Delivering effective Waste Minimisation - Wrap

Delivering effective Waste Minimisation - Wrap

Delivering effective Waste Minimisation - Wrap

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Delivering</strong> <strong>effective</strong> <strong>Waste</strong> <strong>Minimisation</strong> 41<br />

Guidance Note 4: Logistics<br />

Overview<br />

Around 15% (by value) of materials delivered<br />

to construction sites is wasted, i.e. it is not<br />

incorporated in the construction. Efficient<br />

logistics can play a large part in reducing this<br />

figure. The development of a robust logistics<br />

plan is fundamental to <strong>effective</strong>ly reduce waste.<br />

Most construction projects involve complex<br />

materials supply arrangements. A logistics<br />

plan identifies how materials are moved to,<br />

from and on site and how they are stored.<br />

Efficient logistics is based on the rigorous<br />

assessment of the need for materials,<br />

coordinating delivery, storage and distribution.<br />

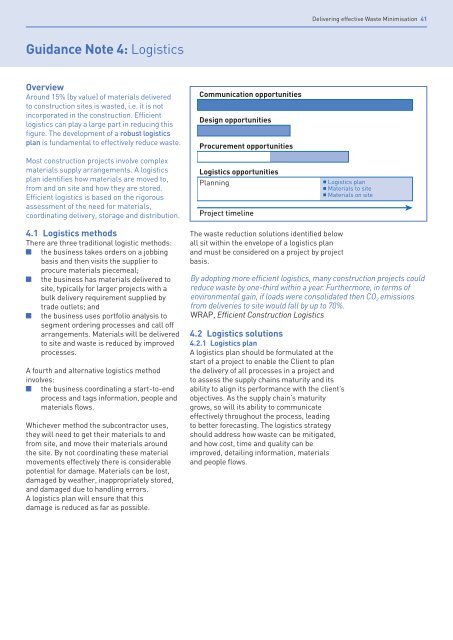

Communication opportunities<br />

Design opportunities<br />

Procurement opportunities<br />

Logistics opportunities<br />

Planning<br />

Project timeline<br />

• Logistics plan<br />

• Materials to site<br />

• Materials on site<br />

4.1 Logistics methods<br />

There are three traditional logistic methods:<br />

the business takes orders on a jobbing<br />

basis and then visits the supplier to<br />

procure materials piecemeal;<br />

the business has materials delivered to<br />

site, typically for larger projects with a<br />

bulk delivery requirement supplied by<br />

trade outlets; and<br />

the business uses portfolio analysis to<br />

segment ordering processes and call off<br />

arrangements. Materials will be delivered<br />

to site and waste is reduced by improved<br />

processes.<br />

A fourth and alternative logistics method<br />

involves:<br />

the business coordinating a start-to-end<br />

process and tags information, people and<br />

materials flows.<br />

Whichever method the subcontractor uses,<br />

they will need to get their materials to and<br />

from site, and move their materials around<br />

the site. By not coordinating these material<br />

movements <strong>effective</strong>ly there is considerable<br />

potential for damage. Materials can be lost,<br />

damaged by weather, inappropriately stored,<br />

and damaged due to handling errors.<br />

A logistics plan will ensure that this<br />

damage is reduced as far as possible.<br />

The waste reduction solutions identified below<br />

all sit within the envelope of a logistics plan<br />

and must be considered on a project by project<br />

basis.<br />

By adopting more efficient logistics, many construction projects could<br />

reduce waste by one-third within a year. Furthermore, in terms of<br />

environmental gain, if loads were consolidated then CO 2 emissions<br />

from deliveries to site would fall by up to 70%.<br />

WRAP, Efficient Construction Logistics<br />

4.2 Logistics solutions<br />

4.2.1 Logistics plan<br />

A logistics plan should be formulated at the<br />

start of a project to enable the Client to plan<br />

the delivery of all processes in a project and<br />

to assess the supply chains maturity and its<br />

ability to align its performance with the client’s<br />

objectives. As the supply chain’s maturity<br />

grows, so will its ability to communicate<br />

<strong>effective</strong>ly throughout the process, leading<br />

to better forecasting. The logistics strategy<br />

should address how waste can be mitigated,<br />

and how cost, time and quality can be<br />

improved, detailing information, materials<br />

and people flows.