Dr. Heinz Jörg Fuhrmann - Schau Verlag Hamburg

Dr. Heinz Jörg Fuhrmann - Schau Verlag Hamburg

Dr. Heinz Jörg Fuhrmann - Schau Verlag Hamburg

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

tubes<br />

Largest individual order in the history of EUROPIPE<br />

Baltic Sea Pipeline contract signed<br />

The order calls for 860,000 tons of large-diameter pipes to be produced in Mülheim.<br />

Capacity utilization is assured<br />

Nord Stream AG and EURO-<br />

PIPE GmbH have signed a<br />

contract for the supply for<br />

steel pipes to construct the<br />

Baltic Sea Pipeline. EUROPIPE will provide<br />

around 75 percent of the pipes for<br />

the first leg of the 1,200 kilometer pipeline<br />

from Vyborg in Russia to Lubmin<br />

near Greifswald in Germany. The order<br />

for the other 25 percent went to Russian<br />

pipe producer OMK.<br />

EUROPIPE’s share of the deal<br />

amounts to 860,000 tons of high-quality<br />

steel pipe, representing an investment in<br />

excess of a billion euros by Nord Stream<br />

AG, the international joint venture set up<br />

to design, build and subsequently operate<br />

the Baltic Sea Pipeline.<br />

The contract is itself an important step<br />

towards completion of the first section<br />

of the line slated for 2010. By the time<br />

construction work begins in 2009,<br />

roughly a third of the pipe – 400 kilo-<br />

Interview with Wolfgang Eging, Director of Tubes<br />

With contracts safely signed, from left: Henning Kothe and Matthias Warnig, both of Nord<br />

Stream, and <strong>Dr</strong>. Michael Gräf and Lauri Malkki, both of EUROPIPE<br />

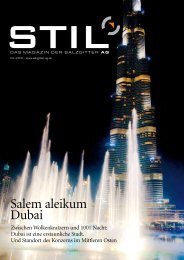

“Securing and extending our leading<br />

position worldwide”<br />

The Tubes Division of Salzgitter AG has undergone some changes: We talked with Tubes<br />

Director Wolfgang Eging about growth strategies and concentration on welded tubes.<br />

stil In business terms, the Tubes Division of<br />

Salzgitter AG is in outstandingly good<br />

shape. How much of this is due to the strategic<br />

decision to focus on welded steel tubes?<br />

wolfgang eging The Tubes Division has<br />

now been highly profitable for 4 years in<br />

succession. In the 20 years before that,<br />

there was never a comparable period in<br />

which we were so successful. Following<br />

the takeover of Tubes by Salzgitter AG in<br />

the year 2000, there was very soon a question<br />

mark over the industrial leverage<br />

that came with our interest in Vallourec<br />

as a manufacturer of seamless tubes. We<br />

had only limited scope to exercise any influence<br />

over the listed Vallourec Group,<br />

and as the Tubes Division evolved, we felt<br />

it made sense to separate ourselves from<br />

V&M and our stake in VLR. With this<br />

in mind it was logical to focus on welded<br />

tubes, at the premium end of the market.<br />

We aim to achieve growth by offering<br />

sophisticated solutions in order to secure<br />

and extend our leading position<br />

worldwide. The resources released from<br />

the seamless side of the business are being<br />

used proactively.<br />

stil The tubes business is becoming increasingly<br />

international – not just in the<br />

field of largediameter pipes. What challenges<br />

do you see facing precision tubes?<br />

eging As a result of our concentration on<br />

the premium segment, based on our activities<br />

and our growth strategy we see ourselves<br />

very well placed to come out on top.<br />

That is particularly due to the acceptance<br />

that our products enjoy in the marketplace<br />

and their popularity among our precision<br />

tubes customers in Europe.<br />

PHOTO: EUROPIPE<br />

meters – must be in store at various logistical<br />

depots, ready to be laid. Which<br />

means that by then the entire production<br />

chain must be completed, from steelmaking,<br />

plate rolling, tube manufacturing<br />

and coating through to transportation<br />

to the storage sites.<br />

The 860,000 tons of large-diameter<br />

pipe booked by EUROPIPE represent the<br />

largest single order in the company’s history.<br />

EUROPIPE will manufacture the entire<br />

order at its Mülheim works. The<br />

plate required to produce the pipes will<br />

be ordered by EUROPIPE from its shareholders<br />

Dillinger Hütte and Salzgitter.<br />

For Salzgitter’s part, the input material<br />

The pipeline will connect<br />

Russia and the European Union<br />

will be supplied from the plate mill at<br />

Mannesmannröhren Mülheim GmbH.<br />

This order alone represents capacity utilization<br />

in excess of 40 percent over 18<br />

months at EUROPIPE. The internal coating<br />

and external corrosion-proofing included<br />

in the order will be carried out by<br />

EUROPIPE’s subsidiary MÜLHEIM<br />

PIPECOATINGS (MPC) GmbH, which<br />

in turn will benefit from as much as<br />

60 percent capacity utilization.<br />

stil What role does the acquisition of manufacturers<br />

in France and the new company in<br />

Mexico have to play?<br />

eging By acquiring VPE and the plant in<br />

Zeithain producing input stock, we have<br />

laid the foundation on which to become<br />

Europe’s market leader. We intend to develop<br />

this position and use it to offer sophisticated<br />

solutions for our customers in the<br />

automotive and other industrial sectors.<br />

The acquisition in Mexico provides a<br />

nucleus for development outside of Europe.<br />

In future, we aim to secure a strong<br />

position for our automotive business in<br />

the NAFTA territories.<br />

stil The high prices for oil and gas are adding<br />

impetus to pipeline projects the world<br />

over. On the other hand, steel and tubes<br />

production is very energyintensive. At<br />

what point will this development become<br />

critical?<br />

eging Let’s think back to the 80’s and 90’s<br />

when an oil price of 30 US dollars a barrel<br />

was judged to be the balance point between<br />

exploration and the risk of under-<br />

The total cost of the Baltic Sea Pipeline<br />

will be in the order of six billion euros.<br />

That’s around 15 percent less than for an<br />

overland pipeline – including the operating<br />

costs for a 25-year period. This is due<br />

mainly to the comparatively high operating<br />

costs for a land-based pipeline and<br />

the associated compressor stations. The<br />

mining the development in gross<br />

national product.<br />

As we now know, this boundary<br />

has shifted with sustained effect.<br />

Worldwide demand for energy<br />

continues without a break and<br />

we have already reached an oil<br />

price of 100 US dollars a barrel.<br />

The demand for tubes for oil and<br />

gas exploration, transportation<br />

and energy generation is huge. Among the<br />

particular factors dictating this demand<br />

are the tremendous growth dynamics in<br />

the BRIC countries (Brazil, Russia, India<br />

and China) and the need to replace existing<br />

power stations.<br />

stil It has long since ceased to be enough<br />

just to make quality tubes – customers demand<br />

comprehensive service. What do we<br />

offer our customers?<br />

eging As a business model, simply manufacturing<br />

tubes is a thing of the past. We<br />

have been offering our customers far more<br />

for a long time now. We support them<br />

with customized solutions, from the initial<br />

pipeline will connect Russia and the European<br />

Union via the Baltic. EU demand<br />

for imports of natural gas is expected to<br />

reach 536 billion cubic meters by 2015 –<br />

compared with 336 billion in 2005. The<br />

Baltic Sea Gas Pipeline will be able to<br />

fulfill around 25 percent of the additional<br />

demand.<br />

The natural gas pipeline across the Baltic Sea<br />

Wolfgang Eging<br />

idea through to production. Our<br />

Trading Division, which is a global<br />

organization, and also the Group’s<br />

own research and product-based<br />

development facilities play an outstanding<br />

role. As a Group, we offer<br />

consultancy, production, supply,<br />

an international logistics network<br />

and other support functions,<br />

all from a single source.<br />

stil The companies that make up the Tubes<br />

Division have changed their names and<br />

logos. What were the reasons behind this?<br />

eging Our brand name is Salzgitter Mannesmann.<br />

What we are doing is combining the<br />

Mannesmann product name, which is recognized<br />

worldwide as a synonym for quality<br />

and competence in tubes, with the success<br />

story that is Salzgitter. For this reason, as has<br />

already happened at the Trading Division,<br />

we have prefixed all of our companies with<br />

the name “Salzgitter Mannesmann”. So both<br />

the Tubes and Trading Divisions now equally<br />

underscore the solidarity between Salzgitter<br />

and the synonym for tubes (Mannesmann).<br />

18 stil stil 19<br />

tubes<br />

Planned Nord<br />

StreamPipeline<br />

Planned service<br />

platform<br />

Pipeline of the<br />

European natural<br />

gas network<br />

Pipeline planned<br />

or in construction<br />

Territorial<br />

border