h 1000 h 10 000 h 50 ans<br />

A pressure pipework can be classified as PN 10 (with a safety factor of 2.5 after 50 years) if it can tolerate, during<br />

one hour, a pressure equal to 4.2 times this PN. The characteristics of the system can only be guaranteed to 50<br />

years by combining these two parameters.<br />

The readings for the breaking pressures for <strong>KRYOCLIM</strong> ® change, as shown in a straight-line in logarithmic co-ordinates.<br />

Considering the safety cœfficients, the pressure ratio between 50 years and one hour ranges from 4.2 to 2.5. This<br />

straight line is drawn on the basis of the 1 hr, 100 hr, 1000 hr and 10,000 hr tests, and is then extrapolated to 50<br />

years.<br />

■ GARANTIES :<br />

• For all applications specified in the technical documentation, regardless of pipe diameter, GIRPI has an insurance<br />

to guarantee installations which are carried out in accordance with its own general recommendations, and which<br />

respect the temperature and pressure conditions and the nature of fluid specified above.

<strong>KRYOCLIM</strong> ® SYSTEM<br />

Technical Sheet<br />

RANGE<br />

2.1<br />

2000<br />

Description<br />

Ref.<br />

Diameters in mm<br />

20 25 32 40 50 63 75 90 110 160<br />

<strong>KRYOCLIM</strong> ® pipe TUB F ● ● ● ● ● ● ● ● ● ●<br />

SOCKETS FMA ● ● ● ● ● ● ● ● ● ●<br />

Description<br />

Réf.<br />

ADAPTOR NIPPLES FEAL 1/2” 3/4”<br />

BRASS THREADED<br />

Diameters in mm<br />

20 25 32 40 50 63 75<br />

ELBOWS 90° F4M ● ● ● ● ● ● ● ● ● ●<br />

ADAPTOR NIPPLES FEA 1” 1”1/4 1”1/2 2” 2”1/2<br />

ELBOWS 45° F8M ● ● ● ● ● ● ● ● ● ●<br />

THREADED ADAPTORS FMML 1/2” 3/4” 1”<br />

Female brass<br />

thread<br />

EQUAL TEES FTE ● ● ● ● ● ● ● ● ● ●<br />

THREADED ADAPTORS FMM 1”1/4 1”1/2 2” 2”1/2<br />

Female thread<br />

CAPS FBO ● ● ● ● ● ● ● ● ● ●<br />

ACCESSORIES<br />

REDUCING BUSHES FRS 20 25 32 40 50 63 75 90<br />

SHORT ● ● ● ● ● ● ● ●<br />

REDUCING BUSHES FRD 20 20 32 25 40 50 110<br />

LONG 25 32 40 50 63<br />

40 50 63 75<br />

SERRATED STUB FCS ● ● ● ● ● ●<br />

FLANGES<br />

FLANGES BPA ● ● ● ● ● ●<br />

BVR<br />

REDUCED TEES FTR 20 20 20 20 20 20<br />

25 25 25 25 25 25 32<br />

32 32 32<br />

40 40 40 40 50<br />

3 PIECE UNIONS F3P ● ● ● ● ●<br />

PLAIN NIPPLES FMC<br />

M/M<br />

lenght (mm)<br />

37 42 49 57 67 80<br />

3 PIECE F3G/L 1/2” 3/4” 1” 1”1/4 1”1/2 2”<br />

UNIONS<br />

F Brass<br />

3 PIECE F3F/L 1/2” 3/4” 1” 1”1/4 1”1/2 2”<br />

UNIONS<br />

M Brass<br />

Description<br />

Ref.<br />

Diameters in mm<br />

20 25 32 40 50 63 75 90 110<br />

FLAT GASKET JPN ● ● ● ●<br />

CEMENT<br />

CLEANER<br />

1 l<br />

HPFIXP<br />

HPFIXB<br />

D171P<br />

MONOKLIP HCK(C) ● ● ● ● ● ●<br />

BRACHETS A9C ● ● ●<br />

+ Wedge h t = 20mm CALE ● ● ● ● ● ●<br />

BASKET TRAY GIRFIL 200 300 400<br />

(For insulated<br />

networks).<br />

ACCESSORIES FOR<br />

BASKET TRAY<br />

• Hanging clip FATT ● ● ●<br />

• Kit (4 bolts + FILKIT ● ● ●<br />

2 splices + 4 clamps)<br />

• CLIPS SUPPORT FSUP ● ●<br />

EXPANSION JOINTS<br />

• Sochet threadet HCD/G 1/2” 3/4” 1”<br />

+ free nut<br />

• 2 brass threaded ends HCD/L 3/4” 1” 1”1/4 1”1/2 2”<br />

ANTIFREEZE FLUIDS NEUTRAGEL ®<br />

* on request<br />

MIXIGEL ®<br />

*

<strong>KRYOCLIM</strong> ® SYSTEM<br />

2000<br />

WORKS ON PIPES AND FITTINGS<br />

TOOLS<br />

Technical Sheet<br />

3.1<br />

■ CUTTING<br />

• The roller plastic pipe-cutter Réf. GIRPI CT1240 Ø 12 to 40 mm<br />

Réf. GIRPI CT1263 Ø 12 to 63 mm<br />

Réf. GIRPI CT50110 Ø 50 to 110 mm<br />

• The chamfering pipe-cutter<br />

This tool cuts and chamfers the pipe after cutting, in one single operation. It is designed<br />

to cut the Ø 160 pipes without accessories.<br />

Réf. GIRPI CTC63<br />

Réf. GIRPI CTC110<br />

Ø 32 to 63 mm<br />

Ø 75 to 110 mm<br />

■ TRIMMING - CHAMFERING<br />

After cutting, the pipe must be trimmed inside and a chamfer must be made<br />

on the outside.<br />

These operations can be performed by means of a 1/2-round bastard file.<br />

IMPORTANT<br />

• Trimming and chamfering cone : This tool can be used on the pipe, on the other side it chamfers the outside.<br />

Réf. GIRPI CONE 50 U for pipes Ø 12 to 50 mm.<br />

Chamfering pipe-cutter See cutting section.<br />

Chamfering tool<br />

This tool chamfers the pipe outside<br />

from Ø 50 to Ø 160.<br />

Réf. GIRPI CHANF160<br />

Trimmer<br />

This reams the inside of pipes of all diameters.<br />

Réf. GIRPI EBAV1 Ø 12 à 160 mm<br />

■ HOLDING TOOLS<br />

Chain vice *<br />

Polyurethane pipe-rests hold the pipe without<br />

any scratching.<br />

Strap wrench *<br />

Maximum gripping power, with no risk of deforming the pipes<br />

or fittings (braided nylon strap).<br />

pipe-rest<br />

Chain bench vice *<br />

Vice (traditionnal) In this case all the necessary precautions must be taken so that the pipe is neither crushed nor scratched<br />

by the jaws. For this purpose, a “hard wood tool” can be cheaply produced. The pipe should be placed in the corresponding<br />

notch ; by tightening up the vice the tool clamps the pipe.<br />

* Thes tools are distributed (among other sellers) by Ets AGI - 75, rue St-Denis - 93300 Aubervilliers - France - Tél. 01 48 34 91 99.

<strong>KRYOCLIM</strong> ® SYSTEM<br />

WORKS ON PIPES AND FITTINGS<br />

TOOLS<br />

Technical Sheet<br />

3.2.1<br />

<strong>2004</strong><br />

CUTTING CHAMFERING BONDING ASSEMBLY<br />

■ CHEKS PRIOR BEFORE BONDING<br />

The operation of abrading and cleaning are canceled.<br />

Before bonding, it is important to make certain checks : the pipes must be clean and dry. The working zone is clean,<br />

otherwise it is necessary to clean the pipes and the fittings with a cleancloth, or even D 171 cleaner.<br />

IMPORTANT<br />

- Water impairs the cement and subsequently the welding quality. No cold welding will therefore be<br />

applied if the parts to be assembled are damp (prior drying).<br />

- With HPFIX the assembly can be made when the temperature is over +5°C and under +35°C, these are<br />

mandatory limits.<br />

- The atmospheric conditions (temperature, humidity) considerably affect the setting time (drying,<br />

evaporation of solvents) of the cement.<br />

- At low temperature, the parts when assembled should be held together for 20 to 30 seconds.<br />

- In hot weather, the cement should be applied rapidly and the parts immediately jointed.<br />

- So as to avoid evaporation of the solvent contained in the cement, the pot must be closed after each cold<br />

welding operation.<br />

■ MARKING OF THE SOCKET LENGTH<br />

- It is useful, in the case of the pipe, to trace on it (using a thick pencil or felt marker) a mark at a<br />

distance equal to the corresponding socket depth.<br />

Mark<br />

This mark enables:<br />

1) applying the cement over the necessary length<br />

2) checking whether the penetration length of the male end in the socket is correct.

<strong>KRYOCLIM</strong> ® SYSTEM<br />

2000<br />

GENERAL CHARACTERISTICS<br />

WELDING PROCEDURE<br />

Technical Sheet<br />

3.2.2<br />

■ COLD WELDING<br />

- When the checks and marking have been done, then apply the cement.<br />

- HPFIX cement must be employed.<br />

Do not use any other cement.<br />

- To apply the cement, use a suitable brush. Do not use: your fingers, a piece of wood or any other utensil; dipping<br />

the pipe or couplings in the cement is prohibited (this way of doing things creates a bead of cement at the bottom<br />

of the socket and in small diameters a film obstructing the bore).<br />

- Apply the cement moderately (in a thin coat) over the whole (the female) interlock length and over the whole length<br />

of the male end (marked on pipe). The cement should be applied in 2 thin cross-coats, the second coat being<br />

in the longitudinal direction. See NF T 54-035 standard. For surfaces with a large diameter, use a brush large<br />

enough.<br />

Cement<br />

Marks<br />

Chamfer<br />

Paint brush<br />

direction<br />

Owing to the standardized tolerance ranges of the male ends and the sockets, some gap may appear.<br />

In this case, double quantities of cement must be applied. This consists in coating the male end once, then the<br />

socket and the male end a second time, then jointing them.<br />

■ JOINTING<br />

Immediately after applying the cement, joint the two elements right home (as far as the marks previously traced)<br />

pushing longitudinally and, above all, without twisting. For surface with a large diameter, two people must be present<br />

in order to assemble the fittings (an operator glues the socket part while the other operator glues the spigot<br />

part.<br />

Mark<br />

Positioning<br />

mark<br />

NB: In certain cases it is necessary to mark the position of one element in relation to the other (see sketch above).<br />

This mark should be done before scouring.<br />

- After jointing and in the case of surplus cement featured by a bead of cement, it is necessary to reduce it without<br />

completely eliminating the trace of cement. This bead should be reduced using a clean cloth or cotton wool.

<strong>KRYOCLIM</strong> ® SYSTEM<br />

WORKS ON PIPES AND FITTINGS<br />

RECOMMENDATIONS - DETERMINING<br />

CEMENT AND CLEANER QUANTITIES<br />

Technical Sheet<br />

3.3<br />

<strong>2004</strong><br />

■ DRYING TIME<br />

With HPFIX cement, the drying times before pressure tests are the following :<br />

Ø (in mm) 20 - 63 75 - 110 160<br />

Ambient<br />

for 6 bar pressure test,<br />

temperature at 20°C<br />

5 to 10°C 2 h 4 h 24 h<br />

11 to 35°C 1 h 2 h 24 h<br />

■ HANDLING AND STORAGE<br />

Like all building materials, the final quality of the installation depends on the conditions in which they are transported,<br />

handled and stored. The pipes and fittings will be stored separately on an even area, away from dust and<br />

the sun. In all cases, take special care to avoid rough handling, impacts and especially with projecting, cutting or<br />

heavy objects, particularly in cold weather.<br />

■ THERMOFORMING<br />

Thermoforming of the <strong>KRYOCLIM</strong> ® pipes is strictly prohibited on the work site and involves cessation of the GIRPI<br />

guarantee. For all changes in direction, make use of standard <strong>KRYOCLIM</strong> ® fittings only. In case of force majeure,<br />

the fabrications will be made in the workshop, without direct flame heating and according to the indications to be<br />

requested in writing from GIRPI.<br />

■ CONNECTIONS OF THE CPVC FITTINGS ONTO THREADED OR TAPPED METAL COMPONENTS<br />

The fittings with screwed or threaded brass inserts molded from a casting : HMML, HEAL, HEBL, H4GL, H4GP<br />

must be used for strong tightening torques on metallic fittings. The waterproofing may be then carried out by traditional<br />

means, except for anaerobic resins.<br />

Excluding connection to wall brackets (GAAP reference), obtained by means of tap connectors (HDR reference),<br />

connections of the CPVC to metal pipes, fittings and equipment, whether tapped or threaded (tapered or<br />

cylindrical), must be made by means of CPVC/metal couplings provided for this purpose.<br />

If sockets, elbows, tees or other <strong>KRYOCLIM</strong> ® fittings are used with the original tapping or threading in the material<br />

itself, they will be screwed by hand, only the last quarter turn if necessary will be made preferably by strap wrench.<br />

In this case, in order to seal tight, the use of tow or a similar material or anaerobic resin is forbidden, as excessive<br />

tightening may provoke irremediable damages.<br />

To obtain this, use:<br />

- Teflon tape type sealing materials, such as GEB’s high density. On male threads, apply 5 layers of<br />

Teflon tape clock wise, starting from 1 st thread;<br />

- Silicone paste (JS 533 by Loctite or Filetplast by GEB). Drying time: 24h. For Ø 1/2" and 3/4", drying<br />

times of 3 hours are sufficient.<br />

In no case should the <strong>KRYOCLIM</strong> ® pipes and fittings be machine-threaded inside or outside.<br />

■ APPROXIMATIVE QUANTITIES FOR 100 JOINTINGS DEPENDING ON PIPE DIAMETER<br />

PIPE Ø<br />

QUANTITY<br />

Welding polymer<br />

20 60 ml<br />

25 - 32 200 ml<br />

40 - 50 0,5 liter<br />

63 - 75 1,5 liters<br />

90 - 110 3 liters<br />

160 6 liters

<strong>KRYOCLIM</strong> ® SYSTEM<br />

2000<br />

INSPECTIONS, TESTS AND PUTTING<br />

INTO SERVICE<br />

Technical Sheet<br />

3.4<br />

■ GENERAL<br />

The <strong>KRYOCLIM</strong> ® system pipes and fittings are inspected throughout their manufacture and are guaranteed for a<br />

use complying with their design within the limits indicated.<br />

During the installation and before putting the <strong>KRYOCLIM</strong> ® network into service, it is advisable to make a certain<br />

number of checks as with all the other materials.<br />

■ INSPECTION<br />

a) Visual inspection<br />

When assembling, the pipes and fittings should be inspected so as to eliminate doubtful elements containing<br />

abnormalities such as impacts or deep scores caused by unsuitable handling. Before the tests, the whole network<br />

will be visually inspected to eliminate any part containing deep cuts or notches, large scale deformations due to<br />

sudden impacts, traces of blow torch burns, etc.<br />

Any damaged part should be replaced before setting into service. The aim of the visual inspection is also to ensure<br />

that the installation complies with the drawings and hence the correct installation of all the component parts<br />

(connections, supports, monitoring and safety mechanisms, etc.).<br />

b) Leak tests<br />

Before completing the network, a leak test will be made (all the parts of the network should be visible and accessible<br />

during the test).<br />

c) Pressure test<br />

The network is filled with water (drive the air out of all the high points), then held under pressure throughout the<br />

time necessary for the visual inspection of all the junctions with a minimum of 30 minutes (for large scale installations,<br />

proceed by sections).<br />

The pressure test will be made at 1,5 times the maximum service pressure with a maximum of 10 bar at a temperature<br />

of 20°C-25°C.<br />

• in case of a leak on a glued joint, replace the faulty section then recommence the test<br />

• in case of a leak on a screwed joint, tighten up the fitting and replace the joint<br />

■ PUTTING INTO SERVICE:<br />

When the leak tests have been made, it is advisable, in order to remove all foreign matter to clean the inside of the<br />

network. Before setting into service, all the tests and inspections must be made in accordance with the rules of the<br />

trace and the regulations applicable to the installation whilst taking account of the characteristics of the material.<br />

OPERATING CONDITIONS:<br />

Whatever the case of use, the safety mechanisms necessary for the traditional protection of networks (regulating,<br />

anti water hammer, pressure reduction and limitation, temperature regulation and limitation, isolating mechanisms,<br />

etc. (should be provided, installed and kept in perfect working order during the operation).<br />

a) Vibrations:<br />

Vibrations can be a source of disorders both on the piping and on the supports; it is highly advisable to install a<br />

suitable system preventing their propagation when necessary.<br />

b) Hot sources and UV:<br />

Being thermoplastic material, the <strong>KRYOCLIM</strong> ® System should in no case be installed close to a hot source causing<br />

a rise in temperature greater than its limits of use, nor in places continuously exposed to the sun (ultraviolet<br />

rays). If this type of installation proves to be inevitable, a minimum number of precautions must be taken such interposing<br />

a protective screen impermeable to ultraviolet or heat rays.<br />

c) Prevention of impacts:<br />

As with all networks conveying pressurised fluids, the piping in the <strong>KRYOCLIM</strong> ® System should be protected<br />

against impacts which might occur in places of passage frequented by handling machinery or suspended loads in<br />

movement (use of safety barriers, railings, etc.).

<strong>KRYOCLIM</strong> ® SYSTEM<br />

CONTRACTION - EXPANSION<br />

PHENOMENON - CALCULATIONS<br />

Technical Sheet<br />

4.1<br />

2000<br />

THE PHENOMENON<br />

All materials not specially stressed, under the effect of thermal variations in relation to the reference<br />

temperature (installation temperature):<br />

- expand when the temperature rises<br />

- contract when the temperature drops<br />

Comparison between coefficients α<br />

Steel<br />

Copper<br />

<strong>KRYOCLIM</strong> ®<br />

P.P.<br />

P.E.<br />

Steel<br />

Copper<br />

<strong>KRYOCLIM</strong> ®<br />

P.P.<br />

P.E.<br />

12,8 x 10 -6 m/m°C<br />

16,5 x 10 -6 m/m°C<br />

90 x 10 -6 m/m°C<br />

140 x 10 -6 m/m°C<br />

150 x 10 -6 m/m°C<br />

mm/m/°C x 10 -6<br />

20 40 60 80 100 120 140 160 180<br />

CALCULATION PARAMETERS FOR THE <strong>KRYOCLIM</strong> ®<br />

The linear expansion coefficient of the <strong>KRYOCLIM</strong> ® is:<br />

α = 0,09 millimeter per meter per °C (mm/m/°C)<br />

The implementation of the system would take account of the elongation<br />

or contraction of the pipe which is calculated by the relation:<br />

∆L = α x L x ∆T<br />

in which α = expansion-contraction coefficient (linear)<br />

L = length of the piping when installed, in meters<br />

∆T = temperature deviation in degrees Celsius<br />

(difference between the maximum or minimum temperature in service and the installlation temperature)<br />

∆L = length deviation<br />

(difference in length between L on installation and L in operation, i.e. elongation or shrinkage length).<br />

Ex 1 : Air Conditioning<br />

. Installation temperature = + 20°C<br />

. Chilled water temperature = + 7°C<br />

L = 5 levels (1 level = 2,7 m) = 13,5 m<br />

∆T = 20 - 7 = 13°C<br />

∆L = 0.09 x 13,5 x 13 = 16 mm contraction<br />

20°C<br />

5°C<br />

L = 13,5 m<br />

∆L<br />

16<br />

mm<br />

Ex 2 : Industrial process (return)<br />

Installation temperature = + 15°C<br />

. Fluid temperature = + 35°C (maximum)<br />

L<br />

= 50 m<br />

∆T = 35 - 15 = 20°C<br />

∆L = 0.09 x 30 x 35 = 95 mm expansion<br />

15°C<br />

35°C<br />

L = 50 m<br />

∆L<br />

90<br />

mm<br />

Ex 3 : Network for industrial kitchen<br />

Installation temperature = + 25°C<br />

. Fluid temperature (glycol) = - 10°C<br />

L<br />

= 30 m<br />

∆T = = 25 -(-10) = 35°C<br />

∆L = 0.09 x 30 x 35 = 95 mm contraction<br />

25°C<br />

-10°C<br />

L = 30 m<br />

∆L<br />

95<br />

mm

<strong>KRYOCLIM</strong> ® SYSTEM<br />

<strong>2004</strong><br />

CONTRACTION - EXPANSION<br />

CONSEQUENCES<br />

Technical Sheet<br />

4.2<br />

CONSEQUENCES OF CONTRACTION-EXPANSION AND SOLUTIONS<br />

In certain conditions, the elongation due to the expansion causes compression of the pipe resulting in buckling,<br />

conversely the shortening due to the contraction of the pipe is the origin of its being tensioned. The sketches below<br />

illustrate a number of cases of compression or tension, which cause abnormal working of the material and risk producing<br />

large-scale disorders.<br />

The DTU, ATEC, GUIDES concerning the installation of piping, whatever their nature, generally indicate that «when<br />

installing, it is necessary, in order to avoid the disorders which may be caused by variations in length, to know<br />

about them and remedy them».<br />

: Fixed Point<br />

a) Expansion (compression between fixed points)<br />

■ buckling of the pipe between fixed points<br />

: Longitudinal Guide<br />

: Action on the stops and couplings<br />

■ Thrust on the works, obstacles, links or on the gear forming a fixed point.<br />

Risk of deformation or separation<br />

b) Contraction (tension between fixed points)<br />

■ Tensioning of pipes, mechanical couplings, bonding between fixed points<br />

■ Tensioning between works, obstacles, links or gear forming a fixed point<br />

Risk of deformation or separation<br />

(1) PF :This is a support blocking the piping system at one point, in order to ”direct” the movements caused by<br />

expansion and contraction.<br />

(2) LG : They uphold the pipes while allowing them to lenghten and shrink (expansion and contraction).

<strong>KRYOCLIM</strong> ® SYSTEM<br />

CONTRACTION - EXPANSION<br />

REMEDIES<br />

Technical Sheet<br />

4.3<br />

2000<br />

c) The remedies<br />

In order to avoid the disorders subsequent to the movements of the pipe, it is necessary to let the latter expand<br />

and contract freely.<br />

It is therefore necessary to:<br />

- use supports whereby the longitudinal movements of the pipe can be guided<br />

- see that there is never a straight length of pipe between 2 fixed points, either by using a change in direction, or<br />

a loop (see illustration below).<br />

1° Change in direction, which is generally efficient<br />

CHANGE IN DIRECTION<br />

BRANCH<br />

expansion<br />

expansion<br />

2° Loop made with <strong>KRYOCLIM</strong> ®<br />

pipes and fittings<br />

≈ B/2<br />

B<br />

L2<br />

contraction<br />

- ∆L<br />

- ∆L<br />

L2<br />

contraction<br />

3° Expansion joint (HCD/L - HCD/G)<br />

L<br />

L1<br />

dilatation expansion<br />

+∆L<br />

+∆L<br />

L<br />

L1<br />

dilatation expansion<br />

(P.F.) (G.L.) (G.L.) (P.F.)<br />

L : Lenght of piping during installation.<br />

L1 : Lenght at Max temperature.<br />

L2 : Lenght at Min temperature (fluid or).<br />

∆L : Lenght difference between L1 (or L2)<br />

and L.<br />

B : Length of leg’s loop.

mouvement (in mm)<br />

<strong>KRYOCLIM</strong> ® SYSTEM<br />

2000<br />

CONTRACTION - DILATATION<br />

DETERMINING OF LEG B<br />

Technical Sheet<br />

4.4<br />

FOR DIAMETERS 20, 25, 32, 40 50, 63 IN <strong>KRYOCLIM</strong><br />

EXAMPLE ➀ :<br />

Determine B for a Ø 40 mm<br />

pipe and a ∆L of 53 mm<br />

Result : B = 1,56 m.<br />

1<br />

Calculation formula of loop arm :<br />

B = Length of leg (in m)<br />

with 34 : constant for <strong>KRYOCLIM</strong> ®<br />

FOR DIAMETERS 75, 90, 110 IN <strong>KRYOCLIM</strong><br />

Ø : external diameter<br />

∆L : length variation<br />

mouvement (in mm)<br />

EXAMPLE ➁ :<br />

Determine B for a Ø 110 mm pipe<br />

and a ∆L of 28 mm<br />

Result : B = 1,88 m<br />

2<br />

B = Lenght of leg (in m)

<strong>KRYOCLIM</strong> ® SYSTEM<br />

EXPANSION - CONTRACTION<br />

REMEDIES - EXPANSION JOINTS<br />

Technical Sheet<br />

4.5<br />

2000<br />

Elbow F4M<br />

(<br />

* )<br />

Expansion joint HCD/L<br />

ou HCD/G<br />

It depends on the expansion :<br />

*<br />

Threaded adaptor : FMM(L)<br />

Adaptor nipple : FEA(L)<br />

3 piece unions : HPF/BRASS - F3G/L<br />

: Direction of expansion .<br />

D : Distance on installation.<br />

d : Absorbed expansion<br />

lenght (∆L).<br />

E : Max. dimension.<br />

Support brachet<br />

(fixed point)<br />

Sliding<br />

brachet<br />

Sliding<br />

brachet<br />

Freely sliding support<br />

(expansion joint installed horizontal).<br />

■ EXPANSION JOINTS SUPPORTS :<br />

1) The first sliding brackets will be at a distance (1) ≈ 75 mm (max<br />

spacing position), the next bracket in line will be at a distance<br />

(2) ≈ 120 mm from the first.<br />

2) The surface finish of the sliding support supporting the hose will<br />

be such that the hose braiding is not deteriorated by rubbing.<br />

<strong>KRYOCLIM</strong><br />

pipe ø<br />

Expansion joint<br />

reference D d E<br />

20 HCD/L 20 (/G20) 220 100 282<br />

25 HCD/L 25 (/G25) 280 100 338<br />

32 HCD/L 32 (/G32) 350 100 407<br />

40 HCD/L 40 420 100 442<br />

50 HCD/L 50 500 100 591<br />

■ PRINCIPLES OF IMPLEMENTING EXPANSION JOINTS :<br />

To guarantee correct operation, the following rules must be respected when designing the installation and installing<br />

the expansion joints.<br />

b) Ensure that the expansion joint is not subjected to twisting during installation or during operation.<br />

c) Provide appropriate supporting in cases where the hose is overhanging.<br />

: Fixed Point<br />

: Longitudinal Guide<br />

: Action on the stops and couplings<br />

branch<br />

direction change<br />

on same level

<strong>KRYOCLIM</strong> ® SYSTEM<br />

<strong>2004</strong><br />

BRACKETS<br />

GENERAL - SPACING<br />

Technical Sheet<br />

5.1.1<br />

■ GENERAL<br />

Monoklip brackets are designed to be used with <strong>KRYOCLIM</strong> ® pipes.<br />

The choices concerning the material of which the supports are constituted, their shape, closing and fastening system<br />

are the responsibility of the installer;<br />

The supports :<br />

- should in no event neither injure nor damage the piping,<br />

- should continue to support the load they have to support even under temperature effects,<br />

- should continue to support the load that they support sufficiently well away from any wall or obstacle so as to provide<br />

for the expansion movements and also the assembly and disassembly of the mechanical couplings and accessories<br />

(unions, flanges, valves, pressure limiters, etc...).<br />

IMPORTANT<br />

Any rise in temperature in the H.P.F. components produces a weakening of their mechanical characteristics.<br />

This weakening is all the greater when the temperature is high.<br />

This state of things can cause punching or compression of the pipe by unsuitable supports or buckling between supports<br />

that are too far from each other, whose effect would be to hinder or even prevent the movements generated by expansion<br />

and contraction.<br />

The monoklips of 16 to 25 may be heightened by wedges (ref wedge 1225) 20 mm high made for that purpose.<br />

For the monoklips of 32 to 63 use the wedges (ref wedge 3263) 20 mm or 4 mm high which can be piled up.<br />

For the monoklips of 75 to 110 use the wedges (ref wedge 75110) 20 mm high which can be piled up.<br />

■ SPACING OF SUPPORTS<br />

These spacings indicated in function of the temperature and the diameter of the pipe enable the latter to remain straight.<br />

Valves or heavy accessories must be indepandantly supported.<br />

NETWORKS FULLFILLED WITH FLUID, SPECIFIC WEIGHT OF FLUID = 1 (T ≤ 20°C)<br />

Pipe Ø (mm) 20 to 32 40 to 50 63 to 75 90 110 160<br />

Spacing of<br />

supports<br />

(in metres)<br />

Horizontal<br />

pipes<br />

Vertical<br />

pipes<br />

1,00 1,25 1,5 1,75 2 2,25<br />

1,3 1,6 2,00 2,3 2,6 3<br />

■ N.B. :<br />

• Fluid temperature > 20°C.<br />

In this case, these distances can be multiplied by 0,9 at 30°C and by 0,8 at 40°C.

<strong>KRYOCLIM</strong> ® SYSTEM<br />

BRACKETS<br />

EXAMPLES<br />

Technical Sheet<br />

5.1.2<br />

2000<br />

■ EXAMPLE OF SUPPORTS :<br />

MONOKLIP brackets<br />

■ FIXED POINT<br />

The saddle pieces are comprised of sections of <strong>KRYOCLIM</strong> ®<br />

the couplings which are cleaned, coated with HPFIX welded<br />

on to the degreased and HPFIX coated pipes.<br />

• Fixed point on a pipe<br />

• Fixed on a tee<br />

Shell

<strong>KRYOCLIM</strong> ® SYSTEM<br />

2000<br />

SUPPORTS<br />

ACCESSORIES - SPECIAL POINTS<br />

Technical Sheet<br />

5.1.3<br />

Various accessories or special points require specific supporting: this supporting must be carefully designed in<br />

each case, to prevent the tubes being subjected to mechanical forces.<br />

CASE<br />

TYPES OF SUPPORT REASONS<br />

➀<br />

• <strong>KRYOCLIM</strong> male and<br />

female threaded fittings and<br />

hose nozzles<br />

free or fixed on either side<br />

(double support)<br />

to avoid tension on threads due to movement<br />

out of axis<br />

➁<br />

• Valves and fittings on pipe<br />

and threads<br />

on either side and often with<br />

fixed point (double support)<br />

weight, must operate without twisting<br />

➂<br />

• Hoses<br />

(see technical sheet 4.5)<br />

to allow movement without rotation, without<br />

moving out of axis and without chaffing<br />

➃<br />

• Column feet<br />

free or fixed depending on<br />

the case<br />

to support the weight of the column<br />

➄<br />

• Direction changes<br />

forming a right angle<br />

to allow translation of the expansion joint<br />

arm, to prevent sag and wear.<br />

IMPORTANT:<br />

The sliding supports must be positioned in such a way that the couplings or accessories do not come in contact<br />

with them when the pipes expand and contract.<br />

➀<br />

no<br />

F.P.<br />

L.G.<br />

F.P.<br />

L.G.<br />

L.G.<br />

expansion<br />

joint<br />

➂<br />

yes<br />

➀<br />

L.G.<br />

➁<br />

F.P.<br />

support<br />

no<br />

➁<br />

valves<br />

F.P.<br />

➁<br />

yes<br />

F.P.<br />

weight<br />

F.P.<br />

➃<br />

L.G.<br />

➂<br />

expansion<br />

joint<br />

F.P.<br />

support<br />

➃<br />

F.P.<br />

L.G.<br />

L.G.<br />

L.G.<br />

F.P.<br />

level 6<br />

F.P.<br />

level 5<br />

F.P.<br />

weight<br />

F.P.<br />

➄<br />

L.G.<br />

F.P.<br />

F.P.<br />

For riser columns, we recommend<br />

that an expansion compensating<br />

element is installed<br />

(expansion joint, hose) at five<br />

level intervals.<br />

Tee<br />

F.P.<br />

L.G.<br />

F.P.<br />

Elbow<br />

level 1<br />

foot support

<strong>KRYOCLIM</strong> ® SYSTEM<br />

Technical Sheet<br />

BASKET TRAY - GIRFIL<br />

5.2.1<br />

<strong>2004</strong><br />

■ GENERAL<br />

In many cases :<br />

- insulated networks,<br />

- need of large spacing,<br />

the use of basket tray GIRFIL is an excellent solution.<br />

GIRFIL are designed to answer the needs (burden, contraction, expansion, branches,...) met on <strong>KRYOCLIM</strong> ® networks.<br />

The standard version allows a spacing of 2,50 meters with a minimal shaft. GIRPI can propose you solutions for exceptional<br />

spacing of 5 ; 7,5 and 10 meters.<br />

The standard treatment (EZ) allows an internal use in many environnents.<br />

The basket trays GIRFIL (lenght : 3 meters) are self splicing.<br />

■ DETERMINATION OF THE GIRFIL WIDTH<br />

• The total burden must be centered on the basket tray.<br />

• Let a space (for contraction and expansion) at the changes in direction.<br />

• Make a clean opening to avoid damaging the insulating material and the pipe.<br />

GIRFIL Width<br />

ØAfter insulation<br />

Space between 2 pipes<br />

(flow and return) : about 10 mm<br />

L<br />

∆L : contraction/dilatation<br />

If the space between the pipe and the basket tray is not enough to compensate the contraction or the expansion, use<br />

one ot the solutions presented on the sheet 4-3 :<br />

• loop • expansion joint<br />

■ BRANCHES<br />

GIRFIL width ≥ ( 2ø + E ) + 2∆L maxi<br />

When basket trays are used, branches can be made above or below the pipes provicet that a sufficiently large opening<br />

is made, so that sharp edges do not damage the insulating material or the pipe during contraction movements.

<strong>KRYOCLIM</strong> ® SYSTEM<br />

<strong>2004</strong><br />

BASKET TRAY - GIRFIL<br />

EXAMPLES - RANGE<br />

Technical Sheet<br />

5.2.2<br />

■ EMPTYING<br />

■ PURGE<br />

Purge<br />

Female brass thread<br />

FMML25<br />

Reducing bushes<br />

long patterm FRD63/32<br />

90° TEES<br />

FTE 63<br />

Make a sufficiently large opening to allow contraction<br />

novements without damaging the insulating material.<br />

<strong>KRYOCLIM</strong><br />

PIPE ø 63<br />

GIRFIL<br />

■ CHANGE IN DIRECTION (FILKIT)<br />

■ BASKET TRAY + MONOKLIP<br />

Pipe<br />

25 mm insulator<br />

CHILLED WATTER NETWORK<br />

(<strong>KRYOCLIM</strong>)<br />

COMPRESSED<br />

AIR<br />

NETWORK<br />

(GIRAIR)<br />

The change in direction is made with the “FILKIT”.<br />

■ HANGING CLIP (FATT)<br />

■ CLIPS SUPPORT (FSUP)<br />

The universal fastener allows to hitch GIRFIL with<br />

small chains or threaded bolts M8. Their shape<br />

makes the disconnection easy in order to place the<br />

tubes.<br />

The multiposition support can be fixed on a wall or<br />

directly on the ceiling in a plenum (versions 200 and<br />

300).

<strong>KRYOCLIM</strong> ® SYSTEM<br />

INSULATION<br />

INSULATED PIPEWORKS<br />

Technical Sheet<br />

5.3.1<br />

2000<br />

■ INSULATION<br />

The low thermal conductivity cœfficient (λ = 0.17 W/mK) of H.P.F. allows to reduce the heat losses and to delay<br />

the condensation phenomena.<br />

Like other materials, <strong>KRYOCLIM</strong> ® must be insulated to be protected against frost, to reduce the heat losses and<br />

to avoid condensation when the outside pipe temperature is lower than the dew temperature.<br />

Most of insulation products can be used if the cement needed for their implementation or if their chemical composition<br />

are compatible with <strong>KRYOCLIM</strong> ® .<br />

Check with the insulation product’s manufacturer or with GIRPI for the compatibility.<br />

Condensation phenomena have no physical action with <strong>KRYOCLIM</strong> ® . H.P.F. ® properties slacken condensation in<br />

comparison with metallic materials.<br />

■ The calculation of the surface temperature shows that <strong>KRYOCLIM</strong> ® provides you with security in case of insulation<br />

failure.<br />

Example :<br />

Surface temperature (non insulated)<br />

Metallic pipe <strong>KRYOCLIM</strong> ® pipe <strong>KRYOCLIM</strong> ® coupling<br />

T fluid = 7° φ25 7°C 9°C 11°C<br />

T ref : ambient : 23°C φ63 7°C 10°C 13°C<br />

he = 8 W/m 2 K<br />

T dew = 16,1°C<br />

φ110 7°C 12°C 15°C<br />

■ The following table shows the heat losses (W/m) of <strong>KRYOCLIM</strong> ® pipeworks (with or without insulation).<br />

T fluid = 7°C Insulation material Insulation material Insulation material<br />

T réf. : ambient = 23°C No insulating materiel (λ=0.039W/mK) (λ=0.039W/mK) (λ=0.039W/mK)<br />

he = 8 W/m 2 K Thickness = 13mm Thickness = 19mm Thickness = 32mm<br />

φ25 8,7 4,1 3,4 2,7<br />

φ63 19,8 7,9 6,4 4,8<br />

φ110 30,5 12,1 9,7 7,1<br />

■ APPLICATIONS : Building, Tertiary, Industry, Food industry.<br />

Preconised thickness<br />

Example<br />

Insulation product<br />

Applications<br />

internal use<br />

Fluid temperature<br />

internal use<br />

(mm)*<br />

Cooling system +15°C Foam rubber 0 - 9<br />

Cold air conditioning<br />

+7/12°C : chilled water<br />

Foam rubber<br />

µ≥5000<br />

Negative temperature network<br />

(Industrial kitchen, ware-house...)<br />

-10°C water and glycol<br />

Foam rubber<br />

µ≥7000<br />

Extruded and cutout polystyren<br />

+ anti vapour treatment<br />

Refrigerated room<br />

-25°C water and glycol<br />

Extruded and cutout polystyren<br />

+ anti vapour treatment<br />

* The thickness are only indicative and depend on each dock-yard and on each network. Check with a specialised<br />

office.<br />

Ask GIRPI for detailled technical sheets for each application and for a personalised heat losses study.<br />

N.B. : µ : material permeability.<br />

: he : external superficial exchange cœfficient (average value : 8).<br />

13 - 19<br />

19 - 32<br />

25 - 30<br />

30 - 40

<strong>KRYOCLIM</strong> ® SYSTEM<br />

<strong>2004</strong><br />

LAGGING PROCEDURES<br />

ELEMENTARY RULES<br />

Technical Sheet<br />

5.3.2<br />

The lagging must be done according to the DTU 61.1 (thermal insulation of refrigerating pipeworks) and to the DTU 65.20.<br />

The <strong>KRYOCLIM</strong> ® system does not need any anti-corrosion treatment before insulation.<br />

The fire resistance of the insulating products must comply the security standard against fire in the public buildings.<br />

It is better not to glue directly the insulating materials on the <strong>KRYOCLIM</strong> ® pipes and fittings.<br />

It is necessary to use cold brackets in order to avoid the crushing of the insulator on the supports.<br />

■ THERMAL RING<br />

To prevent the insulating material from flattening<br />

out at the collar level, a thermal ring must<br />

be used. They allow the <strong>KRYOCLIM</strong> ® tube to<br />

expand and contract freely.<br />

Example for 32<br />

<strong>KRYOCLIM</strong> ® Ø 32<br />

Thermal ring<br />

F32B63<br />

Thermal<br />

ring<br />

Reference<br />

F16B40<br />

F20B50<br />

F25B50<br />

F32B63<br />

F40B75<br />

F50B90<br />

F63B110<br />

F75B125<br />

F90B140<br />

F110B160<br />

Ø tube<br />

<strong>KRYOCLIM</strong> ®<br />

Diameter int.<br />

16<br />

20<br />

25<br />

32<br />

40<br />

50<br />

63<br />

75<br />

90<br />

110<br />

Ø monoklip<br />

Diameter ext.<br />

40<br />

50<br />

50<br />

63<br />

75<br />

90<br />

110<br />

125<br />

140<br />

160<br />

Theoric<br />

thickness<br />

12<br />

13<br />

13<br />

16<br />

18<br />

20<br />

24<br />

25<br />

25<br />

25<br />

Monoklip<br />

Ø 63<br />

HCKC63<br />

■ LAGGING PROCEDURE = FOAM RUBBER<br />

The procedure to install this kind of insulator must be done according<br />

to the manufacturer documentation.<br />

When the couplings of unsplit foam rubber are directly put over the<br />

<strong>KRYOCLIM</strong> ® pipes just before the welding with the fittings, it is<br />

compulsory to insulate the fittings after the testing pressure.<br />

During the testing pressure all the cold welding must be controlled<br />

at sight in order to check eventual leaks.<br />

• No stretching of the foam, but work it by compression during joining.<br />

• Respect the drying time between each part recommended by the<br />

manufacturer.<br />

• This kind of insulator has to be protected against the UV rays and<br />

weather elements in case of an outside use.<br />

Example of installation for :<br />

Reduced tee<br />

90° elbow<br />

small diameter<br />

90° elbow<br />

Large diameter<br />

■ LAGGING PROCEDURE : EXTRUDED AND CUTOUT POLYESTYREN<br />

It is particulary well adapted to external spot or for fluids at negative temperature.<br />

• The straight bars of insulator are dispatched split with a vapour<br />

proof adhesive.<br />

Example of installation for 1/2 shell<br />

• The shells on the fittings are cut out at dimension and need the<br />

application of a vapour proof glue combined with a glass<br />

material all over it.<br />

• The transversal and longitudinal jointing are made owning to an<br />

adapted mastic.<br />

• The rigidity of this kind of insulator must be taken in<br />

consideration for the contraction and the expansion of the<br />

<strong>KRYOCLIM</strong> ® pipework.<br />

Reduced tee<br />

90° elbow

<strong>KRYOCLIM</strong> ® SYSTEM<br />

Technical Sheet<br />

PRESSURE LOSSES<br />

6.1<br />

2000<br />

■ CALCULATION BASIS<br />

The quality of the internal surface condition of the <strong>KRYOCLIM</strong> ® pipes gives the guaranty of a better flow capacity (for an<br />

equivalent cross section) than the one of a metalic pipe.<br />

To calculate the HPF pipes’ pressure losses, taking in consideration a perfect internal surface condition (therefore a low<br />

cœfficient of roughness which is specific to our pipes), GIRPI has ordered to the CATED a nomogram of pressure losses<br />

at 7°C (see sheet 6.2).<br />

This nomogram is established using the REEF formula.<br />

■ THE REEF FORMULA<br />

J : Pressure losses (mmCE/m) - U : fluid speed (m/s)<br />

D : internal pipe diameter<br />

J = k x U 1,75 x D -1,25<br />

(mmCE/m)<br />

V : kinematic viscosity (m 2 /s) - W : volumic mass (kg/m 3 )<br />

g : gravitational acceleration = 9,81 (m/s 2 )<br />

N.B. : ε = absolute roughness of the matter = 0,001 mm.<br />

k = 0,3264 x V 0,25 x W<br />

2g<br />

Corrector cœfficient<br />

• Following the percentage of NEUTRAGEL ® used, the pressure losses increase due to the variation of the kinematic<br />

viscosity and the density of the fluid. Therefore, it is necessary to multiply the pressure losses read on the nomogram<br />

at 7°C - 0 % by a corrector cœfficient in case of a regular and smooth fluid speed.<br />

% NEUTRAGEL<br />

volume<br />

0% 10% 15% 25% 30% 35% 40% 45% 50%<br />

Fluid temperature<br />

(°C)<br />

7 à 5 4 2 -5 -10 -15 -20 -25 -30<br />

Machine protection<br />

temperature (°C)<br />

- -2 -5 -10 -15 -20 -25 -30 -35<br />

Pressure losses<br />

nomogram<br />

corrector cœfficient x 1<br />

x 1,1 x 1,2 x 1,4 x 1,6 x 1,8 x 2 x 2,4 x 2,8<br />

* Estimated values, check with the manufacturer.<br />

• As an example : in case of an air conditioning network at 7°C, during winter when the outside pipework does not<br />

work, the pipes must be protected against the frost. Use one of the following method :<br />

1) Draining the pipework while it is stopped.<br />

2) Protecting the pipework by a self regulated heating cord covered by a lagging with a big wall thickness. (ex. : 32 mm).<br />

3) Using NEUTRAGEL ® in suffisant quantity and oversizing some items of the installation.<br />

% NEUTRAGEL 0% 30% 40%<br />

Fluid temperature (°C) 7°C<br />

Pressure losses<br />

corrector cœfficient<br />

nomogram x 1 x 1,4 x 1,5<br />

• MIXIGEL ® is used pure.<br />

Its viscosity at low temperature is much lower than the one of Propylen Glycol.<br />

% MIXIGEL 0% Pur = 100%<br />

Fluid temperature 7°C -20°C -30°C<br />

Pressure losses<br />

corrector cœfficient<br />

nomogram x 1 x 2,2 x 2,7<br />

Ex 1 :<br />

• Reading on the nomogram (see sheet 6.2), pure water.<br />

Flow rate : 4l/s<br />

Pressure losses : 0,06 mCE/m<br />

➩<br />

Speed : 1,8 m/s<br />

External pipe ø : 63 mm<br />

• In case of a fluid at -20°C, with 35% of NEUTRAGEL ®<br />

Flow rate : 4l/s<br />

Pressure losses : 0,06 x corrector cœfficient = 0,06 x 1,8 = 0,108 mCE/m<br />

➩<br />

Speed : 1,8 m/s<br />

External pipe ø : 63 mm<br />

For the compatibility with the fluids see sheet 8.0.

<strong>KRYOCLIM</strong> ® SYSTEM<br />

2000<br />

PRESSURE LOSSES<br />

NOMOGRAM AT 7°C - FLUID : WATER<br />

Technical Sheet<br />

6.2<br />

U<br />

Speed<br />

(in m/s)<br />

J<br />

Presure loss<br />

(in m/m)<br />

Nominal Ø<br />

(in mm)<br />

Internal Ø<br />

(in mm)<br />

Q<br />

Flow<br />

(in l/s)<br />

Example<br />

Designed and produced by the CATED

<strong>KRYOCLIM</strong> ® SYSTEM<br />

DIMENSION SHEET<br />

Technical Sheet<br />

7.1<br />

<strong>2004</strong><br />

IMPORTANT NOTE :<br />

With the constant concern to improve the range and quality of its products within the context of the standards used<br />

at present, GIRPI reserves the right to modify the dimensional characteristics of its pipes and fittings together with<br />

the scope of its ranges, without prior notice.<br />

<strong>KRYOCLIM</strong> ® PIPES<br />

4 m lengths with plain ends<br />

D Dn Reference<br />

Pack Mini Weight Internal Cont.<br />

PN<br />

(*) thickness kg/m Ø l/m<br />

20 15 TUBF 20 10 10 2,3 0,188 15,4 0,186<br />

25 20 TUBF 25 10 10 2,3 0,235 20,4 0,327<br />

32 25 TUBF 32 10 10 2,4 0,314 27,2 0,581<br />

40 32 TUBF 40 10 10 3 0,490 34,0 0,908<br />

50 40 TUBF 50 5 10 3,7 0,756 42,6 1,425<br />

63 50 TUBF 63 5 10 4,7 1,210 53,6 2,256<br />

75 65 TUBF 75 1 10 5,5 1,680 64,0 3,217<br />

90 80 TUBF 90 1 10 6,6 2,430 76,8 4,632<br />

110 100 TUBF 110 1 10 8,2 3,640 93,6 6,911<br />

160 150 TUBF 160 1 10 11,8 7,800 136,4 14,6<br />

COUPLINGS<br />

(socket)<br />

D Dn Reference Z E L A<br />

20 15 FMA 20 3 17 37 26<br />

25 20 FMA 25 3 19 42 31<br />

32 25 FMA 32 3 23 49 38<br />

40 32 FMA 40 3 27 57 47<br />

50 40 FMA 50 3,5 31 67 59<br />

63 50 FMA 63 4 38,5 80 75<br />

75 65 FMA 75 4 44,5 94 90<br />

90 80 FMA 90 5 52 109 107<br />

110 100 FMA 110 4 61,5 130 132<br />

160 150 FMA 160 10 86 185 185<br />

ELBOWS 90°<br />

(socket)<br />

D Dn Reference Z E A<br />

20 15 F4M 20 11 17 25,5<br />

25 20 F4M 25 13,5 20 31,5<br />

32 25 F4M 32 17 23 39<br />

40 32 F4M 40 21,5 27 49<br />

50 40 F4M 50 27 32 61,5<br />

63 50 F4M 63 32 39 77<br />

75 65 F4M 75 40 44,5 92,5<br />

90 80 F4M 90 46,5 51,5 112<br />

110 100 F4M 110 59 62 136<br />

160 150 F4M 160 81 86,5 190<br />

EQUAL TEES 90°<br />

(socket)<br />

D Dn Reference Z E L A K<br />

20 15 FTE 20 11 16 56 26 28<br />

25 20 FTE 25 13,5 18,5 66 31 33<br />

32 25 FTE 32 17 22 82 39 41<br />

40 32 FTE 40 21,5 26,5 99,5 54 49<br />

50 40 FTE 50 26,5 31,5 118,5 62 59<br />

63 50 FTE 63 33 38,5 143 80 71<br />

75 65 FTE 75 38,5 44,5 166,5 91,5 84<br />

90 80 FTE 90 46 52 195 112 98<br />

110 100 FTE 110 57 61 236 133 118<br />

160 150 FTE 160 84 86 342 191 170<br />

ELBOWS 45°<br />

(socket)<br />

D Dn Reference Z E A<br />

20 15 F8M 20 4,5 17 26<br />

25 20 F8M 25 5,5 19,5 31<br />

32 25 F8M 32 7,5 24 39<br />

40 32 F8M 40 9,5 28 49<br />

50 40 F8M 50 12 32 61<br />

63 50 F8M 63 15 38 78<br />

75 65 F8M 75 19,5 42,5 92<br />

90 80 F8M 90 19 52 114,2<br />

110 100 F8M 110 24 62 135<br />

160 150 F8M 160 34,5 86,5 190

<strong>KRYOCLIM</strong> ® SYSTEM<br />

DIMENSION SHEET<br />

Technical Sheet<br />

7.2<br />

<strong>2004</strong><br />

FLANGES PN 16<br />

According to DIN 16-996<br />

(glass fibre reinforced<br />

polyamide)<br />

Black color<br />

Pipe Flange<br />

ø Dn Reference A B C D E R<br />

Nbre<br />

de trous<br />

Couple de<br />

serrage<br />

50 40 BPA 40 62,5 18 110 150 18 2,5 4 3 mkg<br />

63 50 BPA 50 78,5 18 125 165 19 2,5 4 3 mkg<br />

63 60 BPA 60 78,5 18 135 175 19 2,5 4 3 mkg<br />

75 65/60 BPA 65 92 18 145 185 22 2,5 4 4 mkg<br />

90 80 BPA 80 110 18 160 200 22 2,5 8 4 mkg<br />

110 100 BPA 100 133 18 180 218 24 3 8 5 mkg<br />

160<br />

TEES 90° REDUCED<br />

(socket)<br />

REDUCING BUSHES<br />

LONG PATTERN<br />

Dspig. xd soc.<br />

E1<br />

E2<br />

D-d Dn Reference Z Z1 E E1 L A a<br />

25-20 20-15 FTR 2520 12,5 13,5 18,5 16,5 66 31 26<br />

32-20 25-15 FTR 3220 17 18 23 16 82,5 44,5 30<br />

32-25 25-20 FTR 3225 17 19 23 18,5 82,5 44,5 37<br />

40-20 32-15 FTR 4020 22 23 27 17 99 54 30<br />

40-25 32-20 FTR 4025 22 23 26,5 19 99 54 37<br />

40-32 32-25 FTR 4032 22 21 26,5 23 99 53,3 45<br />

50-25 40-20 FTR 5025 26 27 33 18,5 119 62 37<br />

50-32 40-25 FTR 5032 26 27 33 23 119 62 45<br />

50-40 40-32 FTR 5040 26 27 33 26,5 119 62 53,5<br />

63-20 50-15 FTR 6320 33 - 38,5 - 142 80 -<br />

63-25 50-20 FTR 6325 33 32 38,5 20 142 80 37<br />

63-32 50-25 FTR 6332 33 33,5 38,5 22,5 142 80 45<br />

63-40 50-32 FTR 6340 33 32 38,5 27 142 80 54<br />

75-20 65-15 FTR 7520 38,5 38,5 44,5 - 166,5 92,5 -<br />

75-25 65-20 FTR 7525 38,5 38,5 44,5 19 166,5 92,5 37<br />

75-40 65-32 FTR 7540 38,5 38,5 44,5 27 166,5 92,5 54<br />

90-25 80-20 FTR 9025 45,5 46 52 19,5 197 112 37<br />

90-40 80-32 FTR 9040 45,5 46 52 27 197 112 54<br />

110-32 100-25 FTR 1132 57,5 58 62 23 237,5 135,5 66<br />

110-50 100-40 FTR 1150 57,5 58 62 31 237,5 135,5 66<br />

D-d Dn Reference Z E E1 L D2 E2<br />

32-20 25-15 FRD 3220 31 22,5 16,5 48 25 19<br />

40-20 32-15 FRD 4020 36 27 - - 32 22,5<br />

40-25 32-20 FRD 4025 36 27 19 55,5 32 22,5<br />

50-32 40-25 FRD 5032 44 32 23 66,5 40 27<br />

63-25 50-20 FRD 6325 55 39 19 75 50 -<br />

63-32 50-25 FRD 6332 55 39 23 78 50,5 -<br />

63-40 50-32 FRD 6340 55 39 27 82 50,5 -<br />

75-40 65-32 FRD 7540 62 45 26,5 89 61 38<br />

75-50 65-40 FRD 7550 62 45 31,5 93,5 61 38<br />

90-40 80-32 FRD 9040 74,5 52,5 27 101,5 75 44<br />

90-50 80-40 FRD 9050 75 52,5 31,5 106,5 75 44<br />

90-63 80-50 FRD 9063 75 52,5 38 113 75 44<br />

110-50 100-40 FRD 1150 90 62 32 122 90 52<br />

110-63 100-50 FRD 1163 90 62 38 128 90 52<br />

110-75 100-65 FRD 1175 90 62 44 134 90 52<br />

160-110 150-100 FRD 1611 128 86,5 62 190<br />

NB : Reducer’s large ends for references FRD 32<br />

to 110 (except FRD 7532, 7540 AND 7550) can be<br />

used as sockets and spigots, with one size interval.<br />

D2<br />

SERRATED STUB FLANGES<br />

Soc. for use with flat gasket<br />

REDUCING BUSHES<br />

SHORT PATTERN<br />

D Spig XD Soc.<br />

D Dn Référence Z E D2 M D1<br />

50 40 FCS 50 3 32 73 8 61<br />

63 50 FCS 63 3 38 90 9 76<br />

75 63 FCS 75 3 44 106 10 90<br />

90 80 FCS 90 5 52 125 11 108<br />

110 100 FCS 110 5 62 150 12 130<br />

160 150 FCS 160 6 86 212 16 187<br />

D-d Dn Reference Z E L<br />

25-20 20-15 FRS 25 3 17 20<br />

32-25 25-20 FRS 32 4,5 19 23,5<br />

40-32 32-25 FRS 40 5,5 23 28,5<br />

50-40 40-32 FRS 50 6,5 26 32,5<br />

63-50 50-40 FRS 63 7,5 31,5 39<br />

75-63 65-50 FRS 75 7 37 44,5<br />

90-75 80-65 FRS 90 8,5 43,5 52<br />

110-90 100-80 FRS 110 10 52 62,5

<strong>KRYOCLIM</strong> ® SYSTEM<br />

DIMENSION SHEET<br />

Technical Sheet<br />

7.3<br />

<strong>2004</strong><br />

D Dn Reference Z E A K L<br />

20 15 F3P 20 14 16,5 27,5 42,7 47<br />

25 20 F3P 25 13,5 19 35,8 54,5 51,5<br />

32 25 F3P 32 14,5 22,5 41,4 62,5 59,5<br />

40 32 F3P 40 15 27 52,8 75,3 69<br />

50 40 F3P 50 19 31,5 59 83 82<br />

3 PIECE UNIONS<br />

Soc. x Soc.<br />

(with EPDM gashet)<br />

3 PIECE UNIONS<br />

HPF/BRASS<br />

Soc. x Female thread<br />

(with EPDM gasket)<br />

3 PIECE UNION<br />

HPF/BRASS<br />

Soc. x Male thread<br />

(with EPDM gasket)<br />

D G Dn Reference Z E E1 G1 A1 A2 L<br />

20 1/2” 15 F3G/L20 13 16 16 1” 36 27 45<br />

25 3/4” 20 F3G/L25 12 19 17 1”1/4 45 32 48<br />

32 1” 25 F3G/L32 14 22 19 1”1/2 52 38 55<br />

40 1”1/4 32 F3G/L40 14 26 22 2” 66 47 62<br />

50 1”1/2 40 F3G/L50 13 31 23 2”1/4 72 53 67<br />

63 2” 50 F3G/L63 12 38 27 2”3/4 89 65 77<br />

D F Dn Reference Z E L G1 A1 A2<br />

20 1/2” 15 F3F/L20 39 16 55 1” 36 21<br />

25 3/4” 20 F3F/L25 55 19 74 1”1/4 45 27<br />

32 1” 25 F3F/L32 60 22 82 1”1/2 52 35<br />

40 1”1/4 32 F3F/L40 61 26 87 2” 66 43<br />

50 1”1/2 40 F3F/L50 69 31 100 2”1/4 72 49<br />

63 2” 50 F3F/L63 75 38 113 2”3/4 89 62<br />

Brass threaded<br />

D1<br />

D<br />

E1ADAPTOR NIPPLES<br />

E<br />

THREADED ADAPTORS<br />

Soc. x Female brass thread<br />

L<br />

Z<br />

L1<br />

D-F Reference D1 Z E E1 A L L1<br />

Nombre<br />

de pans<br />

20-1/2” FEAL 20 25 41 19 17 36 60 15 8<br />

25-3/4” FEAL 25 32 43 22,5 19,5 41 65 16 8<br />

32-1” FEAL 32 40 49 27 23 49,5 76 19,5 8<br />

40-1”1/4 FEAL 40 50 55 31 26 60 87 22 8<br />

50-1”1/4 FEAL 50 63 55 37,5 31 66 92 22 8<br />

63-2” FEAL 63 75 63 43,5 37,5 82 106 26 8<br />

F<br />

A<br />

D-G Dn Code D1 Z E L A<br />

de Nombre<br />

pans<br />

20-1/2” 15 FMML 20 25 9 16,5 44 36 8<br />

25-3/4” 20 FMML 25 32 9,5 19,5 49 41,4 8<br />

32-1” 25 FMML 32 40 9,8 23 56,4 49,6 8<br />

40-1”1/4 32 FMML 40 50 7 31 64 60 8<br />

50-1”1/2 40 FMML 50 63 7 37,5 69,5 66 8<br />

63-2” 50 FMML 63 75 8 43,5 80,5 82 8<br />

A1<br />

ADAPTOR NIPPLES<br />

Soc. x Male thread<br />

F1<br />

FEMALE THREADED<br />

ADAPTORS<br />

Soc. x Female thread<br />

(with metal reinforcing ring<br />

D F Reference D1 Z E A L F1 Pans<br />

75 2”1/2 FEA 75 90 49 45 94 95 30 8<br />

D G Dn Reference Z E L D1 A1 Nb pans<br />

75 2”1/2 65 FMM 75 9 47 88 90 91 8

<strong>KRYOCLIM</strong> ® SYSTEM<br />

DIMENSION SHEET<br />

Technical Sheet<br />

7.4<br />

<strong>2004</strong><br />

EXPANSION JOINTS<br />

Brass male threaded end<br />

Brass female threaded end<br />

D-G Dn Reference LF LU ø<br />

20-1/2” 15 HCD/G20 410 457 22<br />

25-3/4” 20 HCD/G25 520 592 28<br />

32-1” 25 HCD/G32 640 720 35<br />

40-1”1/2 32 HCD/G40 760 825 42<br />

50-2” 40 HCD/G50 980 1067 50<br />

MONOKLIP BRACKETS in black polyamide<br />

With threaded metal insert M6, M8, of 7 x 150<br />

Embase 20 - 25<br />

32 - 40<br />

wedge : height 20 mm<br />

D Dn Reference H A B C ø E<br />

M6 INSERT<br />

20 15 HCK 20/6 22 14 32 22 16 1<br />

25 20 HCK 25/6 22 16 39 25 16 1<br />

M8 INSERT<br />

20 15 HCK 20/8 22 14 32 22 16 1<br />

25 20 HCK 25/8 22 16 39 25 16 1<br />

7 x 150 INSERT<br />

20 15 HCK 20/7 22 14 32 22 16 1<br />

25 20 HCK 25/7 22 16 39 25 16 1<br />

To be used with wedge : CALE1225<br />

D Dn Reference H A B C L<br />

M6 INSERT<br />

32 25 HCKC 32/6 28 20 45 25 30<br />

40 32 HCKC 40/6 32 24 55 25 30<br />

50 40 HCKC 50/6 36 30 68 25 52<br />

63 50 HCKC 63/6 40 37 82 25 52<br />

M8 INSERT<br />

32 25 HCKC 32/8 28 20 45 25 30<br />

40 32 HCKC 40/8 32 24 55 25 30<br />

50 40 HCKC 50/8 36 30 68 25 52<br />

63 50 HCKC 63/8 40 37 82 25 52<br />

7 x 150 INSERT<br />

32 25 HCKC 32/7 28 20 45 25 30<br />

40 32 HCKC 40/7 32 24 55 25 30<br />

50 40 HCKC 50/7 36 30 68 25 52<br />

63 50 HCKC 63/7 40 37 82 25 52<br />

M8 INSERT<br />

75 HCKC 75/8 80 42 94 30 80<br />

90 HCKC 90/8 80 50 111 30 80<br />

110 HCKC 63/8 80 61 131 30 80<br />

To be used with wedge : CALE3263<br />

PIPE BRACKETS (HDPE black)<br />

D Dn Reference H A B C G I J<br />

110 100 A9C 110 84 117 162 30 8,5 144 9<br />

75 - 110

<strong>KRYOCLIM</strong> ® SYSTEM<br />

Technical Sheet<br />

CEMENTED SOCKET ENDS<br />

7.5<br />

ø 16 to 63<br />

KEY<br />

<strong>2004</strong><br />

8<br />

1<br />

9<br />

12<br />

2<br />

10<br />

5<br />

10<br />

6<br />

11<br />

7<br />

4<br />

9<br />

13<br />

3<br />

8<br />

1<br />

2<br />

➀<br />

➁<br />

➂<br />

➃<br />

➄<br />

➅<br />

➆<br />

➇<br />

➈<br />

➉<br />

11<br />

12<br />

13<br />

ANCHORING SYSTEM<br />

Nut<br />

Welded/threaded socket end union<br />

Body<br />

Ball<br />

Support<br />

Handle<br />

Stem<br />

Socket o’ring<br />

Seat o’ring<br />

Ball seat<br />

Stem o’ring<br />

Body o’ring<br />

Stem o’ring<br />

HPF<br />

HPF<br />

HPF<br />

HPF<br />

HPF<br />

HPF<br />

HPF<br />

EPDM<br />

EPDM<br />

PTFE<br />

EPDM<br />

EPDM<br />

EPDM<br />

These ball valves have a built-in anchoring<br />

system.<br />

There are two holes underneath fitted with<br />

threaded brass inserts (use screw in<br />

accordance with data below).<br />

Ball<br />

valve<br />

Ø<br />

16<br />

20<br />

25<br />

32<br />

40<br />

50<br />

63<br />

screw Ø<br />

for<br />

brass<br />

insert<br />

5,5<br />

5,5<br />

5,5<br />

6,5<br />

8<br />

8<br />

8<br />

d G DN L Z C E H B g X Ø Fig.<br />

16 3/8” 10 14 69 97 47 45 66 160 31 5,5 A<br />

20 1/2” 15 16 70 102 47 45 66 160 31 5,5 A<br />

25 3/4” 20 19 82 120 57 55 78 260 31 5,5 A<br />

32 1” 25 22 87 131 68 67 86 380 40 6,5 A<br />

40 1 1/4” 32 26 98 150 86 83 100 655 45 8 B<br />

50 1 1/2” 40 31 101 163 98 91 110 925 50 8 B<br />

63 2” 50 38 121 197 122 11 130 1695 50 8 B

<strong>KRYOCLIM</strong> ® SYSTEM<br />

Technical Sheet<br />

ANTIFREEZE FLUIDS<br />

8.0<br />

<strong>2004</strong><br />

In general, it is necessary to use an antifreeze coolant fluid when the temperature is inferior between 3 and 4°C.<br />

Formula based on MEG : Monethylene Glycol :<br />

DEHON<br />

Neutragel<br />

DOW Chemical Dowcal 10<br />

Formula based on MPG : Monopropylene Glycol :<br />

DEHON<br />

Friogel<br />

DOW Chemical Dowcal 20<br />

DOW Chemical<br />

Dowcal N<br />

Solution based on acetate and potassium formiate :<br />

ASPEN<br />

Temper<br />

Solution based on potassium acetate :<br />

DEHON<br />

Mixigel<br />

Solution based on potassium formiate :<br />

CLARIANT<br />

Antifrogen KF<br />

KEMIRA<br />

Freezium<br />

Salt solutions NaCI and CaCI.<br />

Ammonia solutions in acqueous phase.<br />

■ NEUTRAGEL ® (MEG)<br />

It is particulary suitable for industrial refrigeration.<br />

Its red coloration allows a quick and easy identification.<br />

Volumic mass at 20°C (NF R 15-602-1) 1123 kg/m 3<br />

PH 33% volume (NF T 78-103) 7,5 to 8,5<br />

Packaging<br />

Pure or dilute within a certain concentration range<br />

Fabricant : DEHON - SOTRAGAL<br />

26 avenue du Petit Parc<br />

94683 VINCENNES - France<br />

01.43.98.75.00<br />

% NEUTRAGEL 25% 30% 35% 40% 45%<br />

Freezing temperature<br />

in °C (+/-2)*<br />

-13 -16 -21 -27 -32<br />

Volumic mass<br />

at 20°C in kg/m 3 1037 1043 1051 1059 1064<br />

* Warning : it is the freezing temperature and not fluid temperature. Forsee a security.<br />

You must take into account the solution viscosity to calculate the load losses (see nomogram).<br />

For information only, Neutragel can be used on networks working at 70°C (HTA ® System : air conditioning).<br />

■ MIXIGEL ® : POTASSIUM FORMATEC BASED<br />

It is ready to use and fluorescent yellow.<br />

It is non flammable and not toxic.<br />

It is an excellent transfer fluid and particullary under -20°C.<br />

Density at 20°C 1,25<br />

Freezing temperature (°C)

<strong>KRYOCLIM</strong> ® SYSTEM<br />

Technical Sheet<br />

CHEMICAL RESISTANCE TABLES<br />

8.1<br />

<strong>2004</strong><br />

The indications given in the tables below are extracts from French or foreign documents or the result of our<br />

own experiments.<br />

They cannot be considered to be absolute or guaranteed, as they are not valid in all specific operating<br />

conditions. It must also be noted that the nature of chemical agents and their mixtures, the presence of<br />

impurities, and the degree of vulcanisation of elastomers, can lead to large variations in these indications;<br />

only practical tests in these cases can provide valid results.<br />

We cannot be held liable for the indications given.<br />

The chemical agents are classified in alphabetical order.<br />

Meaning of symbols:<br />

2: Good resistance<br />

1: Limited resistance (depending on conditions of use)<br />

0: Not resistant (use not recommended)<br />

REACTIVE<br />

<strong>KRYOCLIM</strong> ®<br />

EPDM<br />

20°C 20°C<br />

Acetaldehyde 0 -<br />

Acetic acid 0 - 20 % 2 2<br />

Acetic acid 20 - 30 % 2 -<br />

Acetic acid 30 - 60 % 2 -<br />

Acetic acid 80 - 100 % 2 -<br />

Acetic anhydride 0 -<br />

Acetone 0 -<br />

Acetylene 2 2<br />

Acid wash water of ore processing 2 -<br />

Adipic acid 2 2<br />

Allyl alcohol 96 % 2 -<br />

Alum 2 2<br />

Aluminium chloride 2 2<br />

Aluminium fluoride 2 2<br />

Aluminium hydroxide 2 -<br />

Aluminium nitrate 2 -<br />

Aluminium oxychloride 2 -<br />

Ammonia (liquid) - 2<br />

Ammonium bifluoride 2 -<br />

Ammonium carbonate 2 2<br />

Ammonium chloride 2 2<br />

Ammonium fluoride 2 2<br />

Ammonium hydroxide 0 -<br />

Ammonium nitrate 2 2<br />

Ammonium methaphosphate 2 -<br />

Ammonium phosphate<br />

(ammoniacal and neutral) 2 2<br />

Ammonium sulphate 2 2<br />

Ammonium sulphite 2 -<br />

Ammonium persulphate 2 -<br />

Ammonium thiocyanate 2 -<br />

Amyl acetate 0 -<br />

Amyle chlorure 0 -

<strong>KRYOCLIM</strong> ® SYSTEM<br />

Technical Sheet<br />

CHEMICAL RESISTANCE TABLES<br />

8.2<br />

<strong>2004</strong><br />

REACTIVE<br />

<strong>KRYOCLIM</strong> ®<br />

EPDM<br />

20°C 20°C<br />

Amy alcohol 2 2<br />

Anhydrous nitric acid 0 -<br />

Aniline 0 -<br />

Aniline chlorate 2 -<br />

Aniline hydrochloride 0 -<br />

Antimony trichloride 2 2<br />

Anthraquinone 2 -<br />

Aqua regia 50 % 2 -<br />

Aqua regia (nitrohydrochloric acid) 2 2<br />

Arsenic acid 80 % 2 2<br />

Asphalt 2 0<br />

Barium carbonate 2 -<br />

Barium chloride 2 2<br />

Barium hydroxide 2 2<br />

Barium sulphite 2 -<br />

Barium sulphate 2 2<br />

Beetroot (sweet liqueur) 2 -<br />

Benzaldehyde 0 -<br />

Benzine 0 -<br />

Benzoic acid 2 2<br />

Benzol 0 -<br />

Bismudth carbonate 2 -<br />

Borax 2 2<br />

Boric acid 2 2<br />

Boric trifluoride 2 -<br />

Bromic water 10 % 2 2<br />

Bromine liquid 0 -<br />

Bromide sodium 2 -<br />

Bromide water 2 -<br />

Brine 2 2<br />

Butadiene 2 0<br />

Butyl alcohol 2 2<br />

Butylene 2 2<br />

Butylnediol (erythritol) 2 2<br />

Butylphenol 100 % 2 -<br />

Calcium bisulfite 2 -<br />

Calcium chlorate 2 -<br />

Calcium chlorate 2 2<br />

Calcium hydroxide 2 -<br />

Calcium hypochlorite 2 2<br />

Calcium nitrate 2 2<br />

Calcium sulphate 2 2<br />

Cane sugar melasses 2 -<br />

Carbonate de calcium 2 -<br />

Carbonic acid 2 2<br />

Castor oil 2 -<br />

Caustic potash 2 2<br />

Cellosolve 2 -

<strong>KRYOCLIM</strong> ® SYSTEM<br />

Technical Sheet<br />

CHEMICAL RESISTANCE TABLES<br />

8.3<br />

<strong>2004</strong><br />

REACTIVE<br />

<strong>KRYOCLIM</strong> ®<br />

EPDM<br />

20°C 20°C<br />

Chloral hydrate 2 -<br />

Chlorate potassium 2 2<br />

Chloroacetic acid 2 -<br />

Chloroforme 0 -<br />

Chloride ferric 2 2<br />

Chloride sodium 2 2<br />

Chlorine water 5 % 2 2<br />

Chlorobenzine 0 -<br />

Chlorosulphonic acid 100 % 2 -<br />

Chlorure d’allyle 0 -<br />