AVIATOR pOinls - American Bonanza Society

AVIATOR pOinls - American Bonanza Society

AVIATOR pOinls - American Bonanza Society

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

I alcon Insurance is one of the largest independently owned<br />

- . • •<br />

has decades of expenence in aviation insurance and we<br />

are uniquel)' qualified to provide complete insurance<br />

r.rotection for !\IlS members.<br />

The AilS Program is one of the most comprehensive<br />

insurance programs available III the industry todaX and<br />

features expanileil coverages, access to a variety of underwriters<br />

and competitive rates. The professional Falcon staff<br />

is dedicated to serving AilS members with an insurance<br />

. I<br />

Amerk~~<br />

<strong>Bonanza</strong> ..-~~<br />

Soclet.!j~<br />

-.".

.m 08 Number 10<br />

Published by <strong>American</strong> <strong>Bonanza</strong> <strong>Society</strong>, Organized January 1967<br />

OCT O BER<br />

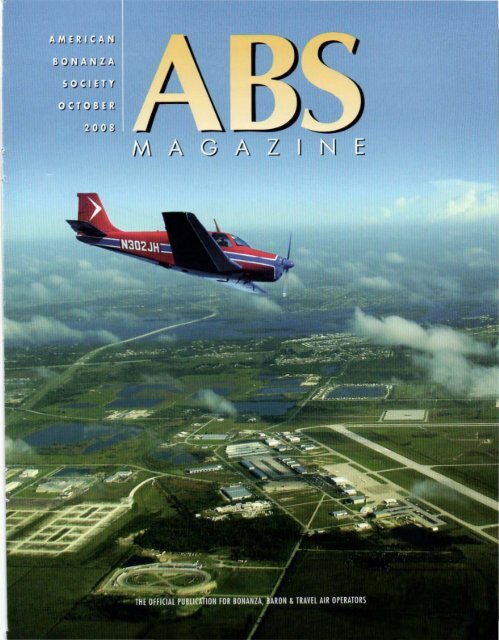

ON THE COVER<br />

10980 Jim Delltseh's red Debonair<br />

flying over C!wr!olle Harbor<br />

(Pllnta Corda, Florida).<br />

Photo by Bill Hare; photo plane<br />

pilot, John TaylOl:<br />

FEATURES<br />

10982 PANEL MODS, PART IV<br />

By Dennis Wolter<br />

10991 ABS BOARD<br />

CALL FOR NOMINATIONS<br />

11000 CRANKCASE REPAIRS<br />

By Jim Cavanagh<br />

11006 STARTER ADAPTERS<br />

By Celie Key/<br />

11001 PREVENTTHE<br />

BATTERY BLUES<br />

By Geary Keilmall<br />

11010 MORE ON CHECKLISTS<br />

By Richard No/all<br />

11010 CIRCUIT BREAKER AD<br />

UPDATE<br />

11011 BEECHCRAFT HERITAGE<br />

MUSEUM<br />

By ROil Vickrey<br />

11014 BIG BEECH BUNCH<br />

10918 BPPP SCHEDULE<br />

10919 PRESIDENT'S COMMENTS<br />

by An Brock<br />

10986 ABS LIFE MEMBERSHIP<br />

10981 FORUM<br />

10988 SAWYOWNER<br />

by Mike Huseh<br />

AEROMEDICAL NEWS 10998<br />

by Charlie DUI'idsOIl, MD<br />

10992 TECH TIPS/NEILS NOTES 11002<br />

10996 BPPP<br />

by Craig Kent 11004<br />

l0996A AD SECTION 11005<br />

10991<br />

WHArSWRONG 11008<br />

by Adrian Eichhom<br />

& Ron TimmenllulIS 11011<br />

AVIONICS<br />

by lo/m Col/illS<br />

CURRENTS<br />

by Lew Gage<br />

11012 INSURANCE<br />

by )oh" AI/ell<br />

Falcoll hWIfYmce<br />

ABS <strong>AVIATOR</strong>S 11013 REGIONAL NEWS<br />

EDITORIAL CALENDAR 11013 SURLY BONDS<br />

GENERATIONS 11015 ABS MEMBERSHIP<br />

APPLICATION<br />

GA NEWS<br />

11016 EVENT CALENDAR<br />

Send articles/letters to:<br />

ASS Magazine Publication Office<br />

PO. Box 128BB. Wichito. KS 67277<br />

Tel: 316-945-1700 Fox: 316-945-1710<br />

E-mail: bonanza1@bonanza.org<br />

Website: http://www.bononza.org<br />

COP) and photographs 5ubmlntd for pohlkation il«oolf tM propert)' 01 thor Societ)<br />

and ~ ha ll not ~ I'ftunlfd. MlCks IUbmllled ""Ill ~t Uffli ~\~ publtcalKlll (IIl'fatnct<br />

EDITOR-iN-CHIEF: Nancy Johnson. ABS Executive Director<br />

MANAGING EDITOR: Betty Rowley<br />

AIRCRAIT TECHNICAL EDITOR: Thomas P_ Turner<br />

ART DIRECfOR: Jim Simpson<br />

Display. Advertising<br />

Director<br />

John Shoemoker<br />

2779 Aero Pork. Orive.<br />

PO Box 966.<br />

Traverse City. MI 49684<br />

1-8CJO.327·7377. exl 3017<br />

Fox: 231-946-9566<br />

E-mol lohns(1i)oJlloQ4!prf'<br />

com<br />

ASS MAGAZll.E. (lSSN IjJS-9\J60) IS published moo!hly b)' the Amtnl:aa <strong>Bonanza</strong><br />

Soc~. 1922 Midf.rkl Road. Wi(:hlla. KS 67209. The prifc 01 . ~., ., l )' WMcnpOon<br />

is llICluded In !he annual dues of Soc~ ITCmtJc,D Ptnl)(bClb ~ paid ;II<br />

....'iduu, K 3n~s. and at addllJOII.tl nwlmg otrlC'e><br />

1"0 pan of Ihis pubhcauon rna)' be repnnted or durliu tN ""1hout tht \\nuen<br />

perrm .. ~io n of !he Ed itor In Ch.ef<br />

The Soc iNy and Publisher C:IlUlI,)\ lCCe"t responsibility fO( lhe com

ABS MEMBERSHIP SERVICES Monlhly ABS Magazine · One-on-One Aircraft Advice<br />

• Beechcraft Piiol Proficiency Program ' Aircraft Service Clinics ' Air Safely Foundation Research &<br />

Developmenl Projects ' Regulolory & Industry Represenlotion • Annual Convention & Trade Show<br />

• Affi liated Aircraft Insurance with Falcon Insurance ' Members-only Website Section ' Educational<br />

Books, Videas & logo Merchandise ' ABS Platinum Visa" (with RAPID Discounls) • Tool Rental<br />

Program ' Professionally Staffed Headquarters<br />

1922 MIDFIELD ROAD, PO. BOX 12888, WICHITA, KS 67277 ABS exisls to promote aviation safely and Hying enjoyment through<br />

TEl: 316-945-1700 FAX 316-945-1710 E-MAil: ABSmail@bonanza.arg education and information-sharing among owners and operators of<br />

OFFICE HOURS: M-F 8:30 am - 5 pm (Cenlral Time)<br />

<strong>Bonanza</strong>s, Berons, Debonoirs and Travel Airs throughout the world.<br />

ABS BOARD OF DIRECTORS<br />

TERM EX~RES<br />

PRESIDENT<br />

ARTHUR W. BROCK (Area B) • 2009<br />

Committee Choir: Events. Executive, Planning,<br />

Technical<br />

2831 Colt Rd., I«lncho Palos Verdes, CA 90275<br />

phone: 310-548-8507. fox: 31Q..548-3767<br />

e-mail: brockort@ool.com<br />

VICE PRESIDENT<br />

Bill STOVAll (Area 6) '2009<br />

Committee Cnair: ABS-ASF Project Funding. Media<br />

32675 Woodside Dr" E'l9fgreen. CO 80439<br />

phone: 303--945-1 700<br />

Eligible for 30 ASS Avialor paints.<br />

DATE<br />

Oct 24-26<br />

Nov 14-16<br />

lOCATION<br />

Richmond, VA<br />

Tulsa, OK<br />

AIRPORT<br />

(RIC)<br />

(RVS)<br />

Visit www.bppp.org for more info or to register. <strong>Bonanza</strong>s/Barons/Debonairs/Travel<br />

Airs ot all locations. Cockpit Companion course available. Call the BPPP<br />

Registratian Office to make arrangements: 970-377-1877 ar fax 970.377-1512.<br />

Eligible for 70 ASS Aviator pOints.<br />

PAST PRESIDENTS<br />

S.J. McClanahan. MO 1967-1971<br />

FronkG.Ross (dec.) 1971 - 1973<br />

Russell W. Rink (dec.) 1973-1975<br />

Hypolile T. Lortdry, Jr" MD 1975-1976<br />

Colvin B. Eorly, MD. PhD 1976-1977<br />

Copt. Jesse F. Adoms USN{R) (dec.) 1977-1978<br />

David P. Borton 1978-J 979<br />

Alden C. Barrios<br />

fred A. Onscoll, Jr. (deC.) 1980-1981<br />

E M. Anderson. Jr (deC.) 1981-1983<br />

Donald L Monday 1983-1984<br />

Harry G Hadler (dec.) 1984-1985<br />

John E Pixton (dec.) 1985-1986<br />

Charles R Gibbs 1986-1987<br />

Roy L leodobrond (dec.) 1990-1991<br />

James C. Cassell, III (dec.)1 991-1992<br />

Worren E.Hoftner 1992-1993<br />

John H. Kilbourne 1993-1994<br />

Borrie Hiem, MD 1994-1996<br />

1996-1997<br />

Jon Roodf~dt<br />

Harold Basi<br />

Jock Threadgill<br />

Jock HOSllngS.MD<br />

CrClO Bailey<br />

Jon luy<br />

200J-2oo1<br />

2001·2002<br />

2002·2003<br />

2003·2004<br />

100'·2006<br />

2006-2007

Here are some highlights from my annual State of The <strong>Society</strong><br />

Report, presented at the annual membership meeting in<br />

Lexington .<br />

BOARD OF DIRECfORS: This year Jon Luy will be leaving<br />

the Board, a his second term has expired. Tom Rosen will<br />

take his place from Area 7. Next year there will be three new<br />

vacancies as Bill Stovall. Charlie Davidson and I, from Areas<br />

6, 3 and 8 respectively, complete our second terms. The call for<br />

nominations is elsewhere in this issue. (page 10997)<br />

We are sorry to have lost two of our newest board members<br />

in August, both resigning due to time limitations and<br />

interests outside of the <strong>Society</strong>'s purview - Greg Keshishian.<br />

Area I, and Andy Reardon, Area 4. The Board is in the process<br />

of filling those vacancies in accordance with the ABS bylaws.<br />

The Board of Directors has elected the following officers<br />

for Fiscal 2009:<br />

President Bill Stova ll , Vice President Ron Less ley,<br />

Secretary Charlie Davidson, and Treasurer Steve Blythe. I<br />

extend my heartiest congratu lations to these gentlemen and<br />

wish them the best of good luck.<br />

TECHNICAL: The spar web cracking srudy continues. We<br />

will have completed the first phase of our current program<br />

prior to the Convention. Assuming the results show satisfactory<br />

progress, the ASF Board will be asked to approve continuation.<br />

To assure rhe highest quality resulL, we have changed<br />

our contract to req uire all the basic engineering be done by a<br />

senior engineer. This change and some other unanticipated<br />

problems are indicating a higher final cost than our earlier estimates;<br />

however, we remain optimistic about a positive outcome.<br />

We continue to learn more about the circuit breakerswirch<br />

AD. Our earlier perception of the problem, apparently<br />

shared by the FAA, was incorrect. We have talked to Hawker<br />

Beechcraft engineering and Tyco, the switch manufacturer.<br />

The problem and its solution are associated with the internal<br />

spring. The new switches have a bend in the end of the spring<br />

that avoids that part shorting out.<br />

Significantly, only the switches sold through Hawker<br />

Beechcraft have thar fix. Although Tyco markers rhe same part<br />

number through other sources, those switches do not have the<br />

fix. See the Members Only page of www.bonanza.erg for more<br />

information , including pictures of the different internal switch<br />

designs.<br />

ABS has asked members to submit, in confidence. information<br />

on failed switches. AlLhough sparse, the information<br />

thus gathered does indicate some failures in singles as well as<br />

twins.<br />

IL has been suggested in some<br />

forums thar removing the old Beech<br />

switches and replacing rhem with<br />

Tyco's (prior to the effecti ve date of<br />

the AD) would be a safe alternative to<br />

compliance. Based on what we know<br />

now, that is not a good idea. The Tyco<br />

switches have not addressed the failure mode and there have<br />

been failures in the fi eld.<br />

The supply of the new sw itches is awaiting a significant<br />

order fro m Beechcraft, which in rum is waiting for significant<br />

orders from owners. An additional hOlding factor is the possible<br />

approval of one or more alternate means of compliance<br />

(AMOCs), although knowing what we now know about the<br />

design change of the Beech part, this may not be as likely as<br />

we once thought.<br />

As for parts availabilit y, the sooner we get our orders in to<br />

RAPID, the sooner production will start. ABS still believes<br />

that this AD is an expensive overkill considering a rea listic risk<br />

assessment, and we intend to continue discussions on this with<br />

the FAA.<br />

FINANCIAL: We are in excellent financial health. The ABS<br />

balance sheet reports assets in excess of liabilities of almost<br />

$900 thousand. Of course, we were affected by the general<br />

market contraction, and we saw the value of our investment<br />

accounts decrease thi s year. However, before applying those<br />

unrea lized losses on investments, we recorded a modest profit<br />

of about S75 thousand.<br />

The ABS Air Safety Foundation has conunitted significant<br />

fu nds to the spar web study but still shows a pos itive fund<br />

balance of over $500 thousand. Our goal is to replace the spar<br />

web study funding promptl y, to be financially ready for whatever<br />

may come next.<br />

The Endowment Fund, which was establi shed to provide<br />

an income source to sustain the activities of the ABS Air<br />

Safety Foundation in an era of declining membership, rema ins<br />

well short of the original goal of $5 million. While we still<br />

have time to build that fund, we have to be realistic; more airplanes<br />

are leaving the active fleet than Hawker Beechcraft is<br />

building. Our need for new funds to sustain the current ac tivities<br />

of the ABS Air Safety Foundation and to grow the<br />

Endowment Fund is very much alive.<br />

SERV ICE CLINlCS & BPPP: Two of our most important<br />

services are the recurrent Beechcraft flight trai ning<br />

provided by BPPP, and the mechanical examination of the<br />

fleet at our Service Clinics. Both programs operate on an<br />

comilllled 011 page 11015<br />

ABS October 2008 www.bonanza.org Page 10979

~ ----<br />

• _ _._.._.. .. ........... . .. . . ..._.___.__...._..._. ........ . .........._..__•.._...._........._..._.._____...._....._._._..._...l<br />

1962 Debonair<br />

OUR LlTILE DEBBIE<br />

e flew 2,200 glorious hours in our<br />

~<br />

beloved Skylane for 14 years.<br />

When we lived in Torrance.<br />

California, prior to 1995, and our<br />

kids lived in Maryland and Mississippi,<br />

we had five trips coast· to-coast under<br />

our belts in the Skylane.<br />

Then along came Hurricane<br />

Charlie! With my insurance check in<br />

hand, [ started looking for an airplane<br />

with more speed. My understanding<br />

wife Penny is always in a hurry; she<br />

wanted a faster plane, too.<br />

[ have had a variety of planes over<br />

the years and have taken many long<br />

cross·country trips, but always wished I<br />

had a Beechcraft. So the quest began for<br />

aEE[~~~~n Of T~E MD~T~<br />

N302JH<br />

Jim Deutsch<br />

Punta Gorda. Florida<br />

a good cross-country airplane. comfortable<br />

for two people and capable of carrying<br />

lots of luggage.<br />

Our search uncovered a 1962<br />

Debonair with a mid·time engine and the<br />

avionics we were looking for, but in need<br />

of a new interior. After a prebuy inspec·<br />

tion, we decided this was the one for us.<br />

When Debbie went in for her first<br />

annual six months after purchase, we<br />

were surprised by an estimate to fix a<br />

list of problems almost as long as War<br />

and Peace, none of which had shown up<br />

in the prebuy.<br />

[ gave the OK for the work, thinking<br />

all would be fine for the next year.<br />

But the next year's annual list of problems<br />

made the previous li st look like a<br />

short story. So I said, "Enough is<br />

enough. Fix EVERYTHING!"<br />

Then, with a new paint job and a<br />

new windshield, I was certain we had a<br />

sound and safe traveling lady.<br />

Our first big trip was with the<br />

Southeastern <strong>Bonanza</strong> <strong>Society</strong> to Long<br />

Island in the Bahamas. We had a ball<br />

and decided to go every December<br />

thereafter! Debbie does the trip easily<br />

and allows my bride to take all her stuff.<br />

Now that we reside in southwest<br />

Florida and have a grandson and three<br />

step-grandkids in Louisiana, and three<br />

great-grandkids in MissisSippi, our<br />

Debbie can make that trip in less than<br />

three hours. Our personal range is<br />

maxed out at three hours. Perfect!<br />

Our longest trip was from southwest<br />

Florida to Colorado Springs to visit I<br />

ong-time good friends; a one- night<br />

stopover in Keokuk, Iowa, to see distant<br />

relatives; and then on to visit our oldest<br />

son and his wife and children in the

EQUIPMENT LIST - 1962 B33, N302JH<br />

MX20 Mu I func:,or d spoy<br />

GX60 GPS W1'h COr'lm<br />

SL3C .2 'od 0 W 'n ILS ood<br />

gl deslope rece~r<br />

SL70 rronspender<br />

1Ol87AOF<br />

KX62DME<br />

S- ec 50 OU';)p1<br />

w,n 01 110 j<br />

Genuv H5I<br />

Hor zon d gllol -och<br />

E!ech)nICS nlernallono'<br />

Supe' clOC,<br />

BocKuo ~ecl(lc anticKli<br />

honzon<br />

JPI 800 eng Ire room'or<br />

VerlICOI cord compess<br />

VlstoNav with WX weo'her<br />

Washington, DC, area before flying<br />

home to Florida.<br />

The only problem was that the alternator<br />

belt kept breaking or coming off.<br />

That was fixed when our local mechanic<br />

The refurbished interior inside is just as nice as the sho...,." red point job outside.<br />

discovered the wrong belt had been<br />

installed. Now we replace that belt every<br />

24 months, no maner what.<br />

While trying to make Debbie like<br />

new, I have serviced every conceivable<br />

system and have not had any issues<br />

during its last 85 hours. We really wanted<br />

to add a nose light to tum on without<br />

lowering the gear, but were told that our<br />

cowl is too short from spinner to air<br />

filter. I saw a mod in ABS Magazine that<br />

was done on the same year Debonair as<br />

ours, but Beech changed the cowl that<br />

same year. I do wish we had a light to<br />

tum on without lowering the gear, but I<br />

guess that is not meant to be.<br />

We recently took a hit from<br />

Tropical Storm Fay, from which we<br />

came out unscathed. Hurricane Gustav<br />

gathers strength off the coast of Cuba<br />

and several yet unnamed tropical<br />

systems lurk in the Atlantic. Who knows<br />

what havoc Mother Nature will wreak<br />

on us this hurricane season. Luckily, our<br />

insurance company will pay us $500 to<br />

rake N302JH out of harm's way should<br />

a hurricane threaten a direct hit.<br />

Now, with Debbie all broken in and<br />

working like a dream, we have great confidence<br />

in her. We are ready for our next<br />

trip to escape threatening hunicanes or<br />

another fun trip with other <strong>Bonanza</strong> owners<br />

to Long Island, Bahamas, and beyond!<br />

@

PANEL MODIFICATIONS - PART IV<br />

DINOSAURS, DUMPSTERS & DOLLARS<br />

BY DENNIS WOLTER, AIR MOD, BATAVIA. OHIO<br />

Writing about the next phase of building this panel presents me with a dilemma , My<br />

wife Cynthia is always telling me that women are multitaskers and men are monotaskers.<br />

I tend to agree with her. That said, to some degree I think she confuses mono·<br />

tasking with a man's desire to be uninterrupted while working on a complex task. To my<br />

way of thinking, the complexity of the custom design and building panels involves inte·<br />

grating several related variables as the fiHlng, fabricating and layout of the panel takes<br />

shape. That sounds like multitasking to'TIPI<br />

For this particular project, we started<br />

with a D'Shannon Aviation panel<br />

kit to get a large shock·mounted<br />

flight panel. a usabte fixed main<br />

panel, gtareshield, and all the floatingpanel<br />

mountings and supports readymade.<br />

In the spirit of retaining some of<br />

the originat classic Beech design, our<br />

plan was to retain the existing piano<br />

keys, wiring, and especially the tower<br />

mounting structure.<br />

Since the D'Shannon panel kit is<br />

designed to replace the piano keys, the<br />

subpanel and related components that<br />

we wanted to retain, our first step is to<br />

cut down the long full panel to fit along<br />

the original lower sub-panel structural<br />

truss located just above the original<br />

piano keys and center quadrant.<br />

I'm a big proponent of mounting<br />

these .090" aluminum panels with structural<br />

8-32 countersunk machine screws<br />

and nut plates. This mounting system<br />

has some distinct advantages, First. the<br />

entire panel can be painted and placarded<br />

outside the airplane, Second, all<br />

wiring and instrument plumbing can be<br />

easily fit, installed, tested and tied up on<br />

the bench, And last, if in the future a<br />

major panel change is planned, the<br />

whole panel can be easily removed.<br />

We have tried building these panels<br />

every way known to man and, regardless<br />

of the type of panel we're bu ilding,<br />

we definitely feel that mounting with<br />

machine screws is the best way to go.<br />

With the new fixed panel cut to fit<br />

the original piano keys and center throt-<br />

tie quadrant, we temporarily cleco this<br />

panel in place, It is then time to confirm<br />

the layout and fit of the customer's<br />

panel design,<br />

Armed with the original panel<br />

drawing made while the customer was<br />

here, and what we call our "six-point<br />

awareness list:' we start to locate the<br />

various components. This list actually<br />

consists of things one must consider<br />

when laying out a new panel.<br />

SIX-POINT AWARENESS LIST<br />

L All structural components must meet<br />

the requirements of FAA AC-4313 lB.<br />

2. All instruments. radios, defrosters,<br />

etc, must clear all controls, structure<br />

and systems.<br />

3. One must provide for electrical<br />

wiring, instrument plumbing, securing<br />

of clamps, etc.<br />

4. Layout all the instruments. switches,<br />

circuit breakers and controls in an<br />

ergonomically correct and intuitive<br />

manner that also includes the<br />

owner's input and priorities.<br />

5. Locate components to ensure that<br />

everything can be seen by the pilot<br />

with little or no parallax. To meet<br />

this very important requirement, the<br />

FAA also has specific limits as to<br />

how far to the left and the right of the<br />

pilot's yoke certain instruments can<br />

be mounted. We call this the primary<br />

cone of vision, It's important to realize<br />

that some electronic screens can<br />

only be seen if you're viewing them<br />

from an almost straight-on angle,<br />

6. Be constantly aware of making the<br />

new panel as maintenance-friendly<br />

as possible, Mounting the whole<br />

thing with machine screws and nut<br />

plates, leaving "work loops" of extra<br />

long wire and plumbing leads allows<br />

instruments and radio stacks to be<br />

pulled out and unhooked from the<br />

front of the panel. Those are just a<br />

few maintenance-friendly and costsaving<br />

features that come to mind.<br />

At this point we need to address an<br />

important structura l issue. Beech<br />

secured the original thin aluminum<br />

instrument panel overlay to the structural<br />

truss that held the piano key switches<br />

with a very minimal al uminum angle. In<br />

the interest of creating additional<br />

The full height D'Shonnon panel, cut 10 accommodate original piano keys and center throttle quadrant.<br />

Page 10982 wwwbonanza,org ABS October 2008

Instrumenl plumbing being installed with Ihe flight panel ouf of the airplane.<br />

strength at this weak point, we add a 1)1"<br />

x W x .125" 20241'3 structural aluminum<br />

angle secured to the original structure<br />

with both cherry max rivets and machine<br />

screws. This will ensure lots of structural<br />

integrity between the new panel and the<br />

original lower panel truss.<br />

With the structural mountings in<br />

place we can temporarily install the hardmounted<br />

fixed panel, shock-mounted<br />

!light panel, defroster and glareshield.<br />

MULTITASKING BEGINS<br />

We begin by having every component<br />

on hand and holding each instrument,<br />

radio, dust cover and defroster<br />

hose in their respective locations, making<br />

sure all six contingencies on our<br />

multitasking list are mel. As we made<br />

our way through this process on the<br />

panel, two very critical problems presented<br />

themselves.<br />

First was that the Garmin 530<br />

would have to be high enough in the<br />

center of the main fixed panel to clear<br />

the behind-the-panel radius scissors<br />

comrol linkage. This meant that we<br />

would be able to mount only the two<br />

3 ~" tach and manifold-pressure gauges<br />

above this large screen. It was possible<br />

to build the whole panel taller, but we<br />

had initially sat customer Rob in the<br />

pilot's seat to determine the maximum<br />

height that he would be comfortable<br />

with. Well, we had to cheat a little as it<br />

was, so after several phone conferences<br />

we decided to give up on the original<br />

design concept and move in the direction<br />

of one long single row of engine<br />

instruments located above a shortened<br />

radio stack.<br />

A second complication in this<br />

design change involved the original<br />

non-sloped windshield structure. As<br />

built, the location of the M35 nonsloped<br />

windshield lower hat structure<br />

allows for about 10" clearance between<br />

the top of the new panel and this<br />

immovable hat section. Here is the frustrating<br />

part - we needed I OX". So that<br />

eliminated our idea of mounting the 530<br />

close to the top of the center section of<br />

the fixed panel.<br />

Stronger mounting angle and nut plates (pilot's side).<br />

Copilot lower panel mounting angle and nut plates.<br />

ABS October 2008<br />

www.bonanza.org<br />

Page 10983

Always leave enough space between (omponents to allow for the option of a future replacement of an instrument with one made by a<br />

different manufacturer. As hard as the industry has tried to standardize the dimensions of these instruments, variations do occur.<br />

The other consideration that had to<br />

be included in this fitting process was<br />

the glareshield. Initially, in the classic<br />

spirit of this project, we wanted to retain<br />

the original non-sloped two-piece windshield.<br />

[t soon became obvious that with<br />

the additional height of the new panel,<br />

the glareshield-to-windshield clearance<br />

could be an issue.<br />

Since we were pushing the dimensional<br />

envelope in almost every direction,<br />

our Plan B was to install a speed-sloped<br />

windshield conversion. The sloped windshield<br />

modification does move the windshield<br />

forward enough to give us the<br />

glareshield clearance we needed. But we<br />

sti ll had to extensively modify the speedsloped<br />

windshield glareshield. More on<br />

that later. .. (One must always be prepared<br />

to compromise.)<br />

FINAL LAYOUT OF COMPONENTS<br />

With the glareshield issues<br />

resolved, it was time to start the final<br />

layout of the instrument and component<br />

locations. We started by laying the new<br />

panel components flat on a workbench<br />

and physically positioning the various<br />

instrument templates on the surface of<br />

the new panel. We are very careful to<br />

check for behind-the-panel spacing, as<br />

well as lateral and vertical clearance<br />

between each instrument.<br />

Here's something else to factor into<br />

this layout process: Always leave<br />

enough space between components to<br />

allow for the option of a future replacement<br />

of an instrument with one made by<br />

a different manufacturer. As hard as the<br />

industry has tried to standardize the<br />

dimensions of these instruments, variations<br />

do occur.<br />

In light of this reality, I would<br />

allow an extra W of clearance on all<br />

sides of every instrument. Horizons and<br />

directional gyros are of particular concern.<br />

What if you decide 10 replace a<br />

directional gyro with an HS[" Most<br />

HSls are larger than a directional gyro.<br />

Extra clearance can save the day.<br />

Limited clearance between the upper fixed panel and the original windshield frame.<br />

Not enough clearance for the gloreshield and the non-sloped windshield.<br />

Using precision cui instrument paNerns to accurately layout the fixed panel.<br />

Page 10984<br />

www.bononzo.org ABS October 2008

USEFUL TIP: Nel'er throw alii all old<br />

illstmlllent pallel. We Clll them lip to<br />

create accurate illstrument alld pallel<br />

compollent telllplates. The old holes are<br />

already perfectly Clll, so al/ aile lIeeds 10<br />

Precision instrument patterns cut out of on old panel.<br />

I<br />

do is LIse the instrumelll as a template 10<br />

outlille the compollent's footprint. lVith<br />

this perfect pattem, just shear alollg the<br />

scribe lille alld "Voila!" you have a<br />

precisioll pattem of the cOlllpollents.<br />

ffi68<br />

/'<br />

· ~-.:t · ---~ .. ~ I,<br />

l .,&.· • ..- 1 ~ .".,<br />

-ffiI l_y~LY. L') - j-' E) 8@<br />

I IA~I..i(!..A<br />

I = ~'*'<br />

--ElJ rl~~'''Yi~ ... ~ i<br />

. ~ I-{--l H ·r:L · _· t(~-+ !>So><br />

After a couple days of measuring,<br />

moving and phone confereneing, we<br />

had a design that Rob liked and that<br />

functioned for him. As [ stated earlier in<br />

this series, this was a very nonstandard<br />

installation. We had to do a lot of, as we<br />

say in the business, "cutting to fit and<br />

wiring to work."<br />

SOME SPECIAL DETAILS<br />

The layout of the shock-mounted<br />

flight panel was fairly straightforward.<br />

The only unique detail was locating the<br />

switching panel above the horizon,<br />

something we had done several times<br />

because many owners like having the<br />

marker beacon and radio switching right<br />

up front. This also helps keep the height<br />

of the traditional canted radio stack as<br />

low as possible. We also cut holes for<br />

the future installation of an electric<br />

backup horizon and eircuit breaker.<br />

[n the fixed panel below the shockmounted<br />

flight panel, we installed (from<br />

left to right) the radio master switch; a<br />

backup avionics buss tie circuit breaker<br />

that can be pushed close to supply power<br />

to the avionics buss in the event of a radio<br />

master-switch failure; and then the<br />

autopilot and electric trim power switch.<br />

Finally, we installed the glareshield<br />

lights rheostat and selector switch.<br />

I O""!...6~!..i( l "..t ' +,0 '). _. I<br />

X '*' ~'*' ,<br />

7.::- i "\ Y i ~ ~ "'\ r i ~<br />

:i

Primary radio and glareshield lighting controls and avionics breakers.<br />

Another switching detail worth<br />

doing is to convert an unused piano key<br />

to the pitot heat switch. I have never<br />

understood why Beech installed the<br />

pitot heat switch in a little add-on bracket<br />

stuck below the subpanel truss.<br />

As panel layout and fitting projects<br />

go, this one had its issues. I feel the<br />

results are worth the effort and Rob got<br />

everything he wanted. The result was a<br />

panel where all the flight instruments<br />

are where they should be; his primary<br />

nav screen as close to the flight instruments<br />

as possible; all the engine and<br />

fuel gauges logically located in one<br />

place; and the electrical and vacuum<br />

monitors right in his basic lFR scan.<br />

Included was a pullable circuit breaker<br />

for each electrical circuit, logically laid<br />

out in an easy-to-access panel, plus<br />

future spaces for additional breakers<br />

and switches.<br />

CUTIING HOLES<br />

With the panel layout confirmed, it<br />

was now time to begin the process of<br />

cutting all the radio and instrument<br />

holes. In the good old days, we would<br />

cut these holes with fly cutters and files.<br />

Today, it's a whole new world. We partner<br />

with Cincinnati Avionics on panel<br />

projects, and have them create a very<br />

accurate computer-generated drawing<br />

of the entire panel.<br />

After the drawing is approved by<br />

the customer, this data is loaded into a<br />

numerically controlled milling machine<br />

that will magically machine-cut perfect<br />

holes. This process increases quality,<br />

saves time and money, and looks great.<br />

Another advantage of this computercontrolled<br />

system is that it allows us to<br />

quickly make a test-cut in .040" aluminum<br />

to confirm any tight clearances<br />

we may encounter.<br />

All the moin ship's buss circUIt breakers are laid oul in one accessible location.<br />

MORE TO COME<br />

While the panel drawing and cutting<br />

is being done, we continue with<br />

wiring, plumbing and insulating, which<br />

will be covered in detail in the next segment.<br />

Until then, fly safe!<br />

Dennis Wolter is an A&P, IA and a 3.000-<br />

hour instrument pilot who started Air<br />

Mod in 1973 to bring innovative design<br />

and high

Landing gear issues<br />

I am the proud new owner of a<br />

1963 P35. I am writing to report how<br />

glad I am that I anended the May ABS<br />

ASF Service Cli nic in Madera,<br />

California. Technician Bob Olson<br />

ca lled my attention to a problem in the<br />

landing-gear motor assembly. The<br />

emergency crank handle had very liule<br />

play left, which means the gear was<br />

coming to rest against the stop of the<br />

sector gear. I was advised to have it<br />

overhauled soon.<br />

I did the annual and in the process<br />

had the landing-gear motor and actuator<br />

assembly overhauled at Cruiseair<br />

Aviation at Ramona. It had been about<br />

500 hours since the last overhaul, so it<br />

was definitely time.<br />

Cruiseair did an incredible job. I<br />

can certai nly recommend their work.<br />

They also took the time to explain what<br />

I should be on the lookout for in the<br />

future. Their customer service was<br />

excellent.<br />

Once the actuator and motor<br />

assembly were put back in by my own<br />

mechanic, it was time to rerig everything.<br />

We did uncover a differe nt problem:<br />

The inner landing-gear doors were<br />

slightly tweaked, probably as a result<br />

of someone putting the gear down at<br />

too high a speed.<br />

When we hand-cranked it until the<br />

microswitches engaged, the front edges<br />

of the doors were sti LI open about a<br />

quarter inch. My guess is that the<br />

microswitches had been adjusted to<br />

have the motor pu ll just a linle longer 10<br />

get the doors completely closed. This is<br />

the wrong fix, obviously. The doors<br />

must be straightened to fit properly<br />

without tension. Stopping the motor<br />

later puts it closer or against the stop of<br />

the sector gear, which could damage it<br />

from percussive force on the stop.<br />

The other danger is that it puts<br />

more tension between the wonn gear<br />

and the sector gear and this will either<br />

bend the worm gear, or both the sector<br />

gear and the wonn gear will wear out<br />

prematurely.<br />

Now that the motor and actuator<br />

have been overhauled, the doors<br />

straightened and all the rigging adjusted,<br />

everything works we ll and has the<br />

proper amount of play left on the<br />

crank. The moral of the story is to<br />

check the al ignment of the gear doors<br />

while checking the amount of travel on<br />

the actuator assembly. It might have<br />

been intentionally adjusted to fix the<br />

wrong problem.<br />

Apparently, landing gear issues<br />

like this are becoming more evident as<br />

our aircraft age. I wanted to share my<br />

own experience, potentially to save<br />

others some headache.<br />

-Marc Zorn<br />

Sherman Oaks, California<br />

Cowling light bulb<br />

In the August Tech Tips, Jonathan<br />

Budd, Richmond Hill, Ontario, complains<br />

that his cowling landing light<br />

bulb keeps go ing out. ABS Tech consultant<br />

Bob Andrews recommended the<br />

Arrow Light or the Knots 2 U as a fi x,<br />

but he didn't mention the Beechcraft<br />

Landing Light Assembly Improvement<br />

Kit (36-4016-00 I).<br />

As I recall, that kit was reasonably<br />

priced and used rubber shock mounts<br />

like the ones on instrument panels. The<br />

instructions were a linle confusing, but<br />

I eventually managed to get it installed.<br />

The kit seems to work we ll , but then I<br />

didn't have an unusually short life with<br />

my nose cowl light after turning the filament<br />

to the vertical.<br />

- Tim Brown<br />

Midlothian, Texas<br />

Appreciation for ABS<br />

I just rejoined ABS in March<br />

2008. In 2004 we sold our wonderful<br />

1968 Model 36 and acquired a pressurized<br />

Piper Aerostar. During the time we<br />

new the Aerostar, we were members of<br />

its national association, a great group<br />

of pilots and staff.<br />

I had been a member of ABS for<br />

more than 25 years; in fact , I had<br />

helped stan the Pacific <strong>Bonanza</strong><br />

<strong>Society</strong>. I am the former owner of<br />

Pe/formance Aero, the well-known<br />

Beechcraft parts and accessories firm<br />

that has a two-page ce nterfold ad in<br />

each ABS Maga zine.<br />

I just want to say to you, the ABS<br />

staff, board of directors and technical<br />

advi sors, how grateful I am to have<br />

recently acquired our beloved Model<br />

36 (£-70 N707WG) and to experience<br />

the remarkable and significant work<br />

that the aforementioned people perform<br />

for the ABS membership.<br />

ASS has always been the premier<br />

GA owners association, both nationally<br />

and internationally, in my opinion.<br />

What has really become more evident<br />

10 me is that despite the obvious stress<br />

and pressures on GA aircraft owners<br />

and service providers in recent years,<br />

ABS presently provides more meaningfu<br />

l services to its members than at<br />

any other time in its history.<br />

The magazi ne conte nt has been<br />

taken to an even higher level since I<br />

last viewed it in 2005. The technical<br />

anicles, photos and graphics ... and<br />

member notifications are consistently<br />

first-rate. The ABS-ASF Service<br />

Clinics, BPPP clinics and ABS Aviator<br />

program continue to set the standard<br />

for the industry.<br />

I just received the August 2008<br />

issue and want to also say how appropriate<br />

I feel it was to commemorate<br />

John Miller's passing with a cover<br />

photo and prominent farewe ll story.<br />

Having been away for nearly four<br />

years, I sincerely appreciate everyone's<br />

contributions to ABS. It's great to be<br />

back!<br />

-Gory J. Boker<br />

Reno, Nevada<br />

Send your letters of recommendotion,<br />

warnings, or odvice to fellow<br />

members to absmail@bonanza.org.

POWERPLANT 112:<br />

FUEL FLOW<br />

AT TAKEOFF<br />

One of the biggest reosons cylinders<br />

fail to go the distance is<br />

insufficient fuel flow at takeoff. Is<br />

yours set high enough<br />

Premature cylinder problems are<br />

epidemic. Hardly a day goes by<br />

that I don't hear or read about a<br />

<strong>Bonanza</strong> or Baron owner having to pull<br />

one or several cylinders at annual due to<br />

poor compression, with leakage past the<br />

exhaust valve. More often than not the<br />

afflicted airplane is powered by a fuelinjected<br />

TCM engine.<br />

The cause of this epidemic seems<br />

to be the confluence of several contributing<br />

factors. TCM apparently had<br />

some manufacturing problems during<br />

the late 1990s and early 2000s that<br />

resulted in less-than-perfect valve-toseat<br />

concentricity. (I think they 've fixed<br />

this problem in current production,<br />

although it's hard to be sure yet.)<br />

Also, maintenance shops and<br />

mechanics have been slow to adopt the<br />

guidance TCM issued in SB03-3 urging<br />

A&Ps not to pull cylinders due 10 low<br />

TELEDYNE CONTINENTAL ® AIRCRAFT ENGINE<br />

compression without performing a<br />

borescope inspection and identifying<br />

the cause of the low compression.<br />

Although it's been five years since TCM<br />

issued that Service Bulletin. I'd guess<br />

that about half the shops that work on<br />

piston-powered GA aircraft still are not<br />

performing regular borescope inspections.<br />

As a result, we're still seeing a lot<br />

of cylinders pulled unnecessarily.<br />

But I think one of the biggest factors<br />

contributing to early cylinder<br />

demise results from insufficient fuel<br />

flow at takeoff. These engines require a<br />

very, very rich mixture to avoid excessive<br />

combustion temperatures and pressures<br />

at full takeoff power. [f the mixture<br />

isn't rich enough, the cylinder<br />

assemblies will suffer- panicularly the<br />

exhaust valves.<br />

How much fuel flow<br />

If you ask pi lots "How much fuel<br />

flow is enough at takeoff," most would<br />

make reference to the POH or the topof-the-green<br />

on the fuel flow gauge. In<br />

fact, I've seen many pilots actually<br />

adjust the mixture control on takeoff to<br />

reduce fuel flow because the fuel flow<br />

needle was flirting with the red line.<br />

This is /lot a good idea.<br />

SERVICE INFORMATION DIRECTIVE<br />

Compliance Will Enhance Safety, Maintenance or Economy Of<br />

Operation<br />

SUBJECT: PROCEDURES AND SPECIFICATIONS FOR ADJUSTMENT<br />

OF TELEDYNE CONTINENTAL MOTORS (rCM)<br />

CONTINUOUS FLOW FtJEL INJECTION SYSTEMS.<br />

PURPOSE:<br />

I CATEGORY 4 I<br />

SID97-3E<br />

Technical Portions<br />

FAA APPROVED<br />

SUPERSEDES M73-22, M8~-10 .<br />

M92·17. 51098-10A,51097-3,<br />

SI[)g7·3A, 51097·38, SIOg7.JC<br />

and 51097·30,<br />

Provide procedures and specifications for the adjustment of Teledyne Continental<br />

Motors (reM) fuel injeclion systems.<br />

COMPLIANCE: At Engine Installalion. 100 hour/Annual Inspection. fuel system component<br />

replacement or as required if operation is not within specificalions.<br />

MODELS<br />

AFFECTED:<br />

All TCM continuous flow fuel injected engine models except 10-240-8 wI Bypass<br />

Fuel System: urSIO-360-RB: TSIO-520-L, LB, WB: GTSIO-520,F, K, N and<br />

GIO-550-A Engine Models.<br />

Figure 1 - SID97-3E is the bible for setting up fuel News on reM fuel-injected engines. 97·3E is linked from Members<br />

Only 01 W'IM.bonanzo.org.<br />

EDITOR'S NOTE: This is /lot to be<br />

eOllfused with properly lea/li/lg /lormally<br />

aspirated engilles as /leeessary for<br />

takeoff at elevatiollS above sea level.<br />

Fuel flow at takeoff is like tire pressure:<br />

too much is better than too little. A<br />

little excess fuel flow on takeoff might<br />

reduce takeoff power by a couple of<br />

percents, but a little shonfaLl can overstress<br />

the engine and fry the exhaust<br />

valves in shon order. I'd much rather<br />

see takeoff fuel flow a tad over redline<br />

than significantly below it.<br />

The "gold standard" for adjusting<br />

fue l flow on fuel-injected TCM engines<br />

is a 39-page Service Bulletin called<br />

SlD97-3E. It's one that every <strong>Bonanza</strong> or<br />

Baron owner should be familiar with.<br />

You can download your own personal<br />

copy of this irnp0l1ant document from<br />

the TCM website at hnp:llwww.tcmlink.<br />

com/pdf2/SlD97-3E.pdf.<br />

[f you look at the preamble of<br />

SlD97-3E (Figure I), you'll see that<br />

TCM recommends adjusting the fuel<br />

system at initial engine installation, at<br />

every annual or lOO-hour inspection,<br />

any time a fuel system component is<br />

replaced, and any time fuel flow seems<br />

to have drifted off-spec. Hardly any<br />

shops actually do this routinely at annual<br />

inspection , but that is<br />

TCM's recommendation.<br />

About half of SlD97-<br />

3E's 39 pages are devoted<br />

to tables of fuel-flow specifications<br />

for every model of<br />

fuel-injected TCM engine.<br />

I've extracted the specs for<br />

the fuel-injected engines<br />

most commonly found<br />

in <strong>Bonanza</strong>s and Barons.<br />

(Figure 2)<br />

For example, if you<br />

have a <strong>Bonanza</strong> with an [0-<br />

S20-BA engine, the table<br />

calls for full-power fuel flow<br />

(standard day, sea level ,<br />

2,700 rpm) to be 23.2 to 24.9

TABLE 3. Fuel System Adjustment Values<br />

IDLE AND FULL POWER FUEL PRESSURES AND FLOWS<br />

ENGINE Prop. RPM & Unmetered Metered Fuellbslhr Fuel gal/hr<br />

SEE OTE7 (MAP) Pump PSI ozzle PSI<br />

-<br />

(NOTE 3) (NOTE 4) (NOTE 5) (NOTE 6)<br />

I0-470-D, E, F, H 600 ~ -11.0 - -<br />

L, M, N, S, U 2625 25 . 0-~ 15.0 - 17.5 124 -[ITIJ 21.1 - 122.31<br />

IO-520-B, BA, 600 (3[Q} 11.0 - -<br />

BB C, CB<br />

*<br />

2700 28.0 -ill]] 14.9 - 17.2 136 - 11461 23.2 -124.9)<br />

600 ([Q]- 10.0 - -<br />

IO-550-B<br />

TSIO-520-UB<br />

3CI(\<br />

300<br />

2700 29.2 -136.2 1 16.5 - 18.4 146 - 1561 24.9 -126.61<br />

600 (DI- 6.5 - -<br />

2700 33.0 -137.01 14.4 - 16.0 195 -12051 33 .2 -134.9 1<br />

(36.0)<br />

600 25 - Minimum - - -<br />

TSIO-520-L, LB<br />

3101<br />

SEE NOTE 1 2700 45.0 -155.01 - 180 -11901 30.7 -132.41<br />

(38.0)<br />

TSIO-520-WB 600 25 - Minimum - - -<br />

SEE NOTE 1<br />

~<br />

2700 45.0 -155.01 - 190 -1200) 32.4 -134.1)<br />

(39.5)<br />

Figure 2 - Here ore the SID97-3E fuel·flow specs for the most common <strong>Bonanza</strong> and Boron engines. The system should be adjusted to achieve the red-boxed values.<br />

Use the actual bulletin for determining pressures and flows. The notes indicated in Figure 2 ore found in SID97-3E.<br />

gph, or equivalently 136 to 146 PPH. It<br />

also calls for unmetered fuel pressure at<br />

idle (600 rpm) to be 9.0 to 11 .0 psi.<br />

Read the fine print<br />

Many A&Ps interpret this to mean<br />

that any fuel flow va lue within that<br />

range is OK, but in fact that's not quite<br />

right. If you read the fine print of<br />

SID97-3E, you'll find a couple of very<br />

imponant notes that mechanics often<br />

miss. Here's one:<br />

NOTE: To ensure optimum coaling during<br />

FULL POWER operations. the FULL POWER<br />

fuel flow should be set to the maximum<br />

specification limit.<br />

In other words, the 10-520-BA fuel<br />

system should be set up to produce 24.9<br />

gph or 146 PPH at takeoff- and anything<br />

less wi ll compromise cooling and<br />

cylinder longevity. That typically translates<br />

to a fuel-flow indication right at<br />

redline on the fuel-flow gauge. (In my<br />

experience, it's not a bad idea to adjust<br />

the system 0.5 gph or 6 PPH higher, just<br />

for a bit of extra cushion .)<br />

Here's another imporlaJ1l note<br />

that's often missed:<br />

NOTE: Maximum port· throttle full·rich fuel<br />

flow will be achieved by seHing the idle<br />

rpm (low) unmetered fuel·pump pressure<br />

to the minimum volue specified.<br />

So not only is it imponant to adjust<br />

full-power fuel flow to the maxi mum<br />

limit, but it's also imponant to adjust<br />

idle-power fuel flow to the minimum<br />

limit (9.0 psi in the case of the 10-520-<br />

BA). Only by adjusting the system this<br />

way can you be sure of getting sufficient<br />

fuel flow at pan-throttle settings.<br />

Aftermarket alterations<br />

Finally, there's the sticky issue of<br />

how to adjust fuel flow for engines that<br />

have been modified with aftermarket<br />

alterations like Gamijectors and turbonormalizers.

Here's what SlD97-3E has to say<br />

on that subj ect:<br />

The setup procedures contained in this<br />

bulletin are only for use on engines that<br />

have not been modified from their original<br />

configuration as shipped from the factory<br />

by Teledyne Continental Motors.<br />

Engines which have been modified by the<br />

installation of aHermarket components<br />

such as turbonormolizing systems. turbocharging<br />

systems. intercoolers. aHercoolers.<br />

fuel nozzles. etc. whether by STC<br />

or field approval. must use the instructions<br />

provided by the STC holder or<br />

installer. TCM will not accept any responsibility<br />

or liability for any modified engine<br />

set up in accordance with procedures<br />

contained in this Service Information<br />

Directive.<br />

In other words, TCM says "Follow<br />

the STC-holder's instructions."<br />

Unfortunately, some STCs do not provide<br />

guidance for fuel-system setup,<br />

which leaves the owner and mechanic<br />

pretty much on their own.<br />

A quick sanity check<br />

If you don't have your copy of<br />

SID97-3E handy, here's a quick rule of<br />

thumb you can use:<br />

• For a normally aspirated fuelinjected<br />

engine designed to run on 100-<br />

octane fuel (8 .5-to- 1 compression<br />

ratio), takeoff power fuel fl ow in gph<br />

should be roughly 9% of the engine's<br />

maximum rated horsepower. (For example,<br />

an 10-520 rated at 285 hp should<br />

flow about 25 to 26 gph.)<br />

• For a factory-turbocharged engine<br />

(7.5-to- l compression ratio), takeoff power<br />

fuel flow in gph should be roughly 10.5%<br />

of the engine's maximum rated horsepower.<br />

(For example, a TS10-520 rated 310 hp<br />

should flow about 32 to 33 gph.)<br />

This rule of thumb isn't as precise<br />

as looking it up in SID97-3E, but it'll at<br />

least make sure you're in the ballpark.<br />

After reading this column, if you<br />

have even the slightest doubt about<br />

whether your takeoff fuel flow is adequate,<br />

get it adjusted-and make sure<br />

you tell your mechanic that you'd like it<br />

to be on the high side. The life you save<br />

may be your own ... cylinders!<br />

E-mail questions to<br />

mi ke. busch@savvyaviator.com.<br />

Mike Busch is on A&P /lA. A pilot for 40+<br />

years with 7,()()() hours, M ike has been an<br />

a ircraft owner and CFI for 35+ years.<br />

Hundreds of his aviation-related technica<br />

l articles have been published. He was<br />

cofounder and editor-In-chief of AVweb.<br />

Mike's weekend ' Savvy Owner Seminars·<br />

focus on better aircraft ma intenance<br />

while spending a lot less. He wa s named<br />

FAA's 2008 AMT of the Yeor.<br />

SID97-3E says: "Engines which have been modified by the installation of aftermarket components such as turbonormalizing<br />

systems. turbocharging systems. intercoolers. after-coolers. fuel nozzles. etc. whether by STC or field approval.<br />

must use the instructions provided by the STC holder or installer. TCM will not accept any responsibility or liability for<br />

any modified engine set up in accordonce with procedures contained in this Service Information Directive.'<br />

: What's the difference between<br />

a $10)000 annual and a $3)500 annual<br />

'"SAMM saved me $7,500 on my recent annual inspection. I am a<br />

periodontist by occupation, and I don't have a lot of time to deal<br />

with a service center between patients. In the past, every annual<br />

inspection was a stressful event. SAMM has been a winner for<br />

me'" -Rik Vanooteghem DDS MS<br />

A:<br />

-My SAMM account manager handled everything. I got my annual<br />

done according to the estimate, with no hassle. It was least<br />

expensive annual I've ever had. I saved several times what I paid<br />

SAMM for the whole year, just in reduced cost for my annual!<br />

Obviously I'm happy with this new service." -Gordon Feingold<br />

-sAMM saved me $6,000 on my annual. It has been a pleasure<br />

working with you guys. "-Jerry Bock MD<br />

-Recently, while on vacation in Montana, my airplane experienced<br />

an alternator failure. I contacted my SAMM account manager.<br />

and he took care of the problem with the local repair facility,<br />

while I was able to go about my vacation and enjoy myself<br />

Not only did SAMM save me a bundle, but also allowed me the<br />

freedom to know that the plane was being repaired. properly by a<br />

shop and mechanics I didn't know. SAMM is worth it's weight In<br />

soIdr -Steve Carvajal<br />

"Mike Busch correctly diagnosed my engine problem after<br />

reviewing data from my engine monitor. After I signed up<br />

with SAMM, I had the work performed that Mike suggested.<br />

The original estimate from my service center was $1,965.10,<br />

but under SAMM's management the final invoice was just<br />

s8n.93. SAMM saved me over $1,000.00 on this one maintenance<br />

task, more than paying for my $750.00 SAMM management<br />

fee for the next 12 months. I suspect 1 will see the same<br />

kind of savings throughout the year and during the an nual<br />

inspection !" - Barry Lerman<br />

"Only an idiot or masochist (or both) could miss the value of<br />

what you offer."- JeffHarris<br />

Mike Busch's aircraft<br />

~ maintenanoe<br />

Page 10990 www. bononzo.org ABS October 2008

MEDICAL CERTIFICATION<br />

NUMBER CRUNCHING<br />

AcouPle of days after returning from Oshkosh, I went<br />

to Washington, D.C., for my compulsory FAA<br />

Aviation Medical Examiner (AME) seminar. AMEs<br />

are required to attend such a seminar every three years. A<br />

computer learni ng and testing program may be substituted<br />

for one seminar, but we must personally attend an FAA-sponsored<br />

AME program every six years.<br />

The live programs provide a great deal of useful information.<br />

Many of them are called "theme" seminars and the<br />

one I attended had a cardiology<br />

theme. This program put emphasis<br />

on topics of medical certification<br />

dealing with the heart and<br />

vascular system. A lot of in fOrtnation<br />

and statistics was di spensed<br />

over 20 hours.<br />

Here are some points from<br />

that meeting that I think you<br />

might find of interest:<br />

There are 4,097 AMEs, 48%<br />

of AMEs are pilots, 7% of AMEs<br />

are female. AMEs are located in Regions, with the Southern<br />

Region the largest and Alaska the smallest.<br />

Fifty percent of AMEs are senior AMEs i.e. those who<br />

can perfortn Class I exams. All international AMEs are<br />

Senior AMEs, to be available for air-transport pilots out of<br />

country.<br />

AMEs come from many medical disciplines. Family<br />

Medicine physicians are the largest group, comprising about<br />

half of all AMEs.<br />

The number of AME exams given in 2007 was 426,182.<br />

You might look at exams divided by AMEs and surmise that<br />

each AME does about 100 exams per year. Wrong. Fifty percent<br />

of AMEs do less than 50 exams per year; 25% do 50 to<br />

250 exams per year. As with any such statistical curve, there<br />

are some out there doing very few and some doing a bunch!<br />

The Aerospace Medical Certification Division (AMCD)<br />

receives about 1,700 exams per day. Of nearly 430,000<br />

exams done annually, only 624 final denials were issued.<br />

That is about one-tenth of one percent.<br />

A word of explanation is needed on the tertn "denial." If<br />

Airtnan X goes to his AME and has recently had a disqualifying<br />

condition- let 's say a recent coronary bypass surgery-the<br />

AME will defer that medical certification to the<br />

AMCD and the pilot will receive a letter asking for more<br />

information that AMCD deems necessary to make a decision<br />

if the airman can receive a special issuance for the disqualifying<br />

condition. If the airtnan provides that infortnation and<br />

the AM CD issues the certificate, there was an "initial"<br />

denial .. . but not a "final" denial.<br />

There were 5,909 initial denials in 2007 of which only<br />

624 were "final." The positive take-home lesson here is that<br />

even though there are situations where the airman just cannot<br />

qualify, most pilots, providing the proper documentation, can<br />

maintain a certificate.<br />

It is anticipated that by 2025 there will be three times the<br />

aircraft and airmen flying. If this turns out to be true, the<br />

AMCD hopes to expand the AME-assisted special issuance<br />

program (AASI) that aUows AMEs to reissue certificates for<br />

certain conditions after initial special<br />

issuance by the AMCD.<br />

Presently there are 25 such conditions.<br />

This speeds the specialissuance<br />

recertification process<br />

for the airman.<br />

New certification news<br />

For pilots under 40, first-class<br />

certificates are valid for 12<br />

months and third-class certificates<br />

for five years (60 months). These<br />

new rulings are retroactive, i.e. if you had your last thirdclass<br />

exam at age 36 in August 2004 and you did not go back<br />

to renew your certificate at age 39 (August 2007, three years<br />

under the old rule), and you have not been flying because<br />

your medical expired, you now have a valid medical again<br />

(until August 2009).<br />

How 'bout that! Good news for the under-40 crowd. Of<br />

course if, at any time, you have been diagnosed with a disqualifying<br />

condition, Part 61.53 of the FARs required you to<br />

not exercise your airtnan privileges.<br />

Last tidbit: The average age of AMEs is 58 years old. At<br />

the meeting they recognized several AMEs for more than 40<br />

years of service. Looks like being an AME may be good for<br />

longevity. I certainly hope so ...<br />

Charles S. Davidson, M.D .. hold s board certification in family<br />

medicine and emergency medicine. He has been an a viation<br />

medical examiner since 1978 a nd serves as a senior AME . He<br />

holds a commercia l pilot license with mulfiengine and instrument<br />

roting. He is an active pilot using general aviation for<br />

business a nd pleasure for 23 years. He is a member of the ABS<br />

Boord of Directors a nd serves on the Executive Committee. He<br />

flies on A36.<br />

This column is intended as general information only for the ASS<br />

membership; it should not be construed as providing medicol<br />

advice or creoting a doctor-patient relationship. Consult your own<br />

doctor for personal advice or your AME for aeromedical advice.

Correcting rigging<br />

Garrett Rose, Bend. Oregon<br />

Q: [recently purchased a 1979 E55.<br />

When I went for a prepurchase test<br />

flight, the plane flew straight. After [<br />

purchased the aircraft, [ had factory<br />

remans installed. My mechanic noticed<br />

that both the aileron and elevator cable<br />

tensions were quite loose so he rigged<br />

them to the Beech Service Manual<br />

specs. He did not adjust the flaps. Now<br />

the planes flies left-wing heavy.<br />

To be able to fly wings level, I have<br />

to input about a quarter tum to the right<br />

on the yoke. To fly hands-off, [ tum the<br />

aileron trim all the way to the right. I<br />

have not found anything in the service<br />

manual that addresses a wing-heavy<br />

issue. The airplane was recently weighed<br />

and there was only a 20-pound difference<br />

between the right and left sides.<br />

A: The first thing [ would look at is<br />

the static rigging of the aircraft. When<br />

rigged correctly, the trailing edge of the<br />

flaps should be even with the bottom of<br />

the fuselage and then the ailerons<br />

should be rigged so they are even with<br />

the flaps and not the wing tip, and the<br />

control wheel centered.<br />

Look at the elevators to see if they<br />

are even in the neutral position. If not,<br />

you will need to rig the elevator system<br />

as per the maintenance manual. In addition,<br />

make sure the aileron trim tab in<br />

neutral matches the trim indicator.<br />

Check your elevator trim tabs in the<br />

neutral position to see if they also agree<br />

with the indicator. -BR<br />

Elevator skin crack<br />

Eric Bale, Madison, Alabama<br />

Q: [have a Baron 58. On the topside<br />

ofthe RH elevator, there is a 1.75" crack<br />

in the elevator skin emanating from the<br />

outboard comer radius of the trim tab<br />

cutout area. 1 have stop-drilled the crack<br />

and it has not grown.<br />

[ cannot find any inspection or<br />

repair data in my Beech service manuals<br />

for this area. [s stop-drilling acceptable<br />

The repair shop I called claimed that 1<br />

must reskin the entire elevator.<br />

A: There are no published approved<br />

repairs to the elevator skins. We tend to<br />

support the reskinning approach. We<br />

have seen some patches in that area, but<br />

none with approval paperwork. -NP<br />

Adjusting wing angle<br />

Barry Beaver. Shelby. North Carolina<br />

Q: [ have a 1960 M35. After the rig<br />

adjustment, the yoke is to the left at 8 and<br />

2 o'clock. The right aileron is I" below<br />

the flap edge in flight. The ball is 114 right<br />

of center. On the ground, yokes are<br />

straight across 9 and 3 o'clock and the<br />

ailerons are level. But in flight it changes.<br />

I had a shop use the rigging tools<br />

and they stated the plane is balanced.<br />

Could this be a wing-adjustment problem<br />

On the previous attempt, the<br />

mechanic did move the chain one<br />

sprocket to the left. Also the current shop<br />

told me there isn't any wing adjustment,<br />

but I think there is.<br />

A: Yes, the wing angle of incidence<br />

can be adjusted slightly. I doubt that<br />

needs to be done though, since many<br />

other maintenance activities could have<br />

caused the problem, such as during the<br />

completion of an AD note, or checking<br />

the rudder rods for corrosion. Many<br />

times they were off a turn or so going<br />

back together and that can attempt to<br />

roll the airplane. A good rigging shop,<br />

Kalamazoo Aircraft in MiChigan (269-<br />

381 -0790), ntight come out to help your<br />

mechanic. - NP<br />

V-Tail elevator hinge play<br />

AI Boyce. Coronado, California<br />

Q: During an ABS-ASF Service<br />

Clinic inspection, Bob Olson found<br />

excessive wear in the left middle hinge<br />

bearing on my K35. I asked to have the<br />

bearing replaced during its annual<br />

inspection to correct the play. They did<br />

so, but did not replace the elevator hinge<br />

bracket, which now seems to me should<br />

have also been done when the elevator<br />

was off.<br />

I find there is sti ll as much radial<br />

play at that middle hinge. Upon close<br />

in spec ti on, movement can be seen<br />

between the hinge bracket (PIN 35-<br />

650122-8) and the attaching AN23-14<br />

bolt, as though the holes in the bracket<br />

are elongated.<br />

I figured that new ntiddIe and outboard<br />

hinge brackets should be<br />

installed, so I ordered the parts from<br />

RAPID along with new AN23-14 bolts.<br />

I was surprised to find that when the<br />

new bolts were inserted into the bracket<br />

holes, the fit was not close and probably<br />

there is now as much playas in the original<br />

bracket.<br />

When J questioned the shop that<br />

installed the new bearing, they said that<br />

the AN23-14 should be tightened down<br />

against the "spacer" (which I assume is<br />

the bearing) to stop the movement. That<br />

would mean pinching the ears of the<br />

hinge bracket against the new bearing.<br />

This does not seem right to me, but<br />

since the new brackets from RAPID<br />

have a loose fit with the A 23 bolts,<br />

maybe that'S the way the installation<br />

was designed. What is the proper<br />

method for that installation<br />

It seems to me that the new brackets<br />

from RAPID should have a close fit<br />

with new AN23-14 attaching bolts, but<br />

they don't. Is it due to bad parts For<br />

safety's sake I'd like to get that movement<br />

out of the hinge assembly, so I'd<br />

appreciate some guidance.<br />

A: We believe that the looseness<br />

experienced with new parts is excessive<br />

and we have repeatedly complained to<br />

Hawker Beechcraft upper-level people<br />

about it. The advice we give is that if<br />

you can feel the play but not see it, you<br />

are better off leaving it alone.<br />

The idea of tightening the bolt to

Answers are marked with initials of the staff or advisors<br />

who answered it. NP-Neil Pobanz. AF-Arky Foulk. TT-Tom<br />

Turner. AM-Arthur Miller. BR-Bob Ripley. BA-Bob Andrews. E-series expert Lew Gage (LG)<br />

and aVIOniCS columnist John Collins (JC) also occasionally contribute answers.<br />

Answers to technical questions are the best information available based<br />

on indications presented by the member asking the question. Actual<br />

inspection of the airplane or system in question may change on initial<br />

telephone or email suggestion. AircroN owners. pilots and readers are<br />

advised 10 physically present airplanes and indications ta a qualified<br />

mechanic before choosing a course of action.<br />

the bushing is correct, and just let the<br />

movemem be between the bushing and<br />

the bearing. Of course, if the bearing has<br />

interference, then that won't do. What<br />

they refer to as a spacer, I call a bushing.<br />

As long as they do not have the ears of<br />

the brackel dragging on the bearing, you<br />

may have a fit that is as good as it will be<br />

until the production is bener. - P<br />

Check the baffles<br />

William Stanek, Punta Gorda. Florida<br />

Q: CHTs on cylinders 2, 4 and 6 are<br />

running 30-40 degrees hotter than 1, 3<br />

and 5. At 7,000', 40 degrees OAT, 23"<br />

MP and 2300 rpm, cylinders 2,4 and 6<br />

were running around 390, while the others<br />

were down around 350.<br />

This 1981 F33A is a new aircraft<br />

for me so 1 don't have a history to help<br />

with other temps. The engine was overhauled<br />

to factory-new specs about 50<br />

hours ago. I have also just had<br />

Gamijectors installed. I was looking for<br />

a more even temperature distribution.<br />

Am I seeing normal numbers or is there<br />

trouble brewing in paradise<br />

A: The f,rst thing I would look for is<br />

correct installation of the barnes on the<br />

right side of the engi ne. We normally<br />

see a slightly higher temp on the right<br />

side because they are located behind the<br />

alternator. Overall your temps are not<br />

out of line for the operating parameters<br />

you stated.<br />

If your shop did not complete fuel<br />

system setup per TCM SID97-3E. I<br />

suggest doing that after looking at the<br />

barnes for proper airflow. GAMI provides<br />

a flight test data form to provide<br />

information to GAMI on each cylinder<br />

fuel flow and temps so they can refine<br />

the fuel nozzle installation if necessary.<br />

Be sure this form is completed after the<br />

other items are looked at and then sent<br />

to GAMl. They can advise if all nozzles<br />

are correct. -BR<br />

Spoiling of valve lifters<br />

Thomas Williams, Columbus. Ohio<br />

Q: On my 1979 A36, 1 have spalling<br />

of valve lifters on its factory-new engine<br />

with 800 hours. 1 run lean of peak with<br />

GAMljectors and six-probe EGTs that<br />

always run 330' to 360' head temps. I<br />

use Avblend in oi l. Mechan ics don't<br />

know what causes spalling or what can<br />

be done to prevent it. Is it poor metallurgy,<br />

a lubrication problem, multigrade<br />

oil or what<br />

A: You did not mention how old the<br />

engine is by calendar years and/or how<br />

many hours it is flown per month and<br />

how often. Spalling is usually caused by<br />

oil having run off the cam and lifter<br />

prior to stan-up from long inactivity.<br />

Pre-oiling might help, depending on<br />

how the pre-oil is set up. -NP<br />

Difficult hot starts<br />

Johnny Alvarez. San Antonio. Texas<br />

Q: What can we do about difficult<br />

hot stans on our 1958 J35 We have<br />

tried many techniques. all of which<br />

work, but not consistently. We think<br />

long and repeated cranking is hard on<br />

the starter and the battery. Do you have<br />

any permanent solution 1 heard shower<br />

of sparks cures the problem, but am<br />

skeptical.<br />

A: The quality of the spark and the<br />

timing of it playa large part in the starting,<br />

therefore shower spark can help but<br />

it can also be achieved by the mags.<br />

Therefore, you should have them<br />

checked for quality of spark output and<br />

timing. I also suggest you allow the<br />

engine to cool while fueling and open<br />

the cowling while waiting. Many times<br />

this alone will help. -NP<br />

Fuel return check valve<br />

Donald AbbeH. Gallatin. Tennessee<br />

Q: How should the fuel return check<br />

valve be positioned on a 1960 35-33<br />

A: The valve is mounted horizontal on<br />

the firewall, with the hinge on top and the<br />

arrow for flow toward the tank. -NP<br />

Electrical instrument failures<br />

David Barnes. Shelbyville, Tennessee<br />

Q: While flying my 1966 C33A<br />

recently 1 had another electrical instrument<br />

failure in fMC, the fourth time this<br />

has happened. I have struggled with this<br />

problem for three years and have had<br />

two alternators and two batteries<br />

replaced. This last time it was determined<br />

to be a dead cell in the battery.<br />

However, I am not convinced the problem<br />

has been resolved and I don't want<br />

to find out again the hard way.<br />

Is it possible that I need an alternator<br />

with higher amps, say a lOOA as<br />

opposed to the 40A Could it be a<br />

defective noise filter or a defective voltage<br />

regulator that is the problem Or do<br />

I need a heavier battery Could it be a<br />

short in one of the aircraft avionic systems<br />

I am beginning to feel my luck<br />

could be running out, so how can I<br />

know for sure that it is really fixed

A: It is very possible your electrical<br />

system may not have enough capacity<br />

for your mission and your equipment.<br />

You should compare the electrical load<br />

to the alternator rating. It is also possible<br />

that resistance in the system, including<br />

the groundside of the system, has a<br />

high resistance and causes the regulator<br />

to think it's doing its job while not keeping<br />

the battery fu ll.<br />

An analysis by someone who<br />

knows the system would be good. A call<br />

to Terry Norris at Aircraft Systems in<br />

Rockford, Illinois (8 15-399-0225)<br />

might be worthwhile. -NP<br />

Automatic prop control<br />

John Berino. Aloha, Oregon<br />

Q: My E35 has an electric prop; the<br />

automatic prop control has stopped<br />

working but the toggle switch still<br />

works. The avionics shop removed a<br />

grey box that has a speedometer cable<br />

out of the back and a cannon plug in the<br />

front where the automatic prop knob<br />

connects. They said, "Most likely this is<br />

yo ur problem, but we don't know anything<br />

about it. Good luck." How should<br />

I proceed in getting this repaired<br />

Also, when it comes to airplane<br />

maintenance, is there a shop manual that<br />

tells how long a cenain repair should<br />

take-similar to what an automobile<br />