Basic Concrete w/Poured Beams - BlazeFrame

Basic Concrete w/Poured Beams - BlazeFrame

Basic Concrete w/Poured Beams - BlazeFrame

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Project Submittal –<strong>Basic</strong> <strong>Concrete</strong> w/<strong>Poured</strong> <strong>Beams</strong><br />

Packet Contains:<br />

1) UL Listings referenced in submittal detail sheets with direct links to UL.com listed assemblies<br />

2) Product Submittal Sheets for DL, DSL (slotted option), JR, ECA (End Cap Angle), Mineral Wool<br />

Cavity Plug, and CJB (control joint backer), FSB (Flat Strap Backer), and NSB (Notched Strong Back)<br />

options<br />

3) Documentation:<br />

-STC<br />

-Installation & repair<br />

-MSDS intumescent<br />

-"Chemical Compatibility" with sealants<br />

-Buy American Act<br />

-Project References<br />

4) Assembly submittal sheets for common details in Flat or PT <strong>Concrete</strong> Substrate<br />

***Click on Blue Highlighted to follow direct link to Listing at UL.com***<br />

HW-D-0496 - Shaft Wall<br />

HW-D-0498 - Single Wall<br />

HW-D-0499 – Parallel Fluted Deck<br />

HW-D-0503 – Under Layer Gypsum<br />

HW-D-0505 - Chase Wall<br />

HW-D-0513 – Parallel to Beam<br />

HW-D-0543 - Stair Shaft (093 Zinc or Vinyl Control Joint Optional)<br />

HW-D-0597 – Parallel Beam Z-clip/Drywall Rip<br />

BW-S-0021 - Bottom of Wall<br />

WW-S-0055 - Wall to Wall<br />

www.blazeframe.com<br />

1

Project Submittal –<strong>Basic</strong> <strong>Concrete</strong> w/<strong>Poured</strong> <strong>Beams</strong><br />

Product Submittal<br />

PS1 - “DL” (Deep Leg) Profiles with two solid legs<br />

Composite Fire Stop/Framing for use in up to 3 hr rated wall assemblies. Provides 100% unencumbered joint<br />

protection accommodates up to 3" overall movement with level III (seismic) certification. Minimum G40 (25ga)<br />

and G60 (18ga and heavier) coating with two solid legs supporting “free floating” studs per listed assemblies in<br />

UL Fire Resistance Directory.<br />

(I)<br />

(L)<br />

Widths (W)<br />

250 (2 1/2")<br />

362 (3 5/8")<br />

400 (4")<br />

600 (6")<br />

800 (8")<br />

Mil (Ga)<br />

.018 (25)<br />

.030 (20)<br />

.033 (20)<br />

.043 (18)<br />

.054 (16)<br />

.068 (14)<br />

Part Identification<br />

Example: 400DL2 - 30<br />

400 DL 2 - 30<br />

Track Width<br />

Profile<br />

Series<br />

Gauge<br />

1 - Series (Fire Stop One Side) 2 - Series (Fire Stop Both Sides)<br />

(W)<br />

(W)<br />

(L) (L) (L) (L)<br />

Profile<br />

DLE<br />

DL<br />

DLW<br />

DLX<br />

DLZ<br />

Leg Length<br />

(L)<br />

Strip Width<br />

(I)<br />

Slot Height<br />

(S)<br />

Joint<br />

Protection<br />

2.00" .75" N/A<br />

.50"<br />

2.00"<br />

2.00"<br />

2.50"<br />

3.00"<br />

1.00"<br />

1.25"<br />

1.75"<br />

2.25"<br />

N/A<br />

N/A<br />

N/A<br />

N/A<br />

.75"<br />

1.00"<br />

1.50"<br />

2.00"<br />

N/A 3.00"<br />

DLY 4.00" 3.25"<br />

UL, ASTM & Code Standards<br />

Leed Points<br />

UL2079 & ULC S115-M95<br />

MR 2.1 & 2.2 - Construction Waste: up to 2pts<br />

ASTM E814, E1966, E2837<br />

MR 4.1 & 4.2 - Recycled Content: up to 2 pts<br />

A1003, A653, A924, C645, C754, C955 MR 5.1 & 5.2 - Regional Proximity<br />

AISI 2004 NAS<br />

EQ 4.1 - Low Emitting Materials<br />

2009 IBC & 2010 CBC EQ 9 - Enhanced Acoustical<br />

Phone: (425) 869-2811 Fax: (425) 869-2300<br />

www.blazeframe.com<br />

2

Project Submittal –<strong>Basic</strong> <strong>Concrete</strong> w/<strong>Poured</strong> <strong>Beams</strong><br />

Product Submittal<br />

PS7 - “DSL” (Slotted Both Sides) Profiles with two slotted legs<br />

Composite Fire Stop/Framing for use in up to 3 hr rated wall assemblies. Provides 100% unencumbered joint<br />

protection accommodates up to 1 1/2” overall movement with level III (seismic) certification. Minimum G40<br />

(25ga) and G60 (18ga and heavier) coating two legs with slots spaced 1” O/C for attachment of studs per listed<br />

assemblies in UL Fire Resistance Directory.<br />

(I)<br />

(S)<br />

(L)<br />

Widths (W)<br />

250 (2 1/2")<br />

362 (3 5/8")<br />

400 (4")<br />

600 (6")<br />

800 (8")<br />

1.00" .25"<br />

Mil (Ga)<br />

.018 (25)<br />

.030 (20)<br />

.033 (20)<br />

.043 (18)<br />

.054 (16)<br />

.068 (14)<br />

Fastener mid-height<br />

of exposed slot<br />

Part Identification<br />

Example:<br />

362<br />

Track Width<br />

Profile<br />

362DSL2-30<br />

DSL<br />

2<br />

Series<br />

- 30<br />

Gauge<br />

1 - Series (Fire Stop One Side) 2 - Series (Fire Stop Both Sides)<br />

(W)<br />

(W)<br />

(L) (L) (L) (L)<br />

Profile<br />

DSLE<br />

Leg Length<br />

(L)<br />

2.00"<br />

Strip Width<br />

(I)<br />

.75"<br />

Slot Height<br />

(S)<br />

1.00"<br />

Joint<br />

Protection<br />

.50"<br />

DSL<br />

DSLW<br />

DSLX<br />

3.00"<br />

3.00"<br />

4.00"<br />

1.00"<br />

1.25"<br />

1.75"<br />

1.50"<br />

1.50"<br />

2.00"<br />

.75"<br />

1.00"<br />

1.50"<br />

UL, ASTM & Code Standards<br />

Leed Points<br />

UL2079 & ULC S115-M95<br />

MR 2.1 & 2.2 - Construction Waste: up to 2pts<br />

ASTM E814, E1966, E2837<br />

MR 4.1 & 4.2 - Recycled Content: up to 2 pts<br />

A1003, A653, A924, C645, C754, C955 MR 5.1 & 5.2 - Regional Proximity<br />

AISI 2004 NAS<br />

EQ 4.1 - Low Emitting Materials<br />

2009 IBC & 2010 CBC EQ 9 - Enhanced Acoustical<br />

www.blazeframe.com<br />

3

Project Submittal –<strong>Basic</strong> <strong>Concrete</strong> w/<strong>Poured</strong> <strong>Beams</strong><br />

Phone: (425) 869-2811 Fax: (425) 869-2300<br />

Product Submittal<br />

PS27 - <strong>BlazeFrame</strong> “JR” profiles with one short (front) and one long (back) leg<br />

Composite Fire Stop/Framing for use in up to 3 hr rated shaft wall assemblies. Provides 100% unencumbered<br />

joint protection accommodating up to 1 1/2" overall movement with level III (seismic) certification. Minimum<br />

G40 (20ga) and G60 (18ga and heavier) coating with one leg (front) having intumescent per listed assemblies in<br />

UL Fire Resistance Directory.<br />

(I)<br />

(FL)<br />

(BL)<br />

Widths (W)<br />

250 (2 1/2")<br />

400 (4")<br />

600 (6")<br />

Gauge<br />

.030 (20)<br />

.033 (20)<br />

.043 (18)<br />

.054 (16)<br />

Pat. Pend<br />

Part Identification<br />

Example: 400JR1 - 30<br />

400 JR1 - 30<br />

Track Width Profile Gauge<br />

JR1 - Series (Fire Stop "short leg")<br />

(W)<br />

(I) (FL)<br />

(FL) (BL)<br />

(BL)<br />

Profile Front Leg Back Leg Strip Width Joint<br />

JRE1 2.00" 3.00"<br />

(I)<br />

.75"<br />

Protection<br />

.50"<br />

JR1<br />

JRW1<br />

JRX1<br />

2.00"<br />

2.00"<br />

2.00"<br />

3.00"<br />

3.00"<br />

3.00"<br />

1.00"<br />

1.25"<br />

1.75"<br />

.75"<br />

1.00"<br />

1.50"<br />

UL, ASTM & Code Standards<br />

Leed Points<br />

UL2079 & ULC S115-M95<br />

MR 2.1 & 2.2 - Construction Waste: up to 2pts<br />

ASTM E814, E1966, E2837<br />

MR 4.1 & 4.2 - Recycled Content: up to 2 pts<br />

A1003, A653, A924, C645, C754, C955 MR 5.1 & 5.2 - Regional Proximity<br />

AISI 2004 NAS<br />

EQ 4.1 - Low Emitting Materials<br />

2009 IBC & 2010 CBC EQ 9 - Enhanced Acoustical<br />

www.blazeframe.com<br />

4

Project Submittal –<strong>Basic</strong> <strong>Concrete</strong> w/<strong>Poured</strong> <strong>Beams</strong><br />

Phone: (425) 869-2811 Fax: (425) 869-2300<br />

Product Profile Dimensions<br />

Product Submittal<br />

PS42 - “ECA” (End Cap Angle) to Cap Track Ends<br />

Composite Fire Stop/Framing for use in up to 3 hr rated wall assemblies. Provides 100%<br />

unencumbered joint protection accommodates up to 3” overall movement with level III (seismic)<br />

certification. Minimum G40 (20ga) and G60 (18ga and heavier) coating installed in end of track<br />

profiles (exterior corners) with fire stop facing outward towards rated joints.<br />

(I)<br />

(L)<br />

Pat. Pend.<br />

3.00"<br />

(L)<br />

(I)<br />

(W)<br />

.25" .25"<br />

Width (W)<br />

362<br />

400<br />

600<br />

800<br />

Gauge<br />

.030 (20)<br />

.043 (18)<br />

.054 (16)<br />

Part Identification<br />

Example: 362ECA-30<br />

Width<br />

362 ECA - 30<br />

Profile<br />

Gauge<br />

Profile Leg Length<br />

(L)<br />

Strip Width<br />

(I)<br />

Slot Height<br />

(S)<br />

Joint<br />

Protection<br />

ECA 2.00" 1.00" N/A .75"<br />

ECAW<br />

ECAX<br />

ECAZ<br />

2.00"<br />

2.50"<br />

3.00"<br />

1.25"<br />

1.75"<br />

2.25"<br />

N/A<br />

N/A<br />

N/A<br />

1.00"<br />

1.50"<br />

2.00"<br />

ECAY 4.00" 3.25" N/A 3.00"<br />

UL, ASTM & Code Standards<br />

Leed Points<br />

UL2079 & ULC S115-M95<br />

MR 2.1 & 2.2 - Construction Waste: up to 2pts<br />

ASTM E814, E1966, E2837<br />

MR 4.1 & 4.2 - Recycled Content: up to 2 pts<br />

A1003, A653, A924, C645, C754, C955 MR 5.1 & 5.2 - Regional Proximity<br />

AISI 2004 NAS<br />

EQ 4.1 - Low Emitting Materials<br />

2009 IBC & 2010 CBC EQ 9 - Enhanced Acoustical<br />

Phone: (425) 869-2811 Fax: (425) 869-2300<br />

www.blazeframe.com<br />

5

Project Submittal –<strong>Basic</strong> <strong>Concrete</strong> w/<strong>Poured</strong> <strong>Beams</strong><br />

Product Submittal<br />

PS37 - Shaft Wall Cavity Plugs – Preformed Mineral Wool<br />

Mineral Wool preformed to wall cavity widths for protection of joints with a 4.0 lbs/ft3 density. Profiles are used<br />

to fill and protect joints occurring in shaft wall cavities.<br />

Stock Lengths: 24"<br />

SWCP-250<br />

SWCP-400<br />

SWCP-600<br />

3.50" 5.50"<br />

3.50"<br />

4.00"<br />

4.00"<br />

2.00"<br />

www.blazeframe.com<br />

6

Project Submittal –<strong>Basic</strong> <strong>Concrete</strong> w/<strong>Poured</strong> <strong>Beams</strong><br />

Product Product Profile Submittal Dimensions<br />

PS44 - “CJB” profiles for Protection of Control Joints<br />

Composite Fire Stop/Control Joint Backer Profiles for use to protect Architectural design joints (optional<br />

control joint over gap) for up to 2 hr rated assemblies. Profile sections are fabricated from hot-dipped<br />

galvanized steel complying with ASTM A653 with a minimum G40 (25ga). Profiles comply with ASTM<br />

C645 and provide a metal profile which support intumescent materials located inside and spanning gap<br />

between opposing drywall edges at control joint locations.<br />

1.00"<br />

Intumescent<br />

1.25" .75" 1.25"<br />

Part #<br />

Intumescent<br />

Width<br />

Profile<br />

Width<br />

Gauge<br />

CJB-18 1.25" 3.25" .018<br />

UL, ASTM & Code Standards<br />

Leed Points<br />

UL263, E814,<br />

MR 2.1 & 2.2 - Construction Waste: up to 2pts<br />

A1003, A653, A924, C645, C754, C955 MR 4.1 & 4.2 - Recycled Content: up to 2 pts<br />

AISI 2004 NAS<br />

MR 5.1 & 5.2 - Regional Proximity<br />

2006 & 2009 IBC EQ 4.1 - Low Emitting Materials<br />

2010 CBC EQ 9 - Enhanced Acoustical<br />

Phone: (425) 869-2811 Fax: (425) 869-2300<br />

www.blazeframe.com<br />

7

Project Submittal –<strong>Basic</strong> <strong>Concrete</strong> w/<strong>Poured</strong> <strong>Beams</strong><br />

Product Submittal<br />

PS20 - “FSB” profiles for Protection of Reveal and Control Joints<br />

Composite Fire Stop/Flat strap Profiles for use to protect Architectural design joints (drywall reveal mold or<br />

control joint over gap) for up to 2 hr rated assemblies. Profile sections are fabricated from hot-dipped galvanized<br />

steel complying with ASTM A653 with a minimum G40 (20ga) and G60 (18ga and heavier) coating. Profiles<br />

comply with ASTM C645 and provide a flat strap metal supporting fire stop materials.<br />

"IW"<br />

"FSW"<br />

Pat. Pend.<br />

Part #<br />

Intumescent<br />

Width "IW"<br />

Flat Strap<br />

Width "FSW"<br />

Gauge<br />

"FSW"<br />

"IW"<br />

FSB075<br />

FSB100<br />

0.75"<br />

1.00"<br />

3.00"<br />

3.00"<br />

.030<br />

.030<br />

FSB125 1.25"<br />

3.00"<br />

.030<br />

UL, ASTM & Code Standards<br />

Leed Points<br />

UL2079, E814, E1966, ULC S115-M95<br />

MR 2.1 & 2.2 - Construction Waste: up to 2pts<br />

ASTM E814, E1966<br />

MR 4.1 & 4.2 - Recycled Content: up to 2 pts<br />

A1003, A653, A924, C645, C754, C955 MR 5.1 & 5.2 - Regional Proximity<br />

AISI 2004 NAS<br />

EQ 4.1 - Low Emitting Materials<br />

2009 IBC & 2010 CBC EQ 9 - Enhanced Acoustical<br />

Phone: (425) 869-2811 Fax: (425) 869-2300<br />

www.blazeframe.com<br />

8

Project Submittal –<strong>Basic</strong> <strong>Concrete</strong> w/<strong>Poured</strong> <strong>Beams</strong><br />

Product Submittal<br />

www.blazeframe.com<br />

9

Project Submittal –<strong>Basic</strong> <strong>Concrete</strong> w/<strong>Poured</strong> <strong>Beams</strong><br />

Product Submittal<br />

www.blazeframe.com<br />

10

Project Submittal –<strong>Basic</strong> <strong>Concrete</strong> w/<strong>Poured</strong> <strong>Beams</strong><br />

Product Submittal<br />

www.blazeframe.com<br />

11

[Type text]<br />

Project Submittal –<strong>Basic</strong> <strong>Concrete</strong> w/<strong>Poured</strong> <strong>Beams</strong><br />

<strong>BlazeFrame</strong> Benefits<br />

Intumescent "gasket" Joint Protection<br />

Direct Attachment - No Caulk at Substrate<br />

Reduced Sound Transfer - No Exposed Steel<br />

Exposed Head of Wall and Deflection Gaps<br />

Level III Dynamic Cycle (seismic) Rated<br />

No Joint Fatigue - Lifetime Indefinite<br />

Protection<br />

NVLAP accredited -ASTM E90-04<br />

Western Electro- Acoustic Laboratory<br />

Reports Available Upon Request<br />

<strong>BlazeFrame</strong> Tested Wall Assemblies<br />

1/2" to 3/4" Exposed Deflection Gaps<br />

5/8" Type X Gypsum Sheathing<br />

3 1/2" Fiberglass Insulation Cavity Fill<br />

STC - 52<br />

Unbalanced - (Report # TL 13-223)<br />

STC - 56<br />

Balanced - (Report #TL 13-229)<br />

STC - 66<br />

Unbalanced - (Report #TL 13-229)<br />

STC - 67<br />

Balanced - (Report #TL 13-230)<br />

www.blazeframe.com<br />

12

AC23 - Installation and Manufacturer Recommendations<br />

Project Submittal –<strong>Basic</strong> <strong>Concrete</strong> w/<strong>Poured</strong> <strong>Beams</strong><br />

Installation/Training, Recommendations, and Repair<br />

Installation/Training<br />

1) Select and install profile to accommodate overall movement and wall framing requirements<br />

2) Attach with approved power actuated or mechanical fasteners per Engineer of Record<br />

3) Profiles (intersecting or aligned) in continuous contact with one another<br />

4) Overlap intumescent with sheathing per UL Listings or <strong>BlazeFrame</strong> "constructability" designs<br />

5) "Chase wall" conditions, locate intumescent in direction of "finished" side of wall<br />

6) Training provided to installer of Blaze Frame product, a onsite review with installers will be<br />

conducted by <strong>BlazeFrame</strong> prior to installation<br />

Recommendations<br />

1) Store <strong>BlazeFrame</strong> products in dry covered area<br />

2) Avoid exposure to excessive heat<br />

3) Install according to UL Listed Assemblies or <strong>BlazeFrame</strong> Constructability designs<br />

4) Compatible with non-solvent based products (caulks, paints, coatings, fire proofing, drywall<br />

"mud")<br />

5) Provide protection of areas adjacent to Blazeframe profile using UL classified applications<br />

6) Penetrations through <strong>BlazeFrame</strong> intumescent must be sealed per UL:<br />

- "non-solvent" mastic materials/caulks may be overlapped onto <strong>BlazeFrame</strong> intumescent<br />

7) Voids adjacent intumescent (deck surface, seams, or embossments and <strong>BlazeFrame</strong>) may be<br />

sealed with a sliver of mineral wool or mastic/caulks per UL to maintain listed L-ratings:<br />

- gaps up to 1/4" (alternate to sliver of mineral wool) mastic/caulks to fill entire gap and<br />

may be overlapped onto <strong>BlazeFrame</strong> intumescent<br />

- gaps greater than 1/4" insert min. 4 pcf mineral wool compressed 33% into and fill void<br />

Repair and Installation Gaps<br />

1) Bare locations on metal profiles where intumescent damaged/torn off:<br />

-clean metal profile "squaring" edges of opposing remaining intumescent<br />

-field apply to match strip width (intumescent provided by <strong>BlazeFrame</strong>)<br />

-apply intumescent covering all surfaces between opposing "squared" edges<br />

2) Gaps 1/8" or smaller between profiles:<br />

-apply UL certified caulk filling gap between opposing edges of intumescent<br />

-alternate: cover gap overlapping both sides min. 1/2" (intumescent by <strong>BlazeFrame</strong>)<br />

3) Gaps up to 1/4" or smaller between profiles:<br />

-cover gap overlapping both sides min. 1/2" (intumescent by <strong>BlazeFrame</strong>)<br />

4) Gaps wider than 1/4":<br />

-install patch per <strong>BlazeFrame</strong> document AC20, AC13, or AC14<br />

www.blazeframe.com<br />

13

AC24 - Intumescent Properties<br />

Project Submittal –<strong>Basic</strong> <strong>Concrete</strong> w/<strong>Poured</strong> <strong>Beams</strong><br />

1. Product Description<br />

A strip of highly intumescent<br />

fire stop material affixed to metal profiles<br />

When exposed to heat, this product<br />

expands and forms a hard char to seal<br />

off joint (gap) preventing passage of flames,<br />

temperature pass through, and hot gases.<br />

2. Material Properties<br />

Asbestos Fillers: None<br />

Solvents: None<br />

Hazardous Ingredients: None<br />

Thickness: 2 mm<br />

Width: Per <strong>BlazeFrame</strong> Profile<br />

Activation of Intumescence:<br />

3. Testing Data<br />

It has been tested as a dynamic and static<br />

joint protection fire stop sealant to ASTM E-<br />

814, UL 1479, and UL 2079. Complies to<br />

Required Environmental Exposure Testing<br />

of Accelerated Aging and High Humidity as<br />

per UL 1479 Fire Test of Through-<br />

Penetration Firestops.<br />

Degree of intumescence per DIN standard<br />

≥18x with weight imposed<br />

≥ 37x free intumescing<br />

ASTM E 84, UL 723 Tunnel Test<br />

Flame Spread 5<br />

Smoke Index 5<br />

Expansion Begins 375 ˚F (190˚C)<br />

Expansion Greatest 575 ˚ (302˚ C)<br />

to 1100˚ F (593˚ C)<br />

Color: Black<br />

Exposed Surface: Poly Coating<br />

Freeze-Thaw: Excellent<br />

www.blazeframe.com<br />

14

Project Submittal –<strong>Basic</strong> <strong>Concrete</strong> w/<strong>Poured</strong> <strong>Beams</strong><br />

AC27 - Chemical Compatibility - Sealants<br />

AC27 - Chemical Compatibility with Sealants<br />

<strong>BlazeFrame</strong> steel/intumescent composite joint framing/protection profiles are produced<br />

using a cured intumescent acting as the "fill, void, cavity" materials with a polyester outer<br />

coating. The intumescent portion of the composite profile is chemically compatible with<br />

"non-solvent" based materials (i.e. caulks, mud, paints, fire proofing, etc..) and as such<br />

will be unaffected and not degrade where contact may occur.<br />

Current sealant manufacturer's products verified as non-solvent and compatible with<br />

<strong>BlazeFrame</strong> profiles are:<br />

Rectorseal:<br />

Metacaulk - 1000, 350i, MC 150+, 950, 1100, 1200, 1500<br />

Biostop - 500+, 350i, BF 150+, 700, 750, 800<br />

Flamesafe - FS1900, FS 900+, FS3000<br />

United States Gypsum (USG):<br />

Type AS<br />

Other brand names may be acceptable based on individual manufacturer of specific brand<br />

providing verification of materials being "non-solvent" and will allow/warranty use of<br />

them in applicable conditions.<br />

www.blazeframe.com<br />

15

Project Submittal –<strong>Basic</strong> <strong>Concrete</strong> w/<strong>Poured</strong> <strong>Beams</strong><br />

AC26 - Buy American Act Certification<br />

<strong>BlazeFrame</strong> steel/intumescent composite joint framing/protection profiles are manufactured and<br />

assembled in US facilities:<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Auburn WA.<br />

Bristol, CT<br />

Warren, OH<br />

Dallas, TX<br />

Riverside, CA<br />

Stockton, CA<br />

Baltimore, MD<br />

Profiles include:<br />

1. Steel (approx. 95% weight of composite profiles) having min 32% recycle content and sourced<br />

100% from combination of following US mills:<br />

USS-Posco Industries - Pittsburg, CA<br />

SteelScape - Kalama, WA or Rancho Cucamonga, CA<br />

California Steel Industries (CSI) - Fontana, CA<br />

2. Intumescent (approx. 5% weight of composite profiles) joint protection material is 100%<br />

manufactured in Houston, TX<br />

Additional information covering <strong>BlazeFrame</strong> Industries and all product, certification, and related<br />

information can be accessed at www.blazeframe.com.<br />

www.blazeframe.com<br />

16

Project Submittal –<strong>Basic</strong> <strong>Concrete</strong> w/<strong>Poured</strong> <strong>Beams</strong><br />

Project References East Coast<br />

Project: CUNY/CCNY Advanced Sciences Research Center<br />

Owner: City University of New York (CUNY)<br />

Architect: KPF – Kohn, Pedersen, Fox<br />

GC/Contractor: Skanska Construction – Donaldson Organization<br />

Project: St. Joseph’s Regional Medical/Children’s Addition – (Paterson, NJ)<br />

Owner: St. Joseph’s<br />

Architect: Francis Cauffman Architects<br />

GC/Contractor: Sterling Barnett Little, Inc. – Sloan and Company<br />

Project: Credit Suisse Data Center – (Clifton, NJ)<br />

Owner: Russo Development<br />

Architect: Russo<br />

GC/Contractor: Component Assembly<br />

Project: The Green at Florham Park _ (Florham Park, NJ)<br />

Owner: The Rockefeller Group<br />

Architect: KPF Architects<br />

GC/Contractor: Sloan and Company<br />

Project: International Gem Tower – (New York, NY)<br />

Owner: Extell Development Co.<br />

Architect: Skidmore, Owings & Merrill, LLP<br />

GC/Contractor: Tishman Construction Corp. – Pabco Construction<br />

Project: Mercer County Courthouse – (Trenton, NJ)<br />

Owner: Mercer County<br />

Architect: Vitetta<br />

GC/Contractor: Ernest Bock & Sons – Sloan and Company<br />

Project: JFK Airport Expansion – (New York, NY)<br />

Owner: Port Authority of New York<br />

Architect: Gensler<br />

GC/Contractor: Component Assembly Systems<br />

Project: Campus Center SUNY Farmingdale State College – (Farmingdale, NY)<br />

Owner: SUNY Farmingdale State College<br />

Architect: Kevin Hom & Andrew Goldman Architects<br />

GC/Contractor: Kokolakis Construction – Pabco Construction<br />

www.blazeframe.com<br />

17

Project Submittal –<strong>Basic</strong> <strong>Concrete</strong> w/<strong>Poured</strong> <strong>Beams</strong><br />

Project References West Coast<br />

Project: 7 th & Fig mall Renovation – (Los Angeles, CA)<br />

Owner: Brookfield Properties<br />

Architect: Gensler<br />

GC/Contractor: Turner Construction<br />

Project: Camp Pendleton Naval Hospistal - (San Diego, CA)<br />

Owner: US Marine Corp – Camp Pendleton<br />

Architect: HKS<br />

GC/Contractor: Clark/McCarthy – Component West<br />

Project: Torrance Memorial Center New Tower – (Los Angeles, CA)<br />

Owner: Torrance Memorial Medical Center<br />

Architect: HMC Architects<br />

GC/Contractor: McCarthy Building Cos. Inc. – Capparelli/KHS&S<br />

Project: 2201 Westlake – (16 story residential condominium tower) – (Seattle, WA)<br />

Owner: Vulcan Real Estate<br />

Architect: Callison<br />

GC/Contractor: Expert Drywall<br />

Project: Hyatt Regency – (20 story hotel addition) – (Bellevue,WA)<br />

Owner: Kemper Development<br />

Architect: Sclater Partners<br />

GC/Contractor: Anning Johnson<br />

Project: Amazon.com Headquarters (5 story blocks & 2-12 story towers) – (Seattle, WA)<br />

Owner: Vulcan Real Estate<br />

Architect: Callison<br />

GC/Contractor: Expert Drywall & Anning Johnson<br />

Project: Oregon State Hospital (Replacement, Remodel, and Addition) – (Salem, OR)<br />

Owner: State of Oregon<br />

Architect: KMD Architects<br />

GC/Contractor: Performance Contracting Inc.<br />

Project: New Long Beach Courthouse/Gov George Deukmejian Courthouse<br />

Owner: State of California<br />

Architect: AECOM<br />

GC/Contractor: KHS&S<br />

www.blazeframe.com<br />

18

Project Submittal –<strong>Basic</strong> <strong>Concrete</strong> w/<strong>Poured</strong> <strong>Beams</strong><br />

DT1 - Wall Perpendicular Flange Penetration Deflection Joint at Base<br />

Joint Movement Capabilities (MC) / Profile Series design based on UL: HW-D-0498 & 0543<br />

¾” MC - (Stock Series) 1” MC - ("W" Series) 1 1/2” MC - ("X" Series)<br />

2” MC - ("Z" Series) 3" MC - ("Y" Series)<br />

3 4<br />

5<br />

1 2<br />

1. Installed Gap:<br />

- (compression only) = movement capability (MC) of profile<br />

- (compress + extension) = ½ movement capability (MC) of profile<br />

2. <strong>BlazeFrame</strong> profile attach to substrate with approved fastener<br />

3. Drywall installed per U400 or V400 UL designs (same above and below <strong>BlazeFrame</strong>)<br />

4. Min. 25ga stud and track framing installed at gypsum board edges<br />

-span between <strong>BlazeFrame</strong> and deck greater than 24" add vertical stud framing a max 24" O/C<br />

5. Seal edges of gypsum to substrate above <strong>BlazeFrame</strong><br />

-<strong>BlazeFrame</strong> profile or UL approved caulk (static joint no movement required)<br />

UL, ASTM & Code Standards<br />

Leed Points<br />

UL2079 & ULC S115-M95<br />

MR 2.1 & 2.2 - Construction Waste: up to 2pts<br />

ASTM E814, E1966, E2837<br />

MR 4.1 & 4.2 - Recycled Content: up to 2 pts<br />

A1003, A653, A924, C645, C754, C955 MR 5.1 & 5.2 - Regional Proximity<br />

AISI 2004 NAS<br />

EQ 4.1 - Low Emitting Materials<br />

2009 IBC & 2010 CBC EQ 9 - Enhanced Acoustical<br />

Phone: (425) 869-2811 Fax: (425) 869-2300<br />

www.blazeframe.com<br />

19

Project Submittal –<strong>Basic</strong> <strong>Concrete</strong> w/<strong>Poured</strong> <strong>Beams</strong><br />

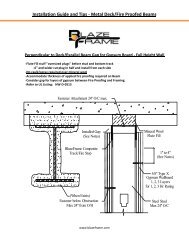

DT2 - Wall Parallel and next to Beam<br />

Joint Movement Capabilities (MC) / Profile Series design based on UL: HW-D-0498 & 0513<br />

¾” MC - (Stock Series) 1” MC - ("W" Series) 1 1/2” MC - ("X" Series)<br />

2” MC - ("Z" Series) 3" MC - ("Y" Series)<br />

Fastener Attachment 24" O/C max.<br />

"Double Tee"<br />

<strong>Concrete</strong> Deck<br />

Installed Gap<br />

(See Notes)<br />

<strong>BlazeFrame</strong> Composite<br />

Track/Fire Stop<br />

1" to 4"<br />

(See Notes)<br />

5/8" Type X<br />

Gypsum Wallboard<br />

Fastener below Flange<br />

Obstruction (max. 24")<br />

(when exists)<br />

Steel Stud<br />

Max 24" O/C<br />

1.Installed Gap (compression only) = movement capability (MC) of profile<br />

2. Installed Gap (compress + extension) = ½ movement capability (MC) of profile<br />

3. Attach to substrate with approved fastener max 24” O.C or per E.O.R.<br />

4. Do not screw drywall or stud to <strong>BlazeFrame</strong> solid leg profile studs "free float"<br />

5. “Slotted” profile metal framing fastener installed center of slot (min. one side)<br />

6. Drywall fasteners 1” to 4" below <strong>BlazeFrame</strong> to accommodate MC or at bottom of obstruction<br />

UL, ASTM & Code Standards<br />

Leed Points<br />

UL2079 & ULC S115-M95<br />

MR 2.1 & 2.2 - Construction Waste: up to 2pts<br />

ASTM E814, E1966, E2837<br />

MR 4.1 & 4.2 - Recycled Content: up to 2 pts<br />

A1003, A653, A924, C645, C754, C955 MR 5.1 & 5.2 - Regional Proximity<br />

AISI 2004 NAS<br />

EQ 4.1 - Low Emitting Materials<br />

2009 IBC & 2010 CBC EQ 9 - Enhanced Acoustical<br />

Phone: (425) 869-2811 Fax: (425) 869-2300<br />

www.blazeframe.com<br />

20

Project Submittal –<strong>Basic</strong> <strong>Concrete</strong> w/<strong>Poured</strong> <strong>Beams</strong><br />

DT3 - Wall Centered Under Beam Overlap Mineral Wool<br />

Joint Movement Capabilities (MC) / Profile Series design based on UL: HW-D-0498 & 0499<br />

1/2” up to 4" MC - (Stock Series)<br />

"Double Tee"<br />

<strong>Concrete</strong> Deck<br />

Fastener Attachment 24" O/C max.<br />

<strong>BlazeFrame</strong> Composite<br />

Track/Fire Stop<br />

Inverted between Substrate<br />

and Deflection Track<br />

Min. 4 pcf Mineral Wool<br />

Compress 33% between<br />

<strong>Concrete</strong> Flange and <strong>BlazeFrame</strong><br />

Deflection Track<br />

1" to 4"<br />

(See Notes)<br />

5/8" Type X<br />

Gypsum Wallboard<br />

Steel Stud<br />

Max 24" O/C<br />

1. Deflection (compression only) = Install gypsum to cover <strong>BlazeFrame</strong> profile<br />

2. Deflection (compress + extension) = Install gypsum ½ of MC requirement above <strong>BlazeFrame</strong><br />

3. Attach to substrate with approved fastener max 24” O.C or per E.O.R.<br />

4. Do not screw drywall or stud to <strong>BlazeFrame</strong> profile<br />

5. Min. 4 pcf mineral wool compressed 33% between substrate flange and <strong>BlazeFrame</strong><br />

6. Drywall fasteners 1” to 4" below Deflection Track to accommodate MC<br />

UL, ASTM & Code Standards<br />

Leed Points<br />

UL2079 & ULC S115-M95<br />

MR 2.1 & 2.2 - Construction Waste: up to 2pts<br />

ASTM E814, E1966, E2837<br />

MR 4.1 & 4.2 - Recycled Content: up to 2 pts<br />

A1003, A653, A924, C645, C754, C955 MR 5.1 & 5.2 - Regional Proximity<br />

AISI 2004 NAS<br />

EQ 4.1 - Low Emitting Materials<br />

2009 IBC & 2010 CBC EQ 9 - Enhanced Acoustical<br />

Phone: (425) 869-2811 Fax: (425) 869-2300<br />

www.blazeframe.com<br />

21

Project Submittal –<strong>Basic</strong> <strong>Concrete</strong> w/<strong>Poured</strong> <strong>Beams</strong><br />

DT4 - Wall Cantilevered Under Beam Drywall Rips<br />

Joint Movement Capabilities (MC) / Profile Series design based on UL: HW-D-0498 & 0503<br />

¾” MC - (Stock Series) 1” MC - ("W" Series) 1 1/2” MC - ("X" Series)<br />

2” MC - ("Z" Series) 3" MC - ("Y" Series)<br />

"Double Tee"<br />

<strong>Concrete</strong> Deck<br />

Fastener Attachment<br />

24" O/C max. 5/8" drywall rips<br />

Installed Gap<br />

(See Notes)<br />

<strong>BlazeFrame</strong> Composite<br />

Track/Fire Stop<br />

5/8" Type X<br />

Gypsum Wallboard<br />

1" to 4"<br />

(See Notes)<br />

Steel Stud<br />

Max 24" O/C<br />

1. Installed Gap (compression only) = movement capability (MC) of profile<br />

2. Installed Gap (compress + extension) = ½ movement capability (MC) of profile<br />

3. Attach to substrate with approved fastener max 24” O.C or per E.O.R.<br />

4. Do not screw drywall or stud to <strong>BlazeFrame</strong> solid leg profile studs "free float"<br />

5. “Slotted” profile metal framing fastener installed center of slot (min. one side)<br />

6. Drywall fasteners 1” to 4" below <strong>BlazeFrame</strong> to accommodate MC or at bottom of obstruction<br />

UL, ASTM & Code Standards<br />

Leed Points<br />

UL2079 & ULC S115-M95<br />

MR 2.1 & 2.2 - Construction Waste: up to 2pts<br />

ASTM E814, E1966, E2837<br />

MR 4.1 & 4.2 - Recycled Content: up to 2 pts<br />

A1003, A653, A924, C645, C754, C955 MR 5.1 & 5.2 - Regional Proximity<br />

AISI 2004 NAS<br />

EQ 4.1 - Low Emitting Materials<br />

2009 IBC & 2010 CBC EQ 9 - Enhanced Acoustical<br />

Phone: (425) 869-2811 Fax: (425) 869-2300<br />

www.blazeframe.com<br />

22

Project Submittal –<strong>Basic</strong> <strong>Concrete</strong> w/<strong>Poured</strong> <strong>Beams</strong><br />

DT5 - Cantilevered Envelope Under Beam Drywall Rips<br />

Joint Movement Capabilities (MC) / Profile Series design based on UL: HW-D-0597<br />

¾” MC - (Stock Series) 1” MC - ("W" Series) 1 1/2” MC - ("X" Series)<br />

2” MC - ("Z" Series) 3" MC - ("Y" Series)<br />

<strong>BlazeFrame</strong> Composite<br />

Track/Fire Stop<br />

1" to 4"<br />

(See Notes)<br />

Fastener Attachment<br />

16" O/C max.<br />

5/8" drywall rips<br />

Steel Stud<br />

Max 24" O/C<br />

<strong>BlazeFrame</strong> "ISA" Profile<br />

min. 16ga angle<br />

Installed Gap<br />

(See Notes)<br />

5/8" Type X<br />

Gypsum Wallboard<br />

1. Installed Gap (compression only) = movement capability (MC) of profile<br />

2. Installed Gap (compress + extension) = ½ movement capability (MC) of profile<br />

3. Attach to substrate with approved fastener max 24” O.C or per E.O.R.<br />

4. Do not screw drywall or stud to <strong>BlazeFrame</strong> solid leg profiles studs "free float"<br />

5. “Slotted” profiles metal framing fastener installed center of slot (min. one side)<br />

6. Drywall fasteners 1” to 4" below <strong>BlazeFrame</strong> to accommodate MC or at bottom of obstruction<br />

UL, ASTM & Code Standards<br />

Leed Points<br />

UL2079 & ULC S115-M95<br />

MR 2.1 & 2.2 - Construction Waste: up to 2pts<br />

ASTM E814, E1966, E2837<br />

MR 4.1 & 4.2 - Recycled Content: up to 2 pts<br />

A1003, A653, A924, C645, C754, C955 MR 5.1 & 5.2 - Regional Proximity<br />

AISI 2004 NAS<br />

EQ 4.1 - Low Emitting Materials<br />

2009 IBC & 2010 CBC EQ 9 - Enhanced Acoustical<br />

Phone: (425) 869-2811 Fax: (425) 869-2300<br />

www.blazeframe.com<br />

23

Project Submittal –<strong>Basic</strong> <strong>Concrete</strong> w/<strong>Poured</strong> <strong>Beams</strong><br />

DT6 - Wall Intersection between <strong>Beams</strong><br />

Joint Movement Capabilities (MC) / Profile Series design based on UL: HW-D-0498 & 0543<br />

¾” MC - (Stock Series) 1” MC - ("W" Series) 1 1/2” MC - ("X" Series)<br />

2” MC - ("Z" Series) 3" MC - ("Y" Series)<br />

Do not attach gypsum<br />

to <strong>BlazeFrame</strong><br />

"Double Tee"<br />

<strong>Concrete</strong> Deck<br />

Fastener Attachment 24" O/C max.<br />

<strong>BlazeFrame</strong> Composite<br />

Track/Fire Stop<br />

1" to 4"<br />

(See Notes)<br />

Steel Stud<br />

Max 24" O/C<br />

5/8" Type X<br />

Gypsum Wallboard<br />

1. Installed Gap (compression only) = movement capability (MC) of profile<br />

2. Installed Gap (compress + extension) = ½ movement capability (MC) of profile<br />

3. Attach to substrate with approved fastener max 24” O.C or per E.O.R.<br />

4. Do not screw drywall or stud to <strong>BlazeFrame</strong> solid leg profile studs "free float"<br />

5. “Slotted” profile metal framing fastener installed center of slot (min. one side)<br />

6. Drywall fasteners 1” to 4" below <strong>BlazeFrame</strong> to accommodate MC or at bottom of obstruction<br />

UL, ASTM & Code Standards<br />

Leed Points<br />

UL2079 & ULC S115-M95<br />

MR 2.1 & 2.2 - Construction Waste: up to 2pts<br />

ASTM E814, E1966, E2837<br />

MR 4.1 & 4.2 - Recycled Content: up to 2 pts<br />

A1003, A653, A924, C645, C754, C955 MR 5.1 & 5.2 - Regional Proximity<br />

AISI 2004 NAS<br />

EQ 4.1 - Low Emitting Materials<br />

2009 IBC & 2010 CBC EQ 9 - Enhanced Acoustical<br />

Phone: (425) 869-2811 Fax: (425) 869-2300<br />

www.blazeframe.com<br />

24

Project Submittal –<strong>Basic</strong> <strong>Concrete</strong> w/<strong>Poured</strong> <strong>Beams</strong><br />

DT7 - Shaft Wall Under Beam<br />

Joint Movement Capabilities (MC) / Profile Series design based on UL: HW-D-0496<br />

¾” MC - (Stock) 1” MC - ("W" Series) 1 1/2” MC - ("X" Series) 2” MC - ("Z" Series)<br />

"Double Tee"<br />

<strong>Concrete</strong> Deck<br />

Min. 4 pcf Mineral Wool<br />

Compress 33%<br />

Fastener Attachment<br />

24" O/C max.<br />

<strong>BlazeFrame</strong> Composite<br />

Track/Fire Stop<br />

Min. 4 pcf Mineral Wool<br />

Compress 33%<br />

5/8" Type X<br />

Gypsum Wallboard<br />

Steel Shaft Stud<br />

Max 24" O/C<br />

1. Finished side gypsum extend past top of <strong>BlazeFrame</strong> (up to 3 hour rating with 3 layers)<br />

2. Installed Gap (compress + extension) = ½ movement capability (MC) of profile<br />

3. Attach to substrate with approved fastener max 24” O.C or per E.O.R.<br />

4. Do not screw drywall or stud to <strong>BlazeFrame</strong> solid leg profile studs "free float"<br />

5. Drywall fasteners 1” to 2" below <strong>BlazeFrame</strong> to accommodate MC<br />

UL, ASTM & Code Standards<br />

Leed Points<br />

UL2079 & ULC S115-M95<br />

MR 2.1 & 2.2 - Construction Waste: up to 2pts<br />

ASTM E814, E1966, E2837<br />

MR 4.1 & 4.2 - Recycled Content: up to 2 pts<br />

A1003, A653, A924, C645, C754, C955 MR 5.1 & 5.2 - Regional Proximity<br />

AISI 2004 NAS<br />

EQ 4.1 - Low Emitting Materials<br />

2009 IBC & 2010 CBC EQ 9 - Enhanced Acoustical<br />

Phone: (425) 869-2811 Fax: (425) 869-2300<br />

www.blazeframe.com<br />

25

Project Submittal –<strong>Basic</strong> <strong>Concrete</strong> w/<strong>Poured</strong> <strong>Beams</strong><br />

DT8 - Shaft Wall Parallel Beam<br />

Joint Movement Capabilities (MC) / Profile Series design based on UL: HW-D-0496 & 0513<br />

¾” MC - (Stock) 1” MC - ("W" Series) 1 1/2” MC - ("X" Series) 2” MC - ("Z" Series)<br />

Fastener Attachment 24" O/C max.<br />

"Double Tee"<br />

<strong>Concrete</strong> Deck<br />

Installed Gap<br />

(See Notes)<br />

<strong>BlazeFrame</strong> Composite<br />

Track/Fire Stop<br />

Min. 4 pcf Mineral Wool<br />

Compressed min. 33%<br />

5/8" Type X<br />

Gypsum Wallboard<br />

Steel Shaft Stud<br />

Max 24" O/C<br />

Fastener below "TEE"<br />

Obstruction (max 24")<br />

(when exists)<br />

1. Finished side gypsum (up to 3 hour rating with 3 layers)<br />

2. Installed Gap (compress + extension) = ½ movement capability (MC) of profile<br />

3. Attach to substrate with approved fastener max 24” O.C or per E.O.R.<br />

4. Do not screw drywall or stud to <strong>BlazeFrame</strong> solid leg profile studs "free float"<br />

5. Drywall fasteners 1” to 2" below <strong>BlazeFrame</strong> to accommodate MC or at bottom of obstruction<br />

UL, ASTM & Code Standards<br />

Leed Points<br />

UL2079 & ULC S115-M95<br />

MR 2.1 & 2.2 - Construction Waste: up to 2pts<br />

ASTM E814, E1966, E2837<br />

MR 4.1 & 4.2 - Recycled Content: up to 2 pts<br />

A1003, A653, A924, C645, C754, C955 MR 5.1 & 5.2 - Regional Proximity<br />

AISI 2004 NAS<br />

EQ 4.1 - Low Emitting Materials<br />

2009 IBC & 2010 CBC EQ 9 - Enhanced Acoustical<br />

Phone: (425) 869-2811 Fax: (425) 869-2300<br />

www.blazeframe.com<br />

26

Project Submittal –<strong>Basic</strong> <strong>Concrete</strong> w/<strong>Poured</strong> <strong>Beams</strong><br />

DT9 - Shaft Wall Perpendicular Beam<br />

Joint Movement Capabilities (MC) / Profile Series design based on UL: HW-D-0496<br />

¾” MC - (Stock) 1” MC - ("W" Series) 1 1/2” MC - ("X" Series) 2” MC - ("Z" Series)<br />

"Double Tee"<br />

<strong>Concrete</strong> Deck<br />

<strong>BlazeFrame</strong> J-Runner Profile<br />

Follow Contour of "Double Tee"<br />

Shaft Wall Assembly<br />

1. Finished side gypsum (up to 3 hour rating with 3 layers)<br />

2. Installed Gap (compress + extension) = ½ movement capability (MC) of profile<br />

3. Attach to substrate with approved fastener max 24” O.C or per E.O.R.<br />

4. Do not screw drywall or stud to <strong>BlazeFrame</strong> solid leg profile studs "free float"<br />

5. Drywall fasteners 1” to 2" below <strong>BlazeFrame</strong> to accommodate MC<br />

UL, ASTM & Code Standards<br />

Leed Points<br />

UL2079 & ULC S115-M95<br />

MR 2.1 & 2.2 - Construction Waste: up to 2pts<br />

ASTM E814, E1966, E2837<br />

MR 4.1 & 4.2 - Recycled Content: up to 2 pts<br />

A1003, A653, A924, C645, C754, C955 MR 5.1 & 5.2 - Regional Proximity<br />

AISI 2004 NAS<br />

EQ 4.1 - Low Emitting Materials<br />

2009 IBC & 2010 CBC EQ 9 - Enhanced Acoustical<br />

Phone: (425) 869-2811 Fax: (425) 869-2300<br />

www.blazeframe.com<br />

27

Project Submittal –<strong>Basic</strong> <strong>Concrete</strong> w/<strong>Poured</strong> <strong>Beams</strong><br />

DT10 - Wall Perpendicular Penetration - Profile Wrap<br />

Joint Movement Capabilities (MC) / Profile Series design based on UL: HW-D-0498<br />

¾” MC - (Stock Series) 1” MC - ("W" Series) 1 1/2” MC - ("X" Series)<br />

2” MC - ("Z" Series) 3" MC - ("Y" Series)<br />

Front View<br />

A<br />

Section A-A<br />

1<br />

2<br />

3<br />

A<br />

1. Installed Gap:<br />

- (compression only) = movement capability (MC) of profile<br />

- (compress + extension) = ½ movement capability (MC) of profile<br />

2. <strong>BlazeFrame</strong> profile attach to substrate with approved fastener (continuous)<br />

3. Drywall installed per U400 or V400 UL designs (same above and below <strong>BlazeFrame</strong>)<br />

UL, ASTM & Code Standards<br />

Leed Points<br />

UL2079 & ULC S115-M95<br />

MR 2.1 & 2.2 - Construction Waste: up to 2pts<br />

ASTM E814, E1966, E2837<br />

MR 4.1 & 4.2 - Recycled Content: up to 2 pts<br />

A1003, A653, A924, C645, C754, C955 MR 5.1 & 5.2 - Regional Proximity<br />

AISI 2004 NAS<br />

EQ 4.1 - Low Emitting Materials<br />

2009 IBC & 2010 CBC EQ 9 - Enhanced Acoustical<br />

Phone: (425) 869-2811 Fax: (425) 869-2300<br />

www.blazeframe.com<br />

28

Project Submittal –<strong>Basic</strong> <strong>Concrete</strong> w/<strong>Poured</strong> <strong>Beams</strong><br />

DT11 - Wall Centered Under Beam<br />

Joint Movement Capabilities (MC) / Profile Series design based on UL: HW-D-0498<br />

1/2” up to 4" MC - (Stock Series)<br />

<strong>Concrete</strong> Floor<br />

Assembly<br />

5/8" Type X<br />

Gypsum Wallboard<br />

Steel Stud<br />

Max 24" O/C<br />

1. Deflection (compression only) = Install gypsum to cover <strong>BlazeFrame</strong> profile<br />

2. Deflection (compress + extension) = Install gypsum ½ of MC requirement above <strong>BlazeFrame</strong><br />

3. Attach to substrate with approved fastener max 24” O.C or per E.O.R.<br />

4. Do not screw drywall or stud to <strong>BlazeFrame</strong> profile<br />

5. Drywall fasteners 1” to 4" below Deflection Track to accommodate MC<br />

UL, ASTM & Code Standards<br />

Leed Points<br />

UL2079 & ULC S115-M95<br />

MR 2.1 & 2.2 - Construction Waste: up to 2pts<br />

ASTM E814, E1966, E2837<br />

MR 4.1 & 4.2 - Recycled Content: up to 2 pts<br />

A1003, A653, A924, C645, C754, C955 MR 5.1 & 5.2 - Regional Proximity<br />

AISI 2004 NAS<br />

EQ 4.1 - Low Emitting Materials<br />

2009 IBC & 2010 CBC EQ 9 - Enhanced Acoustical<br />

Phone: (425) 869-2811 Fax: (425) 869-2300<br />

www.blazeframe.com<br />

29

Project Submittal –<strong>Basic</strong> <strong>Concrete</strong> w/<strong>Poured</strong> <strong>Beams</strong><br />

DT12 - Shaft Wall Perpendicular "Beam" - J-Runner Wrap<br />

Joint Movement Capabilities (MC) / Profile Series design based on UL: HW-D-0496<br />

¾” MC - (Stock) 1” MC - ("W" Series) 1 1/2” MC - ("X" Series) 2” MC - ("Z" Series)<br />

Front View<br />

A<br />

Section A-A<br />

1<br />

2<br />

3<br />

A<br />

1. Installed Gap:<br />

- (compression only) = movement capability (MC) of profile<br />

- (compress + extension) = ½ movement capability (MC) of profile<br />

2. <strong>BlazeFrame</strong> profile attach to substrate with approved fastener (continuous)<br />

3. Drywall installed per U400 or V400 UL designs (same above and below <strong>BlazeFrame</strong>)<br />

UL, ASTM & Code Standards<br />

Leed Points<br />

UL2079 & ULC S115-M95<br />

MR 2.1 & 2.2 - Construction Waste: up to 2pts<br />

ASTM E814, E1966, E2837<br />

MR 4.1 & 4.2 - Recycled Content: up to 2 pts<br />

A1003, A653, A924, C645, C754, C955 MR 5.1 & 5.2 - Regional Proximity<br />

AISI 2004 NAS<br />

EQ 4.1 - Low Emitting Materials<br />

2009 IBC & 2010 CBC EQ 9 - Enhanced Acoustical<br />

Phone: (425) 869-2811 Fax: (425) 869-2300<br />

www.blazeframe.com<br />

30

Project Submittal –<strong>Basic</strong> <strong>Concrete</strong> w/<strong>Poured</strong> <strong>Beams</strong><br />

Vertical & Miscellaneous<br />

Submittal Detail - Exterior Corner ECA Profile<br />

VM21 – “ECA” End Cap Angle Exterior Corner<br />

Joint Protection (JP) / Profile Series design based on UL Listing:<br />

HW-D-0498<br />

¾” MC - (Stock Series) 1” MC - ("W" Series) 1 1/2” MC - ("X" Series)<br />

2” MC - ("Z" Series) 3" MC - ("Y" Series)<br />

Top View<br />

Insert ECA into track<br />

Top View<br />

Side View<br />

Insert ECA into track<br />

ECA inside track<br />

attached with fastener<br />

Intersecting wall<br />

"fresh piece" of<br />

<strong>BlazeFrame</strong> butted<br />

against intumescent<br />

1. Installed Gap (compression only) = movement capability (MC) of profile<br />

2. Installed Gap (compress + extension) = ½ movement capability (MC) of profile<br />

3. Insert ECA profile into end of <strong>BlazeFrame</strong> Track profiles<br />

4. Intumescent strip of ECA and Track profiles in butted contact<br />

5. Attach ECA profile with same fasteners used for track a max 24” O/C<br />

6. Do not screw drywall or stud to <strong>BlazeFrame</strong> track or ECA profile<br />

UL, ASTM & Code Standards<br />

Leed Points<br />

UL2079, E814, E1966, ULC S115-M95<br />

MR 2.1 & 2.2 - Construction Waste: up to 2 pts<br />

A1003, A653, A924, C645, C754, C955 MR 4.1 & 4.2 - Recycled Content : up to 2 pts<br />

AISI 2004 NAS<br />

MR 5.1 & 5.2 - Regional Proximity<br />

2006 & 2009 IBC EQ 4.1 - Low Emitting Materials<br />

2007 CBC & CBC 2010 EQ 9 - Enhanced Acoustical<br />

Phone: (425) 869-2811 Fax: (425) 869-2300<br />

www.blazeframe.com<br />

31

Project Submittal –<strong>Basic</strong> <strong>Concrete</strong> w/<strong>Poured</strong> <strong>Beams</strong><br />

Submittal Detail - Vertical Cavity MEP Bypass<br />

Vertical & Miscellaneous<br />

VM15 – Inside Angle Bypass Cavity Obstruction<br />

Joint Protection (JP) / Profile Series design based on UL Listing:<br />

HW-D-0498<br />

¾” MC - (Stock Series) 1” MC - ("W" Series) 1 1/2” MC - ("X" Series)<br />

2” MC - ("Z" Series) 3" MC - ("Y" Series)<br />

Side View<br />

Top View Cast in Place Bypass<br />

<strong>Concrete</strong><br />

Wall Cavity Penetration<br />

(i.e. conduit/pipe)<br />

<strong>BlazeFrame</strong> Profile<br />

<strong>BlazeFrame</strong> "ISAF or IANF" Profile<br />

Wall Cavity Penetration<br />

(i.e. conduit/pipe)<br />

<strong>BlazeFrame</strong> Profile<br />

<strong>BlazeFrame</strong> "ISAF" or<br />

"IANF" Profile<br />

<strong>BlazeFrame</strong> Profile<br />

1. Installed Gap (compression only) = movement capability (MC) of profile<br />

2. Installed Gap (compress + extension) = ½ movement capability (MC) of profile<br />

3. Install Inside Angle overlapping opposing <strong>BlazeFrame</strong> profiles min. 1" each side<br />

4. Attach Inside Angle with fastener to Overhead max 12" O/C<br />

6. Do not screw drywall or stud to <strong>BlazeFrame</strong> track or Inside Angle profile<br />

UL, ASTM & Code Standards<br />

Leed Points<br />

UL2079 & ULC S115-M95<br />

MR 2.1 & 2.2 - Construction Waste: up to 2pts<br />

ASTM E814, E1966, E2837<br />

MR 4.1 & 4.2 - Recycled Content: up to 2 pts<br />

A1003, A653, A924, C645, C754, C955 MR 5.1 & 5.2 - Regional Proximity<br />

AISI 2004 NAS<br />

EQ 4.1 - Low Emitting Materials<br />

2009 IBC & 2010 CBC EQ 9 - Enhanced Acoustical<br />

Phone: (425) 869-2811 Fax: (425) 869-2300<br />

www.blazeframe.com<br />

32

Project Submittal –<strong>Basic</strong> <strong>Concrete</strong> w/<strong>Poured</strong> <strong>Beams</strong><br />

Submittal Detail - <strong>BlazeFrame</strong> "CJB" (Control Joint Backer)<br />

<strong>BlazeFrame</strong> "CJB" (Control Joint Backer<br />

Certified to ASTM E-119 Standards - (WFCi - Report #12033)<br />

Up to 2 Hour Fire Rated Protection<br />

Install Before or After Cavity Obstructions<br />

Eliminate Drywall Rips/Mineral Wool and Extra Stud<br />

Eliminate Fire Caulking of Penetrations through Cavity Drywall Rips<br />

Zinc or Vinyl Architectural Control Joint (optional)<br />

1.00"<br />

Intumescent<br />

Part #<br />

1.25" .75" 1.25"<br />

Intumescent<br />

Width<br />

Profile<br />

Width<br />

Gauge<br />

CJB-18 1.25" 3.25" .018<br />

www.blazeframe.com<br />

33

Project Submittal –<strong>Basic</strong> <strong>Concrete</strong> w/<strong>Poured</strong> <strong>Beams</strong><br />

Installation:<br />

-Locate first flange of CJB between wall "stud" and wall sheathing<br />

-Fasten CJB max. 8" O/C utilizing wall sheathing fasteners for attachment<br />

-Span wall sheathing from adjacent "stud" and attach to second CJB flange<br />

-Edges of wall sheathing align with edges of intumescent material<br />

Rated 1 hour - Top View CJB at Stud/Jamb (Single Side & Back to Back)<br />

Rated 2 Hour - Top View CJB at Stud/Jamb (Single Side & Back to Back)<br />

Profiles are manufactured with 25ga galvanized steel complying with ASTM A653 having a minimum<br />

G40 coating. Profiles comply with ASTM C645 and are installed behind joints in wall sheathing where<br />

control joints (Zinc or Vinyl 093) are installed to prevent face cracking.<br />

www.blazeframe.com<br />

34

Project Submittal –<strong>Basic</strong> <strong>Concrete</strong> w/<strong>Poured</strong> <strong>Beams</strong><br />

Submittal Detail - <strong>BlazeFrame</strong> "FSB" (Flat Strap Backer)<br />

Certified to ASTM E-119 Standards - (WFCi - Report #12142)<br />

Up to 2 Hour Fire Rated Protection<br />

Install Behind Drywall Reveal Moldings<br />

Eliminate "Extra Layer" of Drywall to Maintain Rated Partition<br />

Metal Strap Support for Drywall and Reveal Attachment - Horizontal and Vertical<br />

Zinc or Vinyl Architectural Reveal Molding Installed Over Gap<br />

Part #<br />

Intumescent<br />

Width "IW"<br />

Flat Strap<br />

Width "FSW"<br />

Gauge<br />

"FSW"<br />

"IW"<br />

FSB075<br />

FSB100<br />

0.75"<br />

1.00"<br />

3.00"<br />

3.00"<br />

.030<br />

.030<br />

FSB125 1.25"<br />

3.00"<br />

.030<br />

www.blazeframe.com<br />

35

Project Submittal –<strong>Basic</strong> <strong>Concrete</strong> w/<strong>Poured</strong> <strong>Beams</strong><br />

Submittal Detail - <strong>BlazeFrame</strong> "FSB" (Flat Strap Backer)<br />

Installation:<br />

-Locate FSB taught between "stud(s)" and wall sheathing<br />

-Edges of wall sheathing align with edges of intumescent material<br />

-Fasten Sheathing Edges max. 8" O/C use sheathing fasteners for attachment<br />

-Install Reveal Moulding over Gap - (1/2" deep profile)<br />

Horizontal - Side View FSB (One and Two Hour)<br />

Vertical - Top View FSB with Stud Backer (One and Two Hour)<br />

FSB Profiles are manufactured with 20ga galvanized steel complying with ASTM A653 having a<br />

minimum G40 coating. Profiles comply with ASTM C645 and are installed behind joints in wall<br />

sheathing where reveal molding (Zinc or Vinyl) are installed.<br />

www.blazeframe.com<br />

36