Bridgestone Medium and Light Truck Tire Data Book - Sullivan Tire ...

Bridgestone Medium and Light Truck Tire Data Book - Sullivan Tire ...

Bridgestone Medium and Light Truck Tire Data Book - Sullivan Tire ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Technical Bulletins Load/Inflation General Technical <strong>Light</strong> <strong>Truck</strong> <strong>Medium</strong> <strong>Truck</strong><br />

General Technical Information<br />

<strong>Tire</strong> rotation is a practical means of reducing tire<br />

costs when irregular or rapid wear are prevalent.<br />

Rotation patterns, such as those recommended by<br />

vehicle manufacturers, may be followed. There are<br />

no restrictions on criss-cross rotation. <strong>Tire</strong>s having<br />

directional type tread patterns should be mounted<br />

in the recommended direction of rotation for<br />

optimum performance.<br />

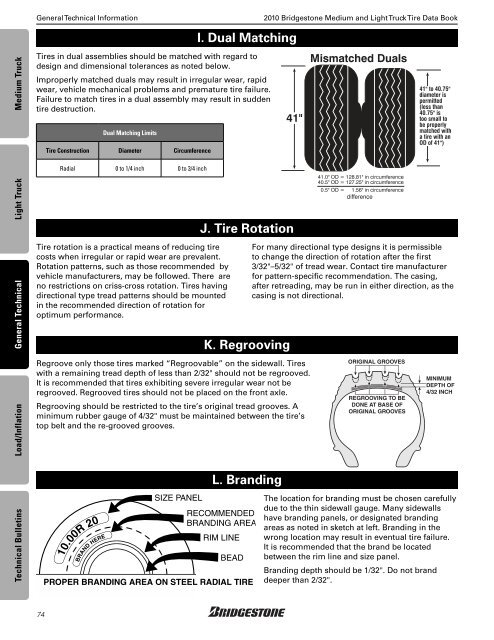

I. Dual Matching<br />

<strong>Tire</strong>s in dual assemblies should be matched with regard to<br />

design <strong>and</strong> dimensional tolerances as noted below.<br />

Improperly matched duals may result in irregular wear, rapid<br />

wear, vehicle mechanical problems <strong>and</strong> premature tire failure.<br />

Failure to match tires in a dual assembly may result in sudden<br />

tire destruction.<br />

Dual Matching Limits<br />

<strong>Tire</strong> Construction Diameter Circumference<br />

Radial 0 to 1/4 inch 0 to 3/4 inch<br />

J. <strong>Tire</strong> Rotation<br />

K. Regrooving<br />

Regroove only those tires marked “Regroovable” on the sidewall. <strong>Tire</strong>s<br />

with a remaining tread depth of less than 2/32" should not be regrooved.<br />

It is recommended that tires exhibiting severe irregular wear not be<br />

regrooved. Regrooved tires should not be placed on the front axle.<br />

Regrooving should be restricted to the tire’s original tread grooves. A<br />

minimum rubber gauge of 4/32" must be maintained between the tire’s<br />

top belt <strong>and</strong> the re-grooved grooves.<br />

L. Br<strong>and</strong>ing<br />

2010 <strong>Bridgestone</strong> <strong>Medium</strong> <strong>and</strong> <strong>Light</strong> <strong>Truck</strong> <strong>Tire</strong> <strong>Data</strong> <strong>Book</strong><br />

For many directional type designs it is permissible<br />

to change the direction of rotation after the first<br />

3/32"–5/32" of tread wear. Contact tire manufacturer<br />

for pattern-specific recommendation. The casing,<br />

after retreading, may be run in either direction, as the<br />

casing is not directional.<br />

The location for br<strong>and</strong>ing must be chosen carefully<br />

due to the thin sidewall gauge. Many sidewalls<br />

have br<strong>and</strong>ing panels, or designated br<strong>and</strong>ing<br />

areas as noted in sketch at left. Br<strong>and</strong>ing in the<br />

wrong location may result in eventual tire failure.<br />

It is recommended that the br<strong>and</strong> be located<br />

between the rim line <strong>and</strong> size panel.<br />

Br<strong>and</strong>ing depth should be 1/32". Do not br<strong>and</strong><br />

deeper than 2/32".<br />

74