Chapter 9

Chapter 9

Chapter 9

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

10-1<br />

<strong>Chapter</strong> 10<br />

VAPOR AND COMBINED POWER CYCLES<br />

Carnot Vapor Cycle<br />

10-1C Because excessive moisture in steam causes erosion on the turbine blades. The highest moisture<br />

content allowed is about 10%.<br />

10-2C The Carnot cycle is not a realistic model for steam power plants because (1) limiting the heat<br />

transfer processes to two-phase systems to maintain isothermal conditions severely limits the maximum<br />

temperature that can be used in the cycle, (2) the turbine will have to handle steam with a high moisture<br />

content which causes erosion, and (3) it is not practical to design a compressor that will handle two phases.<br />

10-3E A steady-flow Carnot engine with water as the working fluid operates at specified conditions. The<br />

thermal efficiency, the quality at the end of the heat rejection process, and the net work output are to be<br />

determined.<br />

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.<br />

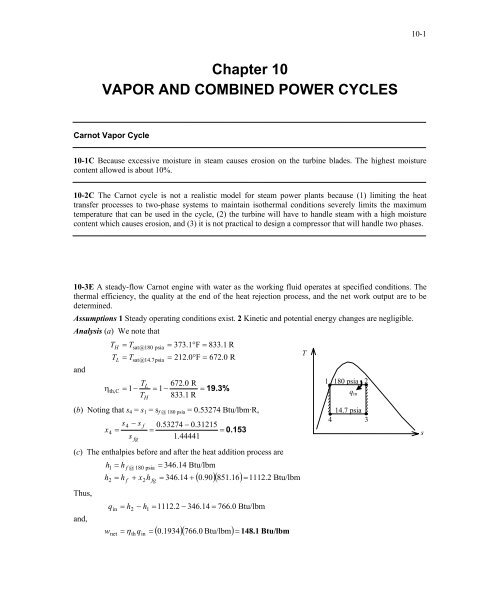

Analysis (a) We note that<br />

and<br />

η<br />

T<br />

T<br />

H<br />

L<br />

th,C<br />

= T<br />

= T<br />

sat@180 psia<br />

sat@14.7psia<br />

T<br />

= 1−<br />

T<br />

L<br />

H<br />

= 373.1°<br />

F = 833.1 R<br />

= 212.0°<br />

F = 672.0 R<br />

672.0 R<br />

= 1−<br />

833.1 R<br />

= 19.3%<br />

T<br />

1<br />

180 psia<br />

q in<br />

(b) Noting that s 4 = s 1 = s f @ 180 psia = 0.53274 Btu/lbm·R,<br />

14.7 psia<br />

4 3<br />

s4<br />

− s f 0.53274 − 0.31215<br />

x 4 = =<br />

= 0.153<br />

s<br />

s<br />

1.44441<br />

fg<br />

(c) The enthalpies before and after the heat addition process are<br />

Thus,<br />

and,<br />

h = h<br />

h<br />

w<br />

1<br />

2<br />

q<br />

= h<br />

in<br />

net<br />

f @ 180 psia<br />

f<br />

= h<br />

+ x h<br />

2<br />

= η q<br />

th<br />

2<br />

− h<br />

in<br />

1<br />

=<br />

fg<br />

= 346.14 Btu/lbm<br />

= 346.14 +<br />

( 0.90)( 851.16) = 1112.2 Btu/lbm<br />

= 1112.2 − 346.14 = 766.0 Btu/lbm<br />

( 0.1934)( 766.0 Btu/lbm) = 148.1 Btu/lbm<br />

2

10-2<br />

10-4 A steady-flow Carnot engine with water as the working fluid operates at specified conditions. The<br />

thermal efficiency, the amount of heat rejected, and the net work output are to be determined.<br />

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.<br />

Analysis (a) Noting that T H = 250°C = 523 K and T L = T sat @ 20 kPa = 60.06°C = 333.1 K, the thermal<br />

efficiency becomes<br />

TL<br />

333.1 K<br />

η th,C = 1−<br />

= 1−<br />

= 0. 3632 = 36.3%<br />

T<br />

T 523 K<br />

H<br />

(b) The heat supplied during this cycle is simply the<br />

enthalpy of vaporization ,<br />

Thus,<br />

q<br />

q<br />

in<br />

out<br />

= h<br />

= q<br />

fg@ 250 C<br />

L<br />

o<br />

T<br />

=<br />

T<br />

L<br />

H<br />

= 1715.3 kJ/kg<br />

q<br />

in<br />

⎛ 333.1 K ⎞<br />

=<br />

⎜<br />

⎟<br />

⎝ 523 K ⎠<br />

(c) The net work output of this cycle is<br />

w η<br />

( 1715.3 kJ/kg) = 1092.3 kJ/kg<br />

( 0.3632)( 1715.3 kJ/kg) 623.0 kJ/kg<br />

net = thqin<br />

=<br />

=<br />

250°C<br />

1<br />

4<br />

q in<br />

20 kPa<br />

q out<br />

2<br />

3<br />

s<br />

10-5 A steady-flow Carnot engine with water as the working fluid operates at specified conditions. The<br />

thermal efficiency, the amount of heat rejected, and the net work output are to be determined.<br />

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.<br />

Analysis (a) Noting that T H = 250°C = 523 K and T L = T sat @ 10 kPa = 45.81°C = 318.8 K, the thermal<br />

efficiency becomes<br />

TL<br />

318.8 K<br />

η th, C = 1 − = 1 − = 39.04%<br />

T<br />

T 523 K<br />

H<br />

(b) The heat supplied during this cycle is simply the<br />

enthalpy of vaporization ,<br />

Thus,<br />

q<br />

q<br />

in = h fg@ 250°<br />

C<br />

out<br />

= q<br />

L<br />

T<br />

=<br />

T<br />

L<br />

H<br />

= 1715.3 kJ/kg<br />

q<br />

in<br />

⎛ 318.8 K ⎞<br />

=<br />

⎜<br />

⎟<br />

⎝ 523 K ⎠<br />

(c) The net work output of this cycle is<br />

( 1715.3 kJ/kg) = 1045.6 kJ/kg<br />

( 0.3904)( 1715.3 ) = 669.7 kJ/kg<br />

w = η q =<br />

kJ/kg<br />

net<br />

th<br />

in<br />

250°C<br />

1<br />

q in<br />

10 kPa<br />

4<br />

q out<br />

2<br />

3<br />

s

10-3<br />

10-6 A steady-flow Carnot engine with water as the working fluid operates at specified conditions. The<br />

thermal efficiency, the pressure at the turbine inlet, and the net work output are to be determined.<br />

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.<br />

Analysis (a) The thermal efficiency is determined from<br />

(b) Note that<br />

TL<br />

60 + 273 K<br />

η th, C = 1− = 1−<br />

= 46.5%<br />

T 350 + 273 K<br />

H<br />

s 2 = s 3 = s f + x 3 s fg<br />

= 0.8313 + 0.891 × 7.0769 = 7.1368 kJ/kg·K<br />

T<br />

350°C<br />

Thus , 60°C<br />

T<br />

s<br />

2<br />

2<br />

= 350°<br />

C ⎫<br />

⎬ P<br />

= 7.1368 kJ/kg ⋅ K ⎭<br />

2<br />

≅ 1.40 MPa (Table A-6)<br />

(c) The net work can be determined by calculating the enclosed area on the T-s diagram,<br />

Thus,<br />

w<br />

s<br />

4<br />

net<br />

= s<br />

f<br />

+ x s<br />

4<br />

= Area =<br />

fg<br />

= 0.8313 +<br />

( 0.1)( 7.0769)<br />

= 1.5390 kJ/kg ⋅ K<br />

( T − T )( s − s ) = ( 350 − 60)( 7.1368 −1.5390) = 1623 kJ/kg<br />

H<br />

L<br />

3<br />

4<br />

1<br />

4<br />

2<br />

3<br />

s<br />

The Simple Rankine Cycle<br />

10-7C The four processes that make up the simple ideal cycle are (1) Isentropic compression in a pump,<br />

(2) P = constant heat addition in a boiler, (3) Isentropic expansion in a turbine, and (4) P = constant heat<br />

rejection in a condenser.<br />

10-8C Heat rejected decreases; everything else increases.<br />

10-9C Heat rejected decreases; everything else increases.<br />

10-10C The pump work remains the same, the moisture content decreases, everything else increases.<br />

10-11C The actual vapor power cycles differ from the idealized ones in that the actual cycles involve<br />

friction and pressure drops in various components and the piping, and heat loss to the surrounding medium<br />

from these components and piping.<br />

10-12C The boiler exit pressure will be (a) lower than the boiler inlet pressure in actual cycles, and (b) the<br />

same as the boiler inlet pressure in ideal cycles.<br />

10-13C We would reject this proposal because w turb = h 1 - h 2 - q out , and any heat loss from the steam will<br />

adversely affect the turbine work output.<br />

10-14C Yes, because the saturation temperature of steam at 10 kPa is 45.81°C, which is much higher than<br />

the temperature of the cooling water.

10-4<br />

10-15 A steam power plant operates on a simple ideal Rankine cycle between the specified pressure limits.<br />

The thermal efficiency of the cycle and the net power output of the plant are to be determined.<br />

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.<br />

Analysis (a) From the steam tables (Tables A-4, A-5, and A-6),<br />

Thus,<br />

and<br />

w<br />

h = h<br />

1<br />

v = v<br />

1<br />

p,in<br />

h<br />

2<br />

f @ 50 kPa<br />

f @ 50 kPa<br />

= 340.54 kJ/kg<br />

= 0.001030 m<br />

/kg<br />

v 1( P2<br />

− P1<br />

)<br />

3<br />

( 0.001030 m /kg)( 3000 − 50)<br />

=<br />

⎛ 1 kJ<br />

=<br />

kPa⎜<br />

1 kPa m<br />

= 3.04 kJ/kg<br />

⎝ ⋅<br />

= h + w = 340.54 + 3.04 = 343.58 kJ/kg<br />

1<br />

p,in<br />

P3<br />

= 3 MPa ⎫ h3<br />

⎬<br />

T3<br />

= 300 ° C ⎭ s3<br />

P4<br />

= 50 kPa ⎫<br />

⎬ x<br />

s4<br />

= s3<br />

⎭<br />

h<br />

q<br />

w<br />

η<br />

q<br />

out<br />

net<br />

th<br />

&<br />

in<br />

= h<br />

3<br />

= h<br />

4<br />

= q<br />

in<br />

q<br />

= 1−<br />

q<br />

&<br />

− h<br />

2<br />

− h<br />

1<br />

− q<br />

out<br />

in<br />

4<br />

4<br />

= 2994.3 kJ/kg<br />

= 6.5412 kJ/kg ⋅ K<br />

s4<br />

− s f<br />

=<br />

s<br />

= h<br />

f<br />

fg<br />

+ x h<br />

4<br />

= 2272.3 kJ/kg<br />

3<br />

= 340.54 +<br />

3<br />

( 0.8382)(<br />

⎞<br />

⎟<br />

⎠<br />

6.5412 −1.0912<br />

=<br />

= 0.8382<br />

6.5019<br />

fg<br />

= 2994.3 − 343.58 = 2650.7 kJ/kg<br />

= 2272.3 − 340.54 = 1931.8 kJ/kg<br />

out<br />

= 2650.7 −1931.8<br />

= 718.9 kJ/kg<br />

1931.8<br />

= 1−<br />

= 27.1%<br />

2650.7<br />

(b) W = m = ( 35 kg/s)( 718.9 kJ/kg) = 25.2 MW<br />

net w net<br />

2304.7<br />

)<br />

T<br />

2<br />

3 MPa<br />

q in<br />

50 kPa<br />

1<br />

q out<br />

3<br />

4<br />

s

10-5<br />

10-16 A steam power plant that operates on a simple ideal Rankine cycle is considered. The quality of the<br />

steam at the turbine exit, the thermal efficiency of the cycle, and the mass flow rate of the steam are to be<br />

determined.<br />

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.<br />

Analysis (a) From the steam tables (Tables A-4, A-5, and A-6),<br />

(b)<br />

and<br />

(c)<br />

h = h<br />

1<br />

v = v<br />

1<br />

2<br />

f @ 10 kPa<br />

f @ 10 kPa<br />

= 191.81 kJ/kg<br />

= 0.00101 m /kg<br />

v1( P2<br />

− P1<br />

)<br />

3<br />

( 0.00101 m /kg)( 10,000 −10<br />

kPa)<br />

wp,in<br />

=<br />

⎛ 1 kJ ⎞<br />

=<br />

⎜ ⎟<br />

3<br />

1 kPa m<br />

= 10.09 kJ/kg<br />

⎝ ⋅ ⎠<br />

h = h + w = 191.81 + 10.09 = 201.90 kJ/kg<br />

1<br />

p,in<br />

P3<br />

= 10 MPa ⎫ h<br />

⎬<br />

T3<br />

= 500 ° C ⎭ s<br />

3<br />

4<br />

3<br />

= 6.5995 kJ/kg ⋅ K<br />

3<br />

= 3375.1 kJ/kg<br />

P4<br />

= 10 kPa ⎫ s4<br />

− s f 6.5995 − 0.6492<br />

⎬ x4<br />

= =<br />

= 0.7934<br />

s4<br />

= s3<br />

⎭ s fg 7.4996<br />

h = h + x h = 191.81 +<br />

q<br />

w<br />

q<br />

in<br />

out<br />

net<br />

= h<br />

3<br />

= h<br />

4<br />

= q<br />

w<br />

η th =<br />

q<br />

W&<br />

m & = w<br />

in<br />

in<br />

net<br />

net<br />

net<br />

− h<br />

2<br />

− h<br />

1<br />

− q<br />

f<br />

4<br />

fg<br />

= 3375.1 − 201.90 = 3173.2 kJ/kg<br />

= 2089.7 −191.81<br />

= 1897.9 kJ/kg<br />

out<br />

= 3173.2 −1897.9<br />

= 1275.4 kJ/kg<br />

1275.4 kJ/kg<br />

=<br />

= 40.2%<br />

3173.2 kJ/kg<br />

210,000 kJ/s<br />

=<br />

= 164.7 kg/<br />

s<br />

1275.4 kJ/kg<br />

( 0.7934)( 2392.1) = 2089.7 kJ/kg<br />

T<br />

2<br />

10 MPa<br />

q in<br />

10 kPa<br />

1<br />

q out<br />

3<br />

4<br />

s

10-6<br />

10-17 A steam power plant that operates on a simple nonideal Rankine cycle is considered. The quality of<br />

the steam at the turbine exit, the thermal efficiency of the cycle, and the mass flow rate of the steam are to<br />

be determined.<br />

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.<br />

Analysis (a) From the steam tables (Tables A-4, A-5, and A-6),<br />

(b)<br />

and<br />

(c)<br />

w<br />

h = h<br />

1<br />

v = v<br />

1<br />

p,in<br />

h<br />

2<br />

=<br />

f @ 10 kPa<br />

f @ 10 kPa<br />

= 191.81 kJ/kg<br />

= 0.00101 m<br />

/kg<br />

v 1( P2<br />

− P1<br />

)/<br />

η p<br />

⎛ 1 kJ ⎞<br />

3<br />

( 0.00101 m /kg)( 10,000 −10<br />

kPa) ⎜ ⎟/<br />

( 0.85)<br />

=<br />

⎜1 kPa m<br />

= 11.87 kJ/kg<br />

⎝ ⋅<br />

= h + w = 191.81+<br />

11.87 = 203.68 kJ/kg<br />

P<br />

s<br />

P<br />

h<br />

4<br />

4<br />

1<br />

4s<br />

4s<br />

p,in<br />

P3<br />

= 10 MPa ⎫ h3<br />

⎬<br />

T3<br />

= 500 ° C ⎭ s3<br />

= 10 kPa ⎫<br />

⎬ x<br />

= s3<br />

⎭<br />

h<br />

h3<br />

− h4<br />

ηT<br />

=<br />

h − h<br />

q<br />

q<br />

w<br />

η<br />

out<br />

net<br />

th<br />

3<br />

4s<br />

4s<br />

⎯⎯→<br />

= h<br />

= 10 kPa ⎫<br />

⎬ x<br />

= 2282.5 kJ/kg⎭<br />

in<br />

= h<br />

= h<br />

= q<br />

3<br />

4<br />

w<br />

=<br />

q<br />

W&<br />

m&<br />

=<br />

w<br />

in<br />

in<br />

net<br />

net<br />

3<br />

= 3375.1 kJ/kg<br />

= 6.5995 kJ/kg ⋅ K<br />

4s<br />

s4s<br />

− s f<br />

=<br />

s<br />

4<br />

h<br />

f<br />

4<br />

fg<br />

+ x h<br />

4<br />

= h3<br />

−ηT<br />

= 3375.1−<br />

h4<br />

− h f<br />

=<br />

h<br />

fg<br />

3<br />

⎟<br />

⎠<br />

6.5995 − 0.6492<br />

=<br />

= 0.7934<br />

7.4996<br />

fg<br />

= 191.81+<br />

( 0.7934)( 2392.1)<br />

( h3<br />

− h4s<br />

)<br />

( 0.85)( 3375.1−<br />

2089.7)<br />

2282.<br />

5 −19181<br />

.<br />

=<br />

= 0.874<br />

23921 .<br />

− h2<br />

= 3375.1−<br />

203.68 = 3171.4 kJ/kg<br />

− h1<br />

= 2282.5 −191.81<br />

= 2090.7 kJ/kg<br />

− q = 3171.4 − 2090.7 = 1080.7 kJ/kg<br />

net<br />

out<br />

1080.7 kJ/kg<br />

=<br />

= 34.1%<br />

3171.5 kJ/kg<br />

210,000 kJ/s<br />

=<br />

1080.7 kJ/kg<br />

= 194.3 kg/s<br />

T<br />

2<br />

2<br />

1<br />

= 2089.7 kJ/kg<br />

= 2282.5 kJ/kg<br />

10 MPa<br />

q in<br />

10 kPa<br />

q out<br />

3<br />

4<br />

4<br />

s

10-7<br />

10-18E A steam power plant that operates on a simple ideal Rankine cycle between the specified pressure<br />

limits is considered. The minimum turbine inlet temperature, the rate of heat input in the boiler, and the<br />

thermal efficiency of the cycle are to be determined.<br />

Assumptions 1 Steady operating conditions exist.<br />

2 Kinetic and potential energy changes are<br />

negligible.<br />

Analysis (a) From the steam tables (Tables A-4E,<br />

A-5E, and A-6E),<br />

h = h<br />

1<br />

v = v<br />

1<br />

2<br />

f @ 2 psia<br />

f @ 2 psia<br />

= 94.02 Btu/lbm<br />

= 0.01623 ft /lbm<br />

v1( P2<br />

− P1<br />

)<br />

3<br />

( 0.01623 ft /lbm)( 1250 − 2 psia)<br />

wp,in<br />

=<br />

⎛ 1 Btu<br />

=<br />

⎜<br />

3<br />

5.4039 psia ft<br />

= 3.75 Btu/lbm<br />

⎝<br />

⋅<br />

h = h + w = 94.02 + 3.75 = 97.77 Btu/lbm<br />

h<br />

s<br />

4<br />

4<br />

= h<br />

= s<br />

f<br />

f<br />

1<br />

+ x h<br />

4<br />

+ x s<br />

4<br />

p,in<br />

fg<br />

fg<br />

= 94.02 +<br />

= 0.17499<br />

3<br />

( 0.9)( 1021.7)<br />

=<br />

+ ( 0.9)( 1.74444)<br />

P3<br />

= 1250 psia ⎫ h3<br />

= 1693.4 Btu/lbm<br />

⎬<br />

s3<br />

= s4<br />

⎭T3<br />

= 1337°F<br />

&<br />

⎞<br />

⎟<br />

⎠<br />

1013.6 Btu/lbm<br />

T<br />

= 1.7450 Btu/lbm ⋅ R<br />

(b) Q = m( h − h ) = ( 75 lbm/s)( 1693.4 − 97.77) = 119,672 Btu/s<br />

in<br />

&<br />

3<br />

2<br />

(c) Q&<br />

= m&<br />

( h − h ) = ( 75 lbm/s)( 1013.6 − 94.02)<br />

out<br />

4<br />

Q&<br />

ηth<br />

= 1 −<br />

Q&<br />

out<br />

in<br />

1<br />

68,967 Btu/s<br />

= 1 −<br />

= 42.4%<br />

119,672 Btu/s<br />

= 68,967 Btu/s<br />

2<br />

1<br />

1250 psia<br />

·<br />

Q in<br />

2 psia<br />

·<br />

Q out<br />

3<br />

4<br />

x 4 = 0.9<br />

s

10-8<br />

10-19E A steam power plant operates on a simple nonideal Rankine cycle between the specified pressure<br />

limits. The minimum turbine inlet temperature, the rate of heat input in the boiler, and the thermal<br />

efficiency of the cycle are to be determined.<br />

Assumptions 1 Steady operating conditions exist. 2 Kinetic<br />

and potential energy changes are negligible.<br />

Analysis (a) From the steam tables (Tables A-4E, A-5E,<br />

and A-6E),<br />

h = h<br />

1<br />

v = v<br />

1<br />

2<br />

f @ 2 psia<br />

f @ 2 psia<br />

= 94.02 Btu/lbm<br />

= 0.01623 ft<br />

/lbm<br />

v 1( P2<br />

− P1<br />

)/<br />

η P<br />

3<br />

( 0.01623 ft /lbm)( 1250 − 2 psia)<br />

w p,in<br />

=<br />

⎛ 1 Btu<br />

=<br />

⎜<br />

5.4039 psia ft<br />

= 4.41 Btu/lbm<br />

⎝<br />

⋅<br />

h = h + w = 94.02 + 4.41 = 98.43 Btu/lbm<br />

1<br />

h<br />

s<br />

4<br />

4<br />

= s<br />

p,in<br />

= h<br />

f<br />

f<br />

+ x h<br />

4<br />

+ x s<br />

4<br />

fg<br />

fg<br />

3<br />

= 94.02 +<br />

= 0.17499<br />

3<br />

T<br />

⎞<br />

⎟ / 0.85<br />

⎠<br />

2<br />

2s<br />

( 0.9)( 1021.7)<br />

= 1013.6 Btu/lbm<br />

+ ( 0.9)( 1.74444) = 1.7450 Btu/lbm ⋅ R<br />

The turbine inlet temperature is determined by trial and error ,<br />

Try 1:<br />

Try 2:<br />

x<br />

h<br />

4s<br />

4s<br />

P3<br />

= 1250 psia ⎫ h<br />

⎬<br />

T3<br />

= 900°<br />

F ⎭ s<br />

s4s<br />

− s f<br />

=<br />

s<br />

= h<br />

f<br />

3<br />

fg<br />

+ x<br />

4s<br />

h3<br />

− h4<br />

ηT<br />

=<br />

h − h<br />

x<br />

h<br />

4s<br />

4s<br />

4s<br />

3<br />

3<br />

s3<br />

− s f<br />

=<br />

s<br />

h<br />

fg<br />

fg<br />

= 94.02 +<br />

P3<br />

= 1250 psia ⎫ h<br />

⎬<br />

T3<br />

= 1000°<br />

F ⎭ s<br />

s4s<br />

− s f<br />

=<br />

s<br />

= h<br />

f<br />

3<br />

fg<br />

+ x<br />

4s<br />

h3<br />

− h4<br />

ηT<br />

=<br />

h − h<br />

4s<br />

= 1439.0 Btu/lbm<br />

= 1.5826 Btu/lbm.R<br />

1.5826 − 0.17499<br />

=<br />

= 0.8069<br />

1.74444<br />

( 0.8069)( 1021.7)<br />

1439.0 −1013.6<br />

=<br />

= 0.8171<br />

1439.0 − 918.4<br />

3<br />

3<br />

s3<br />

− s f<br />

=<br />

s<br />

h<br />

fg<br />

fg<br />

= 94.02 +<br />

= 1498.6 Btu/lbm<br />

= 1.6249 Btu/lbm.R<br />

( 0.8312)( 1021.7)<br />

1498.6 −1013.6<br />

=<br />

= 0.8734<br />

1498.6 − 943.3<br />

= 918.4 Btu/lbm<br />

1.6249 − 0.17499<br />

=<br />

= 0.8312<br />

1.74444<br />

= 943.3<br />

Btu/lbm<br />

1<br />

1250 psia<br />

·<br />

Q in<br />

2 psia<br />

·<br />

Q out<br />

3<br />

4s 4<br />

x 4 = 0.9<br />

By linear interpolation, at η T = 0.85 we obtain T 3 = 958.4°F. This is approximate. We can determine state 3<br />

exactly using EES software with these results: T 3 = 955.7°F, h 3 = 1472.5 Btu/lbm.<br />

&<br />

(b) Q = m( h − h ) = ( 75 lbm/s)( 1472.5 − 98.43) = 103,055 Btu/s<br />

in<br />

&<br />

3<br />

2<br />

(c) Q&<br />

= m&<br />

( h − h ) = ( 75 lbm/s)( 1013.6 − 94.02)<br />

out<br />

4<br />

Q&<br />

η th = 1−<br />

Q&<br />

out<br />

in<br />

1<br />

68,969 Btu/s<br />

= 1−<br />

103,055 Btu/s<br />

= 33.1%<br />

= 68,969 Btu/s<br />

s

10-9<br />

10-20 A 300-MW coal-fired steam power plant operates on a simple ideal Rankine cycle between the<br />

specified pressure limits. The overall plant efficiency and the required rate of the coal supply are to be<br />

determined.<br />

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.<br />

Analysis (a) From the steam tables (Tables A-4, A-5, and A-6),<br />

w<br />

h = h<br />

1<br />

v = v<br />

1<br />

p,in<br />

h<br />

2<br />

f @ 25 kPa<br />

f @ 25 kPa<br />

= 271.96 kJ/kg<br />

= 0.001020 m<br />

/kg<br />

v 1( P2<br />

− P1<br />

)<br />

3<br />

( 0.00102 m /kg)( 5000 − 25 kPa)<br />

=<br />

⎛ 1 kJ<br />

=<br />

⎜<br />

1 kPa m<br />

= 5.07 kJ/kg<br />

⎝ ⋅<br />

= h + w = 271.96 + 5.07 = 277.03 kJ/kg<br />

1<br />

p,in<br />

P3<br />

= 5 MPa ⎫ h3<br />

⎬<br />

T3<br />

= 450°<br />

C ⎭ s3<br />

= 3317.2 kJ/kg<br />

= 6.8210 kJ/kg ⋅ K<br />

P4<br />

= 25 kPa ⎫ s4<br />

− s f 6.8210 − 0.8932<br />

⎬ x4<br />

= =<br />

= 0.8545<br />

s4<br />

= s3<br />

⎭ s fg 6.9370<br />

h = h + x h = 271.96 +<br />

The thermal efficiency is determined from<br />

and<br />

Thus,<br />

q<br />

q<br />

η<br />

in<br />

out<br />

η<br />

= h<br />

= h<br />

th<br />

overall<br />

3<br />

4<br />

− h<br />

− h<br />

= η<br />

2<br />

1<br />

q<br />

= 1−<br />

q<br />

th<br />

4<br />

f<br />

4<br />

fg<br />

= 3317.2 − 277.03 = 3040.2 kJ/kg<br />

= 2276.2 − 271.96 = 2004.2 kJ/kg<br />

out<br />

in<br />

× η<br />

= 1−<br />

comb<br />

× η<br />

2004.2<br />

3040.2<br />

gen<br />

=<br />

3<br />

= 0.3407<br />

(b) Then the required rate of coal supply becomes<br />

and<br />

m&<br />

Q&<br />

in<br />

coal<br />

W&<br />

=<br />

η<br />

Q&<br />

=<br />

C<br />

net<br />

overall<br />

in<br />

coal<br />

3<br />

⎞<br />

⎟<br />

⎠<br />

( 0.8545)( 2345.5) = 2276.2 kJ/kg<br />

( 0.3407)( 0.75)( 0.96) = 24.5%<br />

300,000 kJ/s<br />

=<br />

= 1,222,992 kJ/s<br />

0.2453<br />

1,222,992 kJ/s ⎛ 1 ton ⎞<br />

=<br />

⎜<br />

⎟ = 0.04174<br />

29,300 kJ/kg ⎝1000<br />

kg ⎠<br />

T<br />

2<br />

1<br />

5 MPa<br />

·<br />

Q in<br />

25 kPa<br />

Q·<br />

out<br />

tons/s = 150.3 tons/h<br />

3<br />

4<br />

s

10-10<br />

10-21 A solar-pond power plant that operates on a simple ideal Rankine cycle with refrigerant-134a as the<br />

working fluid is considered. The thermal efficiency of the cycle and the power output of the plant are to be<br />

determined.<br />

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.<br />

Analysis (a) From the refrigerant tables (Tables A-11, A-12, and A-13),<br />

w<br />

h = h<br />

1<br />

v = v<br />

1<br />

p,in<br />

h<br />

2<br />

= v<br />

=<br />

f @ 0.7 MPa<br />

f @ 0.7 MPa<br />

1<br />

( P − P )<br />

3<br />

( 0.0008331 m /kg)( 1400 − 700 kPa)<br />

= 0.58 kJ/kg<br />

= h<br />

1<br />

2<br />

+ w<br />

1<br />

p,in<br />

P3<br />

= 1.4 MPa ⎫ h3<br />

= h<br />

⎬<br />

sat.vapor ⎭ s3<br />

= s<br />

4<br />

= 88.82<br />

kJ/kg<br />

= 0.0008331 m<br />

/kg<br />

= 88.82 + 0.58 = 89.40 kJ/kg<br />

g@ 1.4 MPa<br />

g@ 1.4 MPa<br />

f<br />

4<br />

3<br />

= 276.12 kJ/kg<br />

⎛<br />

⎜<br />

1 kJ<br />

⎝1 kPa ⋅ m<br />

= 0.9105 kJ/kg ⋅ K<br />

P4<br />

= 0.7 MPa ⎫ s4<br />

− s f 0.9105 − 0.33230<br />

⎬ x4<br />

= =<br />

= 0.9839<br />

s4<br />

= s3<br />

⎭ s fg 0.58763<br />

h = h + x h = 88.82 +<br />

Thus ,<br />

and<br />

q<br />

w<br />

η<br />

q<br />

in<br />

out<br />

net<br />

th<br />

&<br />

= h<br />

3<br />

= h<br />

4<br />

= q<br />

w<br />

=<br />

q<br />

in<br />

net<br />

&<br />

in<br />

− h<br />

2<br />

− h<br />

1<br />

− q<br />

fg<br />

= 276.12 − 89.40 = 186.72 kJ/kg<br />

= 262.20 − 88.82 = 173.38 kJ/kg<br />

out<br />

= 186.72 −173.38<br />

= 13.34 kJ/kg<br />

13.34 kJ/kg<br />

=<br />

= 7.1%<br />

186.72 kJ/kg<br />

(b) W = m = ( 3 kg/s)( 13.34 kJ/kg) = 40.02 kW<br />

net w net<br />

3<br />

⎞<br />

⎟<br />

⎠<br />

( 0.9839)( 176.21) = 262.20 kJ/kg<br />

T<br />

2<br />

1<br />

1.4 MPa<br />

q in<br />

R-134a<br />

0.7 MPa<br />

q out<br />

3<br />

4<br />

s

10-11<br />

10-22 A steam power plant operates on a simple ideal Rankine cycle between the specified pressure limits.<br />

The thermal efficiency of the cycle, the mass flow rate of the steam, and the temperature rise of the cooling<br />

water are to be determined.<br />

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.<br />

Analysis (a) From the steam tables (Tables A-4, A-5, and A-6),<br />

w<br />

Thus,<br />

h = h<br />

1<br />

v = v<br />

1<br />

p,in<br />

h<br />

2<br />

= v<br />

=<br />

f @ 10 kPa<br />

f @ 10 kPa<br />

1<br />

( P − P )<br />

3<br />

( 0.00101 m /kg)( 7,000 −10<br />

kPa)<br />

= 7.06 kJ/kg<br />

= h<br />

1<br />

2<br />

+ w<br />

1<br />

p,in<br />

P3<br />

= 7 MPa ⎫ h3<br />

⎬<br />

T3<br />

= 500°<br />

C ⎭ s3<br />

= 191.81 kJ/kg<br />

= 0.00101 m<br />

/kg<br />

= 191.81+<br />

7.06 = 198.87<br />

4<br />

= 6.8000 kJ/kg ⋅ K<br />

3<br />

= 3411.4 kJ/kg<br />

f<br />

4<br />

fg<br />

⎛<br />

⎜<br />

1 kJ<br />

⎝1 kPa ⋅ m<br />

kJ/kg<br />

P4<br />

= 10 kPa ⎫ s4<br />

− s f 6.8000 − 0.6492<br />

⎬ x4<br />

= =<br />

= 0.8201<br />

s4<br />

= s3<br />

⎭ s fg 7.4996<br />

h = h + x h = 191.81 +<br />

q<br />

w<br />

q<br />

in<br />

out<br />

net<br />

= h<br />

3<br />

= h<br />

4<br />

= q<br />

in<br />

− h<br />

2<br />

− h<br />

1<br />

− q<br />

= 2153.6 −191.81<br />

= 1961.8 kJ/kg<br />

3<br />

⎞<br />

⎟<br />

⎠<br />

= 3411.4 −198.87<br />

= 3212.5 kJ/kg<br />

out<br />

= 3212.5 −1961.8<br />

= 1250.7 kJ/kg<br />

wnet<br />

1250.7 kJ/kg<br />

and η th = =<br />

= 38.9%<br />

q 3212.5 kJ/kg<br />

(b)<br />

W&<br />

m & = w<br />

net<br />

in<br />

45,000 kJ/s<br />

=<br />

1250.7 kJ/kg<br />

net<br />

=<br />

36 . 0 kg/<br />

s<br />

( 0.8201)( 2392.1) = 2153.6 kJ/kg<br />

(c) The rate of heat rejection to the cooling water and its temperature rise are<br />

∆T<br />

Q&<br />

out<br />

coolingwater<br />

= mq &<br />

out =<br />

Q&<br />

=<br />

( mc & )<br />

( 35.98 kg/s)( 1961.8 kJ/kg)<br />

out<br />

coolingwater<br />

=<br />

70,586 kJ/s<br />

( 2000 kg/s)( 4.18 kJ/kg ⋅° C)<br />

T<br />

= 70,586 kJ/s<br />

2<br />

= 8.4°C<br />

7 MPa<br />

q in<br />

10 kPa<br />

1<br />

q out<br />

3<br />

4<br />

s

10-12<br />

10-23 A steam power plant operates on a simple nonideal Rankine cycle between the specified pressure<br />

limits. The thermal efficiency of the cycle, the mass flow rate of the steam, and the temperature rise of the<br />

cooling water are to be determined.<br />

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.<br />

Analysis (a) From the steam tables (Tables A-4, A-5, and A-6),<br />

w<br />

Thus,<br />

h = h<br />

1<br />

v = v<br />

1<br />

p,in<br />

h<br />

2<br />

=<br />

=<br />

f @ 10 kPa<br />

f @ 10 kPa<br />

v 1( P2<br />

− P1<br />

)/<br />

η p<br />

⎛ 1 kJ ⎞<br />

3<br />

( 0.00101 m /kg)( 7,000 −10<br />

kPa) ⎜ ⎟/<br />

( 0.87)<br />

= 8.11 kJ/kg<br />

= h<br />

1<br />

+ w<br />

3<br />

p,in<br />

P3<br />

= 7 MPa ⎫ h3<br />

⎬<br />

T3<br />

= 500°<br />

C ⎭ s3<br />

= 191.81 kJ/kg<br />

= 0.00101 m<br />

3<br />

/kg<br />

⎜<br />

⎝1 kPa ⋅ m<br />

= 191.81+<br />

8.11 = 199.92 kJ/kg<br />

4s<br />

= 3411.4 kJ/kg<br />

= 6.8000 kJ/kg ⋅ K<br />

P4<br />

= 10 kPa ⎫ s4<br />

− s f 6.8000 − 0.6492<br />

⎬ x4<br />

= =<br />

= 0.8201<br />

s4<br />

= s3<br />

⎭ s fg 7.4996<br />

h = h + x h = 191.81 +<br />

h3<br />

− h4<br />

ηT<br />

=<br />

h − h<br />

q<br />

w<br />

q<br />

in<br />

out<br />

net<br />

= h<br />

3<br />

= h<br />

4<br />

= q<br />

in<br />

− h<br />

2<br />

− h<br />

1<br />

− q<br />

4s<br />

⎯⎯→<br />

f<br />

h<br />

4<br />

4<br />

fg<br />

= h3<br />

−ηT<br />

= 3411.4<br />

= 2317.1−191.81<br />

= 2125.3 kJ/kg<br />

3<br />

⎟<br />

⎠<br />

= 3411.4 −199.92<br />

= 3211.5 kJ/kg<br />

out<br />

( 0.820)( 2392.1)<br />

( h3<br />

− h4s<br />

)<br />

− ( 0.87)( 3411.4 − 2153.6) = 2317.1 kJ/kg<br />

= 3211.5 − 2125.3 = 1086.2 kJ/kg<br />

wnet<br />

1086.2 kJ/kg<br />

and η th = =<br />

= 33.8%<br />

q 3211.5 kJ/kg<br />

(b)<br />

W&<br />

m & = w<br />

net<br />

in<br />

45,000 kJ/s<br />

=<br />

1086.2 kJ/kg<br />

net<br />

=<br />

41 . 43 kg/<br />

s<br />

T<br />

2<br />

2<br />

1<br />

= 2153.6 kJ/kg<br />

(c) The rate of heat rejection to the cooling water and its temperature rise are<br />

∆T<br />

Q&<br />

out<br />

coolingwater<br />

= mq &<br />

out<br />

=<br />

Q&<br />

=<br />

( mc & )<br />

( 41.43 kg/s)( 2125.3 kJ/kg)<br />

out<br />

coolingwater<br />

=<br />

88,051 kJ/s<br />

= 88,051 kJ/s<br />

( 2000 kg/s)( 4.18 kJ/kg ⋅° C)<br />

= 10.5°C<br />

7 MPa<br />

q in<br />

10 kPa<br />

q out<br />

3<br />

4<br />

4<br />

s

10-13<br />

10-24 The net work outputs and the thermal efficiencies for a Carnot cycle and a simple ideal Rankine<br />

cycle are to be determined.<br />

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.<br />

Analysis (a) Rankine cycle analysis: From the steam tables (Tables A-4, A-5, and A-6),<br />

h = h<br />

1<br />

v = v<br />

1<br />

2<br />

f @ 20 kPa<br />

f @ 20 kPa<br />

= 251.42 kJ/kg<br />

= 0.001017 m /kg<br />

v1( P2<br />

− P1<br />

)<br />

3<br />

( 0.001017 m /kg)( 10,000 − 20)<br />

wp,in<br />

=<br />

⎛ 1 kJ ⎞<br />

=<br />

kPa⎜<br />

⎟<br />

3<br />

1 kPa m<br />

= 10.15 kJ/kg<br />

⎝ ⋅ ⎠<br />

h = h + w = 251.42 + 10.15 = 261.57 kJ/kg<br />

1<br />

p,in<br />

P3<br />

= 10 MPa ⎫ h<br />

⎬<br />

x3<br />

= 1 ⎭ s<br />

P4<br />

= 20 kPa ⎫<br />

⎬ x<br />

s4<br />

= s3<br />

⎭<br />

h<br />

q<br />

w<br />

η<br />

q<br />

in<br />

out<br />

net<br />

th<br />

= h<br />

3<br />

= h<br />

= q<br />

3<br />

4<br />

4<br />

4<br />

3<br />

in<br />

q<br />

= 1−<br />

q<br />

= 5.6159 kJ/kg ⋅ K<br />

= 1845.3 kJ/kg<br />

3<br />

= 2725.5 kJ/kg<br />

s4<br />

− s f<br />

=<br />

s<br />

= h<br />

− h<br />

2<br />

− h<br />

1<br />

− q<br />

out<br />

in<br />

f<br />

fg<br />

+ x h<br />

4<br />

5.6159 − 0.8320<br />

=<br />

= 0.6761<br />

7.0752<br />

fg<br />

= 251.42 +<br />

( 0.6761)(<br />

2357.5<br />

= 2725.5 − 261.57 = 2463.9 kJ/kg<br />

= 1845.3 − 251.42 = 1594.0 kJ/kg<br />

out<br />

(b) Carnot Cycle analysis:<br />

x1<br />

P1<br />

= 20 kPa ⎫<br />

⎬<br />

s1<br />

= s2<br />

⎭ h1<br />

= 2463.9 −1594.0<br />

= 869.9 kJ/kg<br />

1594.0<br />

= 1−<br />

= 0.353<br />

2463.9<br />

P3<br />

= 10 MPa ⎫ h3<br />

= 2725.5 kJ/kg<br />

⎬<br />

x3<br />

= 1 ⎭T3<br />

= 311.0 ° C<br />

T2<br />

= T3<br />

= 311.0 ° C ⎫ h2<br />

= 1407.8 kJ/kg<br />

⎬<br />

x2<br />

= 0<br />

⎭ s2<br />

= 3.3603 kJ/kg ⋅ K<br />

q<br />

w<br />

q<br />

in<br />

out<br />

net<br />

= h<br />

3<br />

= h<br />

4<br />

= q<br />

in<br />

− h<br />

− h<br />

q<br />

η th = 1−<br />

q<br />

1<br />

− q<br />

out<br />

in<br />

s1<br />

− s f 3.3603 − 0.8320<br />

= =<br />

= 0.3574<br />

s fg 7.0752<br />

= h + x h<br />

f<br />

1<br />

fg<br />

= 251.42 + (0.3574)(2357.5) = 1093.9 kJ/kg<br />

2<br />

= 2725.5 −1407.8<br />

= 1317.7 kJ/kg<br />

= 1845.3 −1093.9<br />

= 751.4 kJ/kg<br />

out<br />

= 1317.7 − 752.3 = 565.4 kJ/kg<br />

751.4<br />

= 1−<br />

1317.7<br />

= 0.430<br />

)<br />

T<br />

2<br />

Rankine<br />

cycle<br />

T<br />

1<br />

Carnot<br />

cycle<br />

2 3<br />

1<br />

4<br />

3<br />

4<br />

s<br />

s

10-14<br />

10-25 A binary geothermal power operates on the simple Rankine cycle with isobutane as the working<br />

fluid. The isentropic efficiency of the turbine, the net power output, and the thermal efficiency of the cycle<br />

are to be determined.<br />

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.<br />

Properties The specific heat of geothermal water is taken to be 4.18 kJ/kg.ºC.<br />

Analysis (a) We need properties of isobutane,<br />

which are not available in the book. However,<br />

we can obtain the properties from EES.<br />

Turbine:<br />

P3<br />

= 3250 kPa ⎫h<br />

⎬<br />

T3<br />

= 147°<br />

C ⎭ s<br />

P4<br />

= 410 kPa ⎫<br />

⎬h<br />

s4<br />

= s3<br />

⎭<br />

P4<br />

= 410 kPa ⎫<br />

⎬h4<br />

T4<br />

= 179.5°<br />

C ⎭<br />

h3<br />

− h4<br />

η T =<br />

h − h<br />

3<br />

(b) Pump:<br />

1<br />

1<br />

2<br />

4s<br />

h = h<br />

v = v<br />

3<br />

3<br />

4s<br />

= 761.54 kJ/kg<br />

= 2.5457 kJ/kg ⋅ K<br />

= 670.40 kJ/kg<br />

= 689.74 kJ/kg<br />

761.54 − 689.74<br />

=<br />

= 0.788<br />

761.54 − 670.40<br />

f @ 410 kPa<br />

f @ 410 kPa<br />

= 273.01kJ/kg<br />

= 0.001842 m /kg<br />

v1( P2<br />

− P1<br />

)/<br />

ηP<br />

3<br />

( 0.001842 m /kg)( 3250 − 410)<br />

1<br />

p,in<br />

3<br />

turbine<br />

4<br />

3 2<br />

Geothermal<br />

water in<br />

wp,in<br />

=<br />

⎛ 1 kJ<br />

=<br />

kPa⎜<br />

3<br />

1 kPa m<br />

= 5.81 kJ/kg<br />

⎝ ⋅<br />

h = h + w = 273.01+<br />

5.81 = 278.82 kJ/kg<br />

⎞<br />

⎟<br />

/ 0.90<br />

⎠<br />

T<br />

air-cooled<br />

condenser<br />

heat exchanger<br />

2<br />

2s<br />

W &<br />

T, out = m&<br />

( h3<br />

− h4 ) = (305.6 kJ/kg)(761.54 − 689.74)kJ/kg = 21,941kW<br />

W &<br />

P, in = m&<br />

( h2<br />

− h1<br />

) = m&<br />

wp,<br />

in = (305.6 kJ/kg)(5.81kJ/kg) = 1777 kW<br />

W &<br />

net<br />

Heat Exchanger:<br />

= W&<br />

−W&<br />

= 21,941−1777<br />

= 20,165 kW<br />

T,out<br />

P,in<br />

1<br />

3.25 MPa<br />

q in<br />

410 kPa<br />

Q &<br />

in = m&<br />

geocgeo( Tin<br />

− Tout<br />

) = (555.9 kJ/kg)(4.18 kJ/kg. ° C)(160 − 90) ° C = 162,656 kW<br />

W&<br />

net 20,165<br />

(c) η th = = = 0.124 = 12.4%<br />

Q&<br />

162,656<br />

in<br />

q out<br />

1<br />

Geothermal<br />

water out<br />

3<br />

4s 4<br />

pump<br />

s

10-15<br />

10-26 A single-flash geothermal power plant uses hot geothermal water at 230ºC as the heat source. The<br />

mass flow rate of steam through the turbine, the isentropic efficiency of the turbine, the power output from<br />

the turbine, and the thermal efficiency of the plant are to be determined.<br />

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.<br />

Analysis (a) We use properties of water for<br />

geothermal water (Tables A-4 through A-6)<br />

T1<br />

= 230°<br />

C⎫<br />

⎬ h1<br />

= 990.14 kJ/kg<br />

x1<br />

= 0 ⎭<br />

P2<br />

= 500 kPa ⎫ h2<br />

− h f<br />

⎬x2<br />

=<br />

h2<br />

= h1<br />

= 990.14 kJ/kg⎭<br />

h fg<br />

The mass flow rate of steam through the turbine is<br />

m &<br />

= x & = (0.1661)(230 kg/s) = 38.20 kg/s<br />

3 2m1<br />

(b) Turbine:<br />

P3<br />

= 500 kPa ⎫ h<br />

⎬<br />

x3<br />

= 1 ⎭ s<br />

P4<br />

= 10 kPa ⎫<br />

⎬h<br />

s4<br />

= s3<br />

⎭<br />

3<br />

3<br />

4s<br />

P4<br />

= 10 kPa ⎫<br />

⎬h4<br />

x4<br />

= 0.90 ⎭<br />

3<br />

= 2748.1 kJ/kg<br />

= 6.8207 kJ/kg ⋅ K<br />

= 2160.3 kJ/kg<br />

= h<br />

h3<br />

− h4<br />

η T =<br />

h − h<br />

4s<br />

f<br />

+ x h<br />

4<br />

fg<br />

990.14 − 640.09<br />

=<br />

= 0.1661<br />

2108<br />

production<br />

well<br />

Flash<br />

chamber<br />

= 191.81+<br />

(0.90)(2392.1) = 2344.7 kJ/kg<br />

2748.1−<br />

2344.7<br />

=<br />

= 0.686<br />

2748.1−<br />

2160.3<br />

(c) The power output from the turbine is<br />

W &<br />

2<br />

1<br />

6<br />

separator<br />

= m&<br />

( h − 4 ) = (38.20 kJ/kg)(2748.1−<br />

2344.7) kJ/kg = 15,410 kW<br />

T, out 3 3 h<br />

(d) We use saturated liquid state at the standard temperature for dead state enthalpy<br />

T0<br />

= 25°<br />

C⎫<br />

⎬ h0<br />

x0<br />

= 0 ⎭<br />

= 104.83 kJ/kg<br />

E &<br />

in = m&<br />

1( h1<br />

− h0 ) = (230 kJ/kg)(990.14 −104.83)kJ/kg<br />

= 203,622 kW<br />

W&<br />

T,out 15,410<br />

η th = = = 0.0757 = 7.6%<br />

E&<br />

203,622<br />

in<br />

3<br />

steam<br />

turbine<br />

condenser<br />

4<br />

5<br />

reinjection<br />

well

10-16<br />

10-27 A double-flash geothermal power plant uses hot geothermal water at 230ºC as the heat source. The<br />

temperature of the steam at the exit of the second flash chamber, the power produced from the second<br />

turbine, and the thermal efficiency of the plant are to be determined.<br />

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.<br />

Analysis (a) We use properties of water for geothermal water (Tables A-4 through A-6)<br />

T1<br />

= 230°<br />

C⎫<br />

⎬ h1<br />

= 990.14 kJ/kg<br />

x1<br />

= 0 ⎭<br />

P2<br />

= 500 kPa ⎫<br />

⎬x2<br />

= 0.1661<br />

h2<br />

= h1<br />

= 990.14 kJ/kg⎭<br />

m&<br />

3<br />

m&<br />

6<br />

= x m&<br />

2<br />

= m&<br />

1<br />

1<br />

− m&<br />

P3<br />

= 500 kPa ⎫<br />

⎬ h<br />

x3<br />

= 1 ⎭<br />

= (0.1661)(230 kg/s) = 38.20 kg/s<br />

3<br />

P4<br />

= 10 kPa ⎫<br />

⎬h4<br />

x4<br />

= 0.90 ⎭<br />

P6<br />

= 500 kPa ⎫<br />

⎬ h<br />

x6<br />

= 0 ⎭<br />

P7<br />

= 150 kPa ⎫ T7<br />

⎬<br />

h7<br />

= h6<br />

⎭ x7<br />

P8<br />

= 150 kPa ⎫<br />

⎬h<br />

x8<br />

= 1 ⎭<br />

= 230 − 0.1661 = 191.80 kg/s<br />

8<br />

3<br />

= 2748.1 kJ/kg<br />

= 2344.7 kJ/kg<br />

6<br />

= 640.09 kJ/kg<br />

= 111.35 ° C<br />

= 0.0777<br />

= 2693.1 kJ/kg<br />

2<br />

production<br />

well<br />

6<br />

Flash<br />

chamber<br />

(b) The mass flow rate at the lower stage of the turbine is<br />

m &<br />

8 = x7m&<br />

6 = (0.0777)(191.80 kg/s) = 14.90 kg/s<br />

1<br />

separator<br />

7<br />

Flash<br />

chamber<br />

The power outputs from the high and low pressure stages of the turbine are<br />

W &<br />

T1, out = m&<br />

3( h3<br />

− h4 ) = (38.20 kJ/kg)(2748.1−<br />

2344.7)kJ/kg = 15,410 kW<br />

W &<br />

= m&<br />

( h − 4 ) = (14.90 kJ/kg)(2693.1−<br />

2344.7) kJ/kg = 5191 kW<br />

T2, out 8 8 h<br />

8<br />

3<br />

separator<br />

(c) We use saturated liquid state at the standard temperature for the dead state enthalpy<br />

T0<br />

= 25°<br />

C⎫<br />

⎬ h0<br />

x0<br />

= 0 ⎭<br />

= 104.83 kJ/kg<br />

E &<br />

in = m&<br />

1( h1<br />

− h0)<br />

= (230 kg/s)(990.14 −104.83)kJ/kg<br />

= 203,621kW<br />

W&<br />

T,out 15,410 + 5193<br />

η th = =<br />

= 0.101 = 10.1%<br />

E&<br />

203,621<br />

in<br />

9<br />

4<br />

condenser<br />

5<br />

reinjection<br />

well<br />

steam<br />

turbine

10-17<br />

10-28 A combined flash-binary geothermal power plant uses hot geothermal water at 230ºC as the heat<br />

source. The mass flow rate of isobutane in the binary cycle, the net power outputs from the steam turbine<br />

and the binary cycle, and the thermal efficiencies for the binary cycle and the combined plant are to be<br />

determined.<br />

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.<br />

Analysis (a) We use properties of water for geothermal water (Tables A-4 through A-6)<br />

T1<br />

= 230°<br />

C⎫<br />

⎬ h1<br />

= 990.14 kJ/kg<br />

x1<br />

= 0 ⎭<br />

P2<br />

= 500 kPa ⎫<br />

⎬x2<br />

= 0.1661<br />

h2<br />

= h1<br />

= 990.14 kJ/kg⎭<br />

m&<br />

3<br />

m&<br />

6<br />

= x m&<br />

2<br />

= m&<br />

1<br />

1<br />

− m&<br />

P3<br />

= 500 kPa ⎫<br />

⎬ h<br />

x3<br />

= 1 ⎭<br />

= (0.1661)(230 kg/s) = 38.20 kg/s<br />

3<br />

P4<br />

= 10 kPa ⎫<br />

⎬h4<br />

x4<br />

= 0.90 ⎭<br />

= 230 − 38.20 = 191.80 kg/s<br />

3<br />

= 2748.1 kJ/kg<br />

= 2344.7 kJ/kg<br />

P6<br />

= 500 kPa ⎫<br />

⎬ h6<br />

= 640.09 kJ/kg<br />

x6<br />

= 0 ⎭<br />

T7<br />

= 90°<br />

C ⎫<br />

⎬ h7<br />

= 377.04 kJ/kg<br />

x7<br />

= 0 ⎭<br />

The isobutene properties<br />

are obtained from EES:<br />

P8<br />

= 3250 kPa ⎫<br />

⎬ h<br />

T8<br />

= 145°<br />

C ⎭<br />

P9<br />

= 400 kPa ⎫<br />

⎬ h9<br />

T9<br />

= 80°<br />

C ⎭<br />

P<br />

x<br />

w<br />

10<br />

10<br />

= 400 kPa ⎫ h<br />

⎬<br />

= 0 ⎭v<br />

p,in<br />

h<br />

11<br />

8<br />

= 755.05 kJ/kg<br />

= 691.01 kJ/kg<br />

10<br />

10<br />

= 270.83 kJ/kg<br />

= 0.001839 m<br />

3<br />

/kg<br />

v10( P11<br />

− P10<br />

)/<br />

η p<br />

3<br />

( 0.001819 m /kg)( 3250 − 400)<br />

2<br />

flash<br />

chamber<br />

1<br />

separator<br />

production<br />

well<br />

=<br />

⎛ 1 kJ<br />

=<br />

kPa⎜<br />

1 kPa m<br />

= 5.82 kJ/kg.<br />

⎝ ⋅<br />

= h + w = 270.83 + 5.82 = 276.65 kJ/kg<br />

10<br />

p,in<br />

An energy balance on the heat exchanger gives<br />

m&<br />

( h<br />

− h<br />

) = m&<br />

(191.81kg/s)(640.09 - 377.04)kJ/kg = m&<br />

6<br />

6<br />

7<br />

iso<br />

iso<br />

3<br />

( h<br />

6<br />

3<br />

⎞<br />

⎟<br />

/ 0.90<br />

⎠<br />

8<br />

− h<br />

11<br />

)<br />

steam<br />

turbine<br />

8<br />

7<br />

4<br />

9<br />

isobutane<br />

turbine<br />

heat exchanger<br />

(755.05- 276.65)kJ/kg<br />

(b) The power outputs from the steam turbine and the binary cycle are<br />

W &<br />

⎯⎯→<br />

= m&<br />

( h − 4 ) = (38.19 kJ/kg)(2748.1−<br />

2344.7) kJ/kg = 15,410 kW<br />

T, steam 3 3 h<br />

air-cooled<br />

condenser<br />

1<br />

m&<br />

BINARY<br />

CYCLE<br />

iso<br />

condenser<br />

pump<br />

1<br />

= 105.46 kg/s<br />

5<br />

reinjection<br />

well

10-18<br />

W&<br />

W&<br />

T,iso<br />

= m&<br />

net,binary<br />

iso<br />

( h<br />

= W&<br />

8<br />

T,iso<br />

− h<br />

9<br />

− m&<br />

) = (105.46 kJ/kg)(755.05 − 691.01)kJ/kg = 6753 kW<br />

iso<br />

w<br />

p,<br />

in<br />

= 6753 − (105.46 kg/s)(5.82 kJ/kg) = 6139 kW<br />

(c) The thermal efficiencies of the binary cycle and the combined plant are<br />

Q &<br />

in, binary = m&<br />

iso ( h8<br />

− h11 ) = (105.46 kJ/kg)(755.05 − 276.65)kJ/kg = 50,454 kW<br />

η<br />

th,binary<br />

T0<br />

= 25°<br />

C⎫<br />

⎬ h0<br />

x0<br />

= 0 ⎭<br />

W&<br />

net,binary 6139<br />

= = = 0.122 = 12.2%<br />

Q&<br />

50,454<br />

in,binary<br />

= 104.83 kJ/kg<br />

E &<br />

in = m&<br />

1( h1<br />

− h0 ) = (230 kJ/kg)(990.14 −104.83)kJ/kg<br />

= 203,622 kW<br />

η<br />

th,plant<br />

W&<br />

T,steam + W&<br />

net,binary 15,410 + 6139<br />

= =<br />

= 0.106 = 10.6%<br />

E&<br />

203,622<br />

in<br />

The Reheat Rankine Cycle<br />

10-29C The pump work remains the same, the moisture content decreases, everything else increases.<br />

10-30C The T-s diagram of the ideal Rankine<br />

cycle with 3 stages of reheat is shown on the<br />

side. The cycle efficiency will increase as the<br />

number of reheating stages increases.<br />

T<br />

3 5 7 9<br />

I II III<br />

4 6 8<br />

2<br />

1<br />

10<br />

s<br />

10-31C The thermal efficiency of the simple ideal Rankine cycle will probably be higher since the average<br />

temperature at which heat is added will be higher in this case.

10-19<br />

10-32 [Also solved by EES on enclosed CD] A steam power plant that operates on the ideal reheat Rankine<br />

cycle is considered. The turbine work output and the thermal efficiency of the cycle are to be determined.<br />

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.<br />

Analysis From the steam tables (Tables A-4, A-5, and A-6),<br />

w<br />

h = h<br />

1<br />

v = v<br />

1<br />

p,in<br />

2<br />

=<br />

=<br />

f @ 20 kPa<br />

f @ 20 kPa<br />

v1( P2<br />

− P1<br />

)<br />

3<br />

( 0.001017 m /kg)( 8000 − 20 kPa)<br />

= 8.12 kJ/kg<br />

h = h<br />

1<br />

+ w<br />

p,in<br />

P3<br />

= 8 MPa ⎫ h<br />

⎬<br />

T3<br />

= 500°<br />

C ⎭ s<br />

P5<br />

= 3 MPa ⎫ h<br />

⎬<br />

T5<br />

= 500°<br />

C ⎭ s<br />

P6<br />

= 20 kPa ⎫ x6<br />

⎬<br />

s6<br />

= s5<br />

⎭<br />

h<br />

3<br />

3<br />

P4<br />

= 3 MPa ⎫<br />

⎬ h4<br />

s4<br />

= s3<br />

⎭<br />

5<br />

5<br />

6<br />

= 251.42 kJ/kg<br />

= 0.001017 m /kg<br />

3<br />

⎛ 1 kJ ⎞<br />

⎜ ⎟<br />

3<br />

1 kPa m<br />

⎝ ⋅ ⎠<br />

= 251.42 + 8.12 = 259.54 kJ/kg<br />

= 3399.5 kJ/kg<br />

= 6.7266 kJ/kg ⋅ K<br />

= 3105.1 kJ/kg<br />

= 3457.2 kJ/kg<br />

= 7.2359 kJ/kg ⋅ K<br />

s6<br />

− s f<br />

=<br />

s<br />

= h<br />

f<br />

fg<br />

+ x h<br />

6<br />

7.2359 − 0.8320<br />

=<br />

= 0.9051<br />

7.0752<br />

fg<br />

= 251.42 +<br />

( 0.9051)( 2357.5) = 2385.2 kJ/kg<br />

The turbine work output and the thermal efficiency are determined from<br />

and<br />

Thus,<br />

w<br />

w<br />

T,out<br />

q<br />

net<br />

in<br />

=<br />

=<br />

= w<br />

w<br />

η th =<br />

q<br />

( h − h ) + ( h − h )<br />

3<br />

T<br />

2<br />

1<br />

8 MPa<br />

20 kPa<br />

( h − h ) + ( h − h ) = 3399.5 − 259.54 + 3457.2 − 3105.1 = 3492.0 kJ/kg<br />

3<br />

T , out<br />

net<br />

in<br />

4<br />

2<br />

− w<br />

p,in<br />

5<br />

5<br />

1358.3 kJ/kg<br />

=<br />

= 38.9%<br />

3492.5 kJ/kg<br />

6<br />

4<br />

= 3399.5 − 3105.1+<br />

3457.2 − 2385.2 = 1366.4 kJ/kg<br />

= 1366.4 − 8.12 = 1358.3 kJ/kg<br />

3<br />

4<br />

5<br />

6<br />

s

10-20<br />

10-33 EES Problem 10-32 is reconsidered. The problem is to be solved by the diagram window data entry<br />

feature of EES by including the effects of the turbine and pump efficiencies and reheat on the steam quality<br />

at the low-pressure turbine exit Also, the T-s diagram is to be plotted.<br />

Analysis The problem is solved using EES, and the solution is given below.<br />

"Input Data - from diagram window"<br />

{P[6] = 20 [kPa]<br />

P[3] = 8000 [kPa]<br />

T[3] = 500 [C]<br />

P[4] = 3000 [kPa]<br />

T[5] = 500 [C]<br />

Eta_t = 100/100 "Turbine isentropic efficiency"<br />

Eta_p = 100/100 "Pump isentropic efficiency"}<br />

"Pump analysis"<br />

function x6$(x6) "this function returns a string to indicate the state of steam at point 6"<br />

x6$=''<br />

if (x6>1) then x6$='(superheated)'<br />

if (x6

10-21<br />

vs[6]=volume(Fluid$,s=s_s[6],P=P[6])<br />

Eta_t=(h[5]-h[6])/(h[5]-hs[6])"Definition of turbine efficiency"<br />

h[5]=W_t_lp+h[6]"SSSF First Law for the low pressure turbine"<br />

x[6]=QUALITY(Fluid$,h=h[6],P=P[6])<br />

"Boiler analysis"<br />

Q_in + h[2]+h[4]=h[3]+h[5]"SSSF First Law for the Boiler"<br />

"Condenser analysis"<br />

h[6]=Q_out+h[1]"SSSF First Law for the Condenser"<br />

T[6]=temperature(Fluid$,h=h[6],P=P[6])<br />

s[6]=entropy(Fluid$,h=h[6],P=P[6])<br />

x6s$=x6$(x[6])<br />

"Cycle Statistics"<br />

W_net=W_t_hp+W_t_lp-W_p<br />

Eff=W_net/Q_in<br />

700<br />

600<br />

Ideal Rankine cycle with reheat<br />

500<br />

3<br />

5<br />

T [C]<br />

400<br />

300<br />

200<br />

8000 kPa<br />

3000 kPa<br />

4<br />

100<br />

1,2<br />

20 kPa<br />

6<br />

0<br />

0.0 1.1 2.2 3.3 4.4 5.5 6.6 7.7 8.8 9.9 11.0<br />

s [kJ/kg-K]<br />

SOLUTION<br />

Eff=0.389 Eta_p=1 Eta_t=1<br />

Fluid$='Steam_IAPWS' h[1]=251.4 [kJ/kg] h[2]=259.5 [kJ/kg]<br />

h[3]=3400 [kJ/kg] h[4]=3105 [kJ/kg] h[5]=3457 [kJ/kg]<br />

h[6]=2385 [kJ/kg] hs[4]=3105 [kJ/kg] hs[6]=2385 [kJ/kg]<br />

P[1]=20 [kPa] P[2]=8000 [kPa] P[3]=8000 [kPa]<br />

P[4]=3000 [kPa] P[5]=3000 [kPa] P[6]=20 [kPa]<br />

Q_in=3493 [kJ/kg] Q_out=2134 [kJ/kg] s[1]=0.832 [kJ/kg-K]<br />

s[2]=0.8321 [kJ/kg-K] s[3]=6.727 [kJ/kg-K] s[4]=6.727 [kJ/kg-K]<br />

s[5]=7.236 [kJ/kg-K] s[6]=7.236 [kJ/kg-K] s_s[4]=6.727 [kJ/kg-K]<br />

s_s[6]=7.236 [kJ/kg-K] T[1]=60.06 [C] T[2]=60.4 [C]<br />

T[3]=500 [C] T[4]=345.2 [C] T[5]=500 [C]<br />

T[6]=60.06 [C] Ts[4]=345.2 [C] Ts[6]=60.06 [C]<br />

v[1]=0.001017 [m^3/kg] v[2]=0.001014 [m^3/kg] v[3]=0.04177 [m^3/kg]<br />

v[4]=0.08968 [m^3/kg] vs[6]=6.922 [m^3/kg] W_net=1359 [kJ/kg]<br />

W_p=8.117 [kJ/kg] W_p_s=8.117 [kJ/kg] W_t_hp=294.8 [kJ/kg]<br />

W_t_lp=1072 [kJ/kg] x6s$='' x[1]=0<br />

x[6]=0.9051

10-22<br />

10-34 A steam power plant that operates on a reheat Rankine cycle is considered. The quality (or<br />

temperature, if superheated) of the steam at the turbine exit, the thermal efficiency of the cycle, and the<br />

mass flow rate of the steam are to be determined.<br />

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.<br />

Analysis (a) From the steam tables (Tables A-4, A-5, and A-6),<br />

w<br />

h = h<br />

1<br />

v = v<br />

1<br />

p,in<br />

h<br />

2<br />

=<br />

=<br />

f @ 10 kPa<br />

f @ 10 kPa<br />

v 1( P2<br />

− P1<br />

)/<br />

η p<br />

⎛ 1 kJ ⎞<br />

3<br />

( 0.00101 m /kg)( 10,000 −10<br />

kPa) ⎜ ⎟/<br />

( 0.95)<br />

= 10.62<br />

= h<br />

1<br />

+ w<br />

kJ/kg<br />

p,in<br />

P3<br />

= 10 MPa ⎫ h<br />

⎬<br />

T3<br />

= 500°<br />

C ⎭ s<br />

P<br />

s<br />

4s<br />

4s<br />

η<br />

T<br />

= 1 MPa ⎫<br />

⎬ h<br />

= s3<br />

⎭<br />

h3<br />

− h<br />

=<br />

h − h<br />

3<br />

= 191.81 kJ/kg<br />

= 0.001010<br />

m<br />

/kg<br />

= 191.81+<br />

10.62 = 202.43<br />

4<br />

4s<br />

P5<br />

= 1 MPa ⎫ h5<br />

⎬<br />

T5<br />

= 500°<br />

C ⎭ s5<br />

P<br />

s<br />

6s<br />

6s<br />

= 10 kPa ⎫ x<br />

⎬<br />

= s5<br />

⎭<br />

h<br />

3<br />

3<br />

4s<br />

⎯→<br />

= 6.5995 kJ/kg ⋅ K<br />

= 7.7642 kJ/kg ⋅ K<br />

3<br />

= 3375.1 kJ/kg<br />

= 2783.8 kJ/kg<br />

h = h − η<br />

4<br />

3<br />

= 3375.1<br />

= 3479.1 kJ/kg<br />

6s<br />

6s<br />

s<br />

=<br />

= h<br />

6s<br />

f<br />

s<br />

− s<br />

fg<br />

+ x<br />

f<br />

6s<br />

T<br />

⎜<br />

⎝1<br />

kPa ⋅ m<br />

kJ/kg<br />

3<br />

⎟<br />

⎠<br />

( h3<br />

− h4<br />

s )<br />

− ( 0.80)( 3375.1−<br />

2783.7)<br />

7.7642 − 0.6492<br />

=<br />

= 0.9487<br />

7.4996<br />

h<br />

fg<br />

= 191.81 +<br />

( 0.9487)( 2392.1)<br />

T<br />

2<br />

2<br />

1<br />

= 2902.0 kJ/kg<br />

10 MPa<br />

( at turbine exit)<br />

= 2461.2 kJ/kg<br />

10 kPa<br />

3<br />

4s 4<br />

6<br />

5<br />

6<br />

s<br />

η<br />

T<br />

h<br />

=<br />

h<br />

5<br />

5<br />

− h<br />

− h<br />

6<br />

6s<br />

⎯⎯→<br />

h = h −η<br />

6<br />

5<br />

T<br />

= 3479.1 −<br />

= 2664.8 kJ/kg<br />

( h5<br />

− h6s<br />

)<br />

( 0.80)( 3479.1 − 2461.2)<br />

> h ( superheated vapor)<br />

g<br />

From steam tables at 10 kPa we read T 6 = 88.1°C.<br />

(b) w = ( h − h ) + ( h − h )<br />

T,out<br />

w<br />

q<br />

in<br />

net<br />

=<br />

3<br />

( h − h ) + ( h − h )<br />

= w<br />

3<br />

T,out<br />

4<br />

2<br />

− w<br />

p,in<br />

Thus the thermal efficiency is<br />

η<br />

th<br />

w<br />

=<br />

q<br />

net<br />

in<br />

5<br />

5<br />

6<br />

4<br />

= 3375.1−<br />

2902.0 + 3479.1−<br />

2664.8 = 1287.4 kJ/kg<br />

= 3375.1−<br />

202.43 + 3479.1−<br />

2902.0 = 3749.8 kJ/kg<br />

= 1287.4 −10.62<br />

= 1276.8 kJ/kg<br />

1276.8 kJ/kg<br />

=<br />

= 34.1%<br />

3749.8 kJ/kg<br />

(c) The mass flow rate of the steam is<br />

W<br />

m & =<br />

&<br />

w<br />

net<br />

net<br />

=<br />

80,000 kJ/s<br />

1276.9 kJ/kg<br />

= 62.7 kg/s

10-23<br />

10-35 A steam power plant that operates on the ideal reheat Rankine cycle is considered. The quality (or<br />

temperature, if superheated) of the steam at the turbine exit, the thermal efficiency of the cycle, and the<br />

mass flow rate of the steam are to be determined.<br />

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.<br />

Analysis (a) From the steam tables (Tables A-4, A-5, and A-6),<br />

w<br />

h = h<br />

1<br />

v = v<br />

1<br />

p,in<br />

h<br />

2<br />

=<br />

=<br />

f @ 10 kPa<br />

f @ 10 kPa<br />

v 1( P2<br />

− P1<br />

)<br />

3<br />

( 0.00101 m /kg)( 10,000 −10<br />

kPa)<br />

= 10.09<br />

= h<br />

1<br />

+ w<br />

kJ/kg<br />

p,in<br />

P3<br />

= 10 MPa ⎫ h<br />

⎬<br />

T3<br />

= 500°<br />

C ⎭ s<br />

P4<br />

= 1 MPa ⎫<br />

⎬ h4<br />

s4<br />

= s3<br />

⎭<br />

P5<br />

= 1 MPa ⎫ h5<br />

⎬<br />

T5<br />

= 500°<br />

C ⎭ s5<br />

P6<br />

= 10 kPa ⎫ x6<br />

⎬<br />

s6<br />

= s5<br />

⎭<br />

h<br />

6<br />

3<br />

3<br />

= 191.81 kJ/kg<br />

= 0.00101 m<br />

/kg<br />

= 191.81+<br />

10.09 = 201.90<br />

= 6.5995 kJ/kg ⋅ K<br />

= 2783.8 kJ/kg<br />

= 3479.1 kJ/kg<br />

= 7.7642 kJ/kg ⋅ K<br />

3<br />

= 3375.1 kJ/kg<br />

s6<br />

− s f<br />

=<br />

s<br />

= h<br />

f<br />

fg<br />

+ x h<br />

(b) w = ( h − h ) + ( h − h )<br />

T,out<br />

w<br />

q<br />

in<br />

net<br />

=<br />

3<br />

( h − h ) + ( h − h )<br />

= w<br />

3<br />

T,out<br />

4<br />

2<br />

−<br />

5<br />

5<br />

w p ,in<br />

Thus the thermal efficiency is<br />

η<br />

th<br />

w<br />

=<br />

q<br />

net<br />

in<br />

6<br />

6<br />

4<br />

= 191.81+<br />

⎛<br />

⎜<br />

1 kJ<br />

⎝1 kPa ⋅ m<br />

kJ/kg<br />

3<br />

⎞<br />

⎟<br />

⎠<br />

7.7642 − 0.6492<br />

=<br />

= 0.9487<br />

7.4996<br />

fg<br />

= 1609.4 −10.09<br />

= 1599.3 kJ/kg<br />

1599.3 kJ/kg<br />

=<br />

= 41.3%<br />

3868.5 kJ/kg<br />

(c) The mass flow rate of the steam is<br />

W&<br />

m & = w<br />

net<br />

net<br />

=<br />

80,000 kJ/s<br />

1599.3 kJ/kg<br />

T<br />

( at turbine exit)<br />

( 0.9487)( 2392.1) = 2461.2 kJ/kg<br />

2<br />

1<br />

10 MPa<br />

10 kPa<br />

= 3375.1−<br />

2783.7 + 3479.1−<br />

2461.2 = 1609.3 kJ/kg<br />

= 3375.1−<br />

201.90 + 3479.1−<br />

2783.7 = 3868.5 kJ/kg<br />

= 50 . 0 kg/<br />

s<br />

3<br />

4<br />

5<br />

6<br />

s

10-24<br />

10-36E A steam power plant that operates on the ideal reheat Rankine cycle is considered. The pressure at<br />

which reheating takes place, the net power output, the thermal efficiency, and the minimum mass flow rate<br />

of the cooling water required are to be determined.<br />

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.<br />

Analysis (a) From the steam tables (Tables A-4E, A-5E, and A-6E),<br />

w<br />

h = h<br />

1<br />

v = v<br />

1<br />

T = T<br />

1<br />

p,in<br />

h<br />

2<br />

=<br />

=<br />

sat@ 1 psia<br />

sat@ 1 psia<br />

sat@ 1 psia<br />

v 1( P2<br />

− P1<br />

)<br />

3<br />

( 0.01614 ft /lbm)( 800 −1 psia)<br />

= 2.39 Btu/lbm<br />

= h<br />

1<br />

+ w<br />

p,in<br />

= 69.72 Btu/lbm<br />

= 0.01614<br />

= 101.69°<br />

F<br />

ft<br />

3<br />

/lbm<br />

⎛ 1 Btu ⎞<br />

⎜<br />

⎟<br />

3<br />

5.4039 psia ft<br />

⎝<br />

⋅ ⎠<br />

= 69.72 + 2.39 = 72.11 Btu/lbm<br />

T<br />

2<br />

1<br />

800 psia<br />

1 psia<br />

3<br />

4<br />

5<br />

6<br />

s<br />

P<br />

T<br />

s<br />

3<br />

3<br />

4<br />

= 800 psia<br />

= 900 ° F<br />

= s<br />

3<br />

( sat. vapor )<br />

⎫ h<br />

⎬<br />

⎭ P<br />

⎫ h<br />

⎬<br />

⎭ s<br />

4<br />

4<br />

3<br />

3<br />

= h<br />

= P<br />

= 1456 .0 Btu/lbm<br />

= 1.6413 Btu/lbm ⋅ R<br />

g @ s g = s4<br />

sat @ s g = s4<br />

= 1178 .5 Btu/lbm<br />

= 62.23 psia (the<br />

reheat<br />

pressure)<br />

P<br />

T<br />

P<br />

s<br />

5<br />

5<br />

6<br />

6<br />

= 62 .23 psia<br />

= 800 ° F<br />

= 1 psia<br />

= s<br />

5<br />

⎫ x<br />

⎬<br />

⎭<br />

h<br />

6<br />

6<br />

⎫ h<br />

⎬<br />

⎭ s<br />

=<br />

5<br />

5<br />

s<br />

= h<br />

6<br />

f<br />

= 1431 .4 Btu/lbm<br />

= 1.8985 Btu/lbm ⋅ R<br />

− s<br />

s<br />

fg<br />

f<br />

+ x h<br />

(b) q = ( h − h ) + ( h − h )<br />

Thus,<br />

q<br />

η<br />

in<br />

out<br />

th<br />

= h<br />

6<br />

3<br />

− h<br />

q<br />

= 1−<br />

q<br />

out<br />

in<br />

1<br />

2<br />

5<br />

4<br />

6<br />

1.8985 − 0.13262<br />

=<br />

1.84495<br />

fg<br />

= 69 .72 +<br />

= 1061.0 − 69.72 = 991.3 Btu/lbm<br />

= 0.9572<br />

( 0.9572 )( 1035 .7) = 1061 .0 Btu/lbm<br />

= 1456.0 − 72.11 + 1431.4 −1178.5<br />

= 1636.8 Btu/lbm<br />

991.3 Btu/lbm<br />

= 1−<br />

= 39.4%<br />

1636.8 Btu/lbm<br />

(c) The mass flow rate of the cooling water will be minimum when it is heated to the temperature of the<br />

steam in the condenser, which is 101.7°F,<br />

Q&<br />

m&<br />

out<br />

cool<br />

= Q&<br />

in −W&<br />

Q&<br />

out<br />

= =<br />

c∆T<br />

net<br />

=<br />

4<br />

( 1−η<br />

) Q&<br />

= ( 1−<br />

0.3943)( 6×<br />

10 Btu/s)<br />

th<br />

in<br />

3.634×<br />

10<br />

Btu/s<br />

( 1.0 Btu/lbm⋅°<br />

F)( 101.69 − 45)<br />

4<br />

= 641.0 lbm/s<br />

° F<br />

= 3.634×<br />

10<br />

4<br />

Btu/s

10-25<br />

10-37 A steam power plant that operates on an ideal reheat Rankine cycle between the specified pressure<br />

limits is considered. The pressure at which reheating takes place, the total rate of heat input in the boiler,<br />

and the thermal efficiency of the cycle are to be determined.<br />

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.<br />

Analysis (a) From the steam tables (Tables A-4, A-5, and A-6),<br />

h = h<br />

1<br />

sat@ 10 kPa<br />

= 191.81 kJ/kg<br />

T<br />

w<br />

v = v<br />

1<br />

p,in<br />

h<br />

2<br />

=<br />

=<br />

sat@ 10 kPa<br />

v 1( P2<br />

− P1<br />

)<br />

3<br />

( 0.00101 m /kg)( 15,000 −10<br />

kPa)<br />

= 15.14 kJ/kg<br />

= h<br />

1<br />

+ w<br />

p,in<br />

P3<br />

= 15 MPa ⎫ h<br />

⎬<br />

T3<br />

= 500°<br />

C ⎭ s<br />

3<br />

3<br />

= 0.00101 m<br />

3<br />

/kg<br />

⎛<br />

⎜<br />

1 kJ<br />

⎝1 kPa ⋅ m<br />

= 191.81+<br />

15.14 = 206.95 kJ/kg<br />

10 kPa<br />

1<br />

= 3310.8 kJ/kg<br />

= 6.3480 kJ/kg ⋅ K<br />

P6<br />

= 10 kPa ⎫ h6<br />

= hf<br />

+ x6h<br />

⎬<br />

s6<br />

= s5<br />

⎭ s6<br />

= s f + x6s<br />

T5<br />

= 500°<br />

C ⎫ P5<br />

= 2161kPa<br />

⎬<br />

s5<br />

= s6<br />

⎭ h5<br />

= 3466.53 kJ/kg<br />

fg<br />

fg<br />

= 191.81+<br />

= 0.6492 +<br />

3<br />

( 0.90)( 2392.1)<br />

( 0.90)( 7.4996)<br />

( the reheat pressure)<br />

15 MPa<br />

⎞<br />

⎟<br />

⎠<br />

2<br />

= 2344.7 kJ/kg<br />

= 7.3988 kJ/kg ⋅ K<br />

3<br />

4<br />

5<br />

6<br />

s<br />

P4<br />

= 2.161 MPa ⎫<br />

⎬ h4<br />

s4<br />

= s3<br />

⎭<br />

= 2817.2 kJ/kg<br />

(b) The rate of heat supply is<br />

Q &<br />

in<br />

=<br />

=<br />

m&<br />

[( h3<br />

− h2<br />

) + ( h5<br />

− h4<br />

)]<br />

( 12 kg/s)( 3310.8 − 206.95 + 3466.53 − 2817.2) kJ/kg = 45,038 kW<br />

(c) The thermal efficiency is determined from<br />

Thus,<br />

Q&<br />

out<br />

= m&<br />

h<br />

( − h ) = ( 12 kJ/s)( 2344.7 − )<br />

6<br />

Q&<br />

η th = 1−<br />

Q&<br />

out<br />

in<br />

1<br />

25,834 kJ/s<br />

= 1−<br />

= 42.6%<br />

45,039 kJ/s<br />

191.81 kJ/kg = 25,835 kJ/s

10-26<br />

10-38 A steam power plant that operates on a reheat Rankine cycle is considered. The condenser pressure,<br />

the net power output, and the thermal efficiency are to be determined.<br />

Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible.<br />

Analysis (a) From the steam tables (Tables A-4, A-5, and A-6),<br />

P3<br />

= 12.5 MPa ⎫ h<br />

⎬<br />

T3<br />

= 550°<br />

C ⎭ s<br />

P4<br />

= 2 MPa ⎫<br />

⎬ h<br />

s4s<br />

= s3<br />

⎭<br />

η<br />

T<br />

→h<br />

h3<br />

− h<br />

=<br />

h − h<br />

4<br />

3<br />

= h<br />

= 3476.5<br />

= 3027.3 kJ/kg<br />

P5<br />

= 2 MPa ⎫ h<br />

⎬<br />

T5<br />

= 450°<br />

C ⎭ s<br />

T<br />

5<br />

3<br />

P6<br />

= ⎫<br />

⎬ h<br />

s6<br />

= s5⎭<br />

6s<br />

4<br />

4s<br />

− η<br />

h5<br />

− h<br />

=<br />

h − h<br />

6<br />

T<br />

P6<br />

= ⎫<br />

⎬ h6<br />

=<br />

x6<br />

= 0.95⎭<br />

η<br />

=<br />

6s<br />

4s<br />

= 3476.5<br />

= 6.6317 kJ/kg ⋅ K<br />

= 2948.1 kJ/kg<br />

( h3<br />

− h4<br />

s )<br />

− ( 0.85)( 3476.5 − 2948.1)<br />

5<br />

5<br />

3<br />

3<br />

= 3358.2 kJ/kg<br />

kJ/kg<br />

= 7.2815 kJ/kg ⋅ K<br />

⎯→<br />

h = h − η<br />

6<br />

5<br />

T<br />

= 3358.2<br />

Boiler<br />

2<br />

2s<br />

12.5 MPa<br />

( h5<br />

− h6<br />

s )<br />

− ( 0.85)( 3358.2 − 2948.1) = 3027.3 kJ/kg<br />

2<br />

T<br />

1<br />

4<br />

5<br />

Pump<br />

P = <br />

3<br />

Condenser<br />

3<br />

4<br />

4s<br />

5<br />

6s 6<br />

Turbine<br />

The pressure at state 6 may be determined by a trial-error approach from the steam tables or by using EES<br />

from the above equations:<br />

P 6 = 9.73 kPa, h 6 = 2463.3 kJ/kg,<br />

(b) Then,<br />

w<br />

h = h<br />

1<br />

v = v<br />

1<br />

p,in<br />

h<br />

2<br />

=<br />

=<br />

Cycle analysis:<br />

q =<br />

q<br />

W&<br />

in<br />