Bridgestone Medium and Light Truck Tire Data Book - Sullivan Tire ...

Bridgestone Medium and Light Truck Tire Data Book - Sullivan Tire ...

Bridgestone Medium and Light Truck Tire Data Book - Sullivan Tire ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

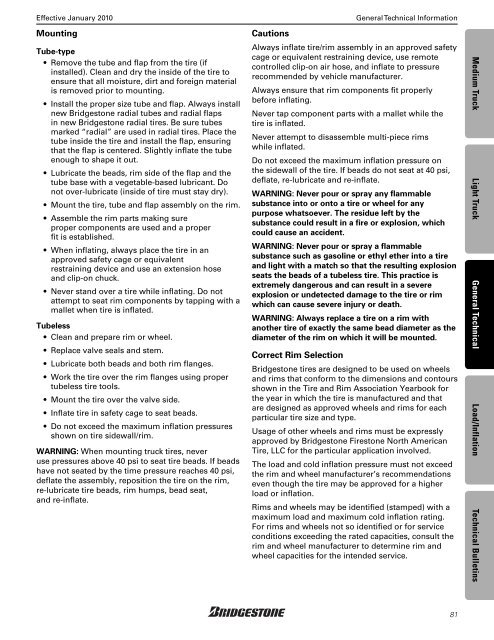

Effective January 2010<br />

Mounting<br />

Tube-type<br />

• Remove the tube <strong>and</strong> flap from the tire (if<br />

installed). Clean <strong>and</strong> dry the inside of the tire to<br />

ensure that all moisture, dirt <strong>and</strong> foreign material<br />

is removed prior to mounting.<br />

• Install the proper size tube <strong>and</strong> flap. Always install<br />

new <strong>Bridgestone</strong> radial tubes <strong>and</strong> radial flaps<br />

in new <strong>Bridgestone</strong> radial tires. Be sure tubes<br />

marked “radial” are used in radial tires. Place the<br />

tube inside the tire <strong>and</strong> install the flap, ensuring<br />

that the flap is centered. Slightly inflate the tube<br />

enough to shape it out.<br />

• Lubricate the beads, rim side of the flap <strong>and</strong> the<br />

tube base with a vegetable-based lubricant. Do<br />

not over-lubricate (inside of tire must stay dry).<br />

• Mount the tire, tube <strong>and</strong> flap assembly on the rim.<br />

• Assemble the rim parts making sure<br />

proper components are used <strong>and</strong> a proper<br />

fit is established.<br />

• When inflating, always place the tire in an<br />

approved safety cage or equivalent<br />

restraining device <strong>and</strong> use an extension hose<br />

<strong>and</strong> clip-on chuck.<br />

• Never st<strong>and</strong> over a tire while inflating. Do not<br />

attempt to seat rim components by tapping with a<br />

mallet when tire is inflated.<br />

Tubeless<br />

• Clean <strong>and</strong> prepare rim or wheel.<br />

• Replace valve seals <strong>and</strong> stem.<br />

• Lubricate both beads <strong>and</strong> both rim flanges.<br />

• Work the tire over the rim flanges using proper<br />

tubeless tire tools.<br />

• Mount the tire over the valve side.<br />

• Inflate tire in safety cage to seat beads.<br />

• Do not exceed the maximum inflation pressures<br />

shown on tire sidewall/rim.<br />

WARNING: When mounting truck tires, never<br />

use pressures above 40 psi to seat tire beads. If beads<br />

have not seated by the time pressure reaches 40 psi,<br />

deflate the assembly, reposition the tire on the rim,<br />

re-lubricate tire beads, rim humps, bead seat,<br />

<strong>and</strong> re-inflate.<br />

Cautions<br />

General Technical Information<br />

Always inflate tire/rim assembly in an approved safety<br />

cage or equivalent restraining device, use remote<br />

controlled clip-on air hose, <strong>and</strong> inflate to pressure<br />

recommended by vehicle manufacturer.<br />

Always ensure that rim components fit properly<br />

before inflating.<br />

Never tap component parts with a mallet while the<br />

tire is inflated.<br />

Never attempt to disassemble multi-piece rims<br />

while inflated.<br />

Do not exceed the maximum inflation pressure on<br />

the sidewall of the tire. If beads do not seat at 40 psi,<br />

deflate, re-lubricate <strong>and</strong> re-inflate.<br />

WARNING: Never pour or spray any flammable<br />

substance into or onto a tire or wheel for any<br />

purpose whatsoever. The residue left by the<br />

substance could result in a fire or explosion, which<br />

could cause an accident.<br />

WARNING: Never pour or spray a flammable<br />

substance such as gasoline or ethyl ether into a tire<br />

<strong>and</strong> light with a match so that the resulting explosion<br />

seats the beads of a tubeless tire. This practice is<br />

extremely dangerous <strong>and</strong> can result in a severe<br />

explosion or undetected damage to the tire or rim<br />

which can cause severe injury or death.<br />

WARNING: Always replace a tire on a rim with<br />

another tire of exactly the same bead diameter as the<br />

diameter of the rim on which it will be mounted.<br />

Correct Rim Selection<br />

<strong>Bridgestone</strong> tires are designed to be used on wheels<br />

<strong>and</strong> rims that conform to the dimensions <strong>and</strong> contours<br />

shown in the <strong>Tire</strong> <strong>and</strong> Rim Association Yearbook for<br />

the year in which the tire is manufactured <strong>and</strong> that<br />

are designed as approved wheels <strong>and</strong> rims for each<br />

particular tire size <strong>and</strong> type.<br />

Usage of other wheels <strong>and</strong> rims must be expressly<br />

approved by <strong>Bridgestone</strong> Firestone North American<br />

<strong>Tire</strong>, LLC for the particular application involved.<br />

The load <strong>and</strong> cold inflation pressure must not exceed<br />

the rim <strong>and</strong> wheel manufacturer’s recommendations<br />

even though the tire may be approved for a higher<br />

load or inflation.<br />

Rims <strong>and</strong> wheels may be identified (stamped) with a<br />

maximum load <strong>and</strong> maximum cold inflation rating.<br />

For rims <strong>and</strong> wheels not so identified or for service<br />

conditions exceeding the rated capacities, consult the<br />

rim <strong>and</strong> wheel manufacturer to determine rim <strong>and</strong><br />

wheel capacities for the intended service.<br />

<strong>Medium</strong> <strong>Truck</strong> <strong>Light</strong> <strong>Truck</strong> General Technical Load/Inflation Technical Bulletins<br />

81