SAFACTIVE FILTER - COMAR CONDENSATORI SpA

SAFACTIVE FILTER - COMAR CONDENSATORI SpA

SAFACTIVE FILTER - COMAR CONDENSATORI SpA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

UNI EN ISO 9001:2000<br />

C<br />

E<br />

R<br />

T<br />

I<br />

F<br />

MANAGEMENT<br />

I<br />

E<br />

D<br />

SYSTEM<br />

ec<br />

UNI EN ISO 14001<br />

H&S<br />

OH SAS 18001<br />

SAF ACTIVE <strong>FILTER</strong>

Shunt active filters for<br />

active compensation of<br />

harmonic currents<br />

The <strong>COMAR</strong> factory, established in 1968, was built with the future in<br />

mind. By installing superior equipment the factory has remained<br />

technologically advanced even by to-day’s standards. Originally, the<br />

production was based on a wide range of “oil-paper” capacitors. The<br />

quality of the product was such that the <strong>COMAR</strong> brand was soon<br />

acknowledged both in Italy and world wide. A large investment in<br />

research and development during this early period made it possible<br />

to commence production of the innovative metallized polypropylene<br />

film capacitors. The capacitors became part of the standard range in<br />

the 1972 and are still produced by all the main manufactures in the<br />

capacitors market. In the following years, the range was enlarged by<br />

addition of electrolytic capacitors and capacitors specifically for power<br />

electronics. Power factor correction equipment and power factor<br />

regulators were also developed in this period.<br />

Within recent years, because of the diffusion of static power converters,<br />

<strong>COMAR</strong> has examined and resolved the intricate problems of reactive<br />

compensation presented by harmonics. Their study of this subject<br />

has been so successful that <strong>COMAR</strong> is on of the leaders in this very<br />

demanding field. At present, due to the complete automation of all<br />

production lines and advanced test equipment it has been possible<br />

to increase production and improve the level of quality. This is <strong>COMAR</strong>.<br />

UNI EN ISO 9001 quality management system<br />

UNI EN ISO 9001:2000<br />

ec<br />

UNI EN ISO 14001<br />

UNI EN ISO 14001 enviromental management system<br />

H&S<br />

OH SAS 18001<br />

OHSAS 18001 occupational health and safety<br />

management system<br />

Products listed in the present catalogue are in conformity with:<br />

73/23/EEC Low voltage Directive, 89/336 Electro-Magnetic<br />

Compatibility and 93/68EEC Directive.

Index<br />

• Introduction ........................................................................................................................ 4<br />

• Why filtering ....................................................................................................................... 4<br />

• Operatine mode ................................................................................................................. 6<br />

• The hysteresis control ........................................................................................................ 8<br />

• SAF interface ..................................................................................................................... 9<br />

• Led interface .................................................................................................................. 10<br />

• Active filter performances ............................................................................................... 10<br />

• Sizing SAF ..................................................................................................................... 11<br />

• Connection of SAF ......................................................................................................... 12<br />

• The SAF system............................................................................................................. 13<br />

• SAF features .................................................................................................................. 14<br />

http://www.comarcond.com<br />

3

Introduction<br />

In the last twenty years the fast introduction on the market of electronic equipment has brought along with<br />

their advantages many problems due to the noise on the electrical distribution network. In particular the most<br />

dangerous phenomena that degrades the power quality is the presence of harmonic currents generated by<br />

these non linear loads that are continuously changing their impedance during their working cycle, the<br />

absorption of current from the mains is not perfectly sinusoidal at the fundamental frequency, but is a sum of<br />

current with a different frequency multiple of the fundamental.<br />

Why Filtering<br />

These loads can cause many problems to the network and to the other loads connected. Here below is a list<br />

of some types of load that can generate harmonic pollution in the installation during our normal working day:<br />

‣ personal computers<br />

‣ welders<br />

‣ UPS<br />

‣ lifts/elevators<br />

‣ printers<br />

‣ motor speed regulator (AC and DC)<br />

‣ rectifier<br />

‣ semiconductor system with angle regulator<br />

‣ fluorescent lamps with ballasts<br />

‣ SMPS<br />

‣ frequency regulator<br />

Some of this equipment if considered alone does not have a large impact on the installation, but the<br />

influence they have on the network and the other loads connected to it became very important and can<br />

cause serious problems to the integrity of the network.<br />

Then other particular loads that work in critical conditions such as medical equipment (X-ray machinery,<br />

magnetic resonance equipment, etc.) not only can generate harmonic distortion in large amounts, but also<br />

they introduce harmonic pollution in an intermittent manner whilst rapidly changing their working conditions<br />

during a cycle of operation.<br />

So the harmonic currents generated by this load causes great problems and it is important to eliminate them<br />

not only for the immediate effects but also for the problem that can arise in the machinery, other equipment<br />

and the installation.<br />

Many problems can be caused by harmonics, the most common are:<br />

‣ vibration of motors<br />

‣ overheating of the cables<br />

‣ tripping of protective devices<br />

4 http://www.comarcond.com

The presence of harmonic current in the installation can be a large problem because while the<br />

equipment works coupled with the impedance network, it creates also voltage distortion: this distortion<br />

can have a so high level to introduce problems with the other connected equipments in the installation as<br />

in example:<br />

‣ vibration and overheating on the electric motors<br />

‣ noise and loss in the transformers<br />

‣ shortened life of components and conductors in the installation<br />

‣ erratic working of the control circuits that synchronize to the zero-crossing point of the sine wave.<br />

In fact there could be errors in reading the synchronizing signal<br />

‣ voltage difference between the neutral conductor and the protective conductor ( Ground / Earth )<br />

‣ voltage fluctuation of the supply system<br />

‣ erratic operation of voltage or phase loss monitoring equipment<br />

Typical absorption current by a non linear load<br />

Then we have to consider the penalties that the electrical distribution companies charge to their customers<br />

for bad power factor correction due to harmonics.<br />

In order to solve all these problems in accordance with international regulations, the usually adopted<br />

standard is IEEE519 “Recommended Practices and Requirements for Harmonic Control in Electric Power<br />

System” this attempts to establish reasonable harmonic goals for an electrical system that contains non<br />

linear loads to satisfy both customer and distribution company requirements.<br />

The objective is to propose steady-state harmonic limits that are considered reasonable both for electrical<br />

utilities and their customers.<br />

The underlying philosophy is that the customer should limit harmonic currents; electrical utilities should limit<br />

harmonic voltage and both parties share the responsibility for holding harmonic level in check avoiding faults<br />

in installations and loads.<br />

To eliminate harmonic current a passive filter can be used. They are efficient but are also not suitable for<br />

some applications where their characteristics don’t exactly match the requirements:<br />

‣ the filter is difficult to dimension<br />

‣ when a change occurs in the filtered installation (for example: it could be necessary to connect a<br />

new machinery or to substitute an old one with new electrical features) the filter has to be changed<br />

‣ it has partial filtering<br />

‣ it has a very slow dynamic response, so it is not responsive to fast load variation<br />

‣ it’s easy to overload<br />

‣ there’s risk of electrical oscillation with the network impedance<br />

‣ the efficiency depends from the voltage network quality (harmonic voltage distortion)<br />

To overcome these growing technical problems Comar Condensatori S.p.A. has developed SAF, a new<br />

innovative active filter designed to eliminate the harmonic distortion phenomena due to industrial non linear<br />

loads (by its filtering action) and at the same time compensate the reactive power demand of the load (power<br />

factor correction) bringing the installation emission within the recommended levels of IEEE519.<br />

SAF is designed to correct latest generation electronic load harmonic problems.<br />

http://www.comarcond.com<br />

5

So:<br />

‣ it recognizes and compensates all the current up to the 50 th harmonic order<br />

‣ it has excellent dynamic response to fast load variation<br />

‣ it compensates if network features change due to new machinery or equipment in the installation<br />

‣ it is impossible to overload<br />

‣ it’s easy to size<br />

‣ every module is easily connected<br />

‣ it fits every kind of load so it will not be obsolete<br />

These good performance of SAF, with the possibility to connect it to existing an installation and its<br />

modular design allows the filter to give the right solution for every problem with harmonic pollution,<br />

in every kind of condition.<br />

Current from a non linear load (top)<br />

and his relative filtered current (bottom)<br />

Operating mode<br />

The active filter is based on “compensation”, that means that in order to eliminate in a three phase<br />

system the harmonic current absorbed by the non linear load, the filter from the current of the load,<br />

calculates and injects the same harmonics (over the fundamental) shifted by 180 degrees. It results in a<br />

complete elimination from the installation of the dangerous component of the current.<br />

Figure 1<br />

LOAD<br />

Active Filter operation scheme<br />

At the same way it is possible to have a power factor correction of the load, producing three sinusoidal shaped<br />

current waveforms, with an amplitude in line with the load.<br />

In order to understand how SAF operates, look at the picture below there are three different blocks, each one<br />

showing different operating stages of the Active Filter:<br />

6 http://www.comarcond.com

Active Filter block schematic<br />

• Input block, it has:<br />

- Main break switch; fuses;<br />

- EMC filter;<br />

- contactor;<br />

- pre-charge circuit for electrolytic capacitors ;<br />

- line filter;<br />

The main break switch with automatic turn-off and the pre-charge relay, allows the filter to turn-off<br />

and completely disconnect from the network when a internal fault occurs. So that an internal<br />

malfunction of the SAF (i.e. capacitor / microprocessor etc.) doesn’t damage the installation.<br />

To guarantee rapid protection of the input line, the filter is connected with ultra-fast fuses. This<br />

protects the line from every internal problem such as short-circuit, overload, etc. Then the input filter<br />

avoids the emission of harmonic current at the switching frequency of the inverter bridge.<br />

• Inverter block it has:<br />

- semiconductor;<br />

- induction coil;<br />

- electrolytic capacitors;<br />

- heatsink;<br />

- fan;<br />

- power board;<br />

It’s the heart of the power module of SAF.<br />

It can be see as the actuator of the regulator block; in fact it converts the current set point (analog<br />

signal with low power given by the regulation, calculated from the load current) in a current that is in<br />

real time the same as the load harmonic current but 180 degree shifted.<br />

It is established by a typical six-switch semiconductor structure, IGBT technology based, with three<br />

smoothing induction coils and an electrolytic capacitor bank for the DC bus voltage.<br />

• The regulation, it has:<br />

- Microprocessor board<br />

With the regulation based on the hysteresis control, the active filter designed by Comar Condensatori<br />

S.p.A. adapts in real time its dynamic response to the real harmonic and reactive load request.<br />

The response at the amplitude of the harmonic load current is in real time so the harmonic<br />

mitigation is good even for loads with very quick variation of the working condition.<br />

These performances are guaranteed in every field of application and the dynamic characteristic of the<br />

control gives to SAF features hard to find in the market.<br />

http://www.comarcond.com<br />

7

Only harmonic<br />

compensation<br />

HP<br />

Filter<br />

Load<br />

current<br />

Line<br />

current ref.<br />

Total<br />

compensation<br />

Vdc_ref<br />

+<br />

Vdc<br />

feedback<br />

–<br />

PI<br />

Regulator<br />

+<br />

– +<br />

–<br />

I_SAF<br />

feedback<br />

Hysteresis<br />

control<br />

SAF current<br />

transducer<br />

SAF<br />

DC voltage<br />

transducer<br />

Control filter chart<br />

The hysteresis control<br />

The typical current emitted by Active Filter with a PWM modulation and hysteresis control is shown in the<br />

figure below where the current has a triangular shape with a carrier frequency of 10 kHz:<br />

This current is then modulated with the next rule: it changes continuously between the upper band and the<br />

bottom band, where it is forced to change. These two bands are shaped from the regulation block based on<br />

the load harmonic current and the internal regulation PWM control rules.<br />

Then a DC internal bus composed by two electrolytic capacitor banks, one with a positive potential and the<br />

other with a negative potential is the current source for the filter (so when the inverter block of the filter<br />

injects on to the network the “correcting” current it takes it from this bus).<br />

When SAF works, it switch on the upper side of the semiconductor bridge, the current flows to the load with an<br />

amplitude up to the upper band of the control shaped waveform (see t1 time in figure).<br />

Then this upper semiconductor is switched off and the lower side IGBT is switched on: so the current<br />

8 http://www.comarcond.com

flows to the load from the negative potential, reaching the lower side of the band control<br />

shaped (t2 time in figure)<br />

With this operations a current wave shape as the calculated one is flowing to the network, after that the<br />

waveform is filtering by the induction coil working in high frequency.<br />

In the same way (with the same method of control) the filter can generate current to correct the reactive power<br />

of the load, giving at the same time correcting the harmonics.<br />

In order to give a full power factor correction of the load, where it is necessary a reactive power greater than<br />

the one available in the active filter, it is possible to connect external capacitor banks to satisfy the full<br />

reactive power demand. The control of these banks can be performed by the filter with a command from a<br />

volt free contact of a relay.<br />

Other important feature of the filter is the possibility to adapt itself to the maximum possible current. So that<br />

when a current higher than the rated one is needed, SAF doesn’t stop the operations and continue to give<br />

the current to correct the harmonic absorption of the load, limiting it’s self to the maximum rating without<br />

cutting out (this could introduce distortion on the network) but modelling in the best way possible the<br />

emission of the current. The critical condition is displayed with an alarm.<br />

SAF interface<br />

In the base version SAF is equipped with an easy interface, based on led indication and can effectively<br />

monitor the active filter operation, all the internal conditions, to allow for a fast diagnosis of any fault.<br />

It is also possible to use a volt free contact on the relay to give a remote indication of the alarm, the state of<br />

the filter, the control of other values or the control to switch-on the filter.<br />

The values shown in the display are also a part of all the possible state that the active filter can monitoring<br />

as security value, control variable, value of current or voltage of the network.<br />

A microprocessor continuously monitoring all the parameters of the system and the filter is working under its<br />

control every time. Sophisticated algorithms allow the equipment to work in the best condition possible so the<br />

internal components are always without electrical stress and consequently this increases their life.<br />

This kind of control:<br />

‣ limits the maximum current flowing;<br />

‣ keeps under control the voltage of the system and of the active filter;<br />

‣ runs in a security way the inverter switch by the control of the “blanking time” and the “dead time”<br />

inside with a precision about a microsecond;<br />

‣ monitors the three phase supply voltage of the network;<br />

‣ controls the current flowing when the power is the maximum rated even if the load is absorbing a<br />

current greater than the rated (so the filter doesn’t turn off);<br />

‣ checks the maximum temperature<br />

In addition to this basic easy version of the interface, Comar Condensatori S.p.A. provides an<br />

advanced interface that can monitor the values of all the parameters run by SAF: an alphanumeric<br />

display updated continuously in real time the changing values of:<br />

‣ network rms voltage and THD v<br />

‣ cosϕ<br />

‣ bus voltage DC<br />

‣ load rms current THD i<br />

‣ filter rms current<br />

‣ power absorption by the filter and the load<br />

‣ current rms value before the load connection<br />

So it possible to see the efficiency of the filter, monitoring the current before the load and the current after it.<br />

It is also possible to check the fault history in order to analyze them for fast error diagnostics.<br />

http://www.comarcond.com<br />

9

Led interface<br />

The easy basic interface allows with leds to understand the system operation and the changing internal<br />

state.<br />

In particular the green led monitors the right function of the system during the compensation, and the startup<br />

procedure, lighting in two different way to show the “pre-charge” operation and the “contactor on”<br />

operation.<br />

The four red leds are monitoring the fault that occurs in the filter:<br />

‣ Power supply out of the rated range (“Supply voltage”)<br />

‣ Fault of the contactor or of the inverter section start-up (“Contactor”)<br />

‣ Fault of the internal temperature (“Temperature”)<br />

‣ Fault on the inverter section (“Inverter”)<br />

Active Filter performances<br />

Harmonic pollution: in the following figure there are two waveform of the absorbed current of a typical non<br />

linear load before and after the filtering. In the upper wave a 42 Arms current with THD i of 73% is filtering<br />

and it results the lower wave with 38 Arms and a residual THD i of 8%.<br />

Absorbed current of a non linear load before and after the filtering<br />

10 http://www.comarcond.com

Power factor correction: It is possible to select on the regulator board the possibility of a partial<br />

power factor correction while filtering with a good final result.<br />

Voltage and current before the filtering (left waveforms) and with the filter with both the<br />

operation of harmonic pollution and power factor correction (right waveforms)<br />

In the two pictures it is possible to see the initial displacement between the voltage and the current<br />

of a non linear load before filtering that is with the current affected by harmonics. In the right figure<br />

it is possible to see that after the filtering the current is not affected by harmonics and it is shifted to<br />

the left nearer the voltage waveform, improving the power factor.<br />

Current limit: When the harmonic current to be compensated is higher than the rated current of the<br />

filter connected, the equipment doesn’t stop its operation, but gives to the network a well shaped<br />

compensated current up to the rated limit. This permits to have compensation of the harmonic<br />

current even if not in the optimum mode, but without cutting off the compensating current at the<br />

rated value thus avoiding additional harmonics.<br />

Sizing SAF<br />

To understand which is the right size of the filter Comar Condensatori S.p.A. it is necessary to take some<br />

measurements on the installation in order to select the right reactive power of the fundamental component<br />

and of the other harmonics.<br />

For this measurement it’s necessary an instrument that can measure the harmonic components (oscilloscope;<br />

data logger etc.).<br />

It is so possible to have a series of value of current of the fundamental component (I1 50Hz ) and of the other<br />

harmonics as in the next example:<br />

I1 50Hz =30A, I5 250Hz =10A, I7 350Hz =5A, I11 550Hz =3A, I13 650Hz =1A, .....<br />

or, that is the same, the value of the parameter of the harmonic current distortion:<br />

THD (Total Harmonics Distortion =X %<br />

THD is a number that represents the harmonic pollution and it mathematically given by the next expression<br />

where I means the rms value of the fundamental current:<br />

THD :=<br />

I 2<br />

2<br />

2<br />

+ I + 3<br />

I + 4<br />

I + 5<br />

......<br />

I<br />

http://www.comarcond.com<br />

11

If SAF is working also as a power factor correction equipment, it is necessary to measure the parameter<br />

cosϕ 1 for the fundamental components, remembering the relation Q 1 =V·I 1·sinϕ 1.<br />

Now it’s easy to find the right current for the filter for the reactive power compensation that is:<br />

( )<br />

2<br />

I FA<br />

:= I . 1 sinφ 1<br />

+ ( ITHD . )<br />

2<br />

When used only for harmonic mitigation it’s possible easily find out the formula giving a zero value to the<br />

sinΦ term in the expression.<br />

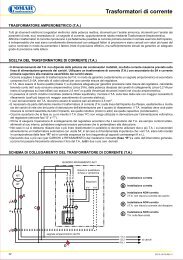

Connection of SAF<br />

The C.T.’s transformer are one of the most important part of the filtering system, because is from<br />

them that we can read the current to compensate. So this reading must be accurate and in order to<br />

read all the harmonic in the network, the quality should be high. And the secondary must be in<br />

according with the input stage of the regulator board of the filter.<br />

All these features combine to allow the component selection with Comar Condensatori S.p.A. after an<br />

accurate analysis of the plant.<br />

12 http://www.comarcond.com

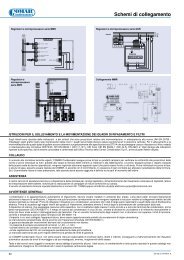

The SAF system<br />

The active filter has an extreme flexibility of connections in the existing plant and in the new ampliable<br />

installation. The possibility to insert a new filter in the installation with the easy connection of a couple of<br />

C.T.’s with the right dimension gives to the equipment great modularity speech.<br />

In every plant it’s easy to find a point for the connection of the current sensor (C.T.’s): for example inside a<br />

distribution panel or directly on the non linear load<br />

The filter has the possibility to be connected in parallel to increase the current to be compensated or in<br />

cascade to permit a new filter to be connected where an other filter is working before.<br />

So we can say that, SAF is the optimal solution to solve all the problems of filtering in harmonic current<br />

distortion.<br />

http://www.comarcond.com<br />

13

Power supply<br />

SAF features<br />

Supply Voltage 400 V ac (+10% -20%)<br />

Frequency 50 Hz / 60 Hz ± 1%<br />

Number of phase<br />

3 phase , 3 wire or 4 wire<br />

Type of load<br />

everything<br />

Standard C.T.’s<br />

Technical speech<br />

200 / 1A 1,5 kHz Cl. 0,5 not included<br />

Harmonic compensation<br />

Up to 50 order<br />

Response time<br />

< 1 ms<br />

Over load capability<br />

1,2 Irms<br />

Short circuit current<br />

120 kA, with fuse<br />

PFC<br />

Partial (selectable on board))<br />

Load with dynamic variation<br />

Yes<br />

Connection in parallel or cascade<br />

Yes<br />

Compatibility with passive filter<br />

Yes<br />

Net impedance<br />

Yes<br />

Limitation of the rated current<br />

Yes<br />

High modularity<br />

Yes<br />

Easy dimensioning<br />

Yes<br />

Auto tuning<br />

Yes<br />

THDi residual after filtering < 10%<br />

Class of protection IP 41<br />

Noise<br />

< 60 dB<br />

Ventilation<br />

forced<br />

Display<br />

Standard<br />

Option<br />

led<br />

LCD<br />

Operation condition<br />

Operating temperature 0 – 40 °C<br />

Operating altitude<br />

< 1000 m o.s.l.<br />

Relative humidity Up to 95%<br />

Electromagnetic compatibility<br />

Immunity<br />

Emission<br />

EN50081-2<br />

EN50082-2<br />

14 http://www.comarcond.com

Grafica Junior - Tel. 051.733020<br />

<strong>COMAR</strong> <strong>CONDENSATORI</strong> S.p.A.<br />

Headquarter:<br />

Via del Lavoro, 80 - CRESPELLANO (Bologna) ITALIA<br />

Export Department:<br />

P.O. Box 150 - 40011 ANZOLA EMILIA (Bologna) ITALY<br />

Tel. +39 051 733.383 - FAX +39 051 733.620<br />

Technical Department: project@comarcond.com<br />

Sales Department: export@comarcond.com<br />

http://www.comarcond.com<br />

I dati e le dimensioni possono essere modificati senza alcun preavviso.<br />

ED.02.62.ING REV.1 - Cod. 383026202